Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 576

6A – 142 ENGINE MECHANICAL

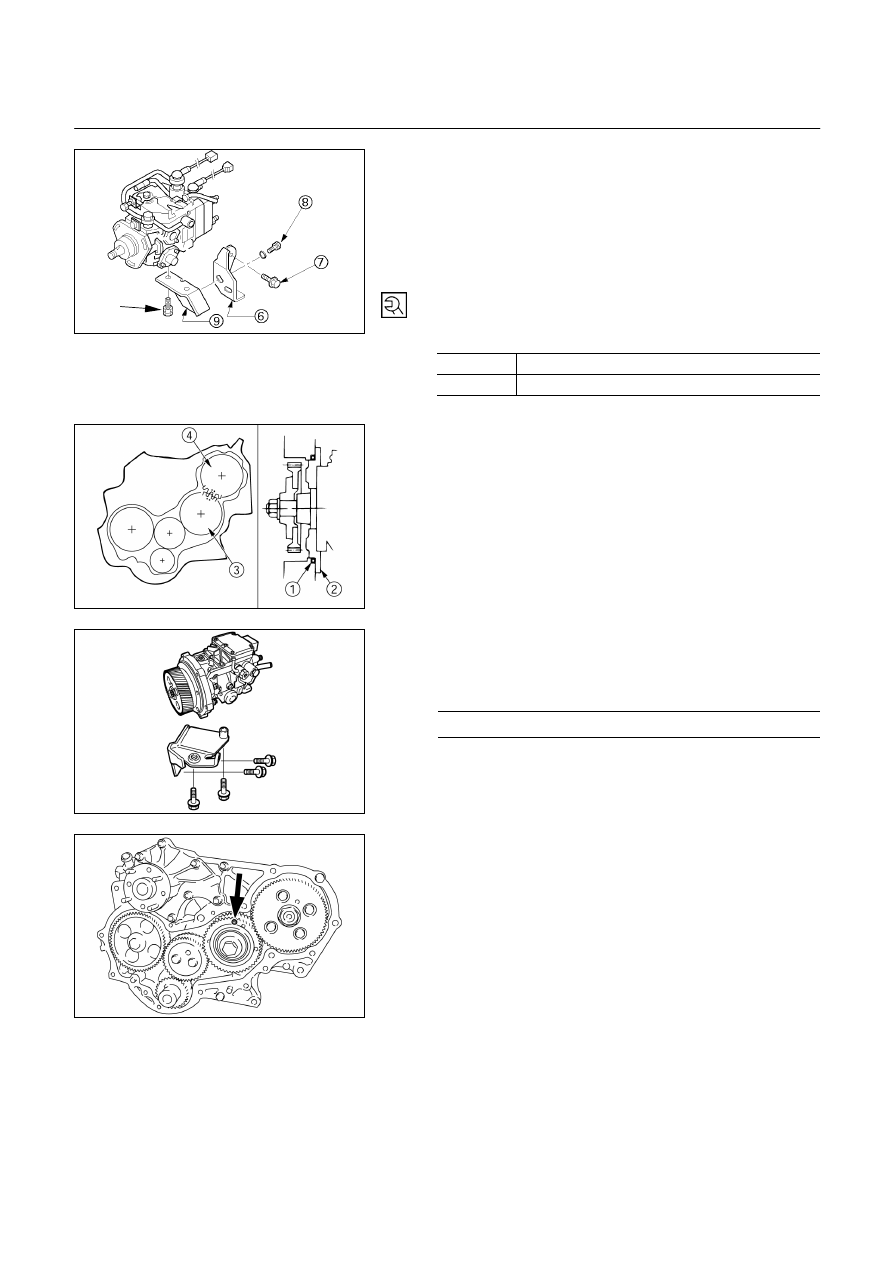

3) Install the injection pump rear bracket

and the rear

bracket bolts

to the cylinder body.

4) Install the rear bracket bolts

to the injection pump

bracket

.

5) Tighten the injection pump bracket bolts to the

specified torque.

Injection Pump Bracket Bolt Torque

kg·m (lb.ft/N·m)

,

1.9

± 0.5 (13.7 ± 3.6/18.6 ± 4.9)

4.1

± 0.6 (29.6 ± 4.3/40.2 ± 5.9)

4JA1TC, 4JH1TC

1) Install

the

O-ring

to the injection pump flange

.

2) Install the injection pump to the timing gear case.

Align the idler gear “B”

“‥” mark with the injection

pump timing gear

“‥” mark.

3) Install the injection pump bracket.

4) Tighten the injection pump bracket bolts to the

specified torque.

Injection Pump Bracket Bolt Torque

kg·m (lb.ft/N·m)

4.1

± 0.6 (29.6 ± 4.3/40.2 ± 5.9)

5) Remove the scissor gear set bolt.

020L200021

080L200006

ENGINE MECHANICAL 6A – 143

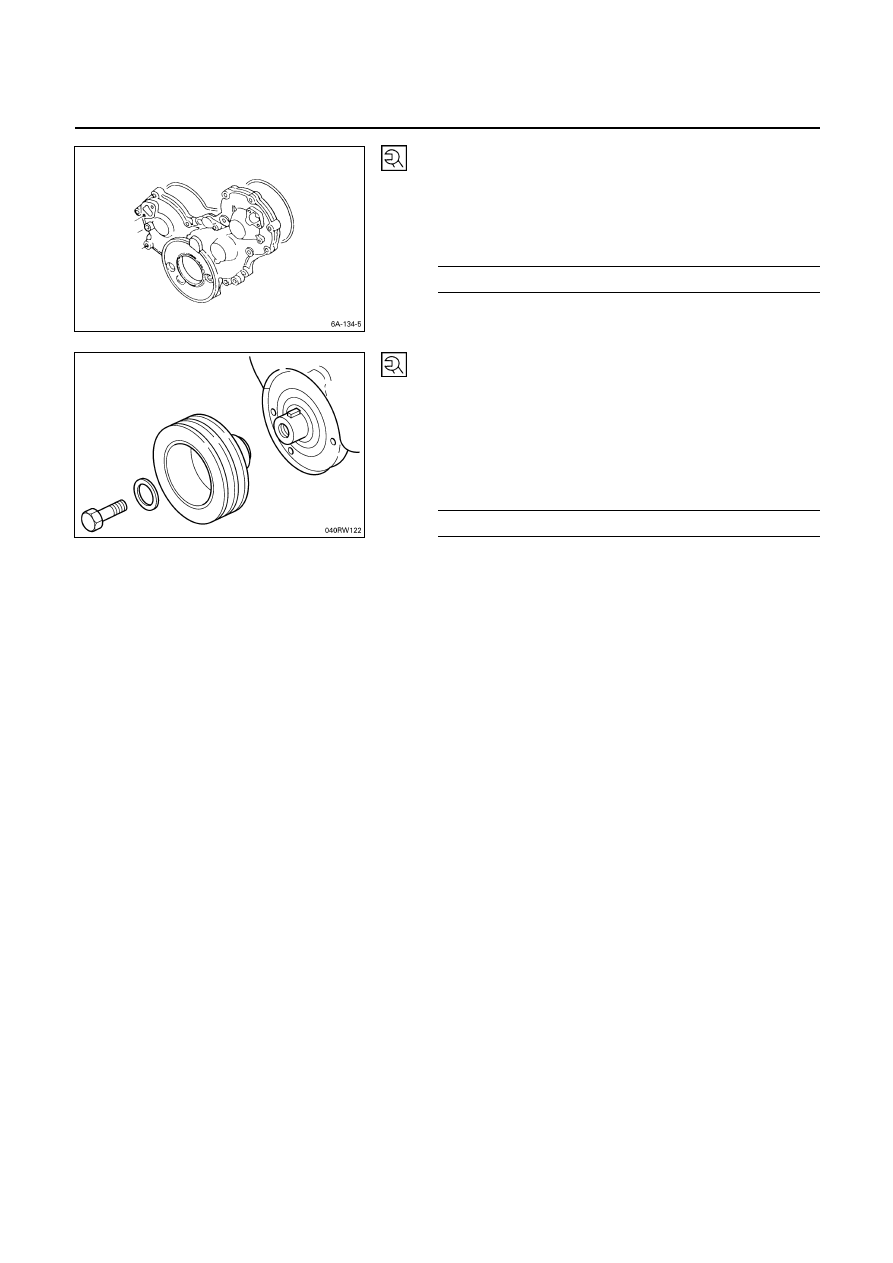

10. Timing Gear Case Cover

6) Align the gear case with the timing gear case knock

pin and then install the timing gear case cover.

7) Tighten the gear case cover bolts to the specified

torque.

Gear Case cover Bolt Torque

kg·m (lb.ft/N·m)

1.9

± 0.5 (13.7 ± 3.6/18.6 ± 4.9)

13. Crankshaft Damper Pulley

Tighten the crankshaft damper pulley bolt to the specified

torque.

Note:

Hold the flywheel ring gear stationary to prevent the

crankshaft from turning when tightening the damper

pulley.

Crankshaft Damper Pulley Bolt Torque

kg·m (lb.ft/N·m)

21.0

± 2.0 (151.9 ± 14.5/206.0 ± 19.6)

Take care not to damage the crankshaft damper pulley

boss.

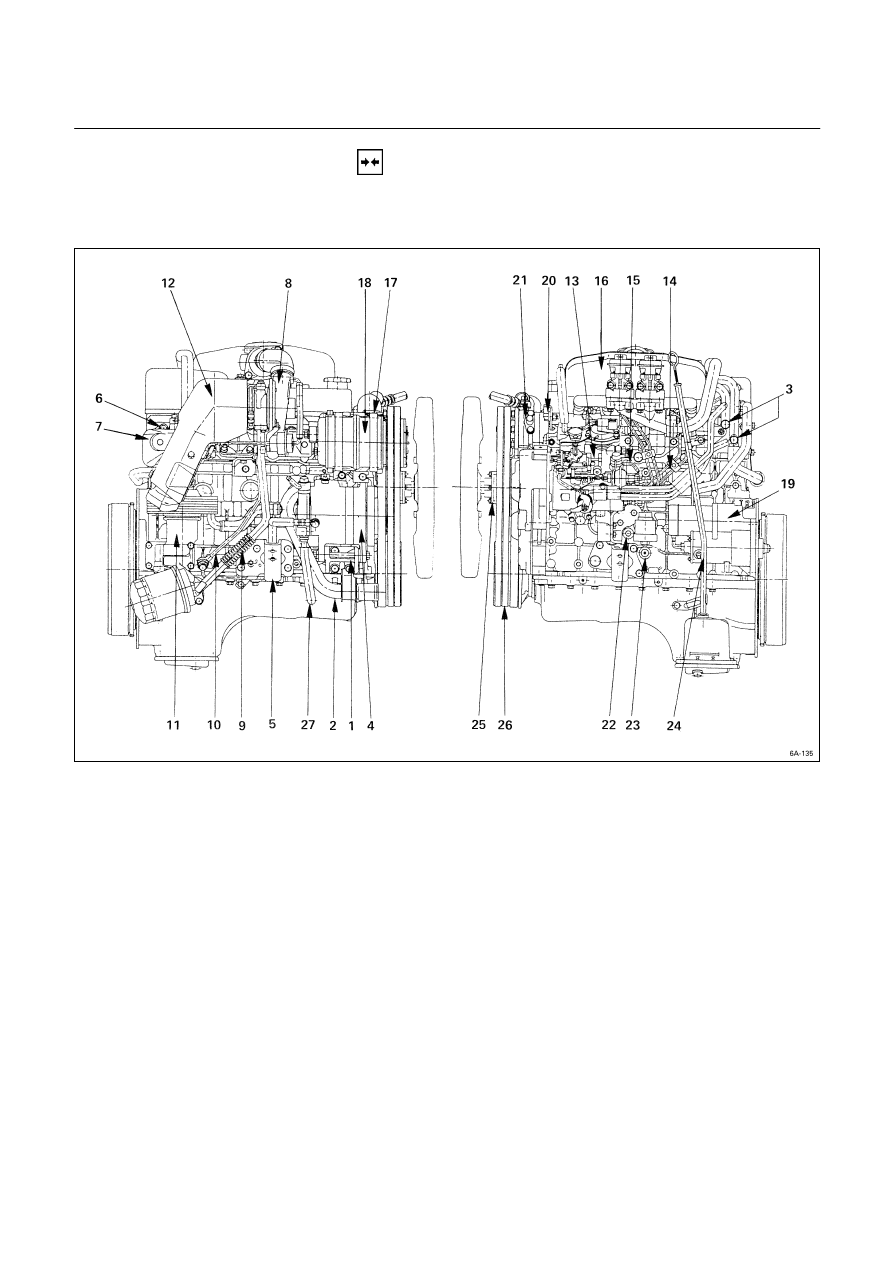

6A – 144 ENGINE MECHANICAL

INSTALLATION

EXTERNAL PARTS

These installation steps are based on the 4JB1T engine.

Installation Steps

J

1.

Generator bracket

J

16. Intake manifold

J

2.

Water inlet pipe

J

17. Compressor bracket

J

3. Heater pipe (Rear side)

J

18. Compressor

J

4. Generator and adjusting plate

J

19. Starter motor

J

5.

Engine mounting bracket

J

20. Power steering oil pump bracket

J

6.

Exhaust manifold

J

21. Power steering oil pump

7.

Exhaust manifold heat protector

22.

Water drain cock

J

8. Turbocharger

23.

Oil pressure warning switch and

J

9. Turbocharger oil return pipe

nipple

J

10. Turbocharger oil feed pipe

24.

Oil level gauge guide tube

J

11. Oil cooler with Oil filter

J

25. Cooling fan pulley

12.

Turbocharger heat protector

J

26. Cooling fan drive belt

13.

Injection

pump

27.

Vacuum

pipe

J

14. Fuel injection pipe with clip

15.

Fuel leak off pipe

ENGINE MECHANICAL 6A – 145

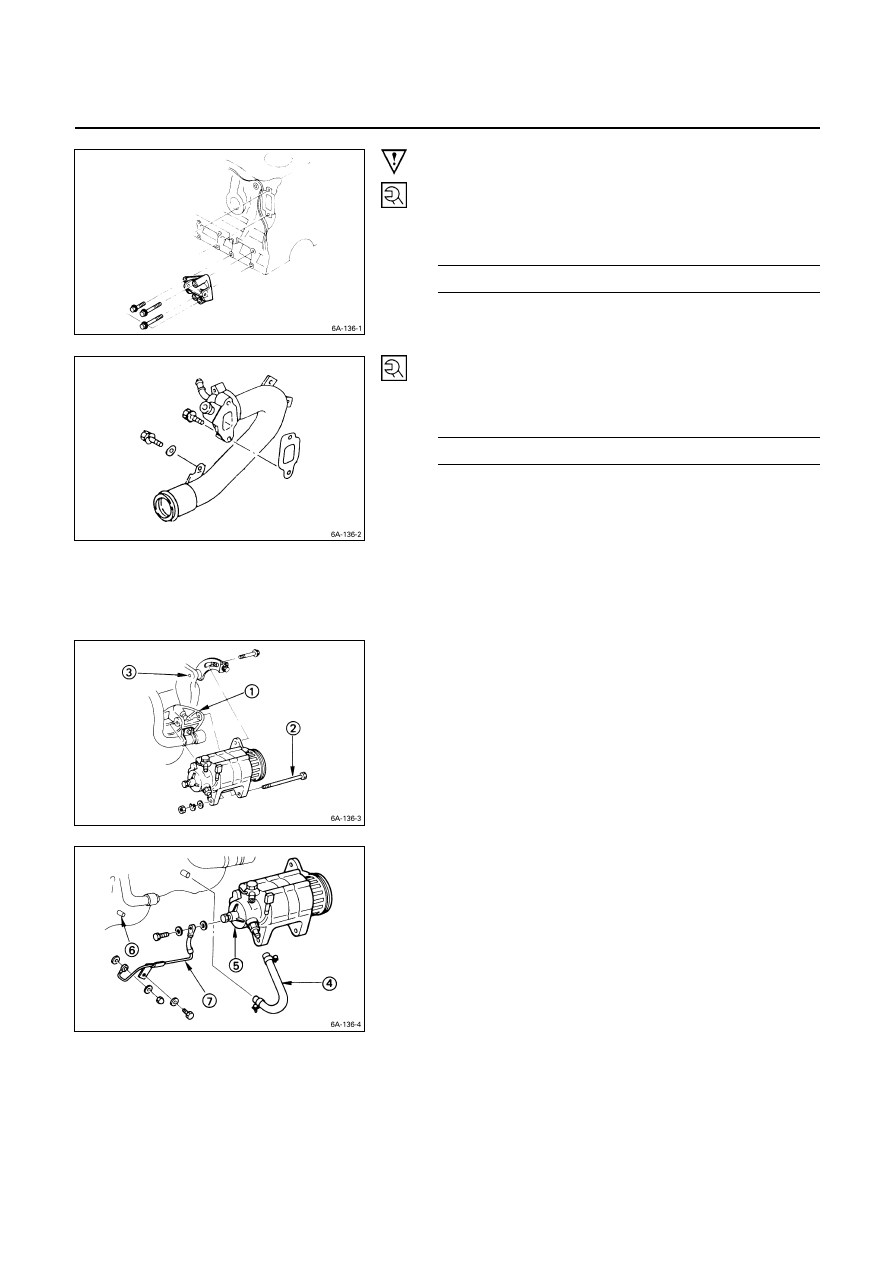

Important Operations

1. Generator

Bracket

Install the generator bracket to the cylinder body and

tighten the bracket bolts to the specified torque.

Bracket Bolt Torque

kg·m (lb.ft/N·m)

4.1

± 0.6 (29.7 ± 4.3/40.2 ± 5.9)

2. Water

Inlet

Pipe

1) Tighten the water inlet pipe bolts to the specified

torque.

Suction Pipe Bolt Torque

kg·m (lb.ft/N·m)

1.9

± 0.5 (13.7 ± 3.6/18.6 ± 4.9)

3. Heater Pipe (Rear Side)

1) Install the heater pipe to the cylinder head.

2) Connect the oil cooler return hose and feed hose to

the oil cooler.

3) Connect the water rubber hose to the heater pipe.

4. Generator and Adjusting Plate

1) Install the generator to the bracket

.

2) Temporarily tighten the generator bolt

and

adjusting plate bolts

.

The bolts will be finally tightened after installation of

the cooling fan drive belt.

3) Connect the vacuum pump rubber hose

to the

vacuum pump

, and the oil pan

.

4) Connect the vacuum oil pipe

to the vacuum pump,

and the cylinder body.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст