Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 577

6A – 146 ENGINE MECHANICAL

5. Engine

Mounting

Bracket

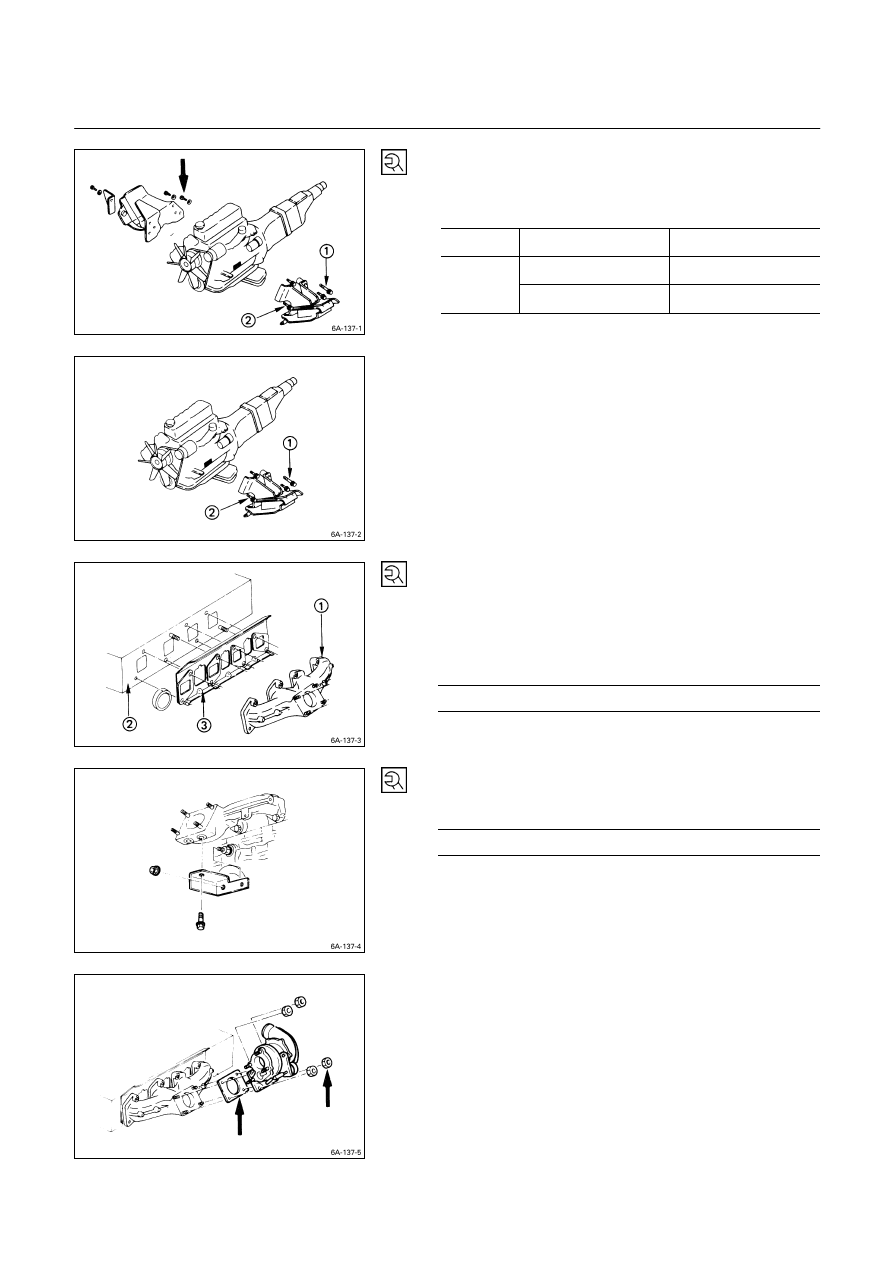

Install the engine mounting bracket to the cylinder body

and tighten the bracket bolts to the specified torque.

Mounting Bracket Bolt Torque

kg·m (lb.ft/N·m)

Right Side M10

× 1.25 (9T)

5.6 (40.5/54.9)

M10

× 1.25 (7T)

4.1 (30/40)

Left Side

M14

× 1.50 (7T)

12 (86.7/118)

6. Exhaust

Manifold

1) Install the exhaust manifold

to the cylinder head

with the manifold gasket

.

2) Tighten the exhaust manifold bolts to the specified

torque a little at a time.

Exhaust Manifold Bolt Torque

kg·m (lb.ft/N·m)

2.7

± 0.5 (19.5 ± 3.6/26.5 ± 4.9)

3) Install the exhaust manifold bracket to the manifold

and the cylinder body.

Manifold Bracket Bolt Torque

kg·m (lb.ft/N·m)

1.9

± 0.5 (13.7 ± 3.6/18.6 ± 4.9)

8. Turbocharger

1) Install the turbocharger and the gasket.

2) Temporarily tighten the turbocharger nuts at this time.

They will be fully tightened after the installation of the

turbocharger oil pipe.

Always install new nuts and new gasket.

ENGINE MECHANICAL 6A – 147

3) Install the exhaust adapter with gasket and tighten the

adapter nut to the specified torque.

Adapter Nut Torque

kg·m (lb.ft/N·m)

2.7

± 0.5 (19.5 ± 3.6/26.5 ± 4.9)

9. Turbocharger Oil Return Pipe

1) Install the oil return pipe with gasket to the

turbocharger.

2) Tighten the turbocharger oil return pipe to the

specified torque.

Turbocharger Oil Reutrn Pipe Torque

kg·m (lb.ft/N·m)

0.8

± 0.2 (5.8 ± 1.4/7.8 ± 2.0)

10. Turbocharger Oil Feed Pipe

1) Before installing the oil feed pipe, supply 10 – 20 cc of

clean engine oil to the turbocharger center housing

through the oil feed opening.

2) Turn the rotating assembly with your hand to

thoroughly lubricate the internal parts.

3) Tighten the oil feed pipe to the specified torque.

Turbocharger Oil Feed Pipe Joint

Bolt Torque

kg·m (lb.ft/N·m)

M10

× 1.5 2.25 ± 0.25 (16.3 ± 1.8/22.1 ± 2.5)

M14

× 1.5 5.5 ± 0.25 (39.8 ± 1.8/53.9 ± 2.5)

4) Tighten the turbocharger nut to the specified torque.

Turbocharger Nut Torque

kg·m (lb.ft/N·m)

2.7

± 0.5 (19.5 ± 3.6/26.5 ± 4.9)

6A – 148 ENGINE MECHANICAL

v

11. Oil Cooler with Oil Filter

1) Install the O-ring to the oil filter flange groove.

2) Tighten the oil filter and oil cooler to the specified

torque.

Oil Filter Flange Bolt Torque

kg·m (lb.ft/N·m)

1.9

± 0.5 (13.7 ± 3.6/18.6 ± 4.9)

3) Lightly oil the O-ring of oil filter cartridge.

4) Turn in the new oil filter cartridge by hand until the

sealing face is fitted again the O-ring.

5) Use the filter wrench to turn in the oil filter and

additional one and 1·1/8 turns.

6) Start the engine and check for oil leakage from oil

filter.

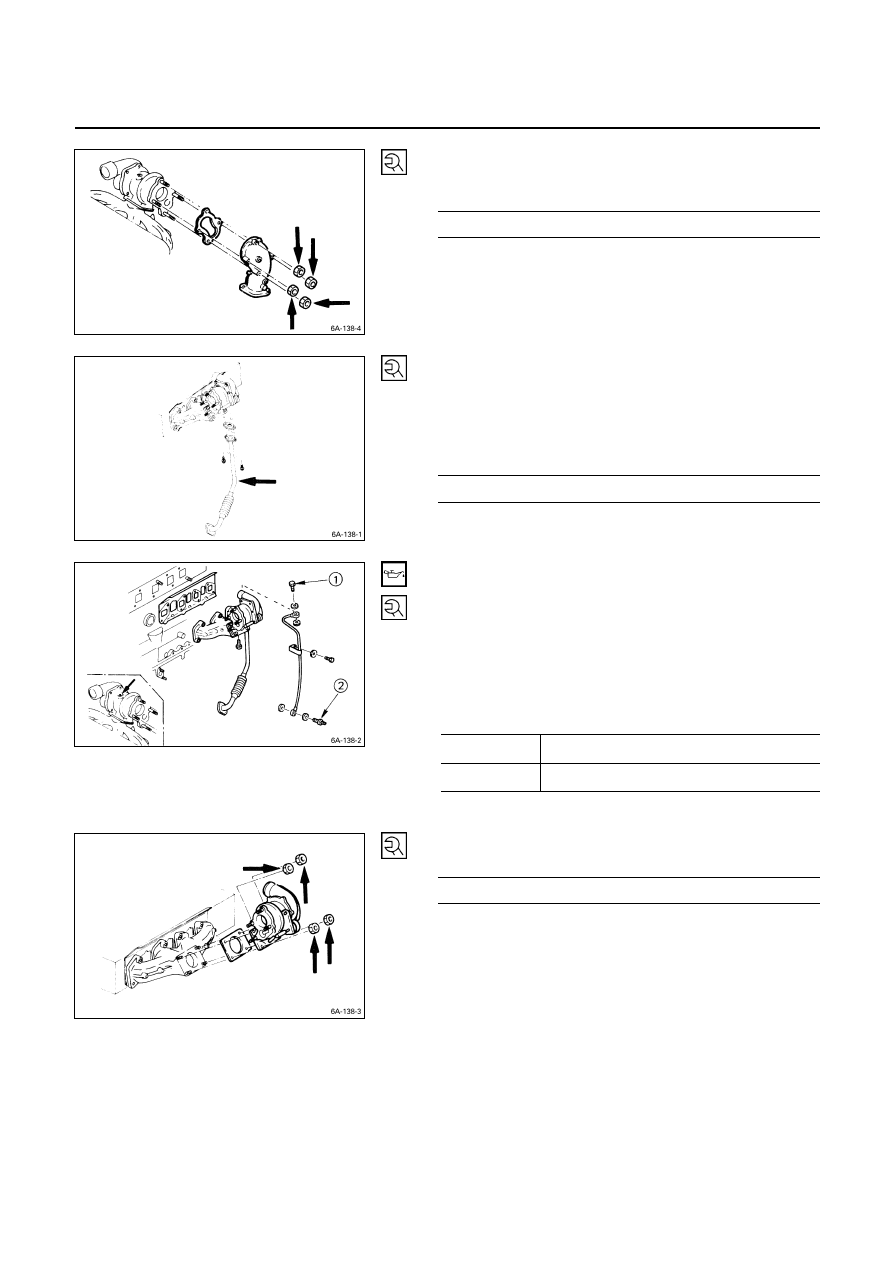

14. Fuel Injection Pipe with Clip

1) Temporarily tighten the injection pipe sleeve nut.

2) Set the clip in the illustrated position.

Note:

Make absolutely sure that the clip is correctly

positioned.

An improperly positioned clip will result in injection

pipe breakage and fuel pulsing noise.

3) Tighten the injection pipe sleeve nut to the specified

torque.

Injection Pipe Sleeve Nut Torque

kg·m (lb.ft/N·m)

3

± 1 (21.7 ± 7.2/29.4 ± 9.8)

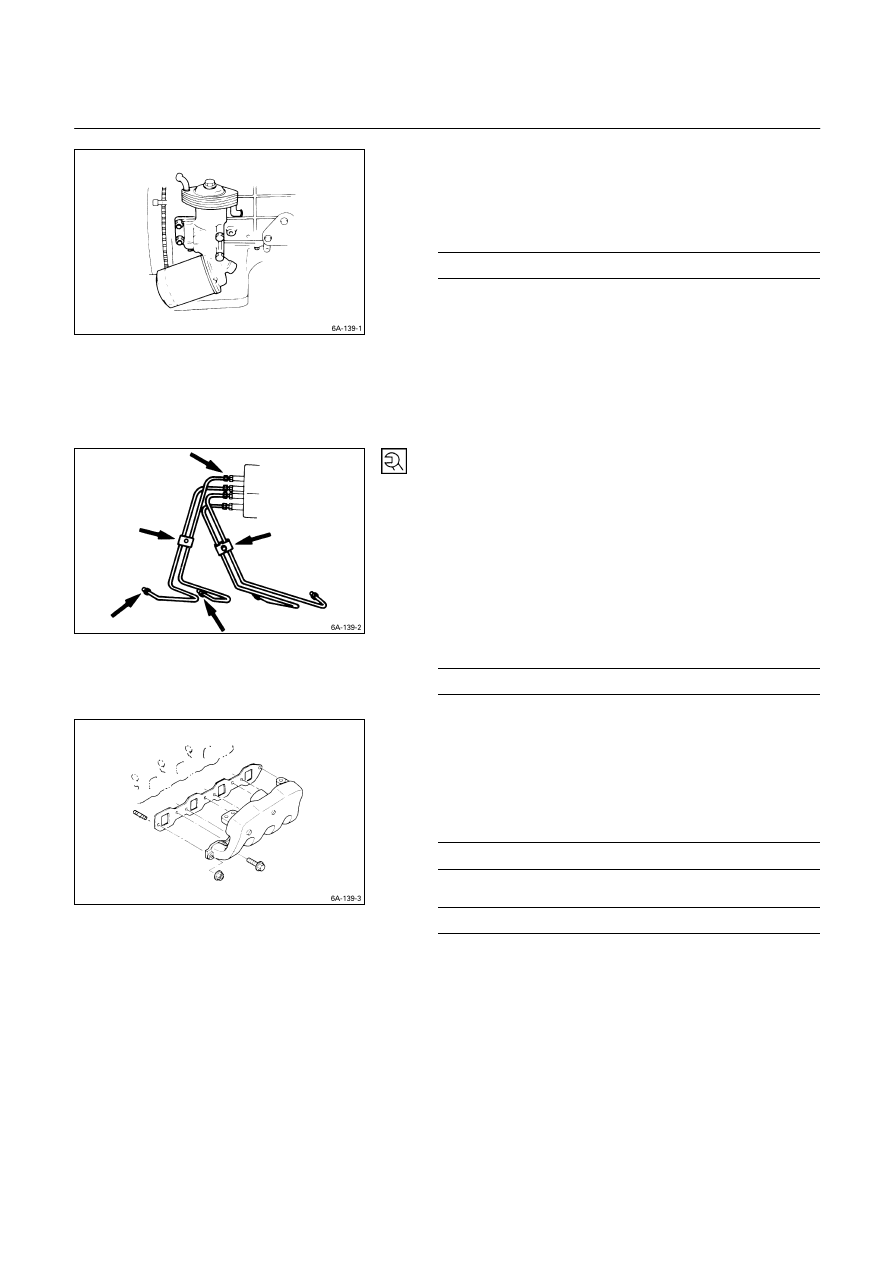

16. Intake Manifold

1) Install the manifold gasket to the intake manifold.

2) Connect the intake rubber hose to the intake duct.

3) Tighten the intake manifold bolts and the flange nuts

to the specified torque.

Intake Manifold Bolt Torque

kg·m (lb.ft/N·m)

1.9

± 0.5 (13.7 ± 3.6/18.6 ± 4.9)

Intake Manifold Flange Nut Torque

kg·m (lb.ft/N·m)

1.9

± 0.5 (13.7 ± 3.6/18.6 ± 4.9)

4) Connect the PCV hose to the cylinder head cover.

ENGINE MECHANICAL 6A – 149

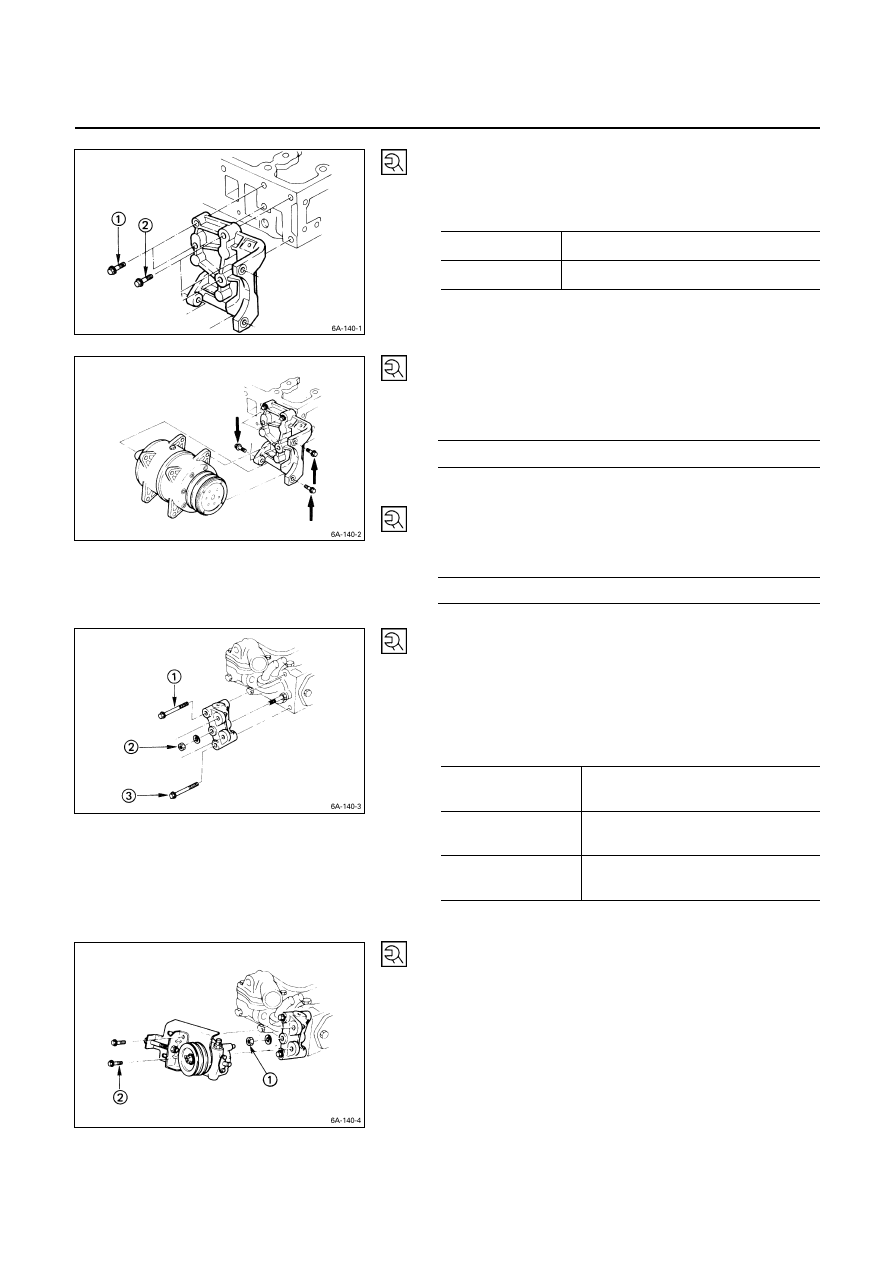

17. Compressor Bracket

1) Install the compressor bracket to the cylinder head.

2) Tighten the bracket bolts to the specified torque.

Bracket Bolt Torque

kg·m (lb.ft/N·m)

M 8

× 1.25

1.9

± 0.5 (13.7 ± 3.6/18.6 ± 4.9)

M10

× 1.25

4.1

± 0.6 (30 ± 7.2/40 ± 6)

18. Compressor

1) Install the compressor to the compressor bracket.

2) Tighten the compressor bolts to the specified torque.

Compressor Bolt Torque

kg·m (lb.ft/N·m)

3.8

± 1.0 (27.5 ± 7.2/37.2 ± 9.8)

19. Starter Motor

Tighten the starter motor bolts to the specified torque.

Starter Motor Bolt Torque

kg·m (lb.ft/N·m)

7.0

± 1.0 (50.6 ± 7.2/68.6 ± 9.8)

20. Power Steering Oil Pump Bracket

21. Power Steering Oil Pump

1) Install the oil pump bracket to the cylinder head.

2) Tighten the pump bracket nut and bolts to the

specified torque.

Oil Pump Bracket Nut and Bolt

Torque kg·m

(lb.ft/N·m)

M10

× 1.25 (7T)

3.75

± 0.95

(27.1

± 6.9/36.75 ± 9.31)

M 8

× 1.25 (7T)

1.75

± 0.55

(12.7

± 4.0/17.75 ± 5.39)

M 8

× 1.25 (4T)

1.30

± 0.50

(9.4

± 3.6/12.74 ± 4.90)

3) Install the oil pump to the bracket.

4) Temporarily tighten the oil pump nut

and bolts

.

The nut and bolts will be finally tightened after

installation of the drive belt.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст