Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 597

FUEL SYSTEM 6C – 47

8. Operate the nozzle tester and increase the in-line

pressure to 34.3 - 44.1 MPa (350 - 450 kg/cm

2

) so that

the nozzle’s needle valve moves through its full lift.

Record full lift ‘L’. (Read dial gauge)

Nozzle Full Lift

mm (in)

0.25 ± 0.02 (0.0098 ± 0.00008)

Note:

The above operation is used to determine whether

the nozzle seat is worn and whether the nozzle

assembly is in good condition.

Pre-lift confirmation

1. With the needle valve at full lift, release the nozzle

tester handle.

Note:

The in-line pressure will decrease and needle

valve lift (as indicated on the dial gauge) will also

decrease a little.

2. Read the needle valve lift ‘liter’ from the dial gauge

indication (once the needle valve has descended when

the second spring has stopped operating). Refer to the

pre-lift measuring point for ‘liter’.

Pre-lift measuring point:

Read the dial gauge at first nozzle opening pressure +approx

1 MPa (10 kg/cm

2

).

Pre-lift mm

Pressure kg/cm

2

(psi/kpa)

Lift mm (in)

204 (2,901/20,000)

0.04 (0.0016)

Note:

This point can be found while the pressure is

decreasing.

040MV007.tif

040M100004

040H100007

040MV008.tif

6C – 48 FUEL SYSTEM

3. Confirm that pre-lift ‘liter’ is as specified.

4. If pre-lift is not as specified, replace the pins, lift piece,

spacer and nozzle assembly as a set with the service

kit.

Service kit

105017-2990 (Bosch AS)

897302-3070 (ISUZU)

Second nozzle opening pressure confirmation

1. After pre-lift confirmation, operate the nozzle tester to

increase in-line pressure to 34.3 - 44.1 MPa (350 - 450

kg/cm

2

) so that the nozzle’s needle valve moves

through its full lift.

2. Release the nozzle tester handle so that in-line

pressure decreases.

Note:

The in-line pressure will decrease and needle

valve lift (as indicated on the dial gauge) will also

decrease a little.

3. Then, read the pressure gauge indication (second

nozzle opening pressure) the instant that the dial

gauge indicates the specified needle valve lift (usually

pre-lift liter

+ 0.05 mm).

Second Nozzle Opening Pressure

Lift mm (in)

Pressure kg/cm

2

(psi/Mpa)

4JA1TC

347 – 362

(4934−5148/34.0−35.5)

4JH1TC

0.09 (0.0035)

350 – 365

(4977−5190/34.3−35.8)

040MV005.tif

040MV031.tif

040MV030.tif

040MV022.tif

040M100006

FUEL SYSTEM 6C – 49

Second nozzle opening pressure adjustment

If the second nozzle opening pressure is not as specified,

disassemble the nozzle from the nozzle holder and

replace the shim until the pressure is as specified.

CAUTION:

• Because the second opening pressure changes

when the first opening pressure changes, the

second opening pressure must be adjusted when

the first opening pressure changes.

• Use a micrometer to measure shim thickness.

• Use some combination of 3 adjusting shims to

adjust the pressure.

• Second nozzle opening pressure adjusting shims

Part No.

(ISUZU)

Thickness

(mm)

Part No.

(ISUZU)

Thickness

(mm)

897116-0290

0.10 897116-0380 0.53

897116-0320

0.20 897116-0390 0.54

897116-0330

0.30 897116-0400 0.55

897116-0340

0.40 897116-0410 0.56

897116-0350

0.50 897116-0420 0.57

897116-0360

0.51 897116-0430 0.58

897116-0370

0.52 897116-0440 0.59

Final inspection

1. Remove the dial gauge, nut and dial gauge holder.

2. Remove the adjustment retaining nut and gasket.

3. Install the original retaining nut, confirm that the pins

are inserted fully into the nozzle, and then hand-tighten

the retaining nut. Then, tighten the original retaining

nut to the specified torque.

Torque: 7.0 kg·m (50.6 Ib·ft/69 N·m)

040MV017.tif

040LX009.tif

040MV028.tif

040MV014-1.tif

6C – 50 FUEL SYSTEM

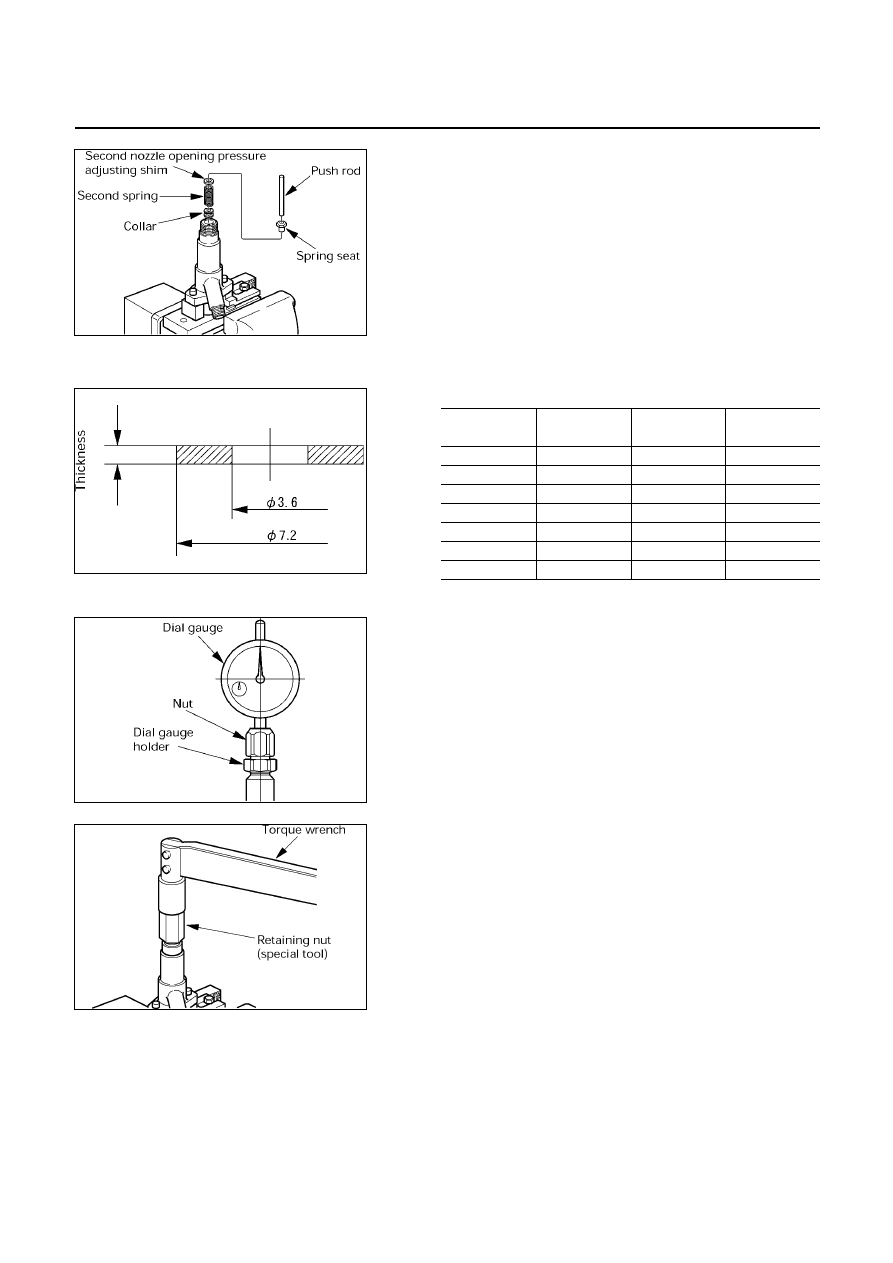

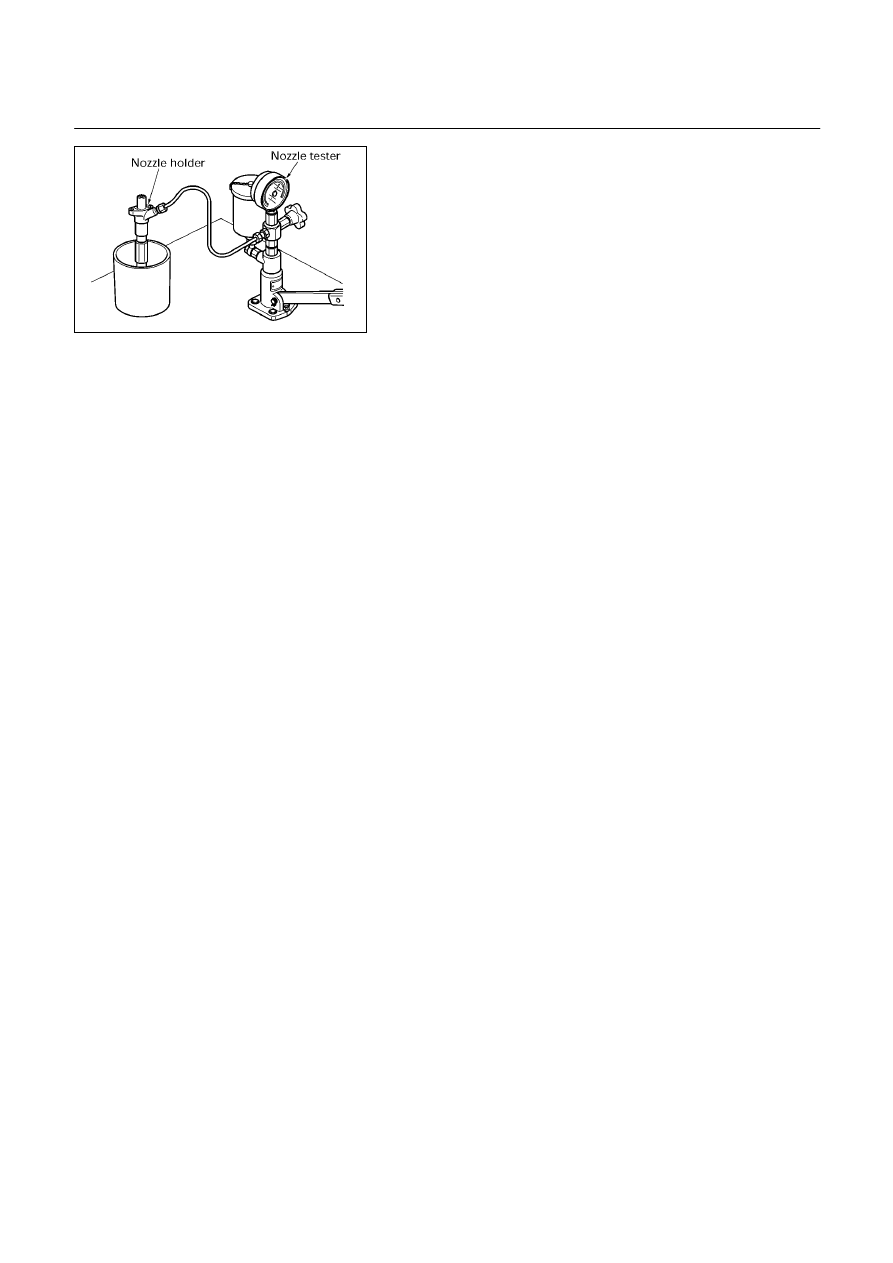

4. Set the nozzle holder to the nozzle tester and check

first nozzle opening pressure, spray condition, seat oil

tightness and each part for oil leaks.

5. When replacing the nozzle, replace the nozzle, lift

piece, pins and spacer as a set with the nozzle service

kit.

CAUTION:

Pre-lift will not be as specified if only the nozzle is

replaced.

040MV030.tif

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст