Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 568

6A – 110 ENGINE MECHANICAL

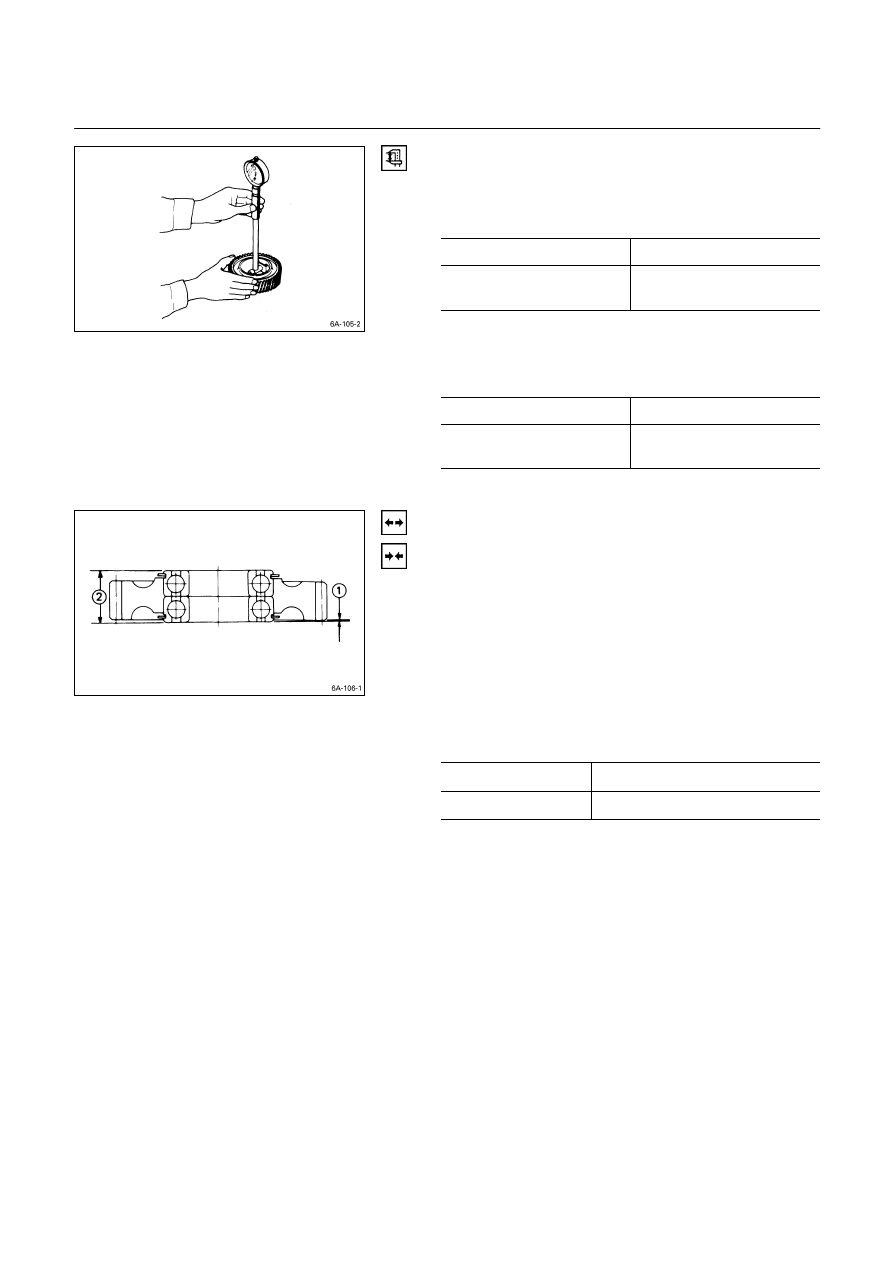

Idler Gear “A” Shaft inside Diameter

1. Use an inside dial indicator or an inside micrometer to

measure the idler gear inside diameter.

Idler Gear Inside Diameter

mm (in)

Standard Limit

45.0 – 45.03

(1.7717 – 1.7718)

45.10 (1.7756)

If the clearance between the idler gear shaft outside

diameter and the idler gear inside diameter exceeds the

limit, the idler gear must be replaced.

Idler Gear Shaft and Idler Gear Clearance

mm (in)

Standard Limit

0.025 – 0.085

(0.0010 – 0.0033)

0.200 (0.008)

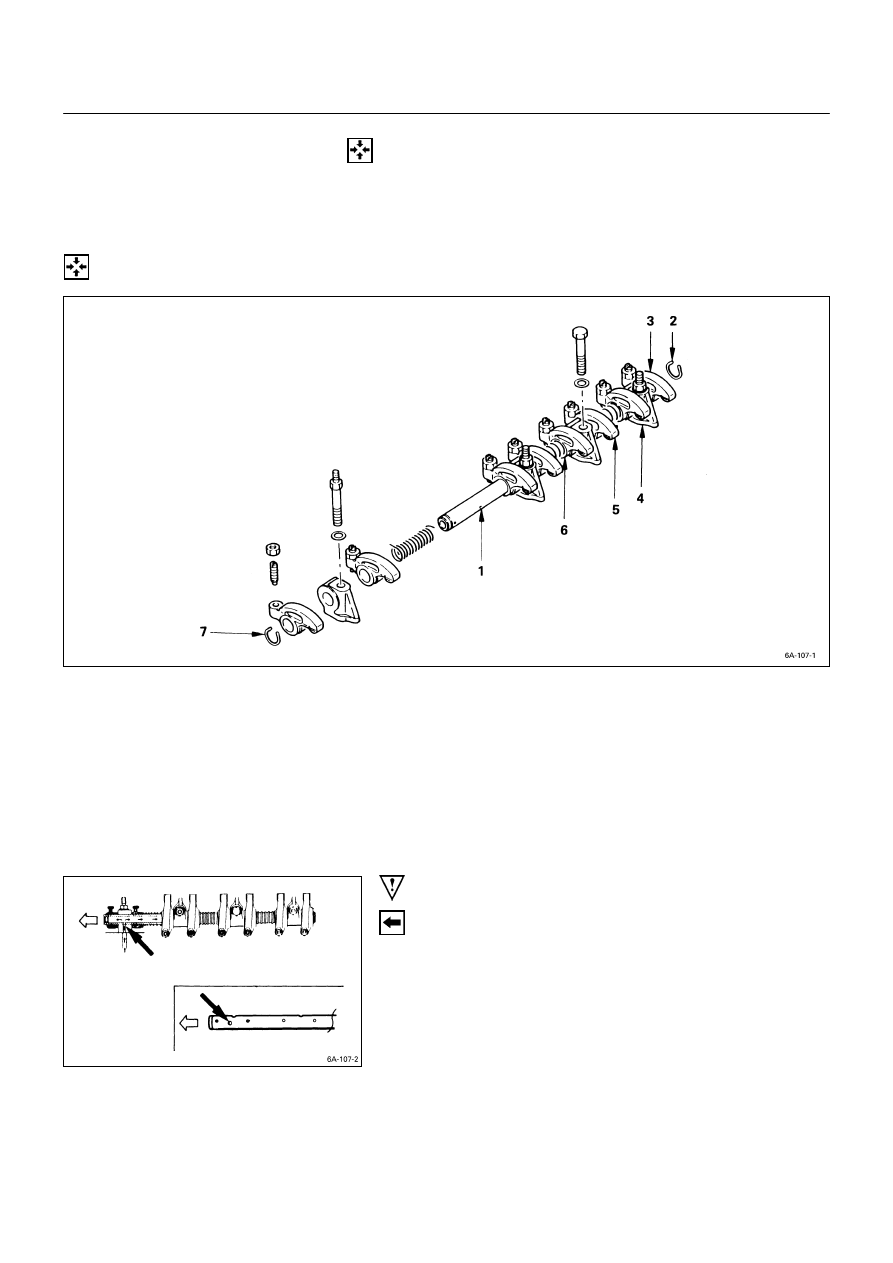

Idler Gear “B”

Bearing Replacement

Bearing Removal

Use a bench press or a hammer and a bar to remove the

bearing from the idler gear.

Bearing Installation

Use a bench press and bar to install the bearing into the

idler gear.

Bearing Projection and Height

mm (in)

Projection

Q

0.4 – 0.6 (0.016 – 0.024)

Height

R

23.7 – 24.0 (0.933 – 0.945)

Note:

The bench press and bar should make contact only

with the bearing outer races. Do not allow them to

make contact with the bearing inner races.

Bearing damage and reduced bearing service life will

result.

ENGINE MECHANICAL 6A – 111

TIMING GEAR CASE COVER

Replace the crankshaft front oil seal if it is excessively

worn or damaged.

Crankshaft Front Oil Seal Replacement

Oil Seal Removal

Use a plastic hammer and a screwdriver to tap around the

oil seal to free it from the gear case cover.

Take care not to damage the oil seal lip surfaces.

Oil Seal Installation

Use the installer to install the front oil seal

Q

to the gear

case cover

R

.

Oil Seal Installer: 5-8840-2061-0

Note the oil seal installation depth

S

shown in the

illustration.

Depth

S

= 1 mm (0.039 in.)

6A – 112 ENGINE MECHANICAL

REASSEMBLY

INTERNAL PARTS

MINOR COMPONENTS

ROCKER ARM SHAFT AND ROCKER ARM

Reassembly Steps

t

1.

Rocker arm shaft

5.

Rocker arm

2.

Rocker arm shaft snap ring

6.

Rocker arm shaft spring

3.

Rocker arm

7.

Rocker arm shaft snap ring

4.

Rocker arm shaft bracket

Important Operations

1. Rocker Arm Shaft

1) Position the rocker arm shaft with the large oil hole

(4

φ

) facing the front of the engine.

2) Install the rocker arm shaft together with the rocker

arm, the rocker arm shaft bracket, and the spring.

ENGINE MECHANICAL 6A – 113

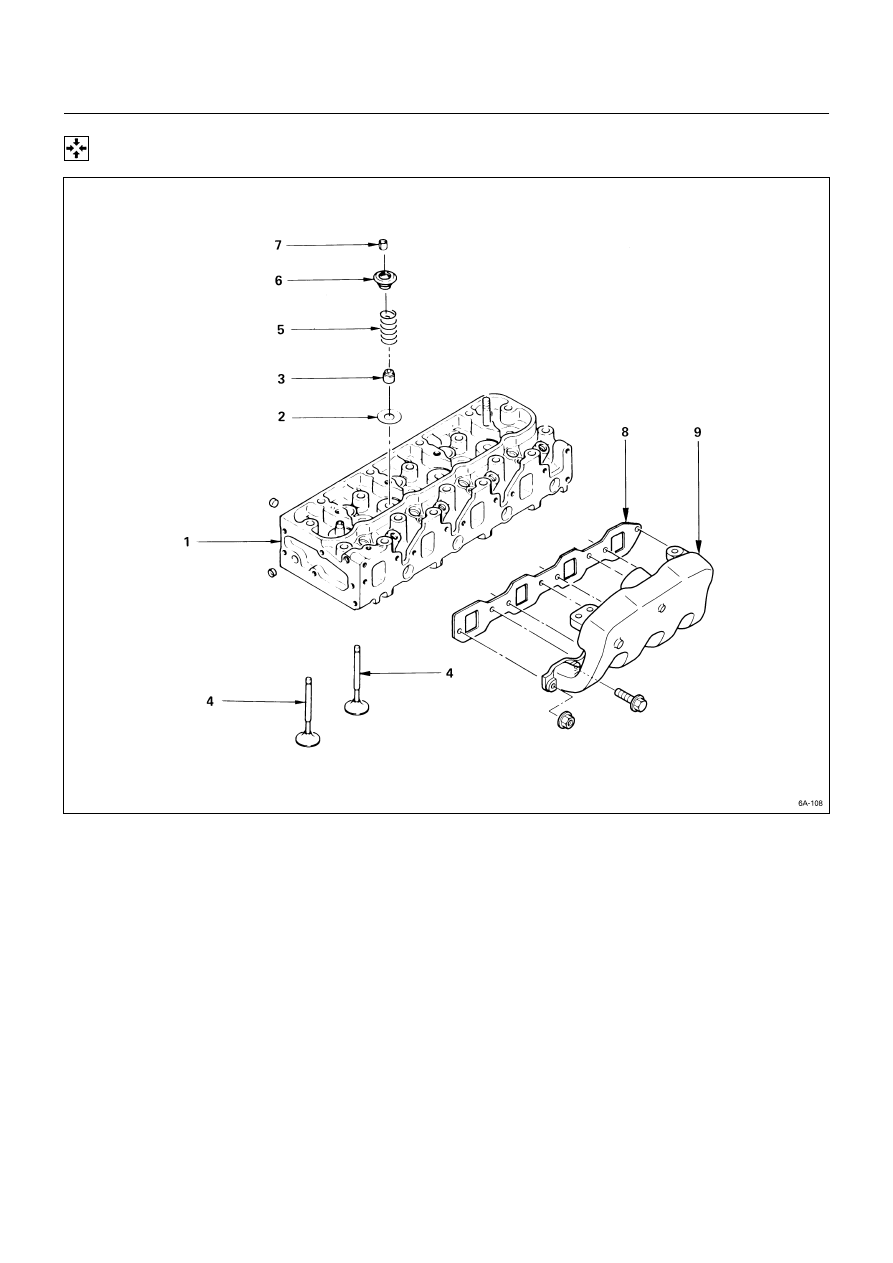

CYLINDER HEAD

Reassembly Steps

1.

Cylinder head

6.

Valve spring upper seat

2.

Valve spring lower seat

t

7.

Split collar

t

3.

Valve stem oil seal

t

8.

Intake manifold gasket

t

4.

Intake and exhaust valve

t

9.

Intake manifold

t

5.

Valve spring

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст