Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 1714

6D3-14 STARTING AND CHARGING SYSTEM

7. To remove the pulley, mount an 8mm Allen key in the vice

with the short end upwards, place a 24mm ring spanner on

the puley nut, position the internal hexagon of the rotor shaft

onto the Allen ken, loosen the nut and remove the pulley.

Note: the pulley has an integral boss which locks up against

the bearing,

therefore no thrust collar is provided.

8. Removing the rotor assembly. Remove the four retaining

screws from the drive end housing, withdraw the rotor

complete with the bearing.

Note: the rotor must not be pressed from the drive end housing

using a press as the bearing retaining plate and drive end

housing will be damaged or distorted. Parts removed in this

way must be replaced if the integrity of the generator is to be

maintained.

9. Remove the drive end bearing from the rotor shaft using a

chuck type puler, take care not to distort the fan assembly

during this process.

10.Remove the slipring end bearing using the same meghod

as in 9.

Clean

Thoroughly clean all components except the rotor and stator

with an approved cleaning agent. Ensure that all traced of oil

and dirt are removed. If an abrasive cleaner is used to remove

scale and paint from the housings take care not to abrade the

bearing and mounting spigot surfaces. The rotor and stator

must be cleaned with compressed air only, the use of solvents

could cause damage to the insulating materials.

Inspection

1. Rectifier assembly

The following test equipment is required.

The recitifier assembly is not repairable and must be replaced

if a faulty diode is detected during inspection.

(a) Adiode tester where the DC output at the test probes does

not exceed 14 volts or in the case of AC testers 12 volts

RMS. This is to ensue that when inspection rectifiers fitted

with zener power diodes the forward and reverse checks

are completer and are not masked by the diode turning on

due to the zener breakdown voltage.

(b) A zenere diode tester with a DC output in excess of 30

volts, the tester should also incorporate internal current

limiting set to 5 Ma. to prevent high currents during

inspection.

(c) Diodes can be destroyed during service due to high

temperature and overload, open circuits are usually a result

of excessive voltage.

STARTING AND CHARGING SYSTEM 6D3-15

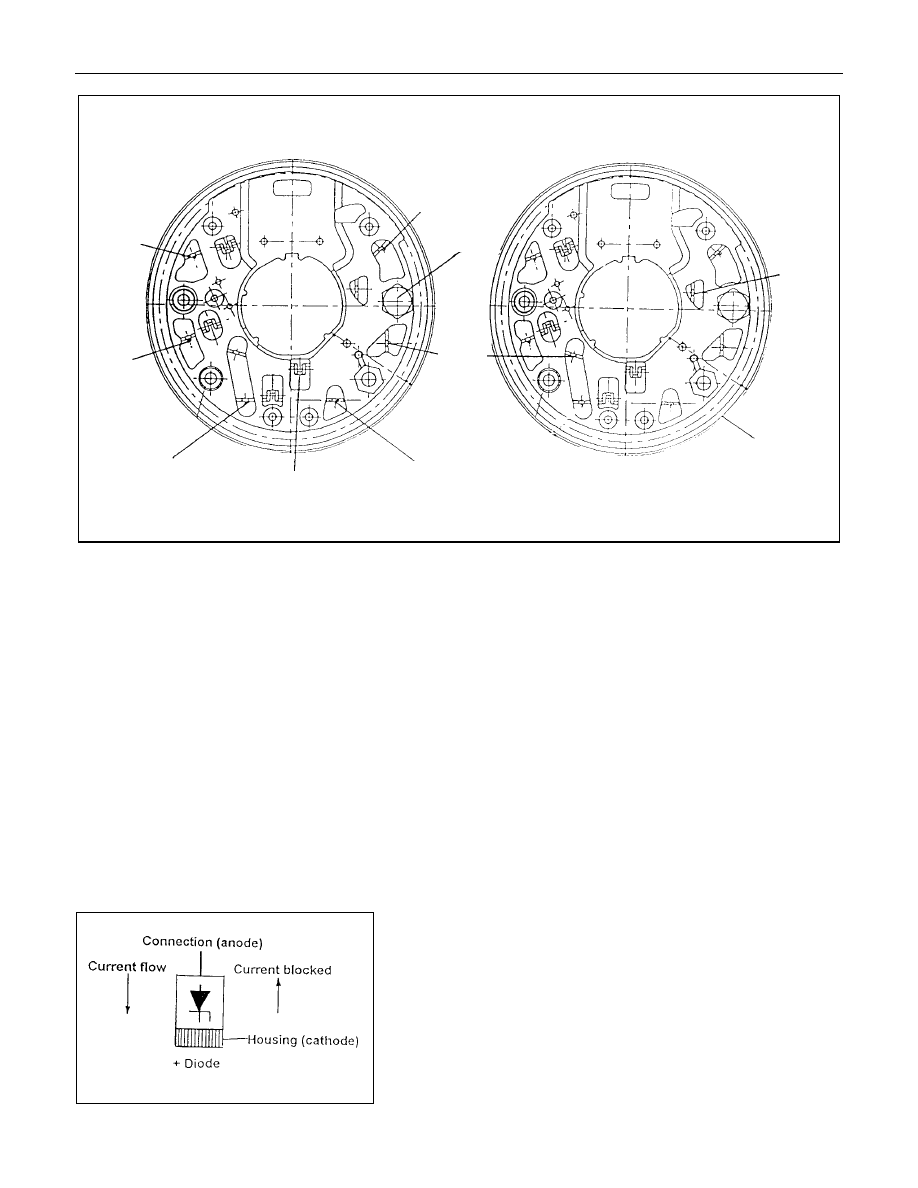

Positive heatsink

8 diode

6 diode

H

G

Negative heatsink

C

B

A

Starpoint

F

E

B+Bolt

D

Diode connections

Stator connection

1.1

Power Diodes.

Apply the negative test probe of the diode tester or a

multimeter with a diode test feature to the positive heatsink and

the positive probe alternatevely to A,B,C, a low resistance

reading, or the forward voltage drop across the diode shoud be

obtained. Reverse the test probes, a high resistance reading or

a higher reverse voltage should be obtained.

Now connect the positive test probe to the negative heatsink

and the negative alternatively to D,E,F, a low resistance or

forward voltage drop across the diode should be obtained.

Reverse the test probes, a high resistance reading or a higher

reverse voltage should be obtained.

For 8 diode rectifier plates tests for G and H should be

included. When the reverse voltage test is done the applied

voltage should be less than 14 volts DC or 12 volts RMS for

AC testers.

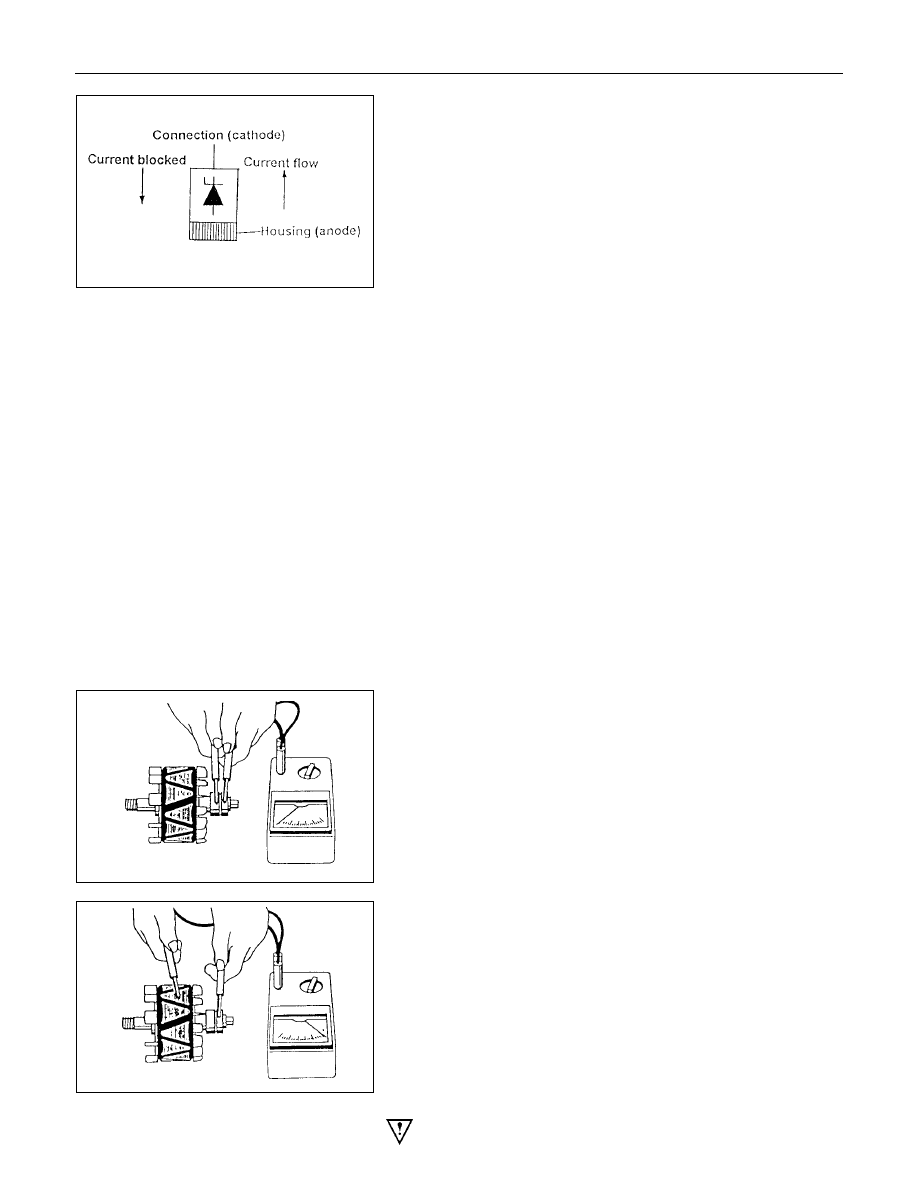

1.2Zener Diode

The basic tests in 1.1 should be undertaken first before the

diode zener voltage is tested. Diodes are grouped together

according to their zener voltag i.e. all diodes within a rectifier

must have the same zener voltage.

Connect the test probes as for the reverese test listed above

i.e. reverse biased apply the test voltage form the zener diode

tester (current limited to 5ma) and read to zener breakdown

voltage this should be a steady reading and not increase with

increased voltage from the tester.

6D3-16 STARTING AND CHARGING SYSTEM

Readings for Zener diode groups 011 to 042

Zener voltage at

5Ma.

Positive

diode

Negative

diode

Fordward

current Rating

17.8v-19.2v

011

012

25A

18.8v-20.2v

013

014

25A

19.8v-21.2v

015

016

25A

20.8v-22.2v

017

018

25A

21.8v-23.2v

019

020

25A

22.8v-24.2v

021

022

25A

17.8v-19.2v

031

032

35A

18.8v-20.2v

033

034

35A

19.8v-21.2v

035

036

35A

20.8v-22.2v

037

038

35A

21.8v-23.2v

039

040

35A

22.8v-24.2v

041

042

35A

Note: Diode number is stamped on the rear of the diode.

2. Stator

Inspect the stator insulation resistance to ground with an

insuation tester or a series test lamp up to 110 volts.

The insulation resistance must be greater than 1 megohm.

The winding reisistance is measured between phases using a

low reading ohmmeter designed for this purpose, the values

are given at the rear of this instruction.

3. Rotor

Inspect the rotor for insulation resistance to ground using an

insulation tester or a series test lamp up to 110 volts.

The insulation resistance must be grater than 1 megohm.

Measure the rotor resistance between the sliprings using an

ohmmeter or apply 12 volts across the sliprings and measure

the rotor current flow, then divide 12 by the measured current,

the results is the rotor resistance in ohms. values are given at

the rear of this instruction.

If the sliprings are worn or out of round they must be re-

machined to a minimum diameter or 26.7 mm and should have

a runout not exceeding 0.060mm. If the slipring is below these

limits it must be replaced with a new one.

Warning; extreme care must be exercised when machining

the slipring as it is possible for the turning tool to foul the fan.

STARTING AND CHARGING SYSTEM 6D3-17

4. Replacing the brushes (inbuilt regulator)

Check the brushes for length, this is measured from the brush

holder to the end of the brush along it's centre line. Also

inspect for any sideways wear. If worn replace both brushes.

The minimum length is 3.8mm. Inspect the brush springs for

signs of corrosion or loss of tension or uneven tension.

Replacing the brushes, using a soldering iron apply heat to the

soldered joints on the rear of the brush holder of the regulator,

using a small lever prise up the retaining tabs to release the

brush lead and spring. Thread the new brush lead up the

brush holder along with the spring, pull the lead through the

tabs until the brush is protruding 12mm from the holder.

Bend down the tabs and solder the brush lead taking care not

to allow the solder to run up the lead which will reduce

flexibility. Use 60/40 resin cored solder.

5. Ball bearing

Please note the bearings used in this KCA generator are a high

tolerance type, only fully sealed bearings of the same

specification are to be used as replacements. It is

recommended that the bearings be replaced during the

reconditioning process to restore the unit to original

specification.

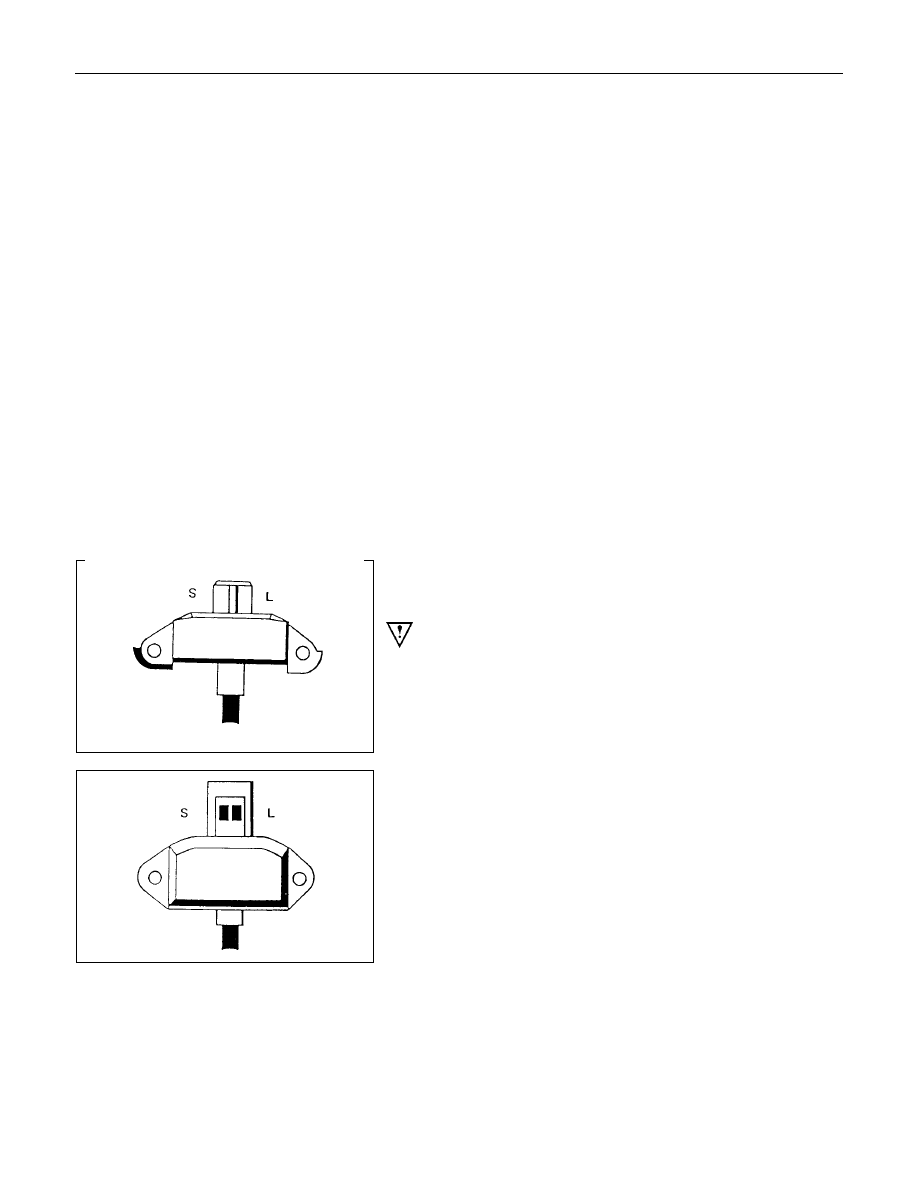

6. Regulator

The regulator can only be tested when fitted into an altenator.

Warning: do not reverse"S" and "L" connections or put 12

volt supply to "L" terminal, this connection must not be

used as a supply source other than to supply the

requirements of the warning lamp 2(watts).

Such action will destroy the regulator warning lamp

circuit.

For test voltages refer to Generator output testing section.

See also additional information on regulator function earlier in

this instruction.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст