Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 606

ENGINE ELECTRICAL 6D – 31

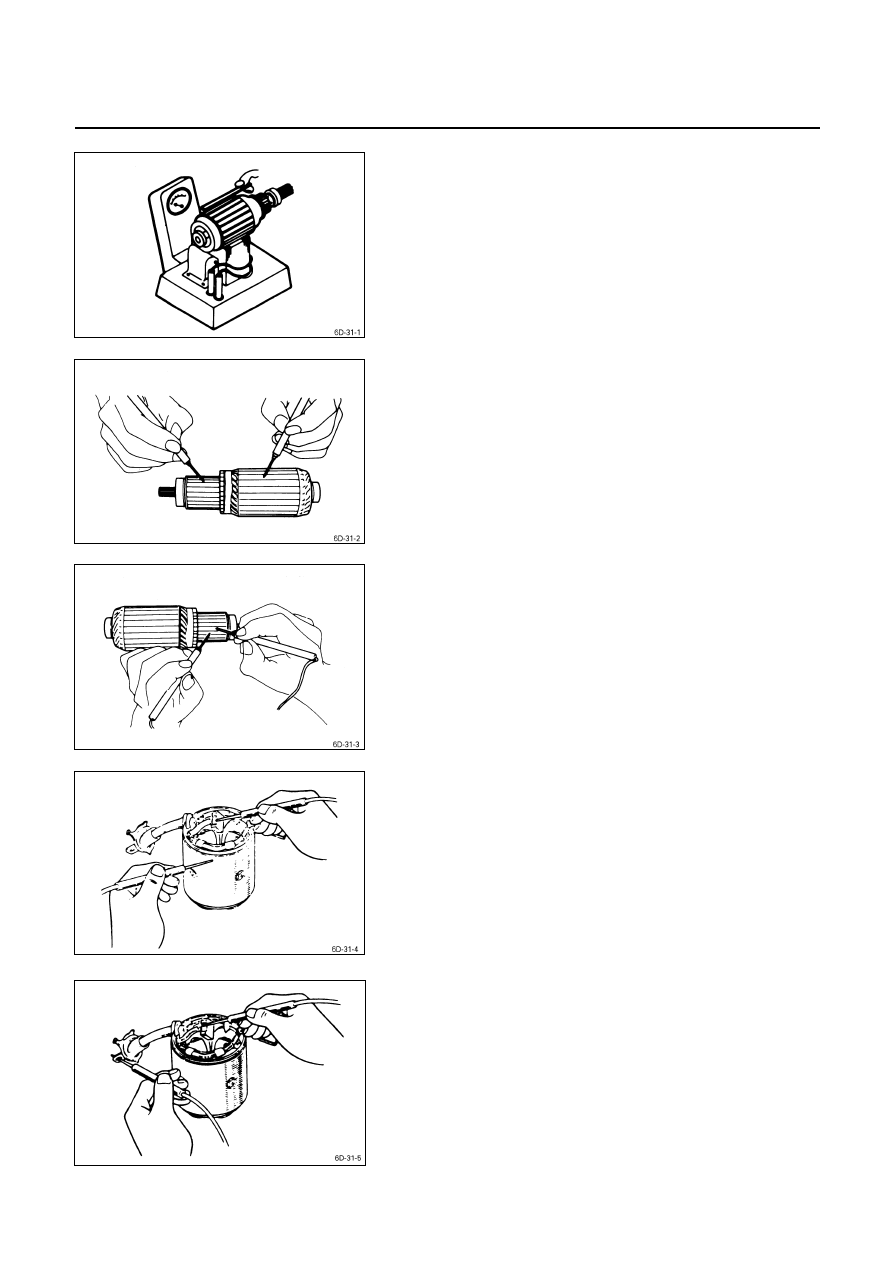

5. Test the armature for short circuiting.

a. Place the armature in a growler tester.

b. Hold a hacksaw blade against the armature core.

If the armature has a short circuit, the hacksaw blade

will vibrate.

Replace the armature if there is a short circuit.

6. Use a circuit tester to check the armature for

grounding.

1) Hold one probe of the circuit tester against the

commutator segment.

2) Hold the other circuit tester probe against the

armature core.

If the circuit tester indicates continuity, the armature is

grounded.

The armature must be replaced.

7. Use the circuit tester to check the armature for

continuity.

1) Hold the circuit tester probes against two armature

core segments.

2) Repear Step 1 at different segments of the

armature core.

There should be continuity between all segments of

the armature core.

If there is not, the armature must be replaced.

YOKE

1. Use a circuit tester to check the field winding ground.

1) Hold one circuit tester probe against the field

winding end or brush.

2) Hold the other circuit tester probe against the bare

surface of the yoke body.

There should be no continuity.

If there is continuity, the field coil is grounded.

The yoke must be replaced.

2. Use the circuit tester to check the field winding

continuity.

1) Hold one circuit tester probe against the “C”

terminal lead wire.

2) Hold the other circuit tester probe against the field

winding brush.

There should be continuity.

If there is no continuity, the yoke must be replaced.

6D – 32 ENGINE ELECTRICAL

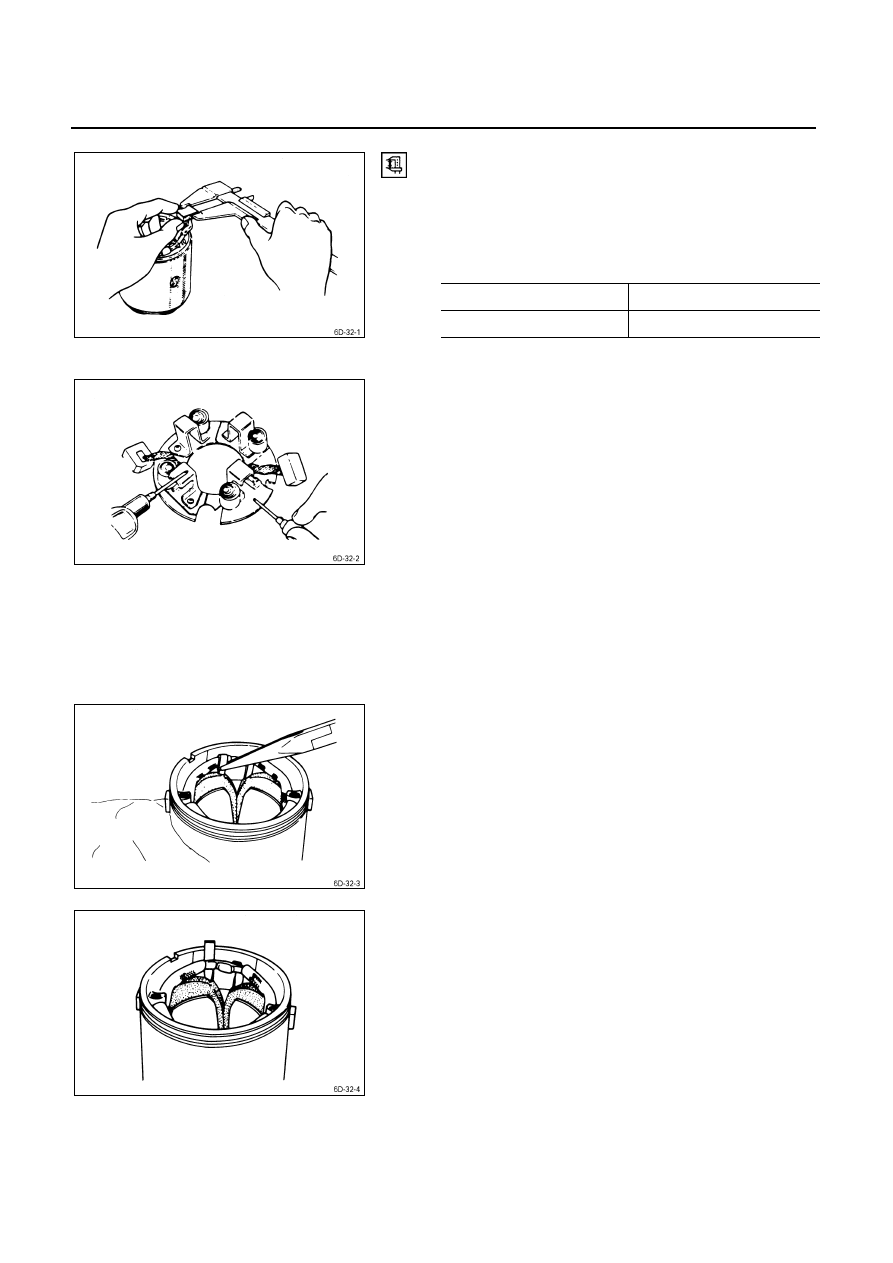

BRUSH AND BRUSH HOLDER

1. Use a vernier caliper to measure the brush length (four

brushes).

Replace the brushes as a set if one or more of the

brush lengths is less than the specified limit.

Brush Length

mm (in)

Standard Limit

14.5 (0.57)

9.5 (0.37)

2. Use a circuit tester to check the brush holder

insulation.

Touch one probe to the holder plate and the other

probe to the positive brush holder.

There should be no continuity.

3. Inspect the brushes for excessive wear.

If the negative brushes have excessive wear, the

entire brush holder assembly must be replaced.

If the positive brushes have excessive wear, only the

brushes must be replaced.

1) Use a pair of side cutters to cut the lead wire from

the brush.

2) File away any foreign material clinging to the edge

of the lead wire.

3) Remove the brushes from the brush holder.

4) Install the new brushes.

5) Straighten the bent portion of the clip.

6) File away any foreign material clinging to the clip

surface.

ENGINE ELECTRICAL 6D – 33

7) Place the lead wire in the clip.

8) Bend the clip shut.

9) Solder the brush lead.

10) Repeat the procedure for each of the brushes.

OVERRUNNING CLUTCH

1. Inspect the overrunning clutch gear teeth for

excessive wear and damage.

Replace the overrunning clutch if necessary.

2. Rotate the pinion clockwise.

It should turn smoothly.

3. Try to rotate the pinion in the opposite direction.

The pinion should lock.

BEARING

Inspect the bearings for excessive wear and damage.

Replace the bearings if necessary.

6D – 34 ENGINE ELECTRICAL

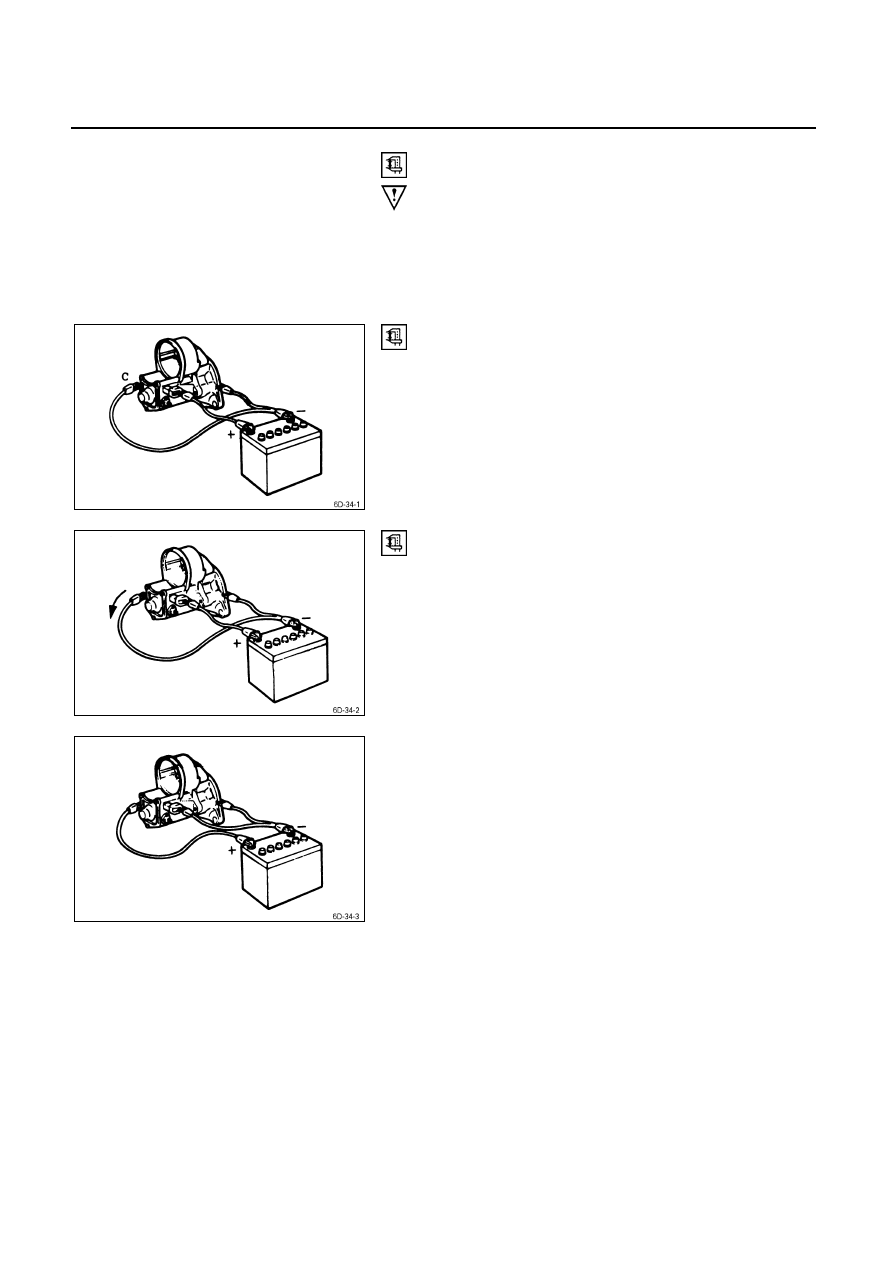

MAGNETIC SWITCH

The following tests must be performed with the starter

motor fully assembled.

The yoke lead wire must be disconnected from the “C”

terminal.

To prevent coil burning, complete each test as quickly as

possible (within three to five seconds).

Temporarily connect the solenoid switch between the

clutch and the housing and run the following test.

Complete each test within three to five seconds.

1. Pull-in

Test

Connect the battery negative terminal with the solenoid

switch body and the C terminal. When current is applied to

the 50 terminal from the battery positive terminal, the

pinion should flutter.

2. Hold-in Maintenance Test

Disconnect the lead at the C terminal. The pinion should

continue to flutter.

3. Return

Test

Connect the battery negative leads to the starter body and

the 50 terminal.

Connect the battery positive lead at the C terminal.

The pinion should return to its home position.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст