Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 607

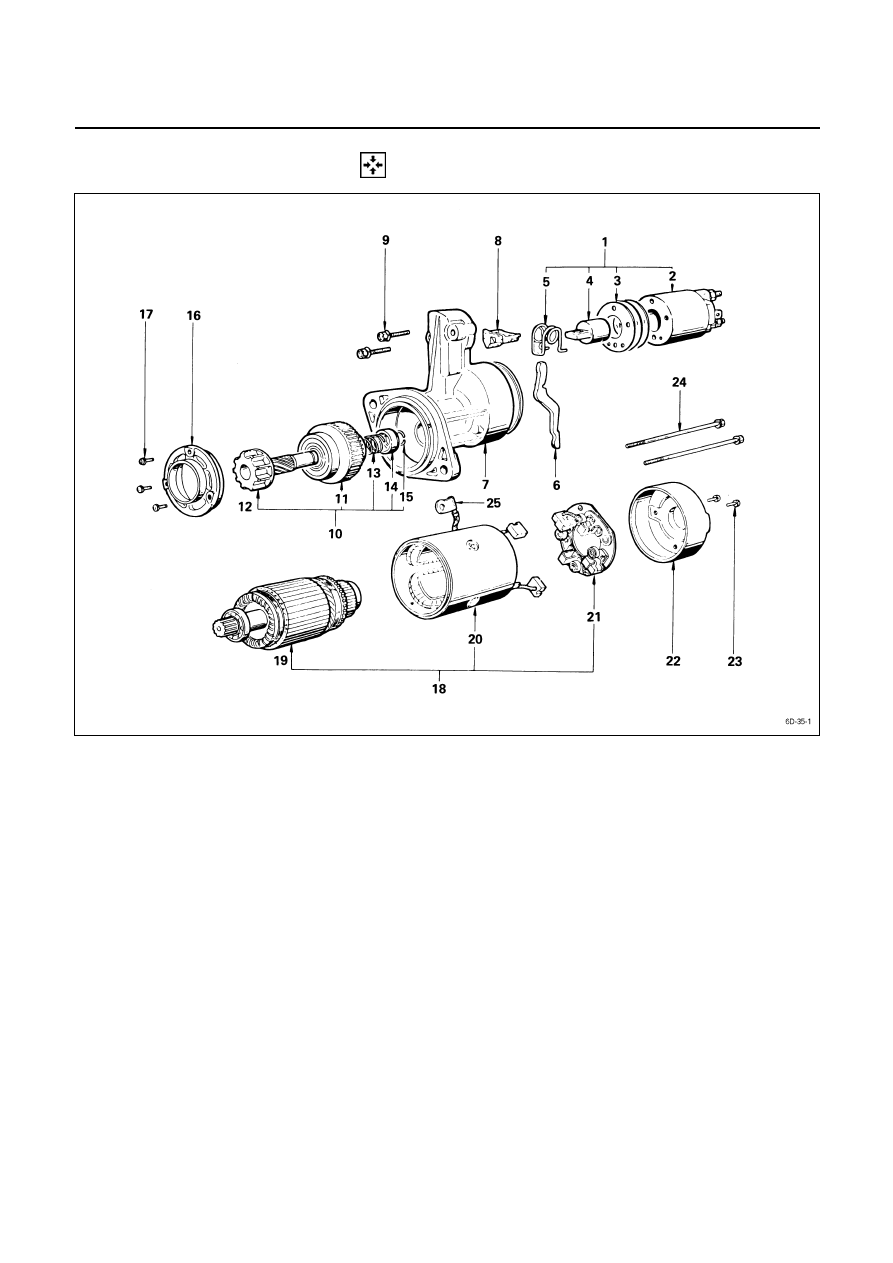

ENGINE ELECTRICAL 6D – 35

REASSEMBLY

Reassembly Steps

J

1. Magnetic switch assembly

14.

Pinion stopper

2. Magnetic switch

15.

Pinion stopper clip

3. Adjusting shims

16.

Bearing retainer

4. Plunger

17.

Screw

5. Torsion spring

18.

Motor assembly

6. Shift lever

19.

Armature

J

7. Gear case

20.

Yoke

J

8. Dust cover

J

21.

Brush holder

9. Bolt

22.

Rear

cover

J

10. Pinion assembly

23.

Screw

11. Clutch

J

24.

Through bolt

12. Pinion shaft

J

25.

Lead wire

13. Rerurn spring

6D – 36 ENGINE ELECTRICAL

Important Operations

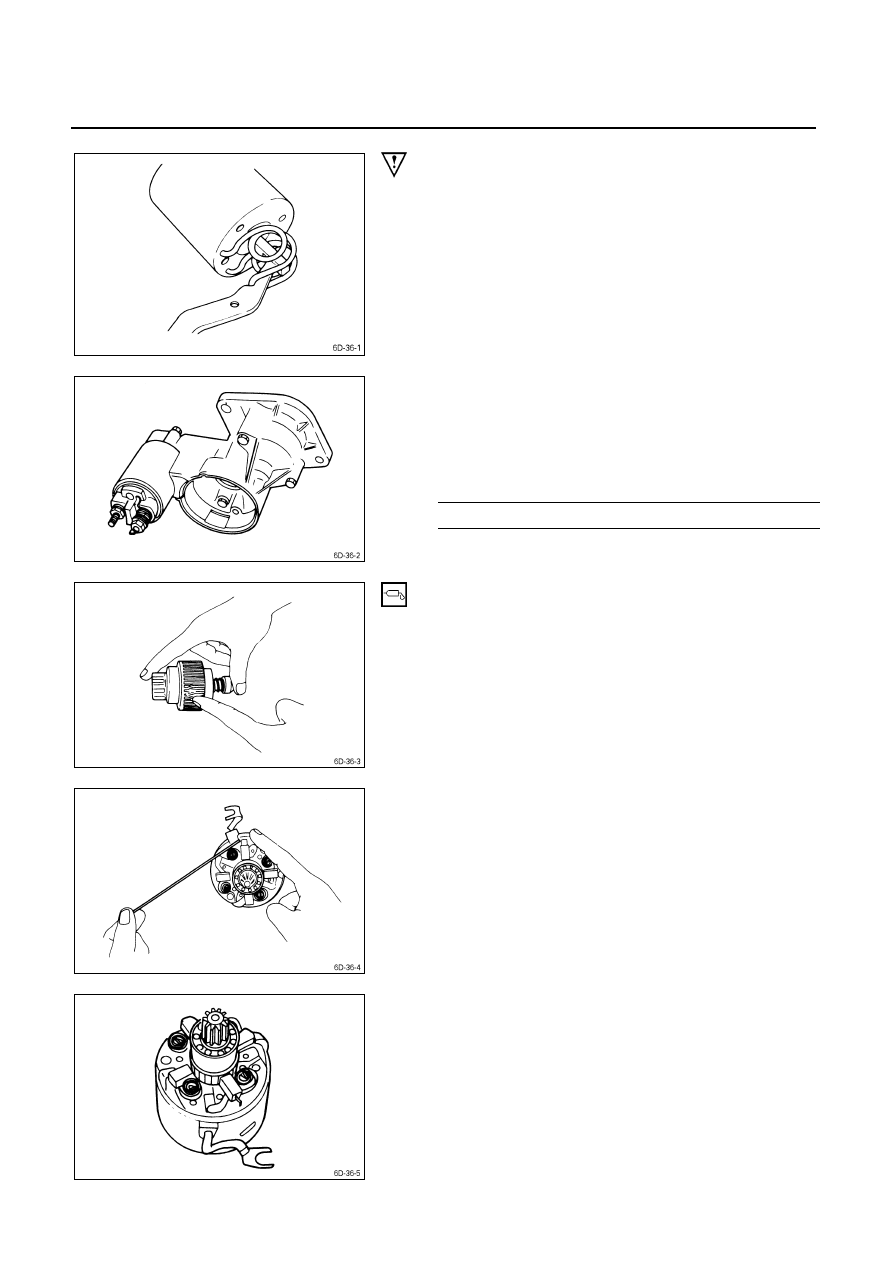

1. Magnetic Switch Assembly

1. Attach the torsion spring to the hole in the magnetic

switch as illustrated.

2. Insert the shift lever into the plunger hole of the

magnetic switch.

7. Gear

Case

8. Dust

Cover

1. Install the magnetic switch assembly in the gear case.

2. Install the dust cover.

Dust Cover Bolt Torque

kg

⋅m(lb⋅ft/N⋅m)

0.75

± 0.5 (5.4 ± 3.6/7.4 ± 5)

10. Pinion Assembly

Apply a coat of grease to the reduction gear and install the

pinion assembly to the armature shaft.

21. Brush Holders

1. Install the brushes into the brush holder with raising

the spring end of the brush spring.

Take care not to damage the commutator face.

2. Install the brush holder with aligning the peripheries of

the yoke and the brush holder.

ENGINE ELECTRICAL 6D – 37

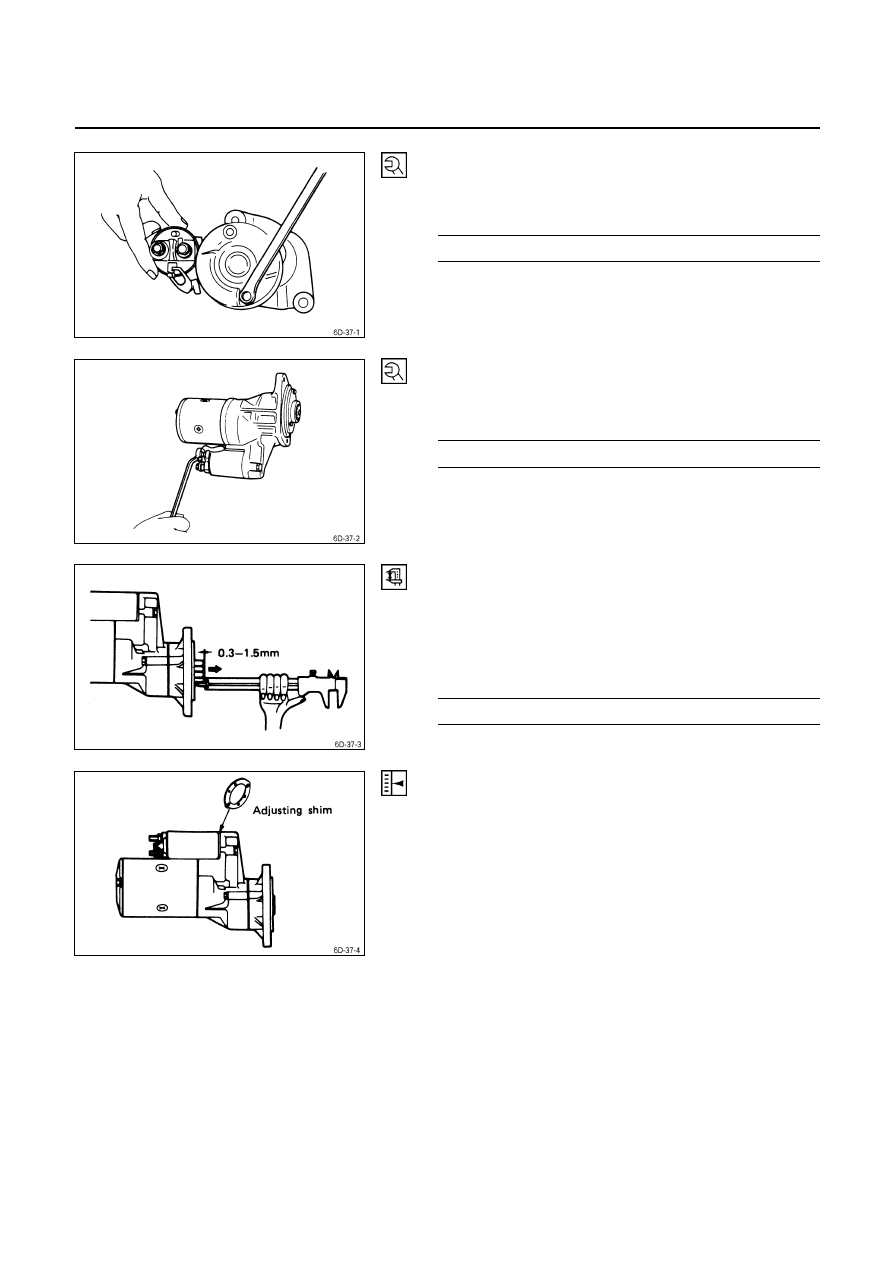

24. Through Bolt

Install the through bolts in the rear cover and tighten them

to the specified torque.

Through Bolt Torque

kg

⋅m(lb⋅ft/N⋅m)

0.6

± 0.1 (4.3 ± 0.7/5.9 ± 1.0)

25. Lead Wire

Connect the lead wire in the magnetic switch and tighten

the terminal nut to the specified torque.

Lead Wire Terminal Nut Torque

kg

⋅m(lb⋅ft)

0.8

± 0.1 (5.8 ± 0.7/7.8 ± 1.0)

Inspection After Assembly

Use a vernier caliper to measure the pinion shaft thrust

play.

The pinion shaft thrust play is equal to the pinion shaft end

and pinion stopper clearance.

Pinion Shaft Thrust Play

mm (in)

0.3 - 1.5 (0.01 – 0.06)

In a case where the pinion gap outside the

specified value;

Make an adjustment using a shim(s).

Adjusting shims are available in 0.5 mm and 0.8 mm (0.02 and

0.03 in.) sizes.

6D – 38 ENGINE ELECTRICAL

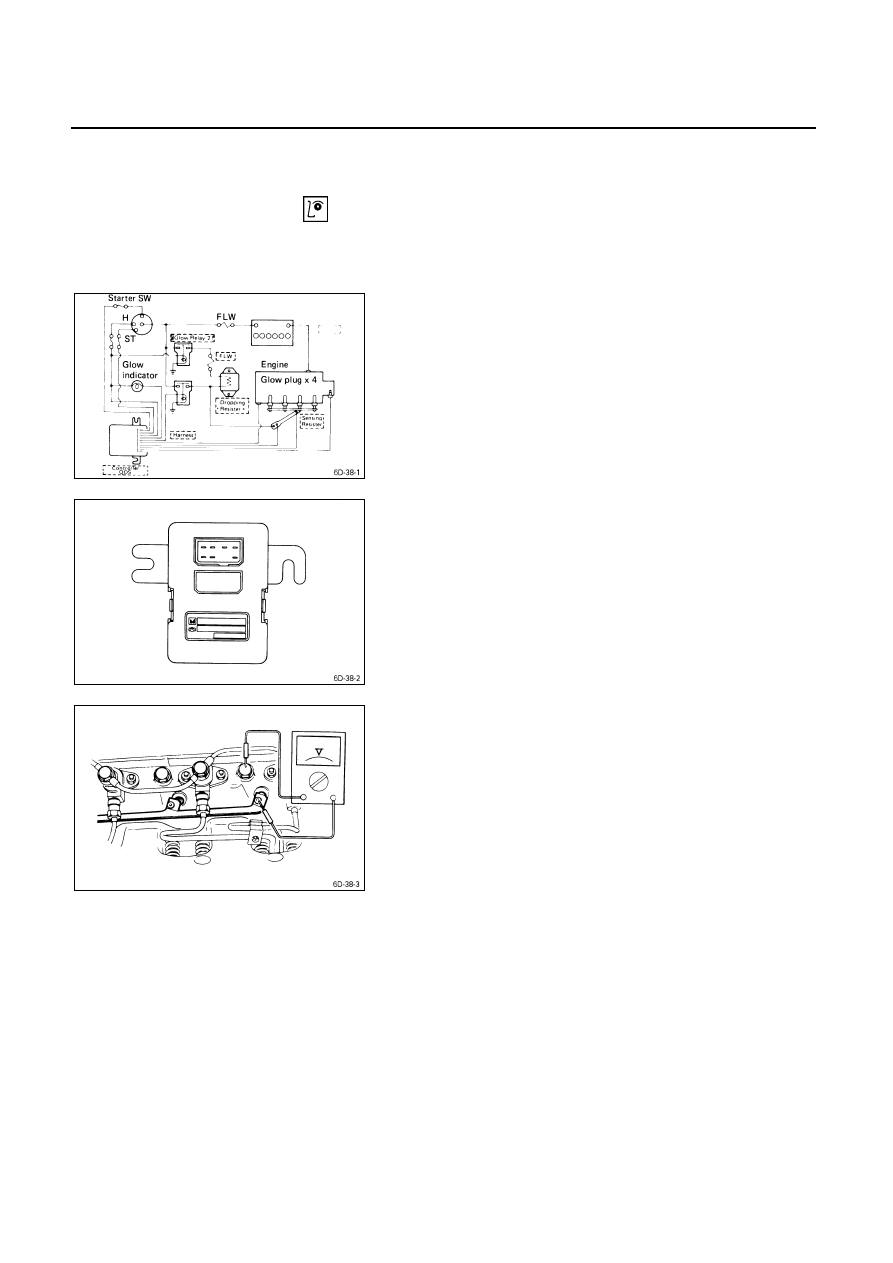

PRE-HEATING SYSTEM

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacement if excessive wear or damage is discovered during

inspection.

SYSTEM CIRCUIT

Visual Check

Check the main fuses and the glow indicator for damage.

Replace the part(s) if required.

GLOW TIMER

The glow timer is initially activated by the starter switch.

Thereafter, signals from the thermoswitch reach the glow

timer to control the glow plug relay operation time.

The thermoswitch and timer unit also act to protect the

battery in the event the starter key is engaged for an

excessively long time.

Glow Timer Operation

1. Disconnect the lead wires at the thermoswitch.

2. Connect a voltmeter between the glow plug and

ground.

3. Turn the starter switch from “OFF” to “ON”.

The engine must be stopped.

4. Note the time the glow indicator remains on.

If the glow indicator remains on for approximately 1~6

seconds (4JG2T Engine model) or 3.5 seconds (4JA1,

4JB1T Engine model), the glow timer “ON” time is

normal.

If the glow indicator does not remain on for

approximately 1~6 seconds or 3.5 seconds, trouble in

the glow timer or, the glow relay, is indicated.

5. Return the starter switch to “OFF”.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст