Isuzu Rodeo UE. Manual — part 23

1A–62 HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

Removal

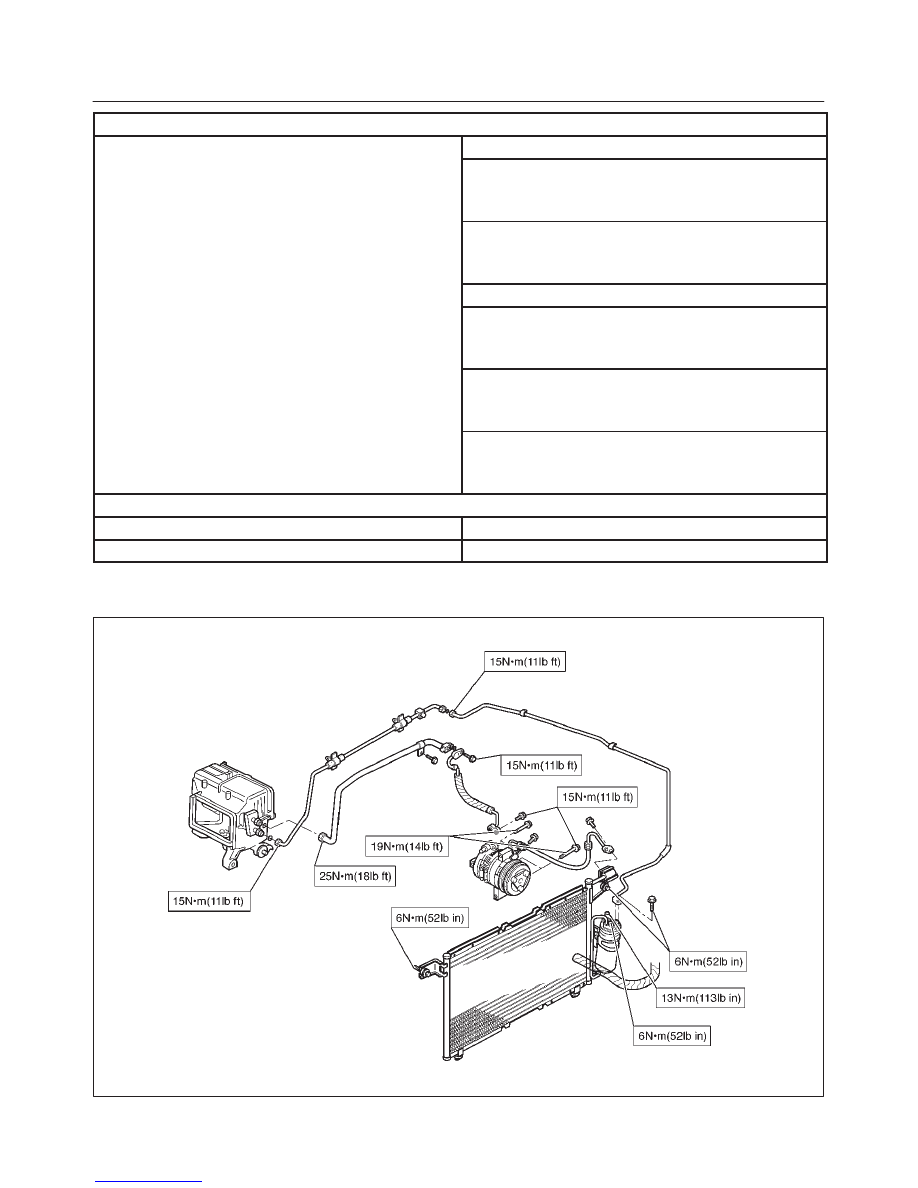

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant.

D

Refer to Refrigerant Recovery in this section.

3. Remove radiator grille.

4. Remove clip and clamp.

5. Disconnect liquid line (High-pressure pipe).

6. Disconnect suction line (Low-pressure pipe) using a

back-up wrench.

7. Disconnect suction line (Low-pressure hose) using a

back-up wrench.

8. Disconnect discharge line (High-pressure hose)

using a back-up wrench.

D

Use a backup wrench when disconnecting and

reconnecting the refrigerant lines.

D

When removing the refrigerant line connecting part,

the connecting part should immediately be plugged

or capped to prevent foreign matter from being

mixed into the line.

Installation

To install, follow the removal steps in the reverse order,

noting the following point:

1. O-rings cannot be reused. Always replace with new

ones.

2. Be sure to apply new compressor oil to the O-rings

when connecting lines.

3. Tighten the refrigerant line to the specified torque.

Refer to Main Data and Specifications for Torque

Specifications in this section.

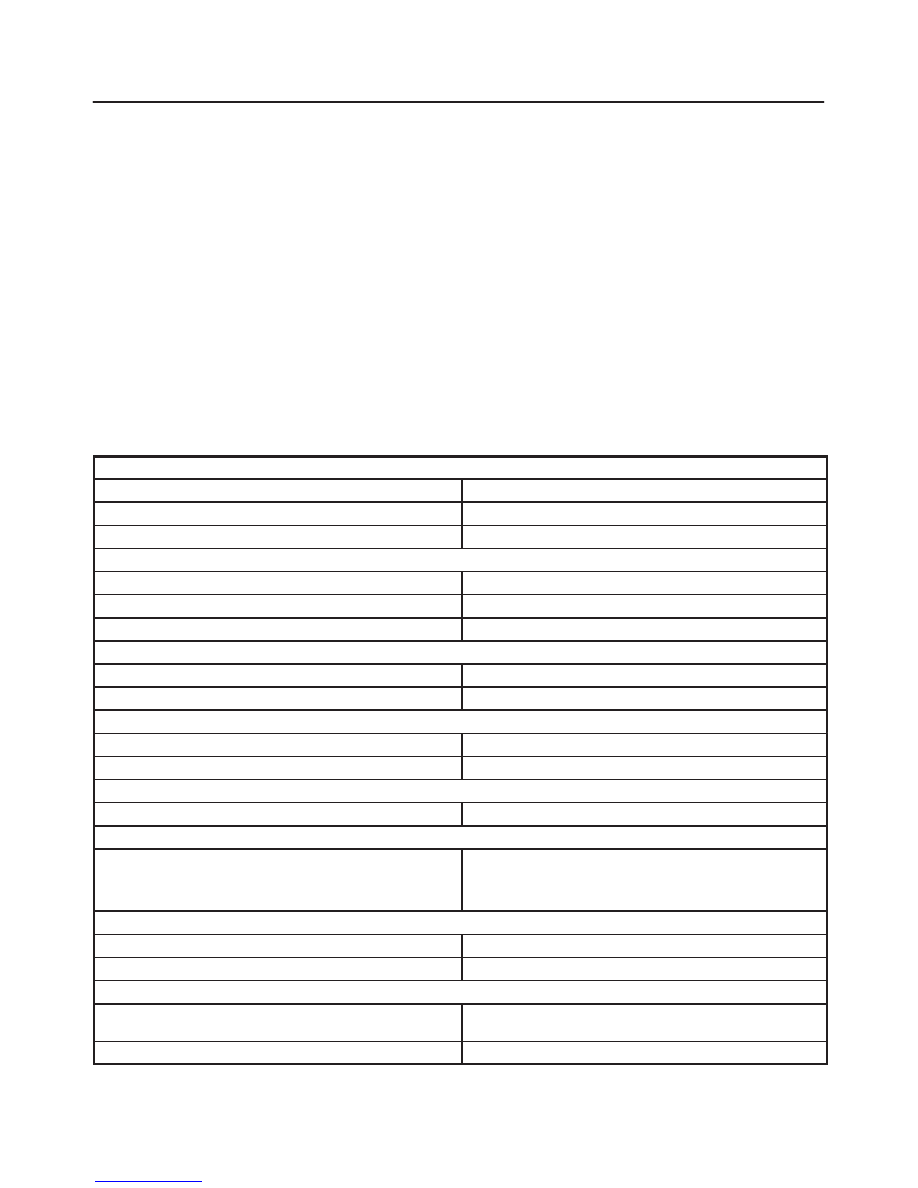

Main Data And Specifications

General Specifications

Heater Unit

Temperature control

Reheat air mix system

Capacity

3,700 Kcal./hr.

Air flow

280 m

#

/h

HEATER CORE

Type

Fin and tube type

Element dimension

167 mm (6.6 in.)

×

151 mm (5.9 in.)

×

35 mm (1.4 in.)

Radiating area

Approx. 2.4 m

@

EVAPORATOR ASSEMBLY

Capacity

4,100 Kcal./hr.

Air flow

430 m

#

/hr

EVAPORATOR CORE

Type

Al-laminate louver fin type

Element dimension

235 mm (9.3 in.)

×

224 mm (8.8 in.)

×

60 mm (2.4 in.)

EXPANSION VALVE

Type

External pressure equalizer type

THERMOSTAT SWITCH

Type

Electronic thermostat

OFF: Below 0.5

±

0.5

°

C (32.9

±

0.9

°

F)

ON: Above 4.5

±

0.5

°

C (40.1

±

0.9

°

F)

CONDENSER

Type

Parallel flow type

Radiation performance

9,400 Kcal./hr

RECEIVER/DRIER

Type

Assembly includes sight glass with dual (triple) pres-

sure switch (V6) or pressure sensor (L14)

Internal volume

300 cc (10 fl.oz.)

HEATING, VENTILATION AND AIR CONDITIONING (HVAC) 1A–63

PRESSURE SWITCH

Type

Dual pressure switch

Low pressure control

ON: 205.9

±

29.4 kPa (29.9

±

4.3 psi)

OFF: 176.5

±

24.5 kPa (25.6

±

3.6 psi)

High pressure control

ON: 2353.6

±

196.1 kPa (341.3

±

28.4 psi)

OFF: 2942.0

±

196.1 kPa (426.6

±

28.4 psi)

Triple pressure switch (V6, A/T)

Low pressure control

ON: 196.3

±

29.4 kPa (27.0

±

4.3 psi)

OFF: 176.5

±

19.6 kPa (25.6

±

2.8 psi)

Medium pressure control

ON: 1471.0

±

98.1 kPa (213.3

±

14.2 psi)

OFF: 1078.7

±

117.7 kPa (156.4

±

17.7 psi)

High pressure control

ON: 2353.6

±

196.1 kPa (341.3

±

28.4 psi)

OFF: 2942.0

±

196.1 kPa (426.6

±

28.4 psi)

REFRIGERANT

Type

HFC-134a

Specified amount

650 g (1.43 lbs.)

Torque Specifications

852RX003

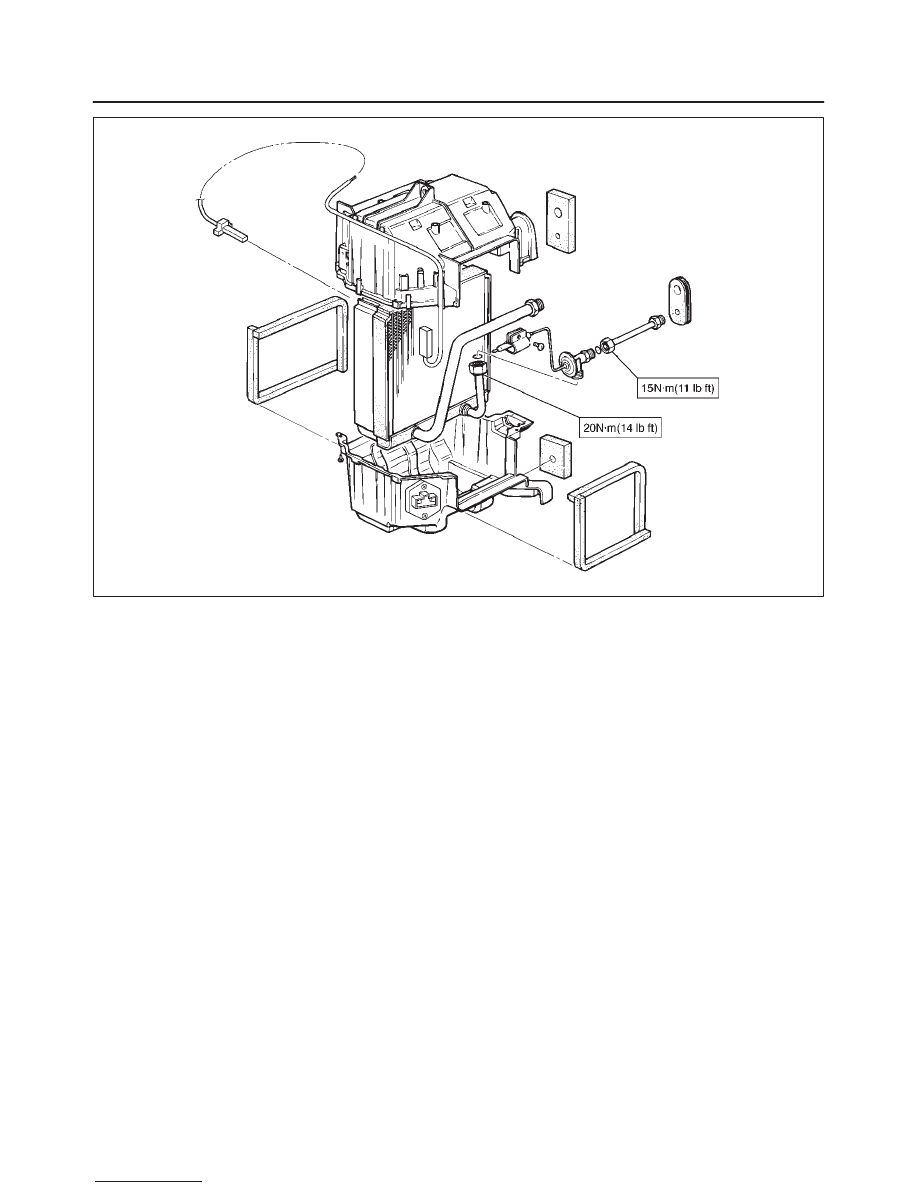

1A–64 HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

874RX006

HEATING, VENTILATION AND AIR CONDITIONING (HVAC) 1A–65

Compressor

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT LOCATION VIEW IN ORDER TO

DETERMINE WHETHER YOU ARE PERFORMING

SERVICE ON OR NEAR THE SRS COMPONENTS OR

THE SRS WIRING. WHEN YOU ARE PERFORMING

SERVICE ON OR NEAR THE SRS COMPONENTS OR

THE SRS WIRING, REFER TO THE SRS ON-VEHICLE

SERVICE INFORMATION. FAILURE TO FOLLOW

CAUTIONS COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

When servicing the compressor, keep dirt or foreign

material from getting on or into the compressor parts and

system. Clean tools and a clean work area are important

for proper service. The compressor connections and the

outside of the compressor should be cleaned before any

”On–Vehicle” repair, or before removal of the

compressor. The parts must be kept clean at all times and

any parts to be reassembled should be cleaned with

Trichloroethane, naphtha, kerosene, or equivalent

solvent, and dried with dry air. Use only lint free cloths to

wipe parts.

The operations described below are based on bench

overhaul with compressor removed from the vehicle,

except as noted. They have been prepared in order of

accessibility of the components. When the compressor is

removed from the vehicle for servicing, the oil remaining

in the compressor should be discarded and new

compressor oil added to the compressor.

Compressor malfunction will appear in one of four ways:

noise, seizure, leakage or low discharge pressure.

Resonant compressor noises are not cause for alarm;

however, irregular noise or rattles may indicate broken

parts or excessive clearances due to wear. To check

seizure, de–energize the magnetic clutch and check to

see if the drive plate can be rotated. If rotation is

impossible, the compressor is seized. Low discharge

pressure may be due to a faulty internal seal of the

compressor, or a restriction in the compressor. Low

discharge pressure may also be due to an insufficient

refrigerant charge or a restriction elsewhere in the

system. These possibilities should be checked prior to

servicing the compressor. If the compressor is

inoperative, but is not seized, check to see if current is

being supplied to the magnetic clutch coil terminals.

The compressor oil used in the HFC–134a system

compressor differs from that used in R–12 systems.

Also, compressor oil to be used varies according to the

compressor model. Be sure to avoid mixing two or more

different types of oil.

If the wrong oil is used, lubrication will be poor and the

compressor will seize or malfunction.

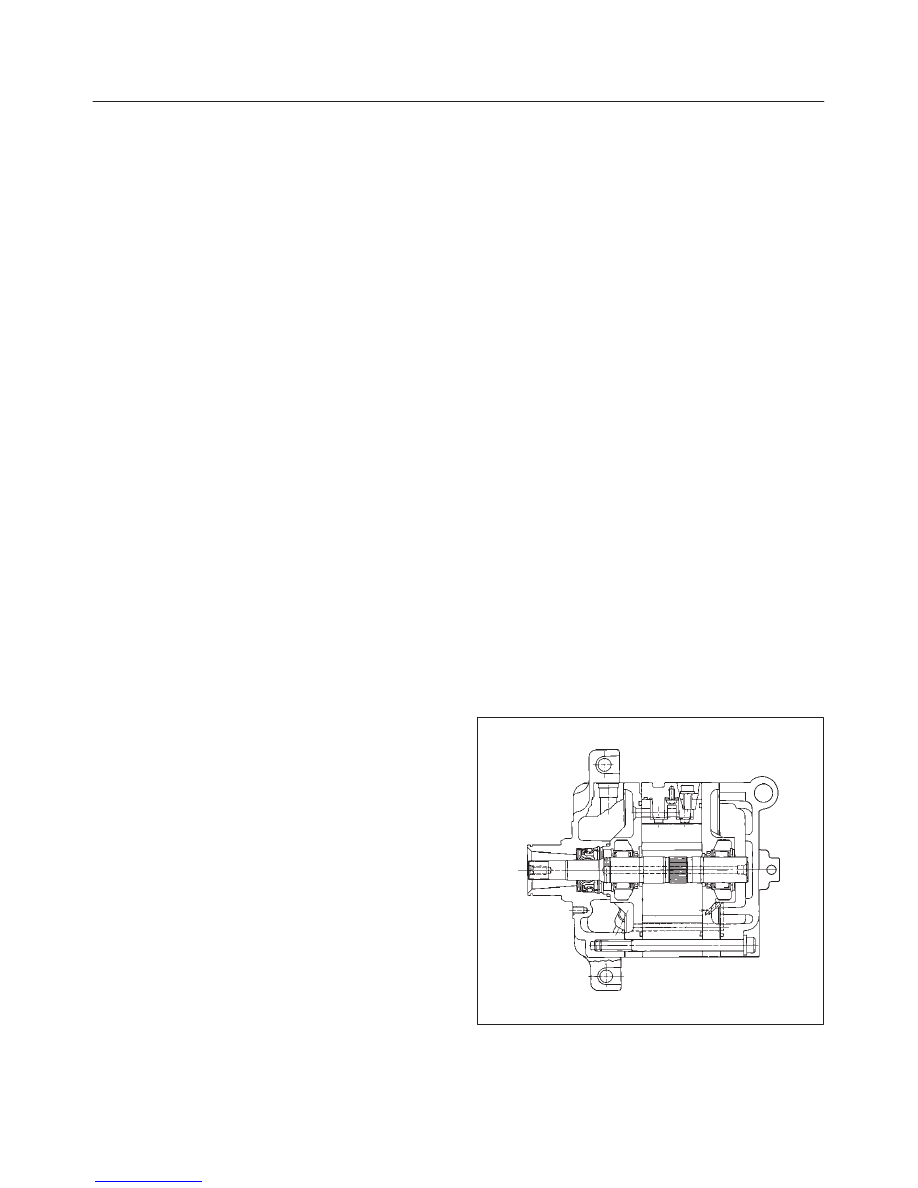

DKV-14G Type Compressor

DKV–14G is equipped with five–vane rotary compressor.

These vanes are built into a rotor which is mounted on a

shaft.

When the shaft rotates, the vanes built into the cylinder

block assembly are operated by centrifugal force.

This changes the volume of the spare formed by the rotor

and cylinder, resulting in the intake and compression of

the refrigerant gas. The discharge valve and the valve

stopper, which protects the discharge valve, are built into

the cylinder block assembly. There is no suction valve but

a shaft seal is installed between the shaft and head; a

trigger valve, which applies back pressure to the vanes, is

installed in the cylinder block and a refrigerant gas

temperature sensor is installed in the front head.

The specified quantity of compressor oil is contained in

the compressor to lubricate the various parts using the

refrigerant gas discharge pressure.

871RX002

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст