Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 1712

6D3-6 STARTING AND CHARGING SYSTEM

Continuity of Contacts

With the plunger faced downward, push down the magnetic

switch. In this state, check for continuity between terminals B

and M. Replace, if there is no continuity (i.e., contacts are

faulty).

Pinion

Check if the pinion rotates smoothly in drive direction by hand,

or if it is locked when it is rotated in reverse. If not, replace the

pinion.

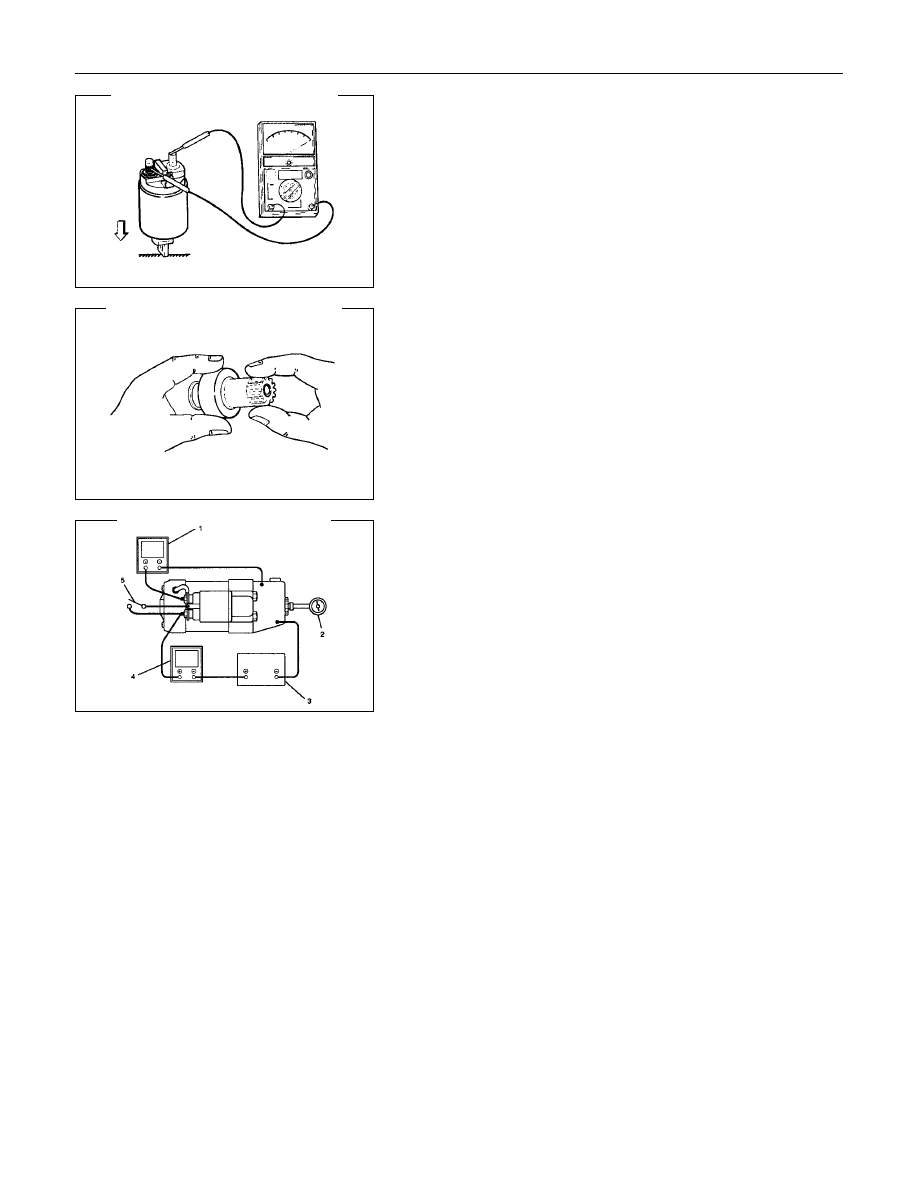

Characteristic Test

For easily confirming the characteristics, conduct the noload

test as follows:

Rating as short as 30 seconds requires rapid testing.

Fix the starter on the test bench, and wire as shown in

illustration. When the switch is closed, the current flows and

the starter runs under no load. At this time, measure current,

voltage and speed to check if they satisfy the standard.

Legend

1 Volt Meter

2 Revolution Indicator

3 Battery

4 Ammeter

5 Switch

STARTING AND CHARGING SYSTEM 6D3-7

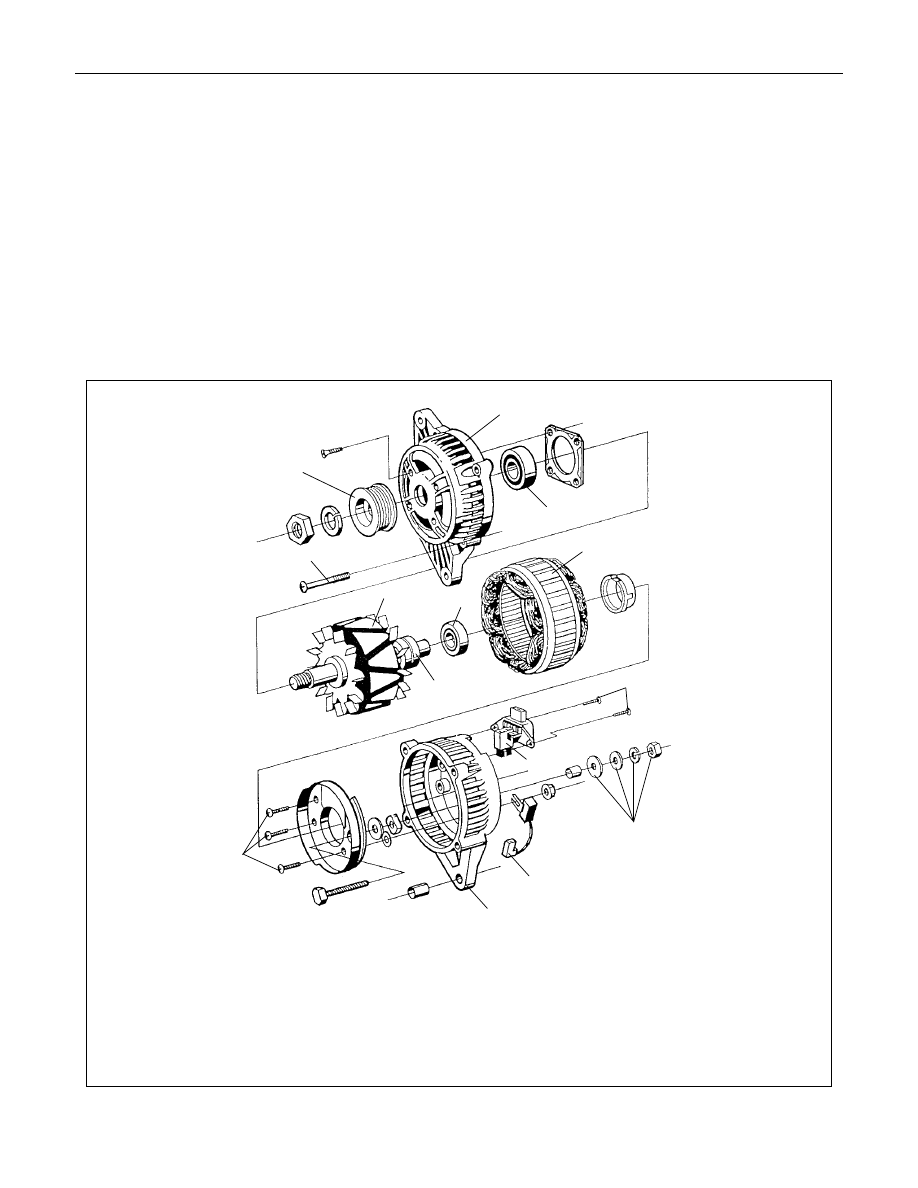

Charging System

General Description

The charging system is an IC integral regulator charging

system and its main components are connected as shown in

illustration.

The regulator is a solid state type and it is mounted along with

the brush holder assembly inside the generator installed on the

rear end cover.

The generator does not require particular maintenance such as

voltage adjustment. The rectifier connected to the stator coil

has eight diodes to transform AC voltage into DC voltage.

This DC voltage is connected to the output terminal of

generator.

Legend

1 Startor assembly

2 Housing

3 Slipring

4 Screws (2)

5 Regulator

6.Bolt (4)

7 Rectifier assembly

8 Retaining assembly

9 B+ terminal nut and washer

10 Pulley

11 Rotor assembly

12 Ball bearing

2

11

12

2

8

5

4

3

1

11

7

6

10

9

6D3-8 STARTING AND CHARGING SYSTEM

General On-Vehicle Inspection

The operating condition of charging system is indicated by the

charge warning lamp. The warning lamp comes on when the

starter switch is turned to "ON" position. The charging system

operates normally if the lamp goes off when the engine starts.

If the warning lamp shows abnormality or if undercharged or

overcharged battery condition is suspected, perform diagnosis

by checking the charging system as follows:

1. Check visually the belt and wiring connector.

2. With the engine stopped, turn the stator switch to "ON"

position and observe the warning lamp.

If lamp does not come on:

Disconnect wiring connector from generator, and ground

the terminal "L" on connector side.

If lamp comes on:

Repair or replace the generator.

Generator

Removal

1. Disconnect battery ground cable.

2. Move drive belt tensioner to loose side using wrench then

remove drive belt.

3. Disconnect terminal "B" wiring connector and connector.

4. Remove generator assembly.

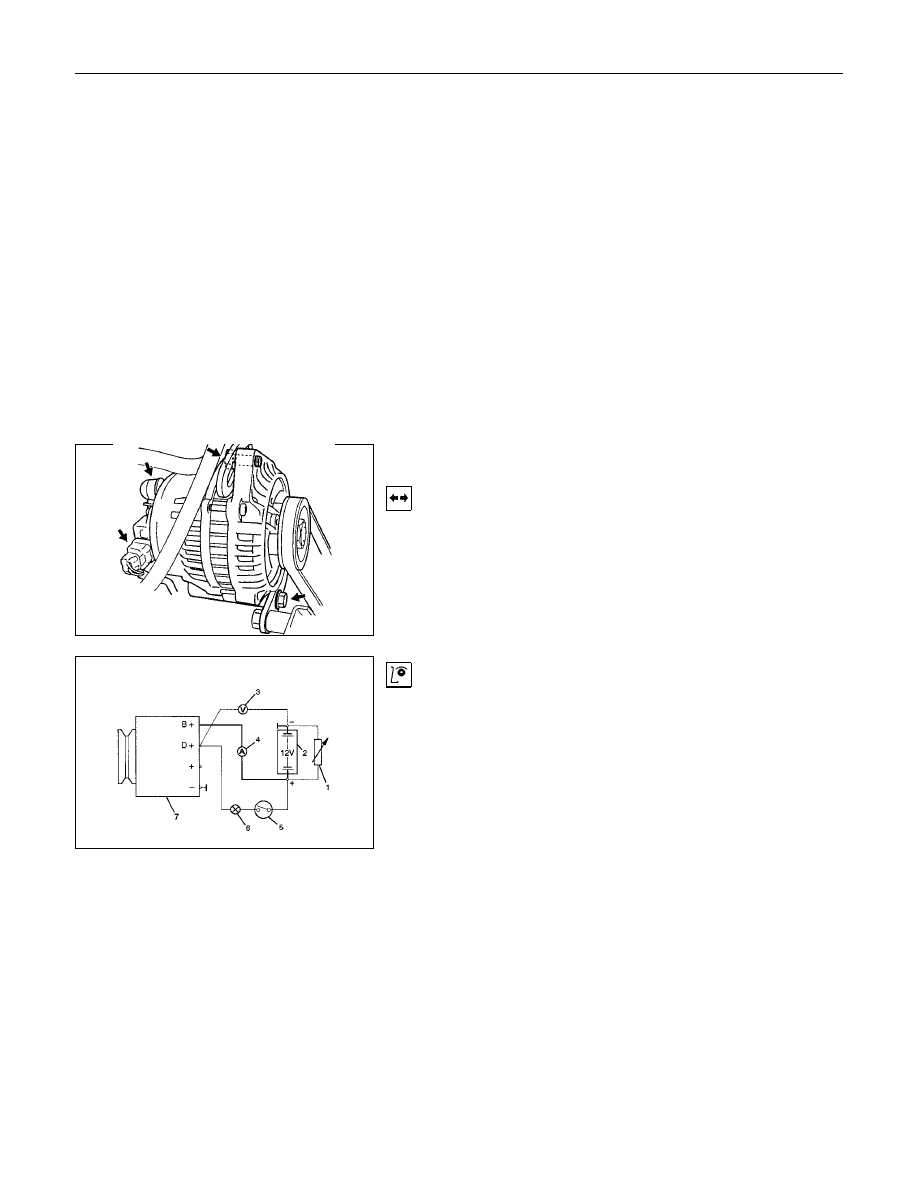

Generator Power and Circuit Diagram

Inspection

Legend

1 Load resistor, set parallel to battery

2 Battery

3 Voltmeter

4 Ammeter

5 Ignition Lock

6 Charge Telltale

7 Generator

1. Disconnect battery.

2. Close off connecting cable from alternator terminal "B+".

3. Set ammeter (measuring range 100A) in disconnected line.

4. Connect controllable load resistor to battery terminal.

5. Set resistor in front of connection to "O"; connect first to

battery, then to resistor.

6. Connect tachometer.

7. Connect

oscilloscope

according

to

manufacturer's

instructions.

8. Connect battery.

9. Start engine and read off resulting current at various engine

speeds.

STARTING AND CHARGING SYSTEM 6D3-9

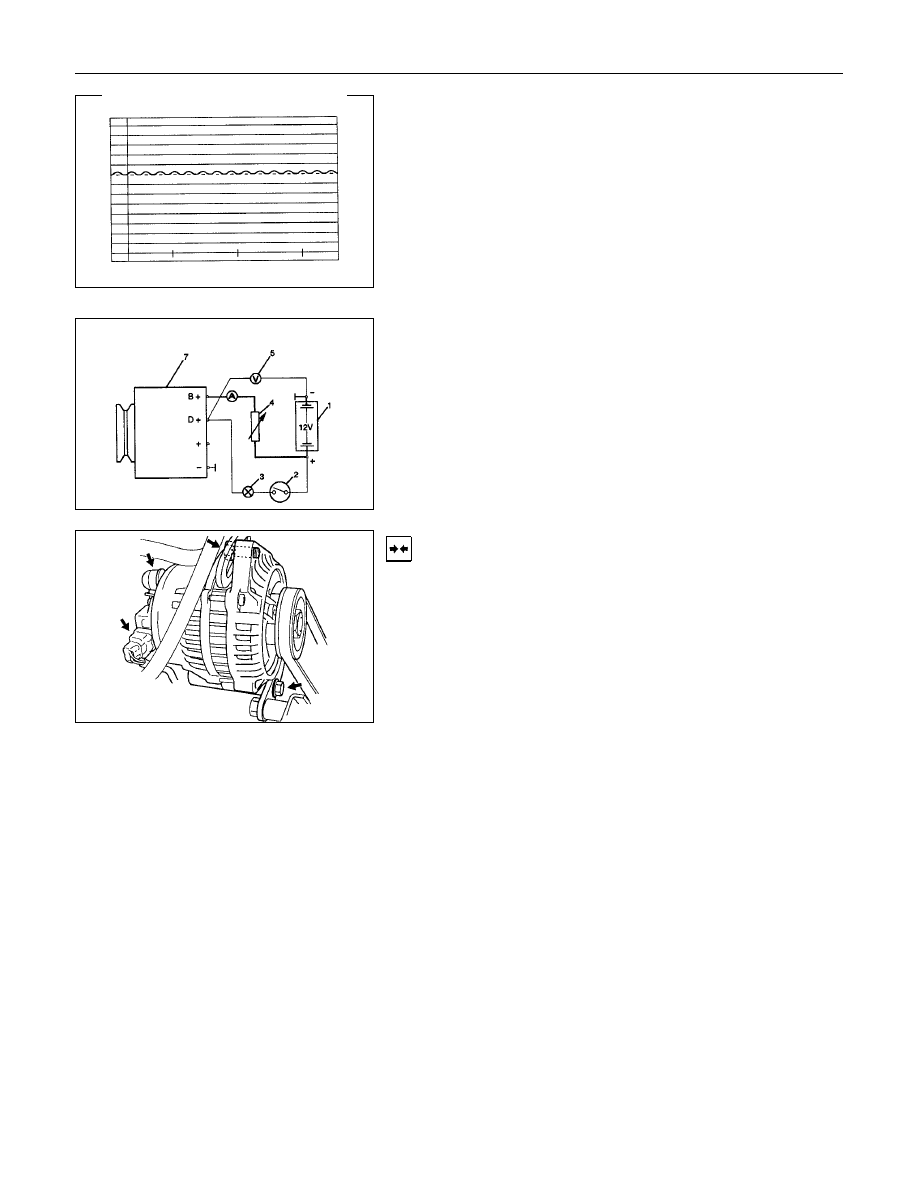

Generator Power

1. Adjust load resistor, if the required load currents are not

attained.

2. The shape of the voltage curves on oscilloscope curve

should be regular.

3. Test value: 5 to 7A.

4. If the required minimum current intensity is not attained, or if

the oscilloscope picture shows variations, the alternator

should be overhauled.

Regulated Voltage Circuit Diagram

Legend

1 Battery

2 Ignition Lock

3 Charge Telltale

4 Resistor, for attainment of load current with the battery set in

series

5 Voltmeter

6 Ammeter

7 Generator

Installation

1. Install generator assembly and bring generator assembly to

the position to be installed.

2. Install generator assembly and tighten to the specified

torque.

Torque:

Long bolt: 35 N

⋅⋅⋅⋅m (3.6 kgf⋅⋅⋅⋅m)

Short bolt: 20 N

⋅⋅⋅⋅m (2.0 kgf⋅⋅⋅⋅m)

3. Connect wiring harness connector.

4. Move drive belt tensioner to loose side using a wrench, then

install drive belt to normal position.

5. Reconnect battery ground cable.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст