Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 563

6A – 90 ENGINE MECHANICAL

Piston Grade Selectin

Measure the cylinder liner bore after installing the cylinder

liner. Then select the appropriate piston grade for the

installed cylinder liner.

1. Measure the cylinder liner bore.

Refer to “Cylinder Liner Bore Measurement”

Note:

It is most important that the correct piston grade be

used. Failure to select the correct piston grade will

result in engine failure. Always measure the cylinder

bore and select the correct piston grade.

2. Measure the piston diameter.

Piston Measuring Point

mm (in)

4JA1 70

(2.76)

4JA1T 78

(3.07)

4JB1T 74

(2.91)

4JG2T, 4JH1TC

71 (2.79)

4JA1TC 68.1

(2.68)

Grade

4JA1T/4JA1 4JB1T

4JG2T

AX

92.979 – 92.994

(3.6606 – 3.6612)

92.974 – 92.989

(3.6604 – 3.6610)

95.369 – 95.384

(3.7547 –3.7553)

CX

92.995 – 93.010

(3.6612 – 3.6618)

92.990 – 93.005

(3.6610 – 3.6616)

95.385 – 95.400

(3.7553 – 3.7559)

Grade

4JA1TC 4JH1TC

AX

92.945 – 92.964

(3.6592 – 3.6600)

95.359 – 95.374

(3.7543 – 3.7549)

CX

92.965 – 92.984

(3.6600 – 3.6607)

95.375 – 95.390

(3.7549 – 3.7555)

Cylinder Liner and Piston Clearance

mm (in)

4JA1T/4JA1

0.041 – 0.071 (0.0016 – 0.0027)

4JB1T

0.046 – 0.076 (0.0018 – 0.0030)

4JG2T

0.051 – 0.081 (0.0020 – 0.0032)

4JA1TC

0.057 – 0.095 (0.0022 – 0.0029)

4JH1TC

0.061 – 0.091 (0.0024 – 0.0036)

Note:

Cylinder liner kit clearances are preset. However, the

cylinder liner installation procedure may result in

slight decreases in cylinder liner clearances. Always

measure the cylinder liner clearance after installation

to be sure that it is correct.

ENGINE MECHANICAL 6A – 91

TAPPET AND PUSH ROD

Visually inspect the tappet contact surfaces for pitting,

cracking, and other abnormal conditions. The tappet must

be replaced if any of these conditions are present.

Refer to the illustration at the left.

Q

Normal contact

R

Cracking

S

Pitting

T

Irregular contact Uneven contact

U

Irregular contact One-sided contact

Note:

The tappet surfaces are spherical. Do not attempt to

grind them with an oil stone or similar tool in an effort

to repair the tappet. If the tappet is damaged, it must

be replaced.

Tappet Outside Diameter

Measure the tappet outside diameter with a micrometer.

If the measured value is less than the specified limit, the

tappet must be replaced.

Tappet Outside Diameter

mm (in)

Standard

Limit

12.97 – 12.99

(0.510 – 0.511)

12.95 (0.510)

Tappet and Cylinder Body Clearance

mm (in)

Standard

Limit

0.01 – 0.046

(0.0004 – 0.0018)

0.10 (0.004)

6A – 92 ENGINE MECHANICAL

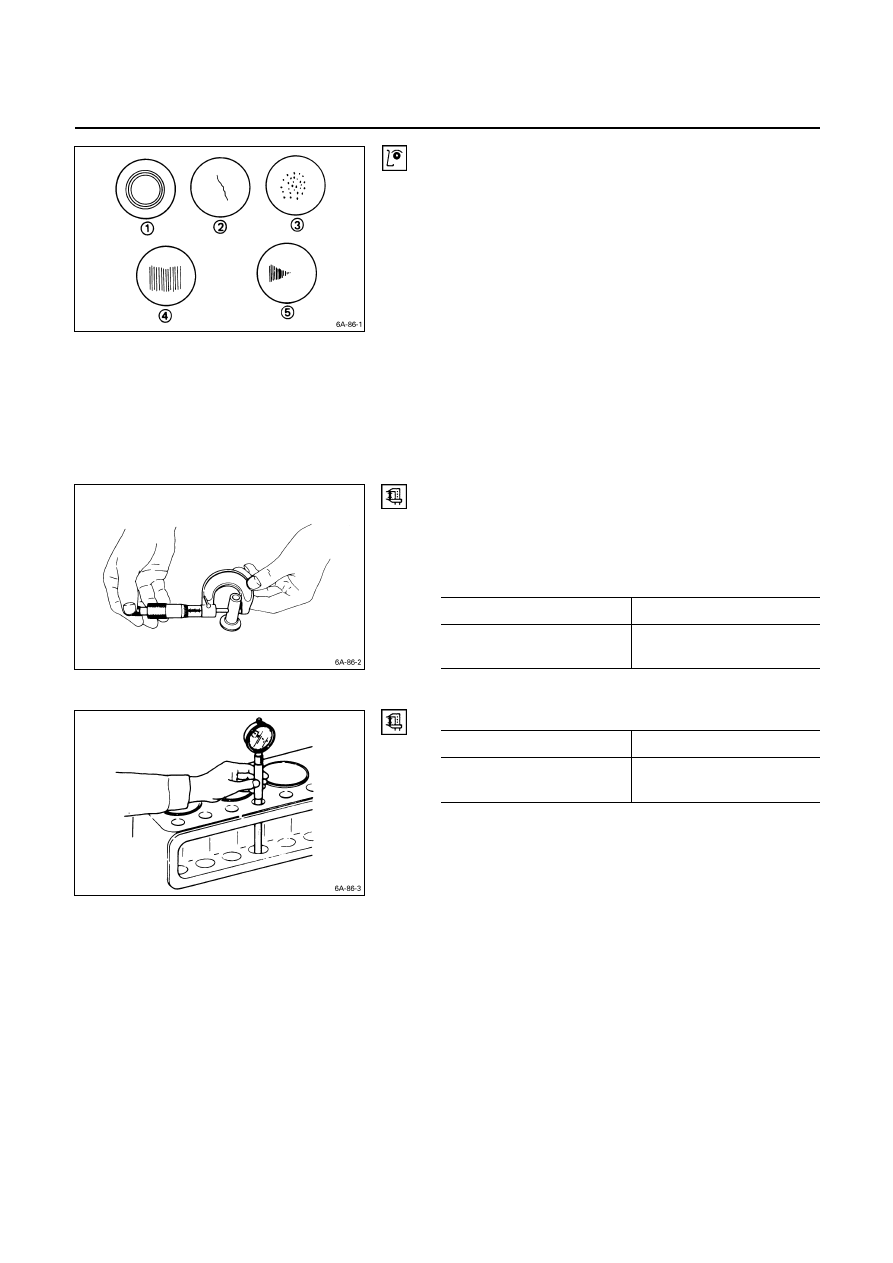

Push Rod Curvature

1. Lay the push rod on a surface plate.

2. Roll the push rod along the surface plate and measure

the push rod curvature with a thickness gauge.

If the measured value exceeds the specified limit, the

push rod must be replaced.

Pushrod Curvature

mm (in)

Limit

0.3 (0.012)

3. Visually inspect both ends of the push rod for

excessive wear and damage. The push rod must be

replaced if these conditions are discovered during

inspection.

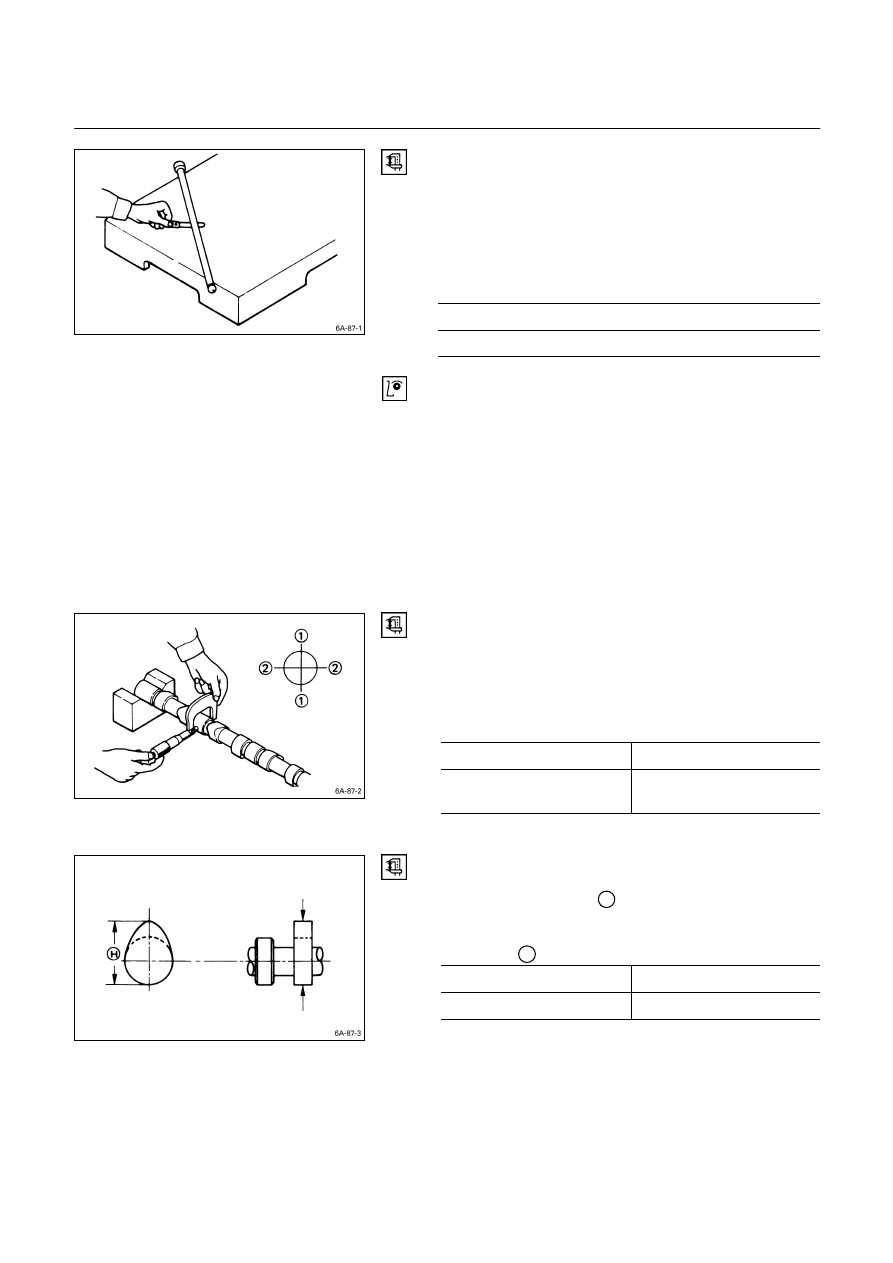

CAMSHAFT

Visually inspect the journals, the cams, the oil pump drive

gear, and the camshaft bearings for excessive wear and

damage. The camshaft and the camshaft bearings must

be replaced if these conditions are discovered during

inspection.

Camshaft Journal Diameter

Use a micrometer to measure each camshaft journal

diameter in two directions (

Q

and

R

). If the measured

value is less than the specified limit, the camshaft must be

replaced.

Camshaft Journal Diameter

mm (in)

Standard

Limit

49.945 – 49.975

(1.9663 – 1.9675)

49.60 (1.953)

Cam Height

Measure the cam height

H

with a micrometer. If the

measured value is less than the specified limit, the

camshaft must be replaced.

Cam Height

H

mm

(in)

Standard

Limit

42.08 (1.657)

41.65 (1.640)

ENGINE MECHANICAL 6A – 93

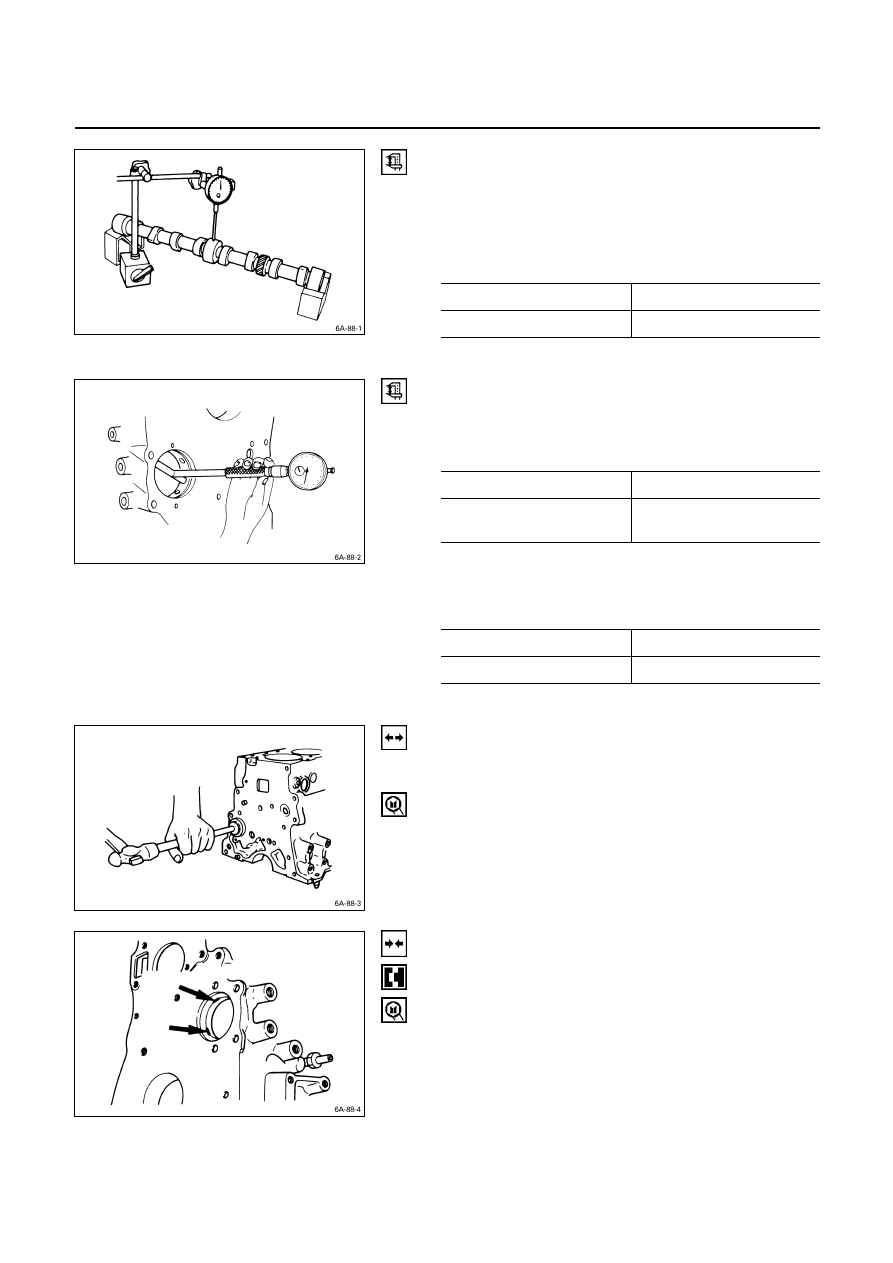

Camshaft Run-Out

1. Mount the camshaft on V-blocks.

2. Measure the run-out with a dial indicator.

If the measured value exceeds the specified limit, the

camshaft must be replaced.

Camshaft Run-Out

mm (in)

Standard Limit

0.02 (0.0008)

0.10 (0.004)

Camshaft and Camshaft Bearing Clearance

Use an inside dial indicator to measure the camshaft

bearing inside diameter.

Crankshaft Bearing Inside Diameter

mm (in)

Standard Limit

50.00 – 50.03

(1.968 – 1.970)

50.08 (1.972)

If the clearance between the camshaft bearing inside

diameter and the journal exceeds the specified limit, the

camshaft bearing must be replaced.

Camshaft Bearing Clearance

mm (in)

Standard Limit

0.05 (0.002)

0.12 (0.005)

Camshaft Bearing Replacement

Camshaft Bearing Removal

1. Remove the cylinder body plug plate.

2. Use the bearing replacer to remove the camshaft

bearing.

Bearing Replacer: 5-8840-2038-0

Camshaft Bearing Installation

1. Align the bearing oil holes with the cylinder body oil

holes.

2. Use the replacer to install the camshaft bearing.

Bearing Replacer: 5-8840-2038-0

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст