Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 566

6A – 102 ENGINE MECHANICAL

FLYWHEEL AND RING GEAR

Flywheel

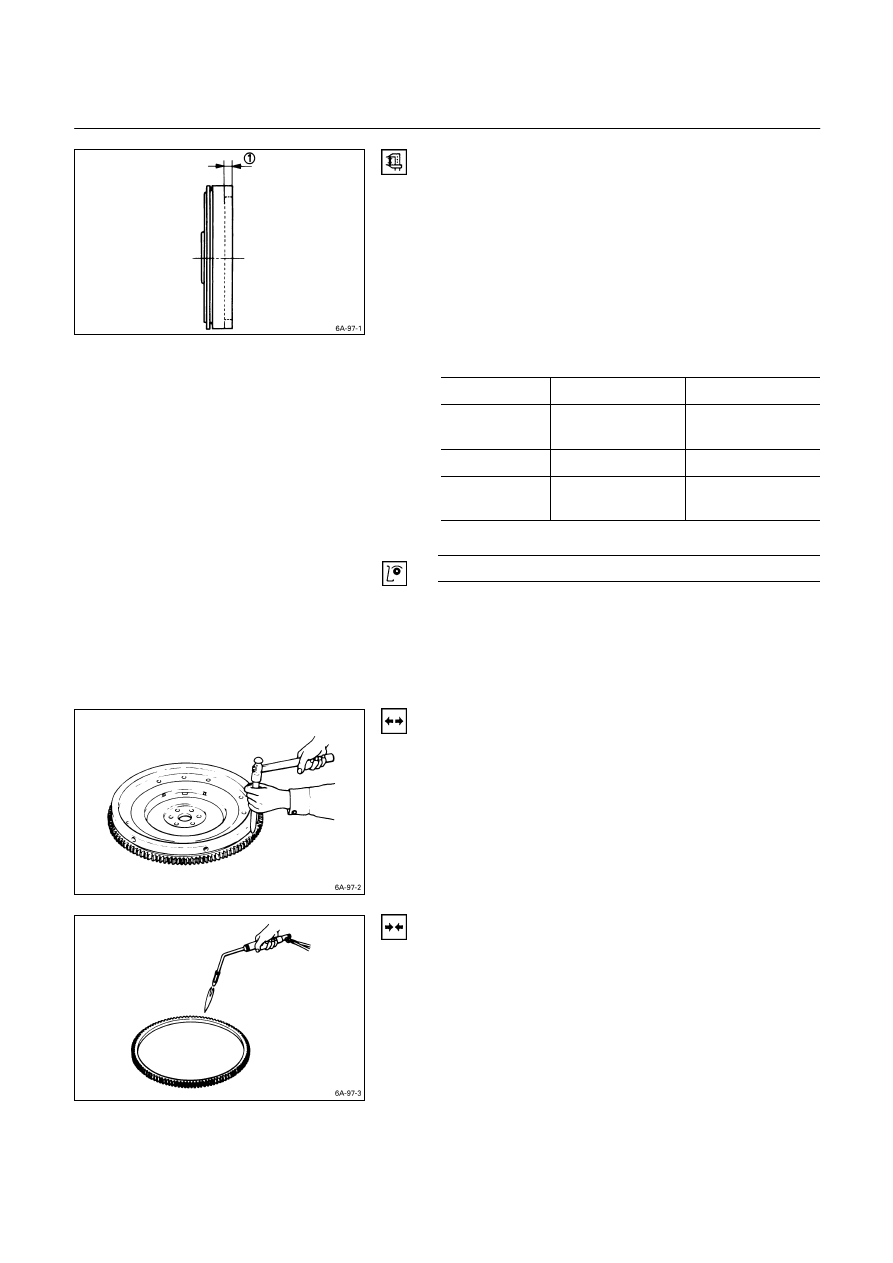

1. Inspect the flywheel friction surface for excessive wear

and heat cracks.

2. Measure the flywheel friction surface depth.

If the measured value is within the specified limit, the

flywheel may be reground.

If the measured value exceeds the specified limit, the

flywheel must be replaced.

Flywheel Friction Surface Depth

Q

mm

(in)

Standard

Limit

4JA1, 4JA1T,

4JA1TC

20 (0.787)

21 (0.827)

4JB1T 14

(0.551)

15

(0.591)

4JG2T,

4JH1TC

18 (0.708)

19 (0.748)

Flywheel Friction Surface Roughness

mm (in)

Less than 0.006 (0.00024)

Ring Gear

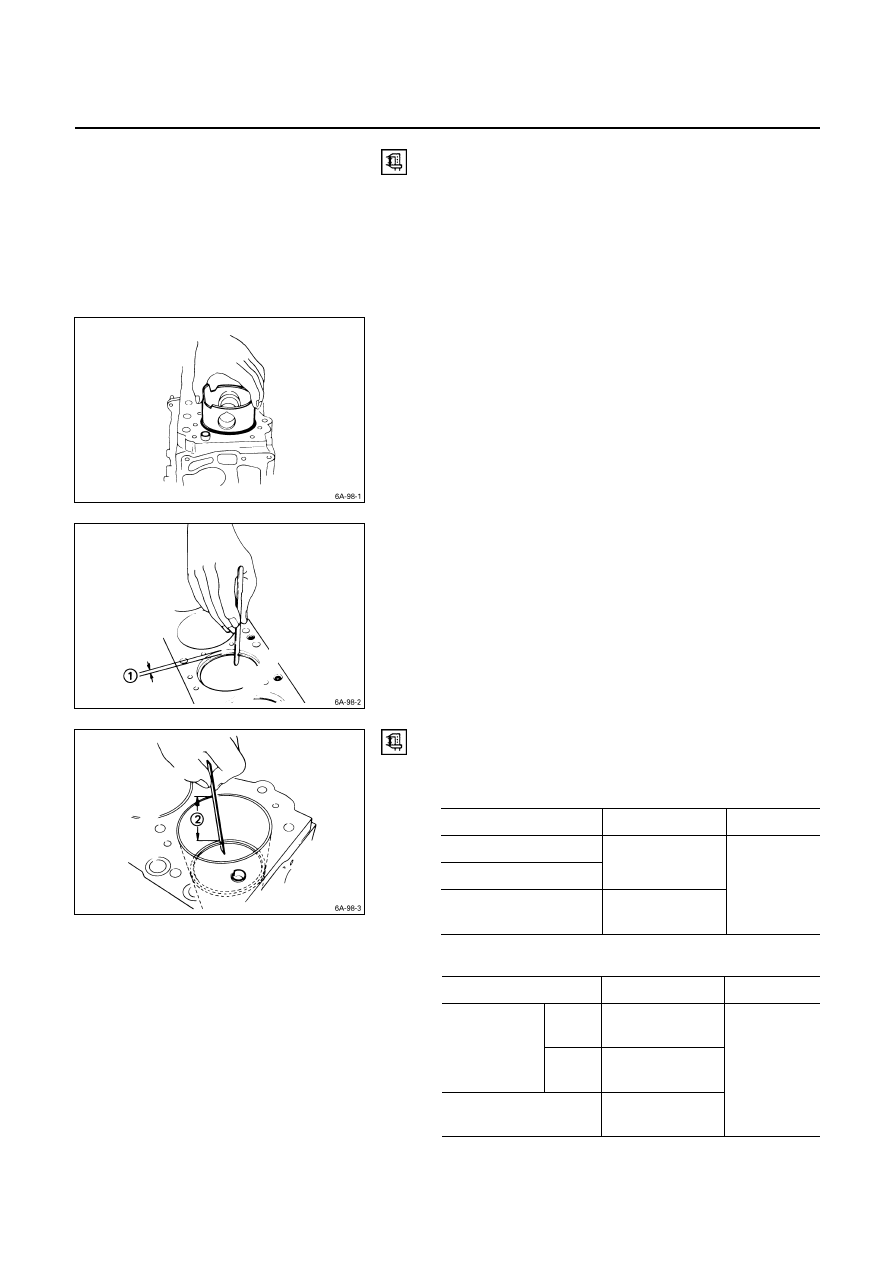

Inspect the ring gear.

If the ring gear teeth are broken or excessively worn, the

ring gear must be replaced.

Ring Gear Replacement

Ring Gear Removal

Strike around the edges of the ring gear with a hammer

and chisel to remove it.

Ring Gear Installation

1. Heat the ring gear evenly with a gas burner to invite

thermal expansion.

Do not allow the temperature of the gas burner to

exceed 200

°C (390°F).

2. Install the ring gear when it is sufficiently heated.

The ring gear must be installed with the chamfer

facing the clutch.

ENGINE MECHANICAL 6A – 103

PISTON

Piston Grade Selection and Cylinder Bore

Measurement

Refer to the Section “CYLINDER BODY”, Item “Cylinder

Liner Bore Measurement” for details on piston grade

selection and cylinder liner bore measurement.

PISTON RING

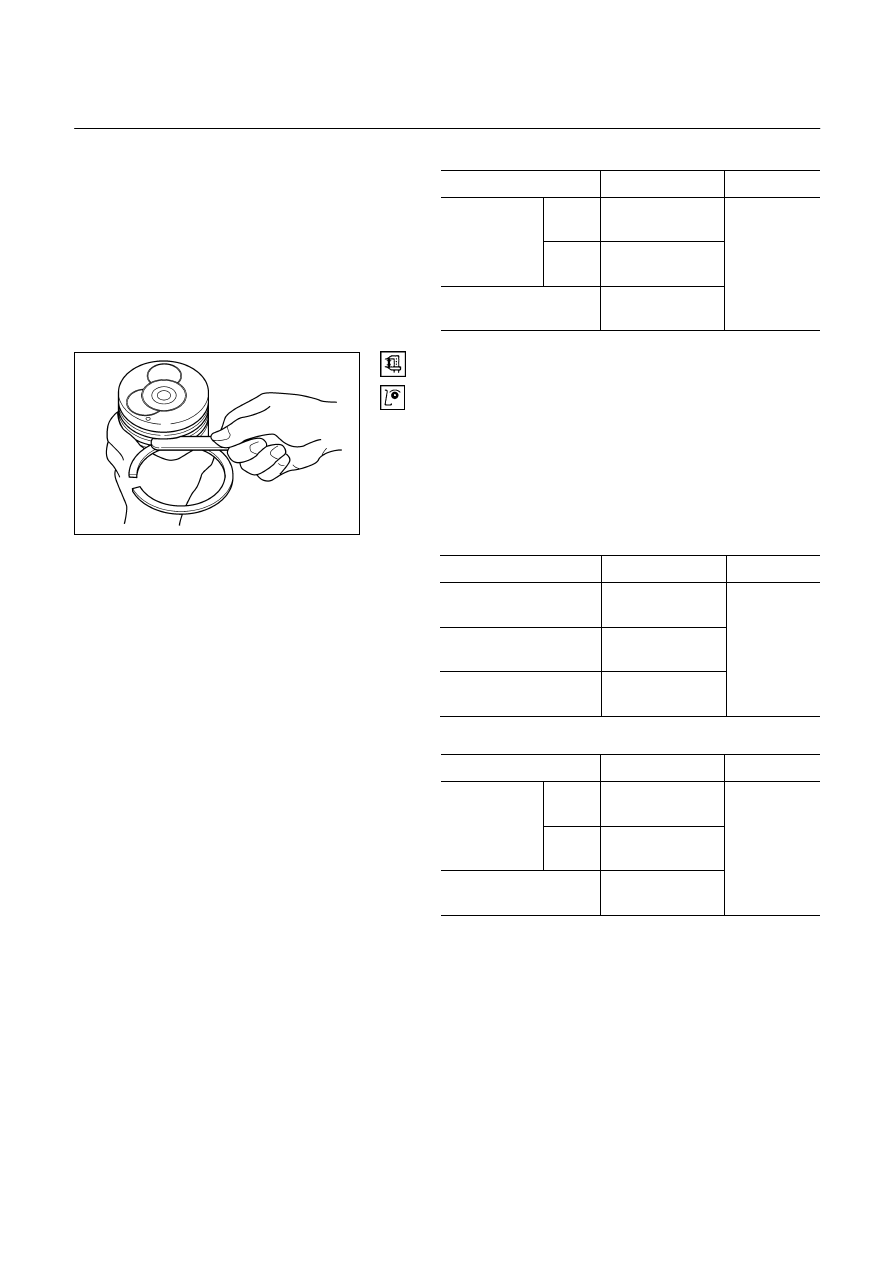

Piston Ring Gap

1. Insert the piston ring horizontally (in the position it

would assume if it were installed to the piston) into the

cylinder liner.

2. Push the piston ring into the cylinder bore until it

reaches the measuring point

Q

or

R

where the

cylinder liner bore is the smallest.

Do not allow the piston ring to slant to one side or the

other. It must be perfectly horizontal.

Measuring Point

Q

10 mm (0.4 in)

or

Measuring Point

R

120 mm (4.7 in)

3. Use a feeler gauge to measure the piston ring gap.

If the measured value exceeds the specified limit, the

piston ring must be replaced.

Piston Ring Gap

mm (in)

Standard

Limit

1st Compression Ring

2nd Compression Ring

0.2 – 0.4

(0.008 – 0.016)

Oil Ring

0.1 – 0.3

(0.004 – 0.012)

1.5

(0.059)

4JG2

mm (in)

Standard Limit

1st

0.20 – 0.35

(0.0079 – 0.0138)

Compression

ring

2nd

0.37 – 0.52

(0.0146 – 0.0205)

Oil ring

0.20 – 0.40

(0.0079 – 0.0157)

1.5

(0.059)

6A – 104 ENGINE MECHANICAL

4JH1TC

mm (in)

Standard Limit

1st

0.30 – 0.50

(0.0118 – 0.0197)

Compression

ring

2nd

0.30 – 0.50

(0.0118 – 0.0197)

Oil ring

0.25 – 0.45

(0.0098 – 0.0117)

0.15

(0.0059)

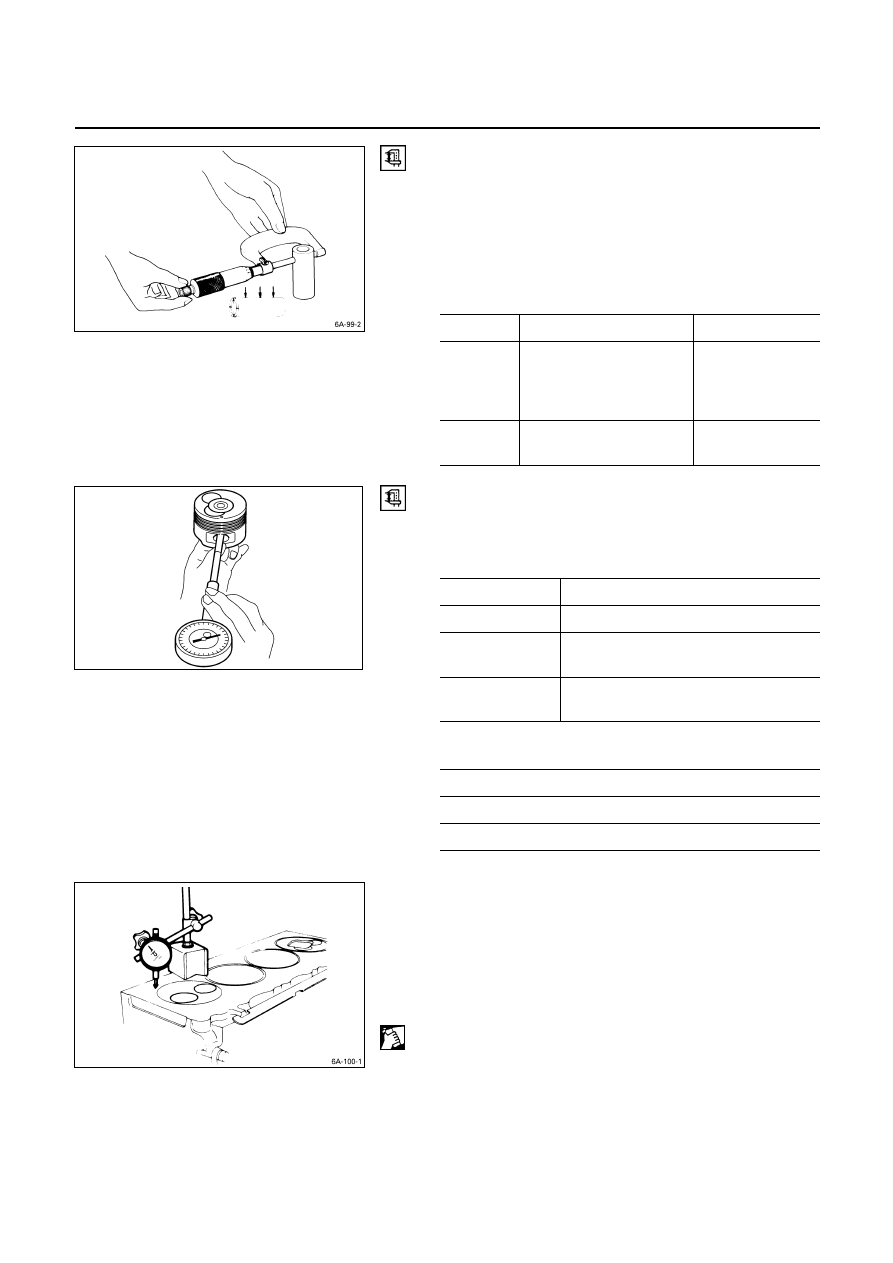

Piston Ring and Piston Ring Groove Clearance

Use a feeler gauge to measure the clearance between the

piston ring and the piston ring groove at several points

around the piston.

If the clearance between the piston ring and the piston ring

groove exceeds the specified limit, the piston ring must be

replaced.

Piston Ring and Piston Ring Groove

Clearance

4JA1, 4JB1T, 4JA1T, 4JA1TC mm (in)

Standard

Limit

1st Compression Ring

0.09 – 0.125

(0.0035 – 0.0049)

2nd Compression Ring

0.05 – 0.085

(0.002 – 0.0033)

Oil Ring

0.03 – 0.070

(0.0012 – 0.0028)

0.15

(0.0059)

4JG2, 4JH1TC mm (in)

Standard Limit

1st

0.09 – 0.13

(0.0035 – 0.0051)

Compression

ring

2nd

0.05 – 0.09

(0.0020 – 0.0035)

Oil ring

0.03 – 0.07

(0.0012 – 0.0028)

0.15

(0.0059)

4. Visually inspect the piston rings.

If a piston ring groove is damaged or distorted, the

piston must be replaced.

015RY00029

ENGINE MECHANICAL 6A – 105

PISTON PIN

Piston Pin Diameter

Use a micrometer to measure the piston pin diameter at

several points.

If the measured value is less than the specified limit, the

piston pin must be replaced.

Piston Pin Diameter

mm (in)

Standard Limit

4JA1

4JA1T

4JA1TC

4JH1TC

30.995 – 31.000

(1.2202 – 1.2204)

30.97 (1.219)

4JB1T

4JG2T

33.994 – 34.000

(1.3383 – 1.3386)

33.97 (1.337)

Piston Pin and Piston Clearance

Use and inside dial indicator to measure the piston pin

hole (in the piston).

Piston Pin Hold

mm (in)

Standard

4JA1, 4JA1T

31.002 – 31.010 (1.2206 – 1.2208)

4JB1T

4JG2T

34.002 – 34.010 (1.3387 – 1.3390)

(1.3383 – 1.3386)

4JA1TC

4JH1TC

31.005 – 31.013 (1.2207 – 1.2210)

Piston Pin and Piston Pin Hole Clearance

mm (in)

0.002 – 0.015 (0.00008 – 0.0006)

4JA1TC, 4JH1TC

0.005 – 0.018 (0.00019 – 0.0007)

CYLINDER HEAD GASKET SELECTION

Cylinder head gasket is determined by the piston head

projection from the cylinder body upper surface, in order to

improve engine performance.

Three types of gasket are provided by the difference of

thickness. Select the adequet one out of three grades of

gasket, according to the following procedure.

Before measurement, clear off carbon from the piston

head and cylinder body surface and also clean the place

where a gasket was installed.

015RY00030

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст