Isuzu Rodeo UE. Manual — part 141

6A–53

ENGINE MECHANICAL (X22SE 2.2L)

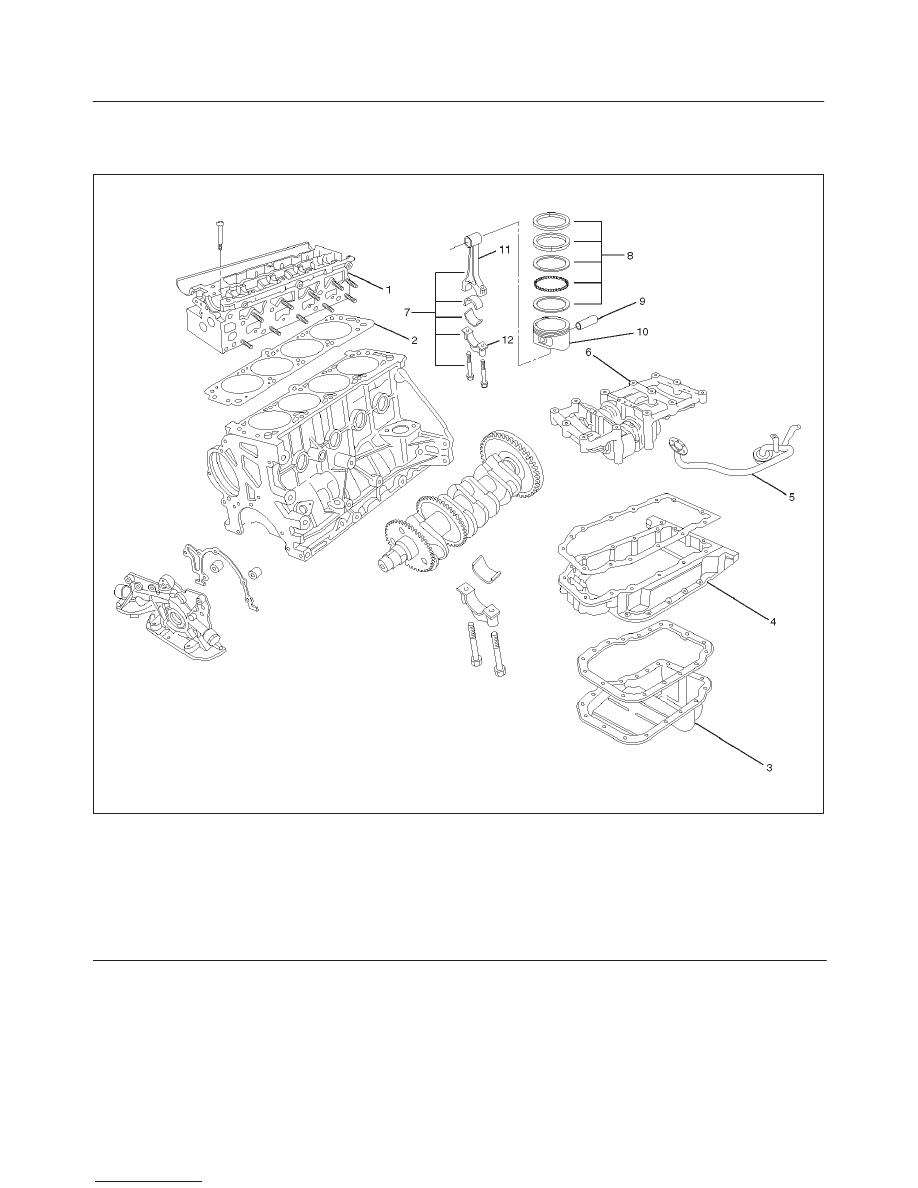

Piston and Connecting Rod

Piston, Connecting Rod and Associate Parts

015RW037

Legend

(1) Cylinder Head Assembly

(2) Cylinder Head Gasket

(3) Oil Pan Assembly

(4) Pan Support

(5) Oil Strainer

(6) Balance Unit Assembly

(7) Piston and Connecting Rod Assembly

(8) Piston Ring

(9) Piston Pin

(10) Piston

(11) Connecting Rod

(12) Connecting Rod Cap

Disassembly

1. Remove cylinder head assembly (1), refer to

“Cylinder Head Removal” in this manual.

2. Remove cylinder head gasket (2).

3. Remove oil pan assembly and oil pan support (3)

refer to“Oil Pan and Oil Pan Support” in this manual.

4. Remove oil strainer.

5. Remove balance unit assembly.

6. Remove connecting rod cap with connecting rod

lower.

6A–54

ENGINE MECHANICAL (X22SE 2.2L)

7. Remove piston and connecting rod assembly (7).

NOTE: Before removing piston and connecting rod

assembly, measure thrust clearance.

f

Remove any ridge or carbon build up from the top

end of the cylinder.

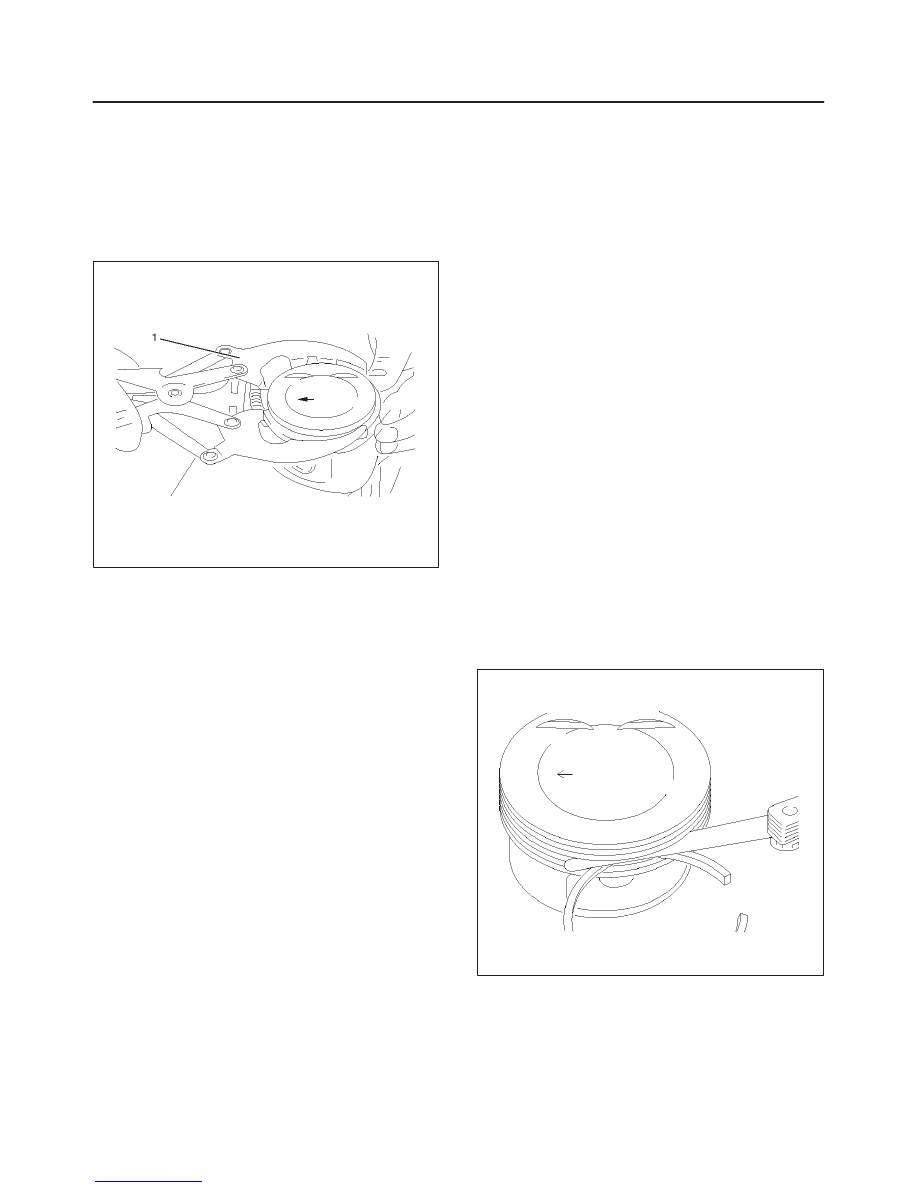

8. Remove the piston rings (8) with a piston ring

expander. Arrange the removed piston rings in the

cylinder number order.

015RW024

9. Remove the piston pin (9).

f

Heat the connecting rod and the piston pin with oil

heater, when it temperature is keep at

280

°

C–320

°

C.

f

Push the piston pin with brass bar.

NOTE: Keep the parts removed from each cylinder

separate. All parts must be reinstalled in their original

positions.

10. Piston (10).

11. Connecting rod (11).

Inspection and Repair

Pistons (10)

Carefully clean away all the carbon adhering to the piston

head and the piston ring grooves.

NOTE: Never use a wire brush to clean the pistons.

Damage will result. Visually check each piston for

cracking, scoring, and other signs of excessive wear. If

any of the above conditions are found, the piston must be

replaced.

Piston Rings (8)

Any worn or damaged part discovered during engine

overhaul must be replaced with a new one.

1. Ring end gap measurement

f

Insert the piston ring into the bore.

f

Push the ring by the piston, at a right angle to the

wall, into the point at which the cylinder bore

diameter is the smallest.

f

Measure the ring end gap.

Compression Ring

1st ring

Standard:

0.30 mm–0.50 mm

(0.0118 in–0.0195 in)

2nd ring

Standard:

0.30 mm–0.50 mm

(0.0118 in–0.0195 in)

Oil ring

Standard:

0.40 mm–1.40 mm

(0.0156 in–0.0546 in)

2. Measure the clearance between the piston ring

groove and the piston ring with a feeler gauge. If the

piston ring groove / piston ring clearance exceeds the

specified limit, the piston must be replaced.

Compression Ring Clearance

Standard : 0.02 mm–0.04 mm

(0.0008 in.–0.0016 in)

015RW025

6A–55

ENGINE MECHANICAL (X22SE 2.2L)

Piston Pin (9)

NOTE: Do not reuse the old piston pin.

1. Use a micrometer to measure the new piston pin

outside diameter in both directions at three different

positions.

2. Measure the inside diameter of the connecting rod

small end. If the fitting interference between the small

end and pin does not conform to the specified value,

the connecting rod must be replaced.

Standard : 0.02 mm–0.041 mm

(0.0008 in–0.0016 in)

014RW077

3. Insert the new pin into the piston and rotate it. If the

pin rotates smoothly with no backlash, the clearance

is normal. If there is backlash or roughness, measure

the clearance. If the clearance exceeds the specified

limit, the piston must be replaced.

Clearance

Standard : 0.011 mm–0.014 mm

(0.0004 in.–0.0005 in)

Connecting Rods (11)

1. Measure the oil clearance between the connecting

rod and the crankshaft.

1. Remove the connecting rod cap nuts and the rod

caps (12).

Arrange the removed rod caps in the cylinder

number order.

2. Clean the rod bearings and the crankshaft pins.

3. Carefully check the rod bearings. If even one

bearing is found to be damaged or badly worn, the

entire bearing assembly must be replaced as a

set. Reinstall the bearings in their original

positions. Apply plastigage to the crank pin.

4. Reinstall the rod caps (12) to their original

positions.

Tighten the rod cap nuts.

1st step: 35 N·m (26 lb ft)

2nd step: 45

°

3rd step: 15

°

NOTE: Do not allow the crankshaft to rotate.

5. Remove the rod caps.

6. Measure the width of the plastigage and

determine the oil clearance. If the oil clearance

exceeds the limit, replace the rod bearing as a

set.

Standard : 0.006 mm–0.031 mm

(0.0002 in–0.0012 in)

Limit : 0.12 mm (0.0047 in)

7. Clean the plastigage from the bearings and the

crankshaft pins.

6A–56

ENGINE MECHANICAL (X22SE 2.2L)

Crankshaft grinding dimensions

mm (in)

(continued)

Production and Service

Con–rod bearing journal dia.

Standard size

(no color code)

48.970 to 48.988 (1.9098–1.9105)

Undersize 0.25 (0.0097)

blue

48.720 to 48.738 (1.9001–1.9008)

Undersize 0.5 (0.0195)

white

48.470 to 48.488 (1.8903–1.891)

Con–rod bearing journal width

Standard size

(no color code)

26.460 to 26.580 (1.0319–1.036)

Undersize 0.25 (0.0097)

blue

26.460 to 26.580 (1.0319–1.036)

Undersize 0.5 (0.0195)

white

26.460 to 26.580 (1.0319–1.036)

Con–rod width

26.338 to 26.390 (1.0271–1.0292)

Reassembly

1. Install connecting rod

2. Install piston

3. Install piston pin

f

Apply a thin coat of engine oil to the piston pin. Try to

insert the piston pin into the piston pin hole with

normal finger pressure.

NOTE: When changing piston / connecting rod

combinations, do not change the piston / piston pin

combination and do not reuse the old piston pin.

f

Attach the piston to the connecting rod with the

piston front mark and the connecting rod front mark

on the same side.

f

Heat the connecting rod small end to a suitable

temperature to ensure smooth installation.

4. Install piston ring with the piston ring expander.

f

New piston rings with “Top” uppermost — use

commercially available pliers.

f

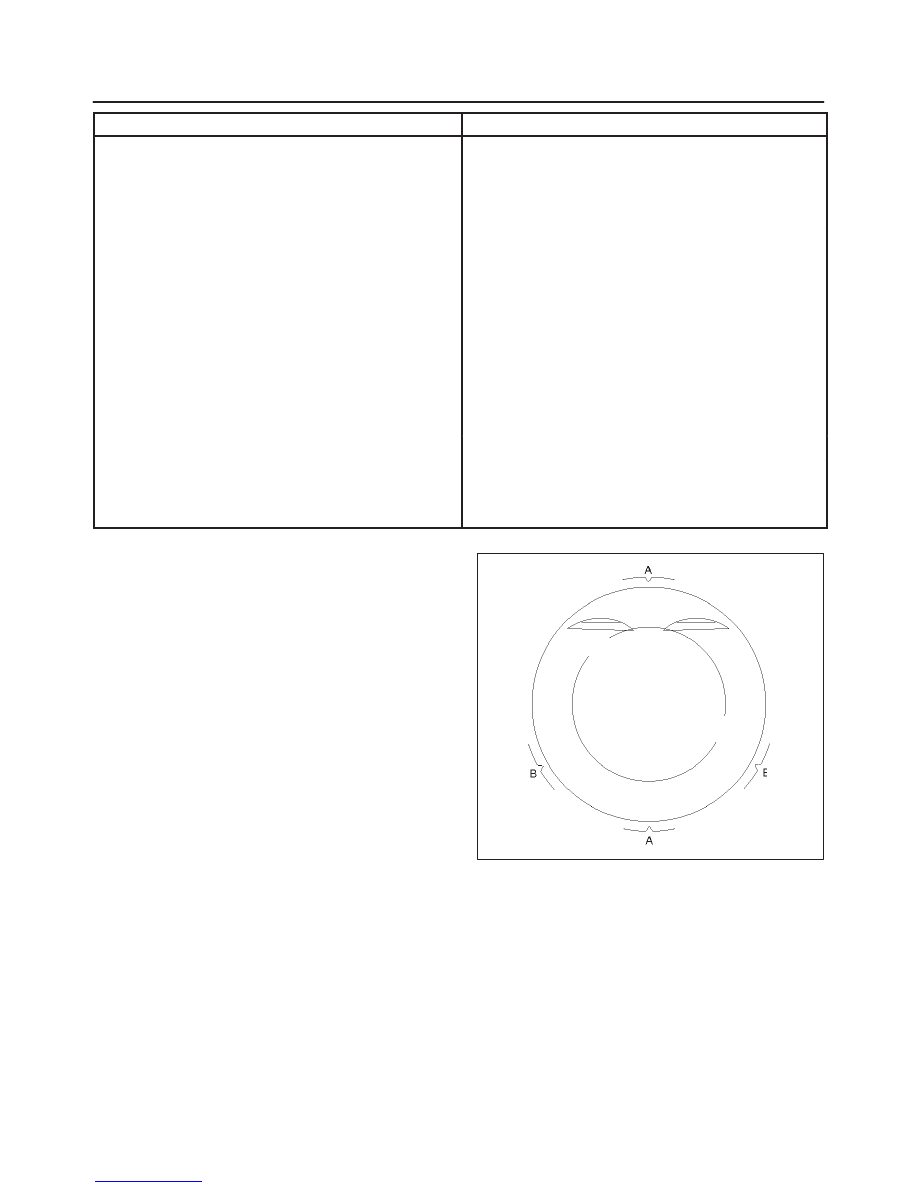

Position ring gaps:

1 — Compression rings 180

°

to each other as

illustrated.

2 — Offset oil control rings 25 to 50 mm/1 to 2 in.

from gap of second compression ring.

015RW026

f

After installation, apply engine oil to the entire

circumference of the piston rings. Check to see that

all the rings rotate smoothly.

5. Install piston and connecting rod assembly.

f

Insert the bearings into the connecting rods and

caps. Apply new engine oil to the bearing faces and

nuts.

f

Tighten the connecting rod cap nuts in 3 steps:

1st step : 35 N·m (26 lb ft)

2nd step: 45

°

3rd step: 15

°

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст