Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 1875

7A2-116 DIAGNOSIS

No. D1: Faulty Gear Shifting (Different from Shift Pattern)

Description:

•

Gear is shifted, different from the specified shift pattern.

Diagnosis Hints:

•

When inspecting faulty gear shifting, it is important to distinguish between the fault of electric system and

mechanical system (AT main unit).

•

Fault of electric system.

Monitor the output signal (each solenoid driving signal) using with Tech 2. If a trouble signal is sent to the

solenoid synchronously with the faulty gear shifting, the fault is originated in the electric system.

Monitor the input signal (signal from each sensor) using with Tech 2 and find an input signal by which the output

signal (each solenoid driving signal) is subjected to fault.

Fault of the electric system may be derived from temperature or vibration. For instance, though the engine is

normal while it is cold, fault may occur when the engine is warmed up or vehicle is running.

•

Fault of mechanical system.

If the gear is incorrectly shifted irrespective of operating signal (ON-OFF) of each solenoid, the faulty is

originated from the machine system (AT).

If the clutch slips, ATF smells burnt, contaminated to be black or the stall speed increases.

Possible Cause:

•

Disordered select cable.

•

Disordered inhibitor switch.

•

Slip

of

clutch.

If slip of clutch is caused, a DTC (gear ratio error) is stored.

•

Fixing at 3rd position (fail-safe activated)

Since the gear is fixed at the 3rd position because of the fail-safe function, a trouble that "Faulty gear

shifting" is resulted. In this case, the DTC is memorized.

When TCM stops operation because of faulty TCM ground, the gear is fixed at the 3rd position because

of a mechanical reason. In this case, no DTC is memorized.

••••

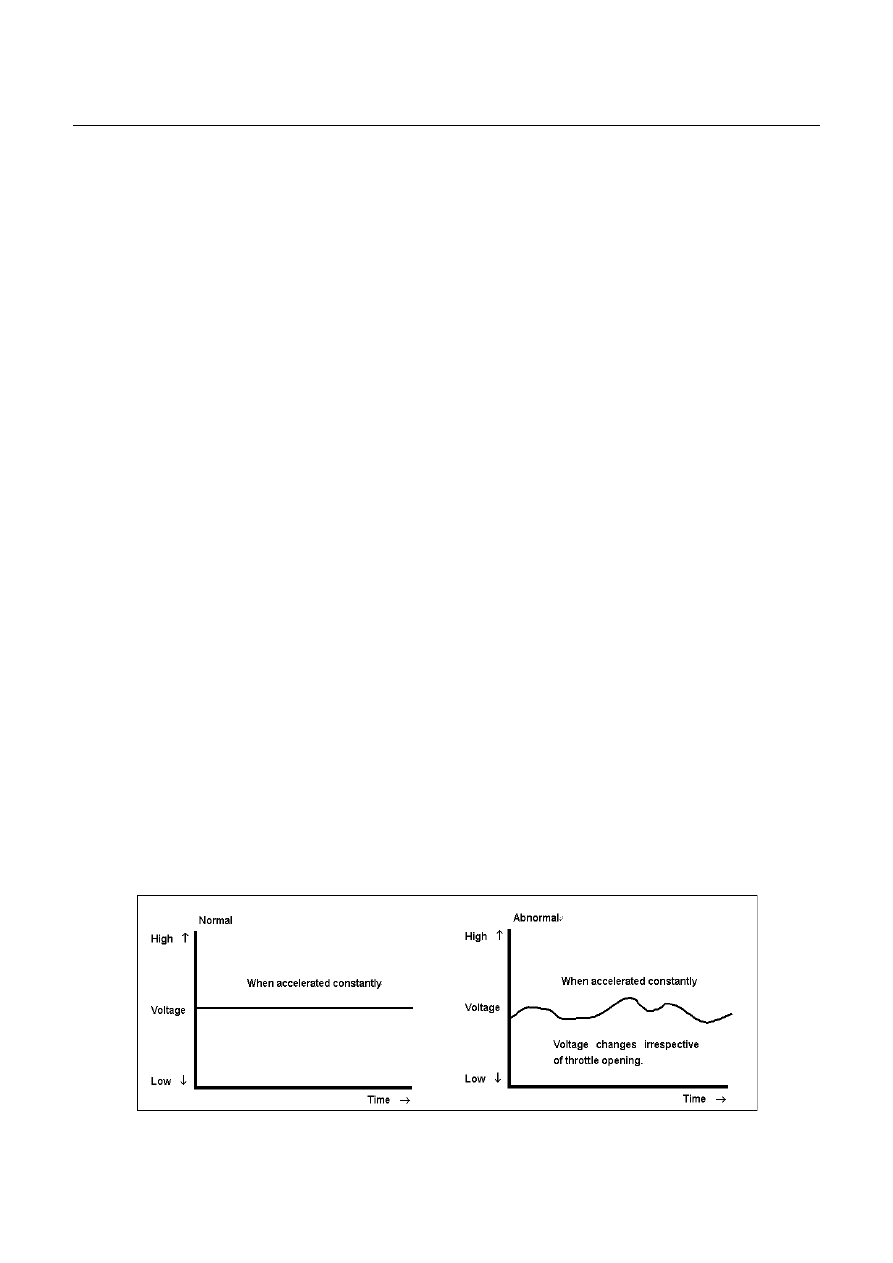

Incorrect properties of throttle opening signal (serial communication) of throttle position sensor.

The throttle opening signal which is sent by serial communication from ECM and TCM is an important

signal for gear shifting. In case of ECM fault or when the throttle position sensor does not issue voltage

signal according to the throttle opening, the gear is not shifted by stepping over the accelerator.

If the output voltage of the throttle position sensor changes freely even though the throttle opening is

constant, the gear is shifted incorrectly.

•

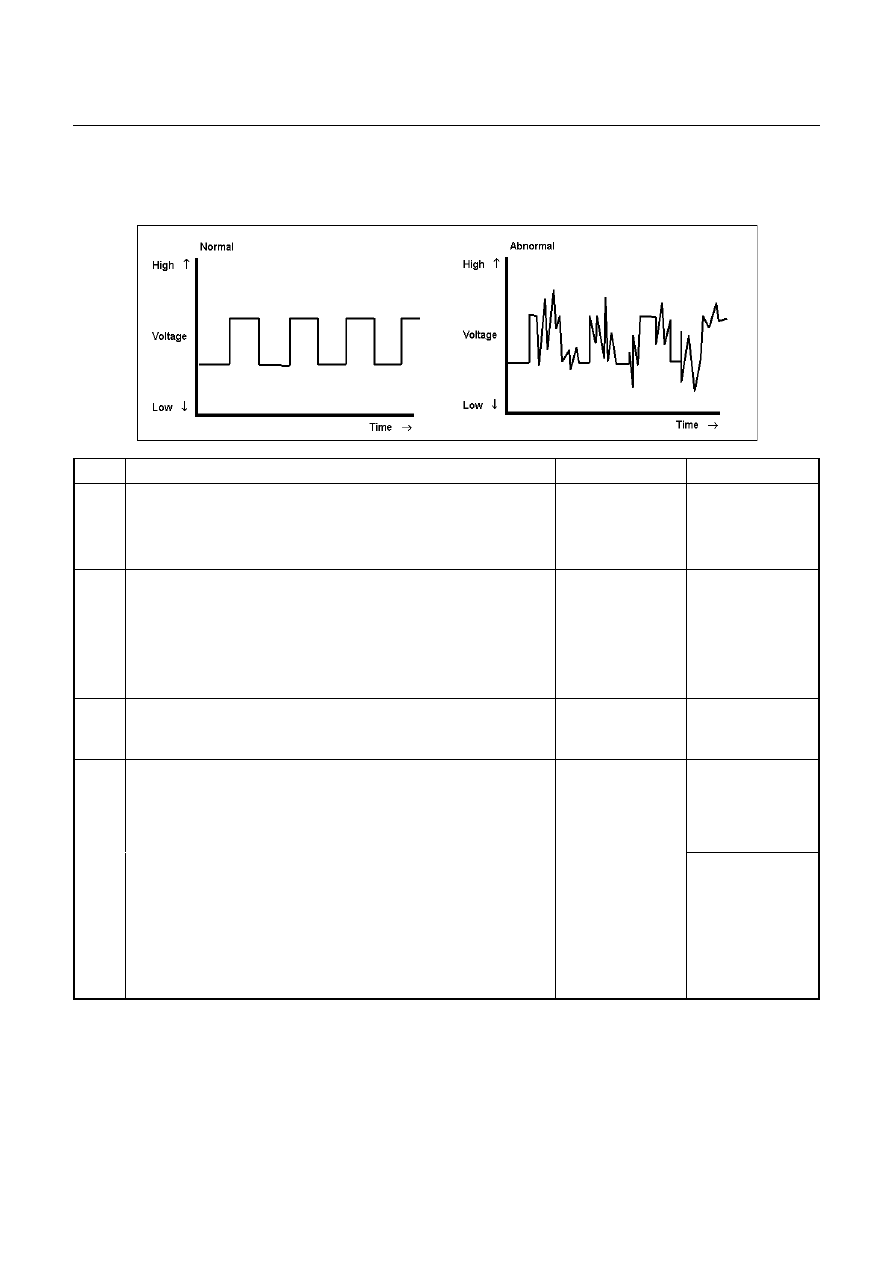

Faulty speed sensor.

DIAGNOSIS 7A2-117

When signal from the speed sensor becomes out of order, it may be judged a result of changed vehicle

speed and faulty gear shifting may be the causes.

••••

Trouble in control valve body (faulty operation, sticking, clogged oil passage)

Step

Action

Yes

No

1

Dislocation or disordered of select lever.

Does the vehicle move when the brake is released in a position

other than the P range and the vehicle is pushed?

Go to Step 2

Adjust the select

cable.

2

Gear ratio trouble diagnosis.

Travel in the following sequence for about 7 seconds or more in

each range: Start in the L range (1st) to 2 range (2nd) to 3 range

(3rd) to D range (4th) (to detect the gear ratio trouble exactly, this

process should be carried out)

Go to Step 3

Go to Step 3

3

Are any DTCs stored?

Go to DTC Chart

Go to Step 4

4

Are the quantity, contamination and smell normal?

If the ATF level is

low, replenish up to

the specified level.

Go to Step 5

If ATF is extremely

black and

contaminated and

smells burnt, slip of

the clutch is

supposed.

7A2-118 DIAGNOSIS

Step

Action

Yes

No

5

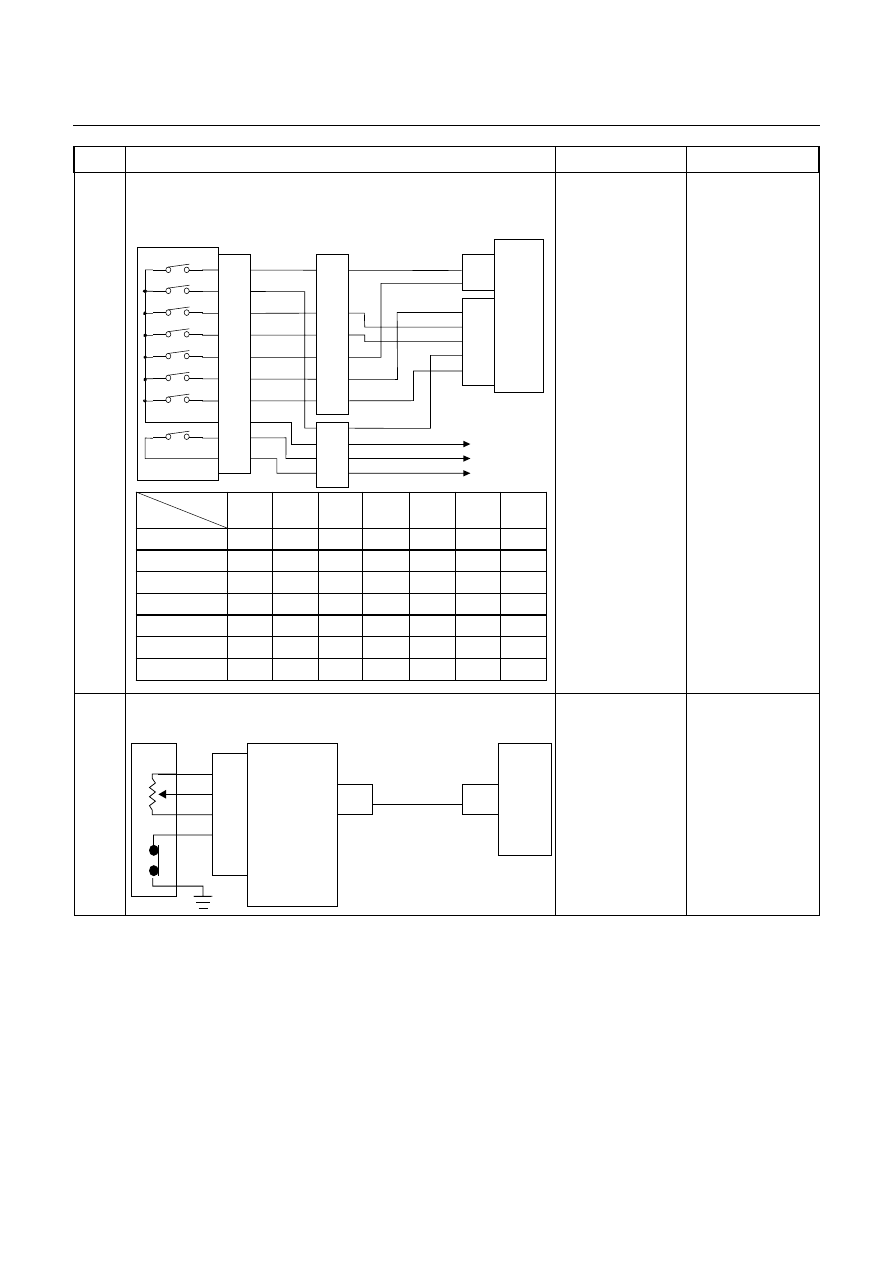

Inspection of electrical or mechanical fault

Is signal to each solenoid and pressure switch changed

synchronously to the faulty gear shift?

Control Valve

TCM

B1

B12

B20

RED/YEL

WHT/BLK

2-4 Brake Pressure SW

Terminal

Assembly

YEL

E54

(7)

(12)

(1)

H23

(12)

(10)

C95

(1)

(12)

(20)

RED/YEL

YEL

WHT/BLK

L&R Brake Pressure SW

High Clutch Pressure SW

H22

(8)

Control Valve

TCM

B6

B7

B8

B9

B22 (GND)

BLU/BLK

W HT/BLU

L&R Brake Solenoid

Terminal

Assembly

BLK/YEL

RED

2-4 Brake Solenoid

High Clutch Solenoid

Low Clutch Solenoid

E54

(5)

(9)

(10)

(3)

(11)

H23

(11)

(5)

(7)

(2)

(1)

GRY/RED

C95

(6)

(7)

(8)

(9)

(22)

BLU/BLK

BLK/YEL

RED

W HT/BLU

GRY/RED

Range

TCM terminal

Gear

B20

(High clutch

pressure SW)

B1

(2-4 brake pressure

SW)

B12 (Low & reverse

brake pressure SW)

P

-

More than 10V

More than 10V

More than 10V

R

Reverse

More than 10V

More than 10V

-

N

-

More than 10V

More than 10V

More than 10V

D, 3, 2

1st

More than 10V

More than 10V

More than 10V

2nd

More than 10V

-

More than 10V

3rd

-

More than 10V

More than 10V

4th

-

-

More than 10V

L

1st

More than 10V

More than 10V

-

2nd

More than 10V

-

More than 10V

3rd

-

More than 10V

More than 10V

4th

-

-

More than 10V

R a n g e

T C M te rm in a l

G e a r

B 8

(H ig h c lu tc h

s o le n o id )

B 9

(L o w c lu tch

s o le n o id )

B 7

(2 -4 b ra k e

s o le n o id )

B 6

(L o w & re v e rs e

b ra k e s o le n o id )

P

-

A p p ro x . 6 .8 V

(A C ra n g e )

-

A p p ro x . 6 .8 V

(A C ra n g e )

A p p ro x . 6 .2 V

(A C ra n g e )

R

R e v e rs e

A p p ro x . 6 .8 V

(A C ra n g e )

-

A p p ro x . 6 .8 V

(A C ra n g e )

-

N

-

A p p ro x . 6 .8 V

(A C ra n g e )

-

A p p ro x . 6 .8 V

(A C ra n g e )

A p p ro x . 6 .8 V

(A C ra n g e )

D , 3 , 2

1 s t

A p p ro x . 6 .8 V

(A C ra n g e )

-

A p p ro x . 6 .8 V

(A C ra n g e )

A p p ro x . 6 .8 V

(A C ra n g e )

2 n d

A p p ro x . 6 .8 V

(A C ra n g e )

-

-

A p p ro x . 6 .8 V

(A C ra n g e )

3 rd

-

-

A p p ro x . 6 .8 V

(A C ra n g e )

A p p ro x . 6 .8 V

(A C ra n g e )

4 th

-

A p p ro x . 6 .8 V

(A C ra n g e )

-

A p p ro x . 6 .8 V

(A C ra n g e )

L

1 s t

A p p ro x . 6 .8 V

(A C ra n g e )

-

A p p ro x . 6 .8 V

(A C ra n g e )

-

2 n d

A p p ro x . 6 .8 V

(A C ra n g e )

-

-

A p p ro x . 6 .8 V

(A C ra n g e )

3 rd

-

-

A p p ro x . 6 .8 V

(A C ra n g e )

A p p ro x . 6 .8 V

(A C ra n g e )

4 th

-

A p p ro x . 6 .8 V

(A C ra n g e )

-

A p p ro x . 6 .8 V

(A C ra n g e )

Go to Step 6

In case of fault in

the machine

system, repair that

portion or replace

the unit.

Slip of clutch or fault

of control valve.

DIAGNOSIS 7A2-119

Step

Action

Yes

No

6

Inspection of inhibitor switch using a Tech 2 or circuit tester.

Inspect the output voltage and throttle opening signal of the

throttle position sensor using a Tech 2 or circuit tester.

Inhibitor SW

TCM

A2 (P)

A17 (3)

B2 (2)

B10 (N)

B11 (D)

B19 (R)

B21 (L)

C95

(2)

(10)

(11)

(19)

(21)

YEL/VIO

RED/BLK

BLU

BLK/GRN

Starter Relay

C94

(2)

(3)

B

H22

(1)

(6)

(4)

(7)

(5)

(2)

P

2

R

N

D

3

L

Start SW

PNK/BLU

E51

(2)

(4)

(8)

(5)

(1)

(9)

(6)

(3)

(10)

(7)

(38)

(15)

(3)

(37)

H4

PNK/BLK

RED/YEL

YEL/VIO

BLK/GRN

PNK/BLK

RED/BLK

BLU

RED/YEL

PNK/BLU

BLK/WHT

BLK

BLK

BLK/WHT

Key Switch

WHT

WHT

Immobiliser Control Unit

TCM terminal

Range

A2

B19

B10

B11

B17

B2

B21

P

Battery

voltage

-

-

-

-

-

-

R

-

Battery

voltage

-

-

-

-

-

N

-

-

Battery

voltage

-

-

-

-

D

-

-

-

Battery

voltage

-

-

-

3

-

-

-

-

Battery

voltage

-

-

2

-

-

-

-

-

Battery

voltage

-

L

-

-

-

-

-

-

Battery

voltage

Go to Step 7

Adjust the inhibitor

switch.

7

Is a voltage value in proportion to the throttle opening output?

TPS

TCM

A16

C56

(28)

C94

(16)

RED/WHT

C56

(49)

(38)

(57)

(69)

ECM

A47 (GND)

A35 (Output)

A26

A55 (+5V)

A69 (Idle SW)

Go to Step 8

Repair the defect or

replace.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст