Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 1773

DIAGNOSIS 7A2-143

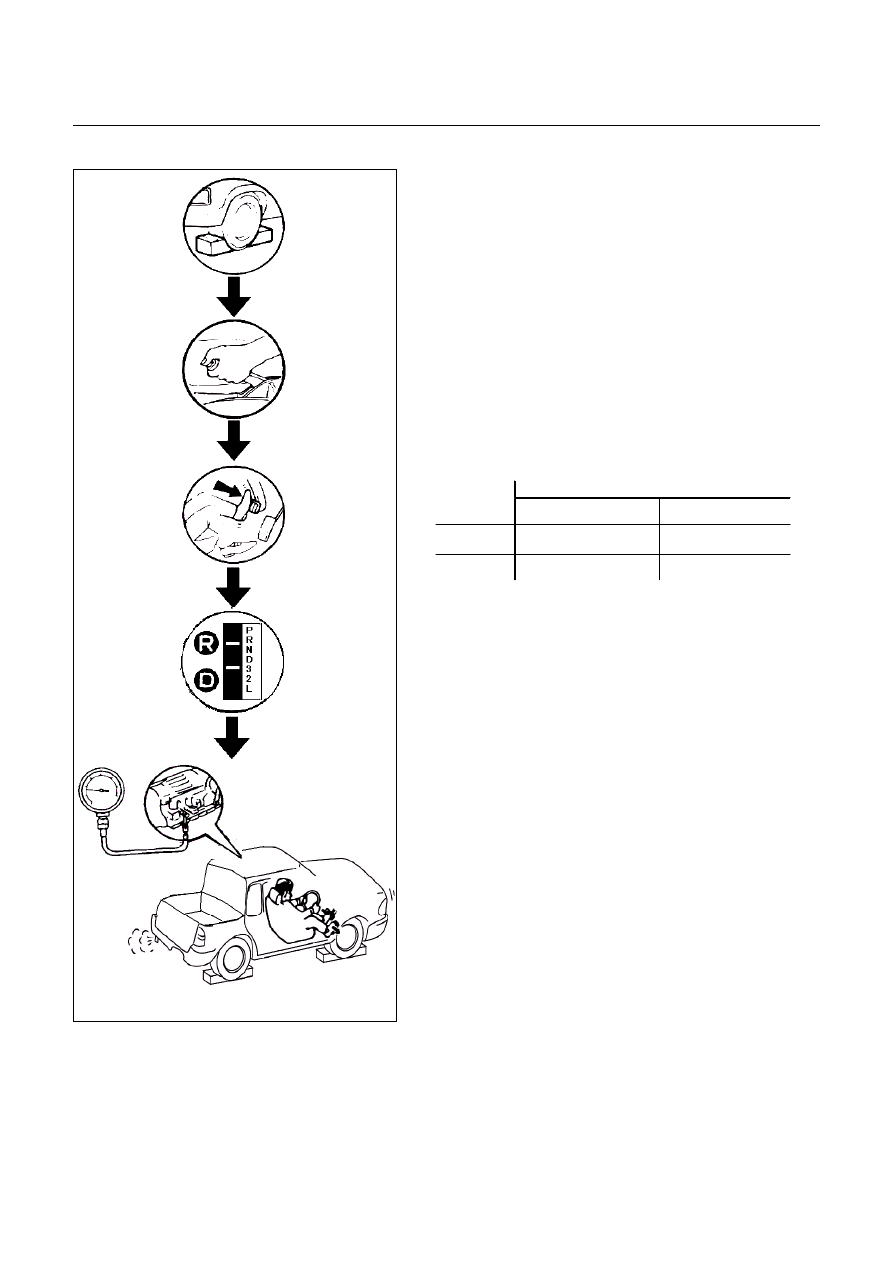

LINE PRESSURE TEST

Procedure

1.

Chock the four wheels.

2.

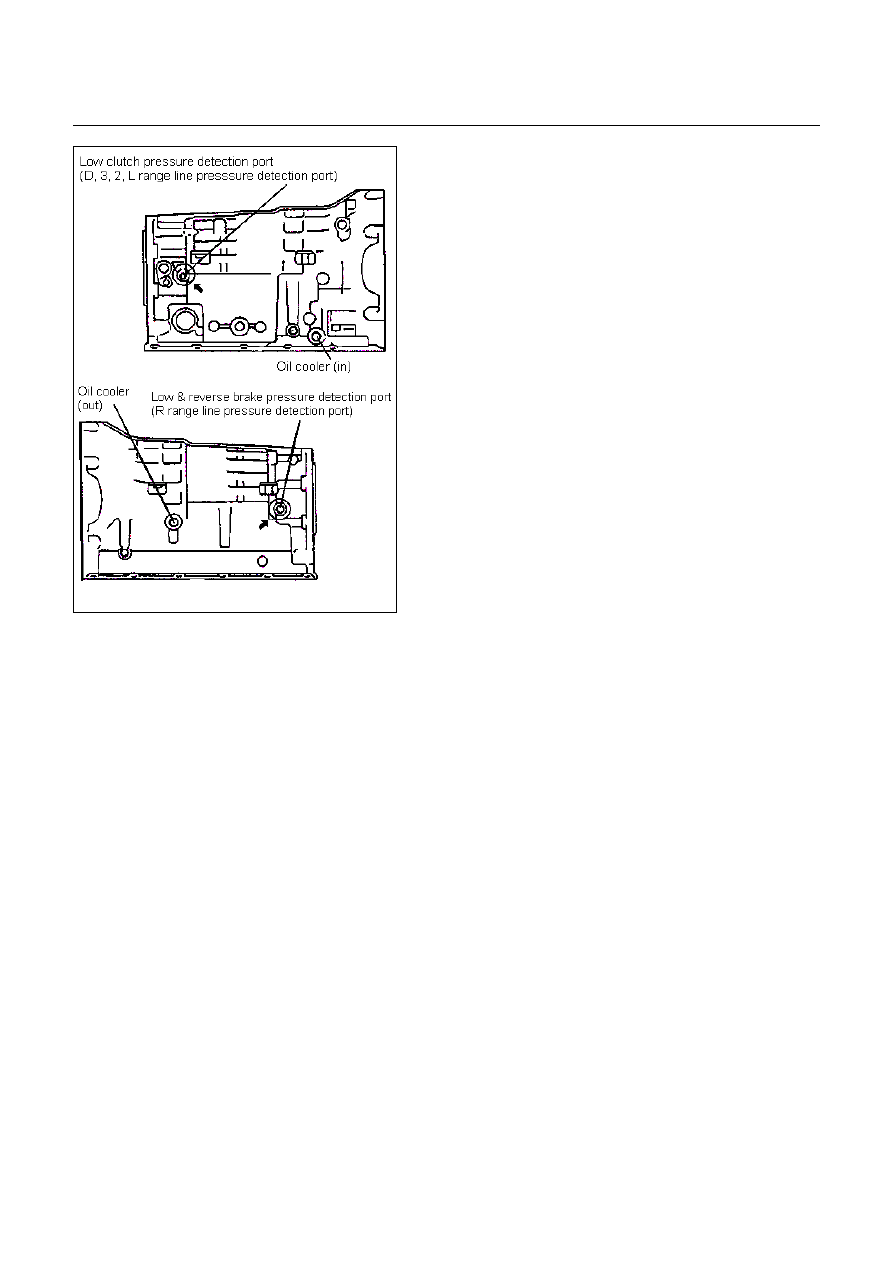

Remove the test plug of the transmission case and fit the oil

pressure gauge.

3.

Warm up the engine.

4.

Apply the parking brake.

5.

Step on the foot brake fully.

6.Set the select lever to either D, 3, 2, L or R range.

7.

Record the oil pressure at idling.

8.

When stepping over the accelerator pedal fully and the

engine speed becomes constant, record the oil pressure

quickly.

Line Pressure

Standard:

Engine

Line Pressure (Kpa)

Speed

D, 3, 2 or L Range

R Range

Idling

350 - 480

450 - 650

Stall

1,050 - 1,250

1.400 - 1,630

Evaluation

1.

If the line pressure is lower than standard value at

idling in all ranges.

•

Abraded oil pump.

•

Faulty operation of each solenoid.

•

Sticking of pressure regulator valve or pilot valve.

•

Fatigued pressure regulator valve or pilot valve spring.

•

ATF leaking from oil strainer, oil pump, pressure

regulator valve, torque converter relief valve or pressure

relief valve.

2.

If the line pressure is lower than standard value at

idling in D, 3, 2 and L ranges.

•

ATF leaking from low clutch hydraulic circuit.

3.

If the line pressure is lower than standard value at

idling in R range.

•

ATF leaking from reverse hydraulic circuit.

•

ATF leaking from low and reverse brake hydraulic

circuit.

DIAGNOSIS 7A2-144

4. If the line pressure is lower than standard value at

idling in L and R ranges.

•

ATF leaking from low and reverse brake hydraulic

circuit.

5.

If the line pressure is higher than standard value at

idling in all ranges.

•

Throttle opening signal reception error.

•

Faulty oil temperature sensor.

•

Faulty operation of low clutch solenoid.

•

Sticking pilot valve.

•

Sticking pressure regulator valve or plug.

6.

If the line pressure is lower than standard value at stall

speed in all ranges.

•

Throttle opening signal reception error.

•

Faulty operation of line pressure solenoid.

•

Faulty operation of low clutch solenoid.

•

Sticking pilot valve.

•

Sticking pressure regulator valve or plug.

DIAGNOSIS 7A2-145

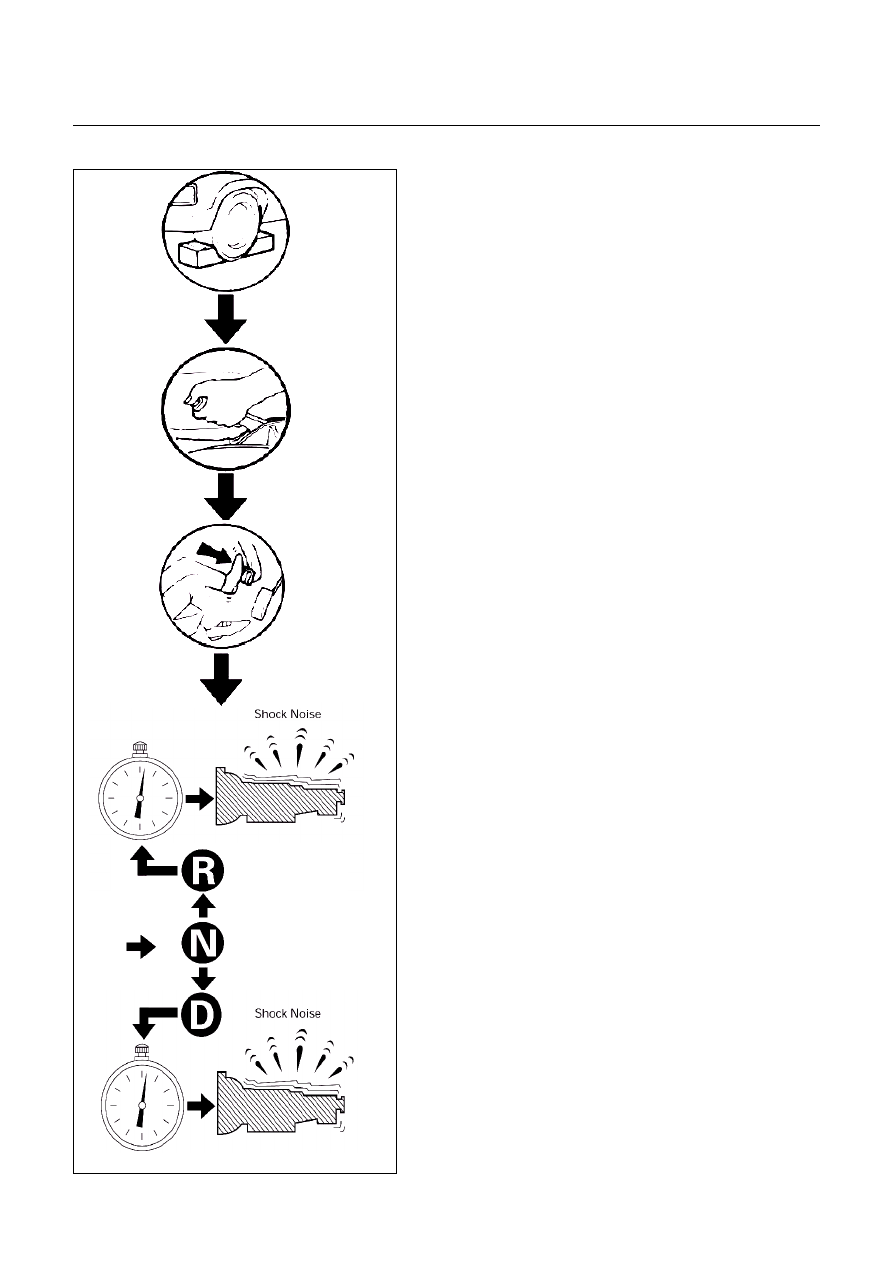

TIME LAG TEST

Procedure

1.

Chock the four wheels.

2.

Warm up the engine.

3.

Apply the parking brake.

4.

Step on the foot brake fully.

5.

Set the select lever from N to D or N to R range.

6.

Record the time from when moving the select button until

feeling shock.

Time Lag

Standard:

N to D Range: Below 0.7 Seconds

N to R Range: Below 1.2 Seconds

Evaluation

1.

If the time lag is out of standard value when shifting N

to D range.

•

Forward range line pressure is low.

•

Slip of low clutch.

•

Slip of low one-way clutch.

•

Trouble in control valve body (faulty operation, sticking,

clogged oil passage).

•

Faulty low clutch duty solenoid operation.

•

Shortage or faulty quality of ATF.

2.

If the time lag is out of standard value when shifting N

to R range.

•

Reverse range line pressure is low.

•

Slip of low & reverse brake.

•

Slip of reverse clutch.

•

Trouble in control valve body (faulty operation, sticking,

clogged oil passage).

•

Faulty low & reverse brake duty solenoid operation.

•

Shortage or faulty quality of ATF.

DIAGNOSIS 7A2-146

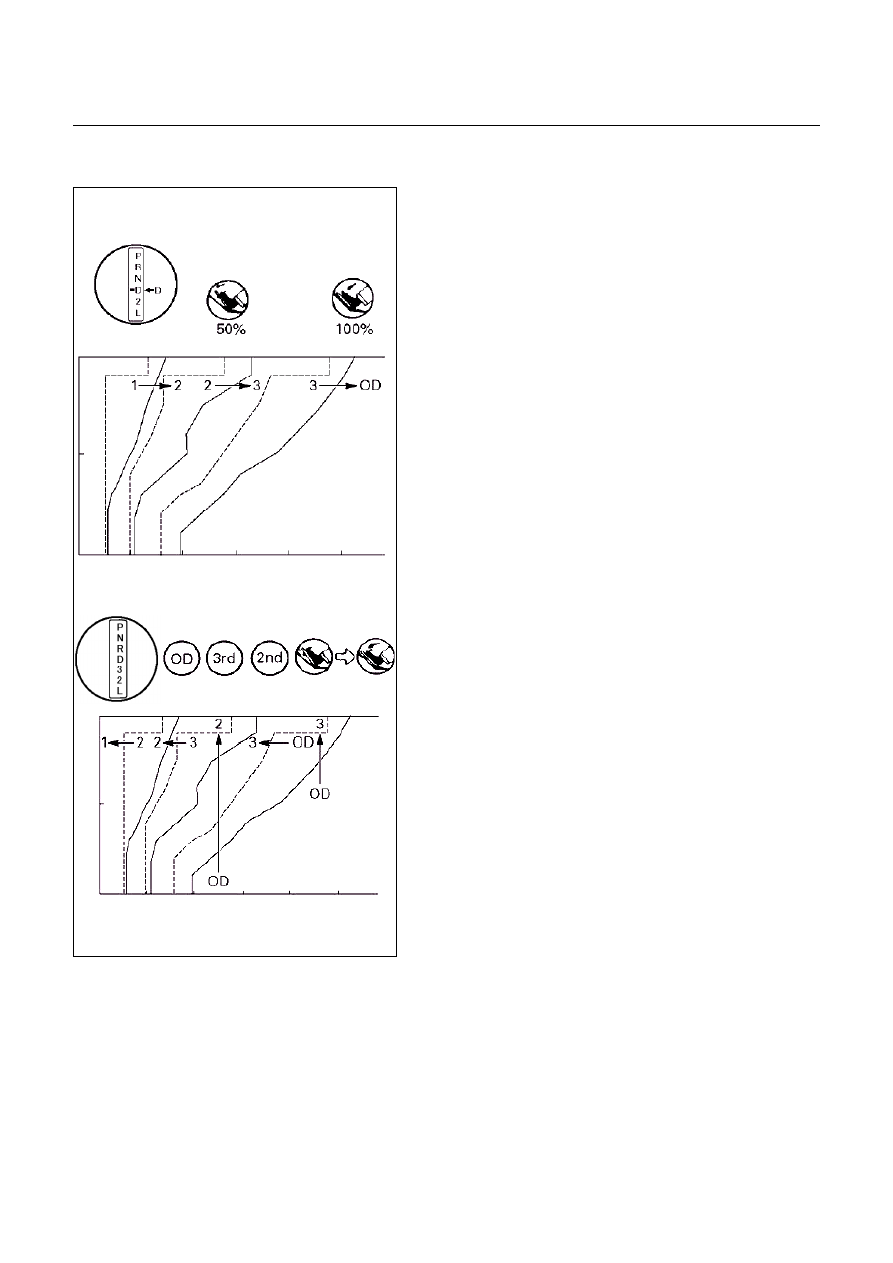

TEST DRIVE

NOTE:

Perform the test at normal operation ATF temperature 50 -

80

°°°°

C.

Drive the vehicle on level ground so as not to change to

up and down hill control.

1.

D range test in Normal and Power shift pattern.

1)

Shift into the D range and hold the accelerator pedal

constant at the 50% and 100% throttle angle.

2)

1-2, 2-3, 3-4 and lock-up, up-shift should take place, and

shift points should confirm to those shown in the

diagram.

3)

Also check to see that downshift is made from 4-3, 3-2

and 2-1 down-shift point is within the limits shown in the

diagram.

2.

3 range test in Normal and Power shift pattern.

1)

Shift into the 3 range and hold the accelerator pedal

constant at the 50% and 100% throttle angle.

2)

1-2, 2-3 and lock-up, up-shift should take place, and

shift points should confirm to those shown in the

diagram.

3)

While running in the 3 rages, does not up-shift 3-4.

4)

Also check to see that down-shift is made from 4-3, 3-2

and 2-1 down-shift point is within the limits shown in the

diagram.

3.

2 range test in Normal shift pattern.

1)

Shift into the 2 range and hold the accelerator pedal

constant at the 50% and 100% throttle angle.

2)

1-2 and up-shift should take place, and shift points

should confirm to those shown in the diagram.

3)

While running in the 2 rages, does not up-shift 2-3 or 3-

4, and lock-up does not operate.

4)

Also check to see that down-shift is made from 4-3, 3-2

and 2-1 down-shift point is within the limits shown in the

diagram.

4. L range test in Normal shift pattern.

1)

While running in the L rages, does not up-shift 1-2, 2-3

or 3-4, and lock-up does not operate.

2)

Also check to see that down-shift is made from 4-3, 3-2

and 2-1 down-shift point is within the limits shown in the

diagram.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст