Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 562

6A – 86 ENGINE MECHANICAL

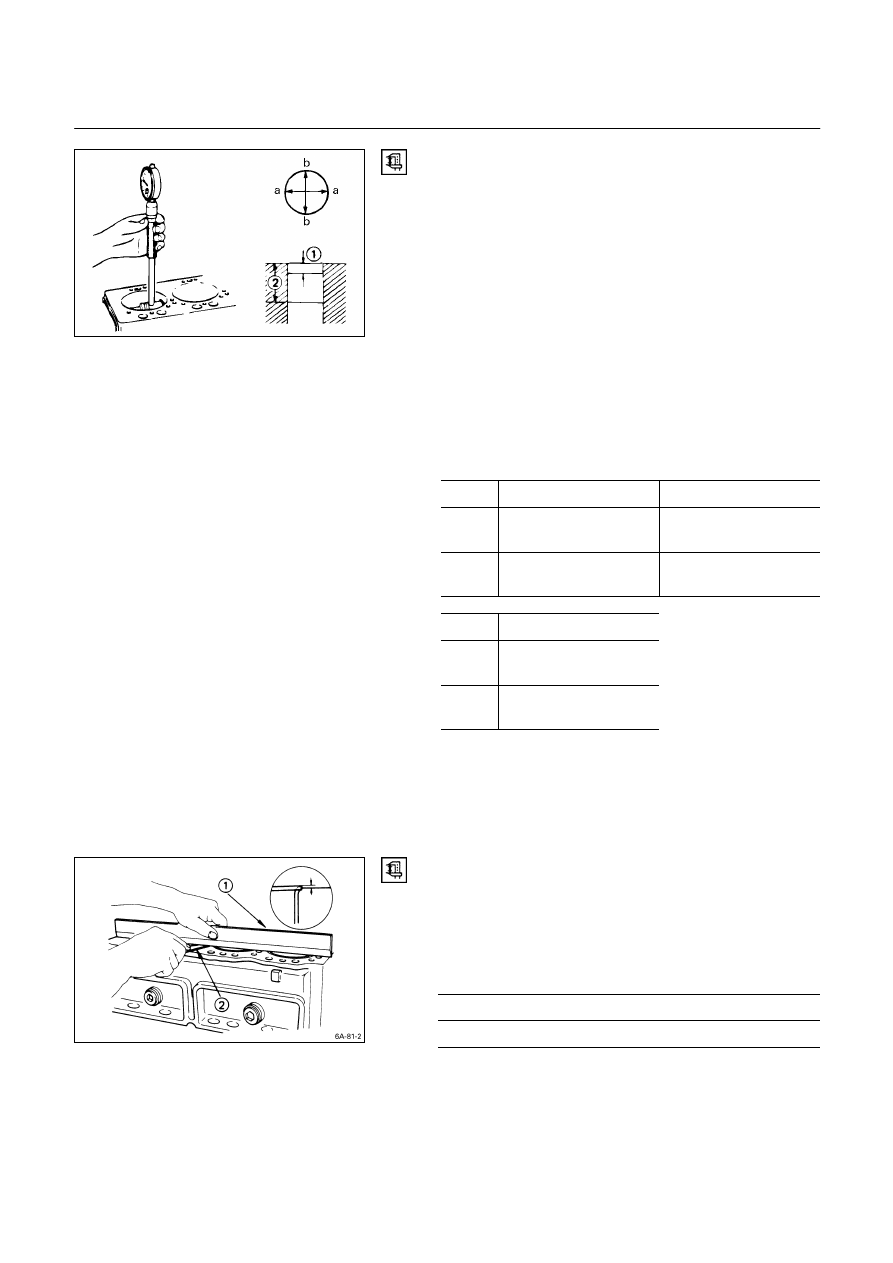

Cylinder Liner Bore Measurement

Use a cylinder indicator to measure the cylinder bore at

measuring point

Q, R

in the thrust a-a and axial b-b

directions of the crankshaft.

If the measured value exceeds the specified limit, the

cylinder liner must be replaced.

Measuring Points

Q

20 mm (0.8 in) for 4JA1, 4JA1TC

and 4JB1T, 4JG2T,

4JH1TC

R

140 mm(5.5 in) for 4JA1, 4JA1TC

R

160 mm(6.3 in) for 4JB1T, 4JG2T,

4JH1TC

Cylinder Liner Bore (Service Part)

mm (in)

Grade

4JA1, 4JA1T, 4JB1T

4JG2T, 4JH1TC

AX

93.035 – 93.050

(3.6628 – 3.6634)

95.435 – 95.450

(3.7573 – 3.7579)

CX

93.051 – 93.066

(3.6634 – 3.6640)

95.451 – 95.466

(3.7579 – 3.7585)

Grade

4JA1TC

AX

93.021 – 93.040

(3.6622 – 3.6630)

CX

93.041 – 93.060

(3.6630 – 3.6638)

012L200001

Note:

The inside of the dry type cylinder liner is chrome

plated. It cannot be rebored or honed.

If the inside of the cylinder liner is scored or

scorched, the cylinder liner must be replaced.

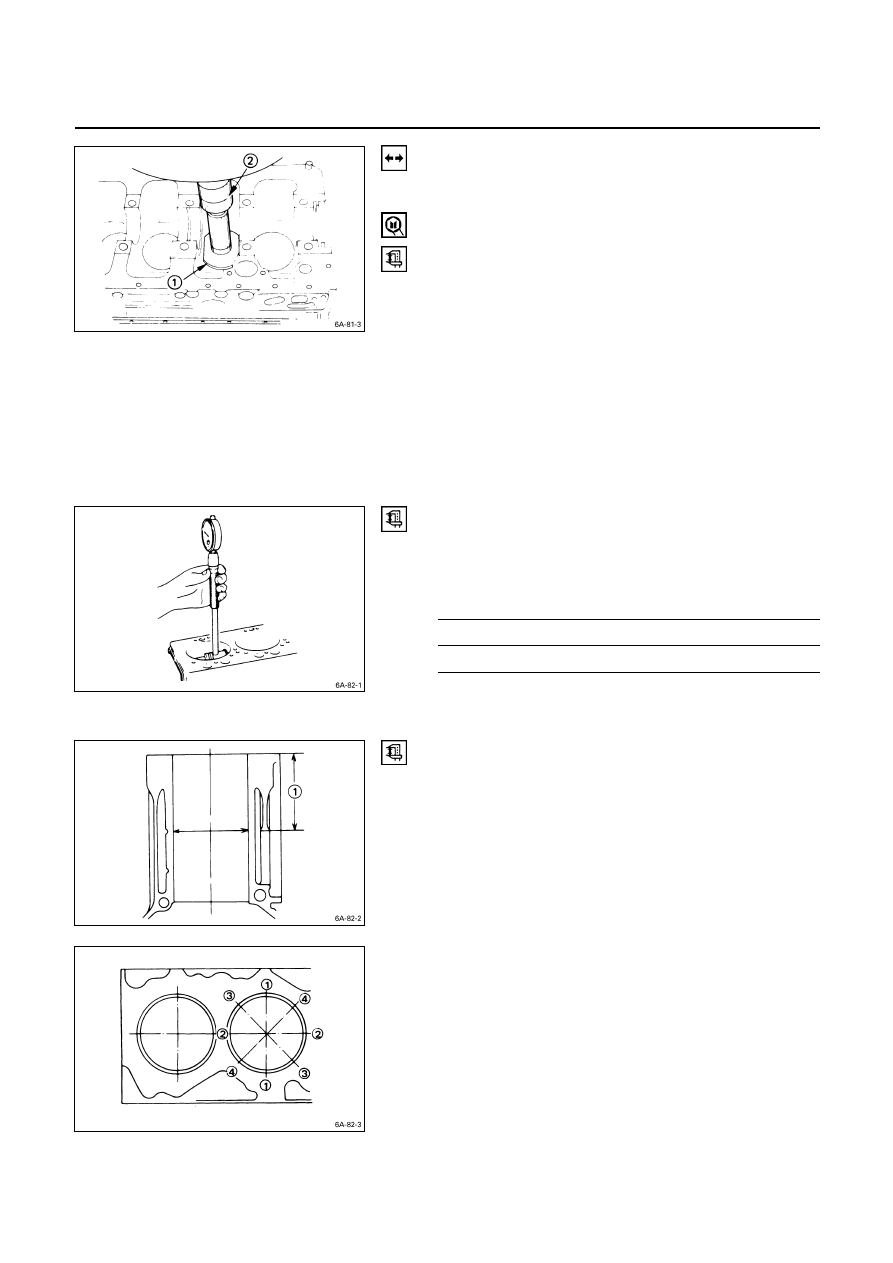

Cylinder Liner Projection Inspection

1. Hold a straight edge

Q

along the top edge of the

cylinder liner to be measured.

2. Use a feeler gauge

R

to measure each cylinder liner

projection.

Cylinder Liner Projection

mm (in)

Standard

0 – 0.1 (0 – 0.004)

The difference in the cylinder liner projection height

between any two adjacent cylinders must not exceed

0.03 mm (0.0012 in).

ENGINE MECHANICAL 6A – 87

Cylinder Liner Replacement

Cylinder Liner Removal

1. Insert the cylinder liner remover

Q

into the cylinder

body (from the lower side of the cylinder body) until it

makes firm contact with the cylinder liner.

Cylinder Liner Remover:

5-8840-2039-0

5-8840-2304-0: 4JG2T, 4JH1TC

Engine

2. Use a bench press

R

to slowly force the cylinder liner

from the cylinder body.

Note:

Take care not to damage the cylinder body upper face

during the cylinder liner removal procedure.

3. Measure the cylinder body upper face warpage.

Refer to “Cylinder Body Upper Face Warpage”.

Cylinder Liner Grade Selection

Subtract the average cylinder body bore from the average

cylinder liner outside diameter to obtain the fitting

interference.

Fitting Interference

mm (in)

Standard

– 0.0010* – 0.019 (– 0.00004* – 0.0007)

* A minus (–) value indicates that the cylinder body bore

is smaller than the liner outside diameter.

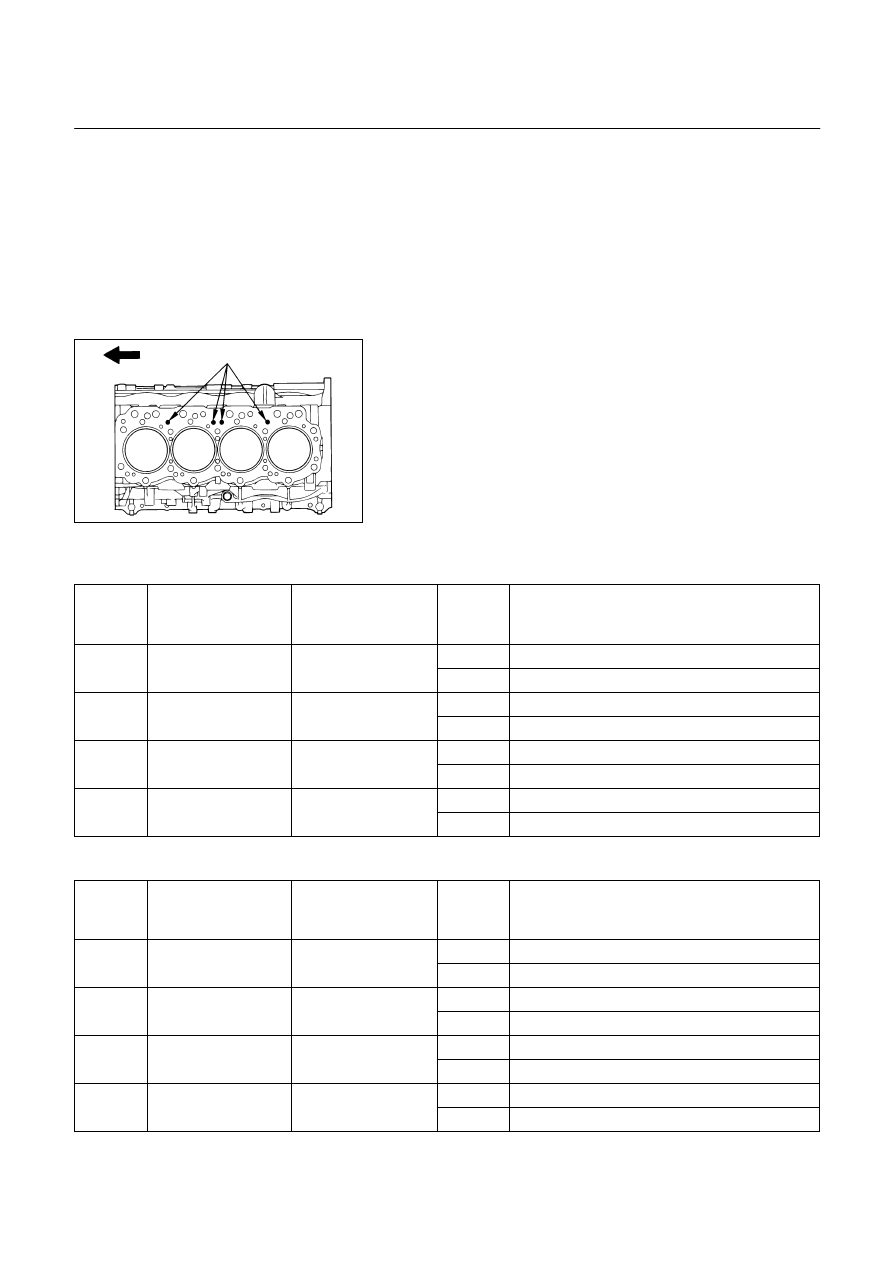

Cylinder Body Bore Measurement

1. Take measurements at measuring point

Q

across

positions

Q

-

Q

,

R

-

R

,

S

-

S

, and

T

-

T

.

Measuring Point

Q

98 mm (3.86 in)

2. Calculate the average value of the four measurements

to determine the correct cylinder grade.

3. Consult the following table with the resultant diameter

for the correct liner application.

6A – 88 ENGINE MECHANICAL

Cylinder Liner Grade Selection and Standard

Fitting Interference

Accurately measured fitting interference and proper

cylinder liner grade selection are extremely important.

If the cylinder liner fitting interference is too small, engine

cooling efficiency will be adversely affected.

If the cylinder liner fitting interference is too large, it will be

difficult to insert the cylinder liner into the cylinder body.

A mark was stamped on the upper of the cylinder block

during production to indicate the correct liner.

The liner grade (i.e.1.2.3.4) is indicated in metal stamp.

Cylinder Liner Grade

4JA1, 4JA1T, 4JB1T, 4JA1TC

mm (in)

Liner

Outside

Grade

Cylinder Body

Bore Diameter

Liner Outside

Diameter

Liner

Bore

Grade

Service Liner Bore Measurement

AX

93.035 – 93.050 (3.6628 – 3.6634)

1

95.001 – 95.010

(3.7402 – 3.7405)

95.011 – 95.020

(3.7406 – 3.7409)

CX

93.051 – 93.066 (3.6634 – 3.6640)

AX

93.035 – 93.050 (3.6628 – 3.6634)

2

95.011 – 95.020

(3.7406 – 3.7409)

95.021 – 95.030

(3.7410 – 3.7413)

CX

93.051 – 93.066 (3.6634 – 3.6640)

AX

93.035 – 93.050 (3.6628 – 3.6634)

3

95.021 – 95.030

(3.7410 – 3.7413)

95.031 – 95.040

(3.7414 – 3.7417)

CX

93.051 – 93.066 (3.6634 – 3.6640)

AX

93.035 – 93.050 (3.6628 – 3.6634)

4

95.031 – 95.040

(3.7414 – 3.7417)

95.041 – 95.050

(3.7418 – 3.7421)

CX

93.051 – 93.066 (3.6634 – 3.6640)

4JG2T, 4JH1TC

mm (in)

Liner

Outside

Grade

Cylinder Body

Bore Diameter

Liner Outside

Diameter

Liner

Bore

Grade

Service Liner Bore Measurement

AX

95.435 – 95.450 (3.7573 – 3.7579)

1

97.001 – 97.010

(3.8189 – 3.8193)

97.011 – 97.020

(3.8193 – 3.8197)

CX

95.451 – 95.466 (3.7579 – 3.7585)

AX

95.435 – 95.450 (3.7573 – 3.7579)

2

97.011 – 97.020

(3.8193 – 3.8197)

97.021 – 97.030

(3.8197 – 3.8200)

CX

95.451 – 95.466 (3.7579 – 3.7585)

AX

95.435 – 95.450 (3.7573 – 3.7579)

3

97.021 – 97.030

(3.8197 – 3.8200)

97.031 – 97.040

(3.8200 – 3.8205)

CX

95.451 – 95.466 (3.7579 – 3.7585)

AX

95.435 – 95.450 (3.7573 – 3.7579)

4

97.031 – 97.040

(3.8200 – 3.8205)

97.041 – 97.050

(3.8205 – 3.8209)

CX

95.451 – 95.466 (3.7579 – 3.7585)

012RY00022

ENGINE MECHANICAL 6A – 89

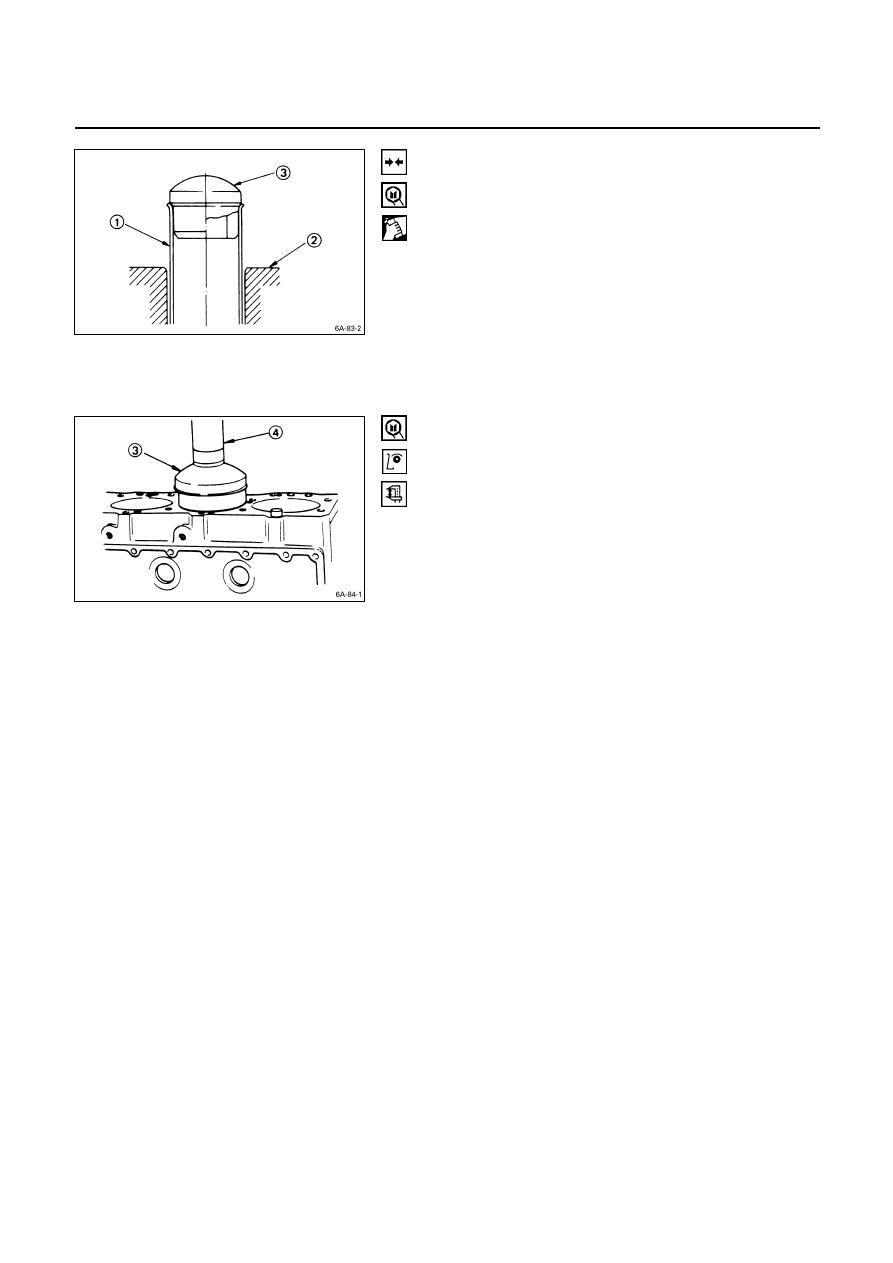

Cylinder Liner Installation

1. Cylinder Liner Installation Using The Special Tool

1) Use new kerosene or diesel oil to thoroughly clean

the cylinder liners and bores.

2) Use compressed air to blow-dry the cylinder liner

and bore surfaces.

Note:

All foreign material must be carefully removed from

the cylinder liner and the cylinder bore before

installation.

3) Insert the cylinder liner

Q

into the cylinder body

R

from the top of the cylinder body.

4) Set the cylinder liner installer

S

to the top of the

cylinder liner.

Cylinder

Liner

Installer:

5-8840-2040-0

5-8840-2313-0

(4JG2T,

4JH1TC)

5)

S

is directly beneath the bench press shaft center

T

.

Note:

Check that the cylinder liner is set perpendicular to

the bench press and that there is no wobble.

6) Use the bench press to apply a seating force of

500 kg (1,100 lb/4,900 N) to the cylinder liner.

7) Apply a force of 2,500 kg (5,500 lb/24,500 N) to

fully seat the cylinder liner.

8) After installing the cylinder liner, measure the

cylinder liner projection.

Refer to “Cylinder Liner Projection Inspection”.

2. Cylinder Liner Installation Using Dry Ice

Cylinder liner is a chrome plated dry type, it is

advisable to use dry ice during the installation

procedure.

Cooling the cylinder liner with dry ice will cause the

cylinder liner to contract, thus making installation

easier.

Note:

It is important that the cylinder liner be inserted to the

cylinder body immediately after it has been cooled.

Warning:

Dry ice must be used with great care. Careless

handling of dry ice can result in severe frostbite.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст