Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 1819

MSG MODEL (4WD) 7B-53

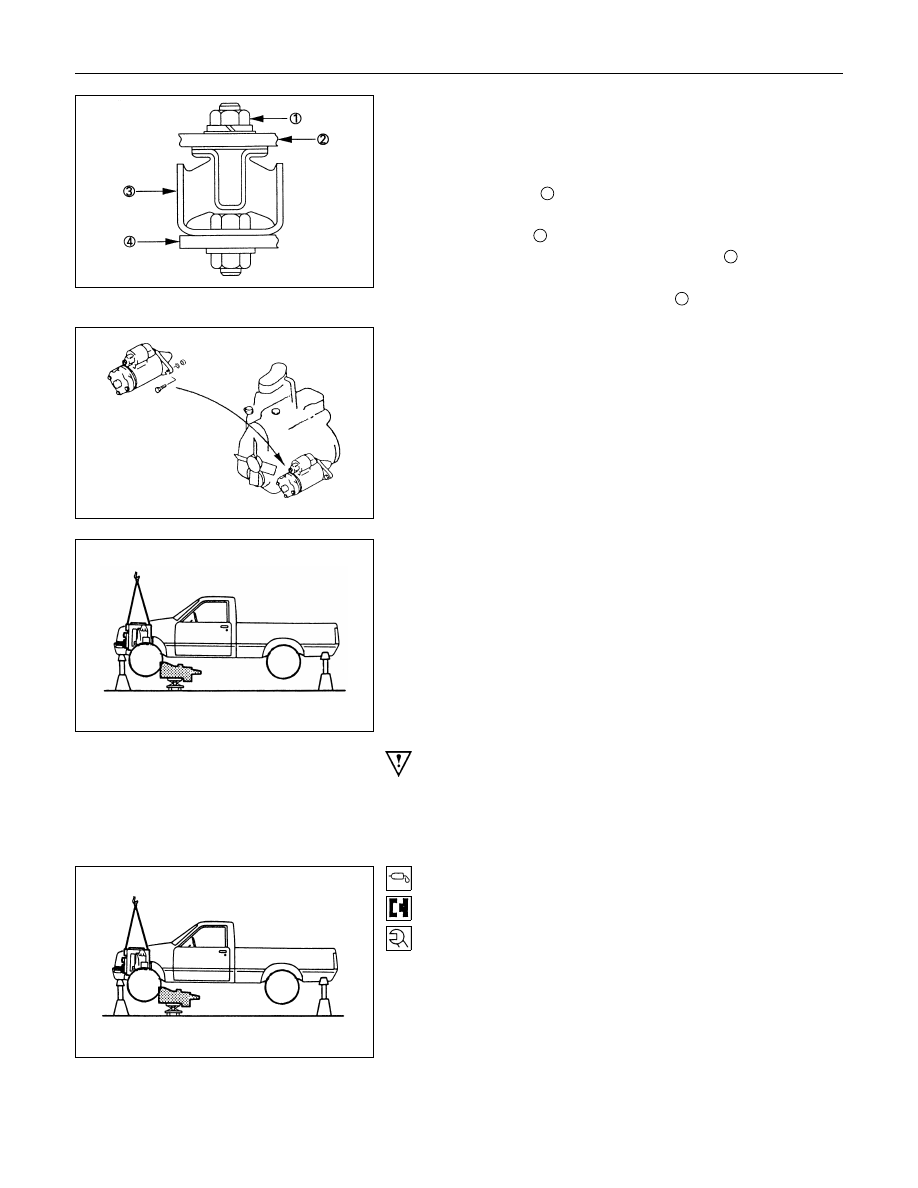

Engine Rear Mounting and Crossmember

1. Support the transmission with a transmission jack.

2. Remove No.2 crossmember.

3. Remove the engine rear mounting nuts from No.3

crossmember

3

.

4. Remove the engine rear mounting bolts from the

transmission

1

.

5. Remove No.3 crossmember and bolts

3

from the side

frame.

6. Remove the engine rear mounting

2

.

Starter Motor

Remove the starter motor from the engine real plate.

Transmission with Transfer

1. Remove the transmission nuts and bolts from the engine

rear plate.

2. Carefully pull the transmission with the transmission jack

toward the rear of the vehicle.

3. Operate the transmission jack to slowly lower the

transmission.

Important Operations - Installation

Follow the removal procedure in the reverse order to perform

the installation procedure.

Pay careful attention to the important points during the

installation procedure.

Transmission with Transfer

1. Apply a thin coat of molybdenum disulfide grease to the top

gear shaft spline.

2. Place the transmission on a transmission jack.

3. Carefully move the transmission jack and transmission into

position behind the cab.

7B-54 MSG MODEL (4WD)

4. Slowly raise the transsmission jack until the front of the

transmission is aligned with the rear of the engine.

The slope of the engine and the transmission must be the

same.

5. Align the top gear shaft spline with the clutch driven plate

internal spline.

6. Install the transmission to the engine.

Tighten the transmission nuts and bolt to the specified

torque.

Transmission Nut and Bolt Torque

N

⋅m (kgf⋅m/lb⋅ft)

M10 : 40

± 10 (4.1 ± 1.0 / 30 ± 7.2)

M12: 78

± 16 (8.0 ± 1.6 / 58 ± 12)

Starter Motor

Install the starter motor to the engine rear plate.

Starter Motor Bolt Torque

N

⋅m (kgf⋅m/lb⋅ft)

78

± 16 (8.0 ± 1.6 / 58 ± 12)

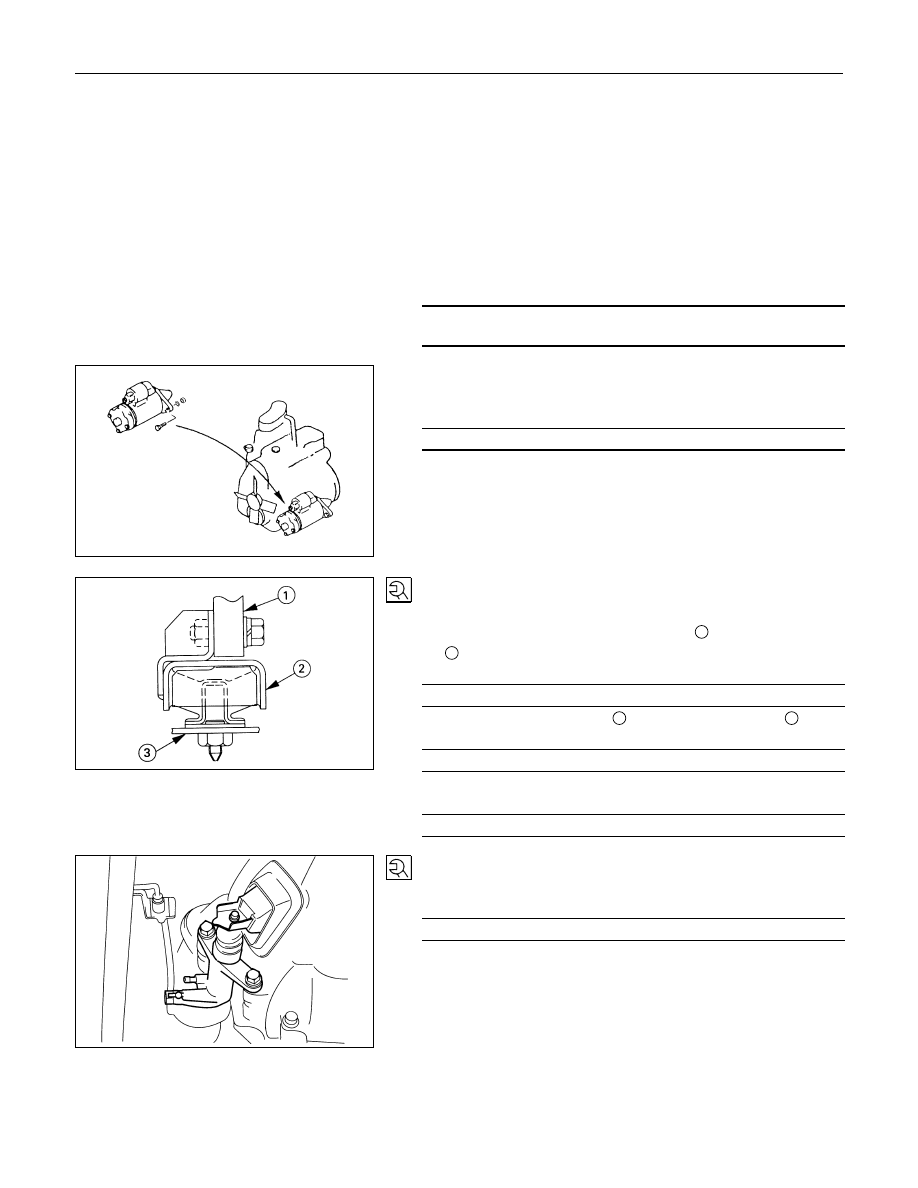

Engine Rear Crossmember and Mounting

Member

1. Install the engine rear crossmember

2

to the transmission

1

.

Rear Mounting Bolt Torque

N

⋅m(kgf⋅m/lb⋅ft)

83.3

± 4.9 (8.5 ± 0.5 / 61.5 ± 3.6)

2. Install the cross member

3

to the mounting rubber

2

.

Mounting Rubber Nut Torque

N

⋅m(kgf⋅m/lb⋅ft)

41

± 4.9 (4.2 ± 0.5 / 30 ± 3.6)

3. Install the cross member to the sideframe.

Mounting Member Bolt Torque

N

⋅m(kgf⋅m/lb⋅ft)

36.8

± 9.8 (3.8 ± 1.0 / 27.1 ± 7.2)

Slave Cylinder

Install the slave cylinder to the transmission case.

Slave Cylinder Bolt Torque

N

⋅m(kgf⋅m/lb⋅ft)

78

± 16 (8.0 ± 1.6 / 58 ± 12)

MSG MODEL (4WD) 7B-55

Harness Connector

Connect the 4WD switch connector, back up light switch

connector and speedometor sensor connector.

Front Propeller Shaft

1. Connect the propeller shaft flange yoke to the matching

flange.

2. Tighten the propeller shaft flange yoke bolt to the specified

torque.

Propeller Shaft Flange Yoke Bolt Torque

N

⋅m(kgf⋅m/lb⋅ft)

62.7

± 3.92 (6.4 ± 0.4 / 46.3 ± 2.90)

Note:

If the splined yoke and the front propeller shaft have

accidentally separated, align their setting marks and

recouple them.

Refer to "FRONT PROPELER SHAFT REMOVAL".

Rear Propeller Shaft (Single Shaft Type)

1. Insert the splined yoke

1

with the propeller shaft into the

transmission main shaft spline

2

.

2. Install the propeller shaft flange yoke

3

to the drive pinion

side.

3. Tighten the propeller shaft flange yoke bolt to the specified

torque.

Propeller Shaft Flange Yoke Bolt Torque

N

⋅m(kgf⋅m/lb⋅ft)

M8 : 35.3

± 2.94 (3.6 ± 0.3 / 26.0 ± 2.2)

M10 : 62.7

± 3.9 (6.4 ± 0.4 / 46.3 ± 2.9)

Rear Propeller Shaft (Dual Shaft Type)

1. Place the center bearing

1

together with the 1st peopeller

shaft

2

and 2nd propeller shaft

7

on the No.4

crossmember

3

.

2. Insert the splined yoke

4

into the transmission main shaft

spline

5

.

3. Tighten the center bearing retainer bolts

6

to the specified

torque.

Center Bearing Retainer Bolt Torque

N

⋅m(kgf⋅m/lb⋅ft)

60.8

± 11.8 (6.2 ± 1.2 / 44.8 ± 8.7)

4. Connect the 2nd propeller shaft

7

and drive pinion side

8

.

Be sure to align the setting marks applied at disassembly.

5. Tighten the coupling bolts to the specified torque.

Propeller Shaft Flange Yoke Bolt

Torque

N

⋅m(kgf⋅m/lb⋅ft)

M10 : 35.3

± 2.94 (3.6 ± 0.3 / 26.0 ± 2.2)

M12 : 62.7

± 3.9 (6.4 ± 0.4 / 46.3 ± 2.9)

7B-56 MSG MODEL (4WD)

Exhaust Pipe

1. Install the 2nd exhaust pipe.

Transfer Case Protector

1. Install the transfer case protector

1

to the mounting

member

2

and the sidemembers

3

.

2. Tighten the transfer case protector bolts to the specified

torque.

Transfer Case Protector Bolt Torque

N

⋅m(kgf⋅m/lb⋅ft)

36.3

± 9.8 (3.7 ± 1.0 / 26.8 ± 7.2)

Gear Shift Lever and Transfer Change

Lever

1. Replenish the transmission case and the transfer case with

the specified engine oil.

Transmission and Transfer Case Oil

lit (US gal.)

4.4 (1.16)

2. Install the gear shift lever to the gear control box.

Shift Lever Cover Torque

N

⋅m(kgf⋅m/lb⋅ft)

19.6

± 1.96 (2.0 ± 0.2 / 14.5 ± 1.5)

3. Install the dust cover.

4. Insert the transfer change lever to the transfer case.

Change Lever Retainer Bolt Torque

N

⋅m(kgf⋅m/lb⋅ft)

19.6

± 1.96 (2.0 ± 0.2 / 14.5 ± 1.5)

5. Install the grommet

6. Install the front console assembly and center console

assembly.

7. Install the gear shift lever and the transfer change lever

knobs.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст