Isuzu Rodeo UE. Manual — part 174

6E1–67

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

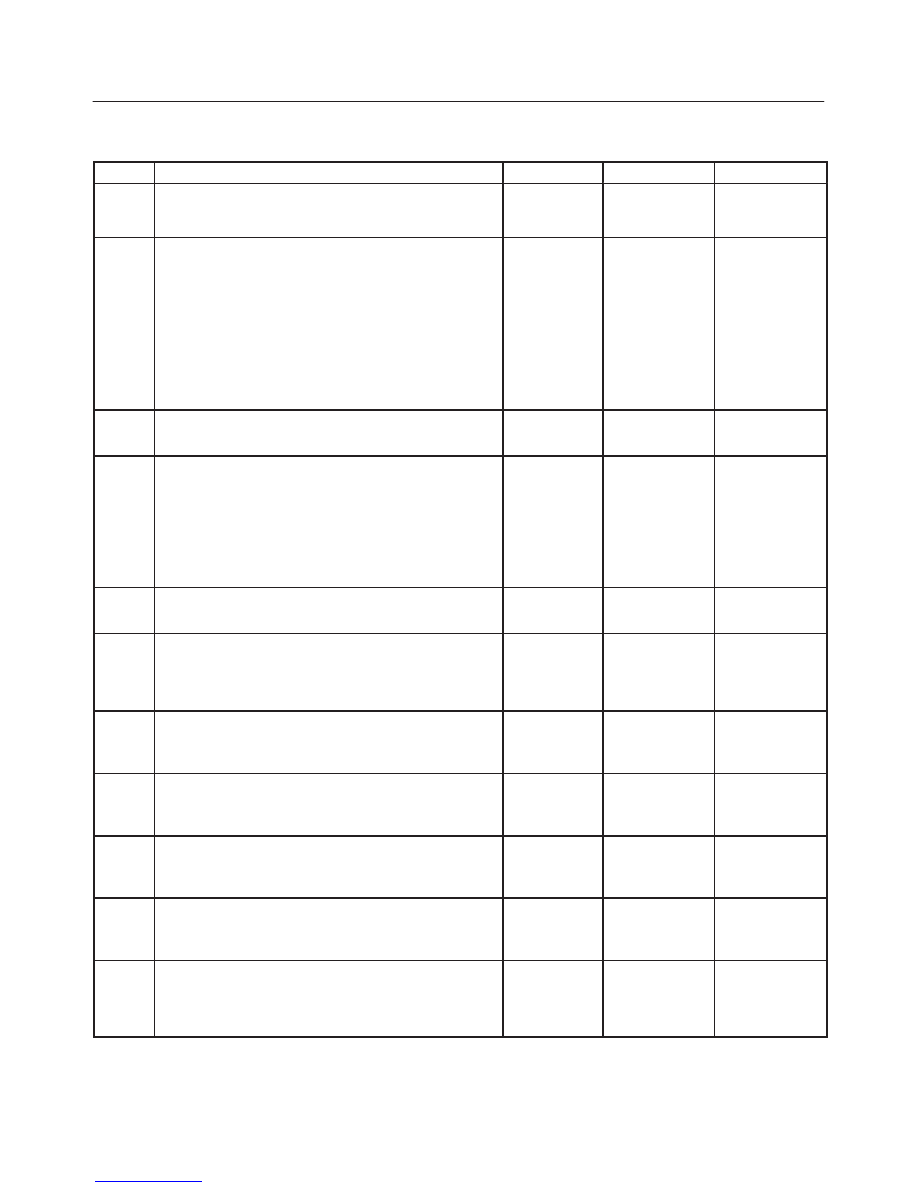

Multiple PCM Information Sensor DTCs Set

Step

Action

Value(s)

Yes

No

1

Was the ”On–Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Turn the ignition OFF, disconnect the PCM.

2. Turn the ignition ON, check the 5 volt reference

circuits for the following conditions:

f

A poor connection at the PCM.

f

An open between the PCM connector and the

splice.

f

A short to ground.

f

A short to voltage.

Is there an open or short?

—

Go to

Step 3

Go to

Step 4

3

Repair the open or short.

Is the action complete?

—

Verify repair

—

4

Check the sensor ground circuit for the following

conditions:

f

A poor connection at the PCM or the affected

sensors.

f

An open between the PCM connector and the

affected sensors.

Is there an open or a poor connection?

—

Go to

Step 5

Go to

Step 6

5

Repair the open or the poor connection.

Is the action complete?

—

Verify repair

—

6

Measure the voltage between the EGR pintle position

sensor signal circuit at the PCM harness connector and

ground.

Does the voltage measure near the specified value?

0 V

Go to

Step 7

Go to

Step 13

7

Measure the voltage between the MAP sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 V

Go to

Step 8

Go to

Step 14

8

Measure the voltage between the TP sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 V

Go to

Step 9

Go to

Step 15

9

Measure the voltage between the IAT sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 V

Go to

Step 10

Go to

Step 16

10

Measure the voltage between the ECT sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 V

Go to

Step 20

Go to

Step 17

11

Measure the voltage between the A/C Pressure

Sensor circut at the PCM harness connector and

ground.

Does the voltage measure near the specified value?

0 V

Go to

Step 13

Go to

Step 19

6E1–68

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

Multiple PCM Information Sensor DTCs Set

(Cont'd)

Step

No

Yes

Value(s)

Action

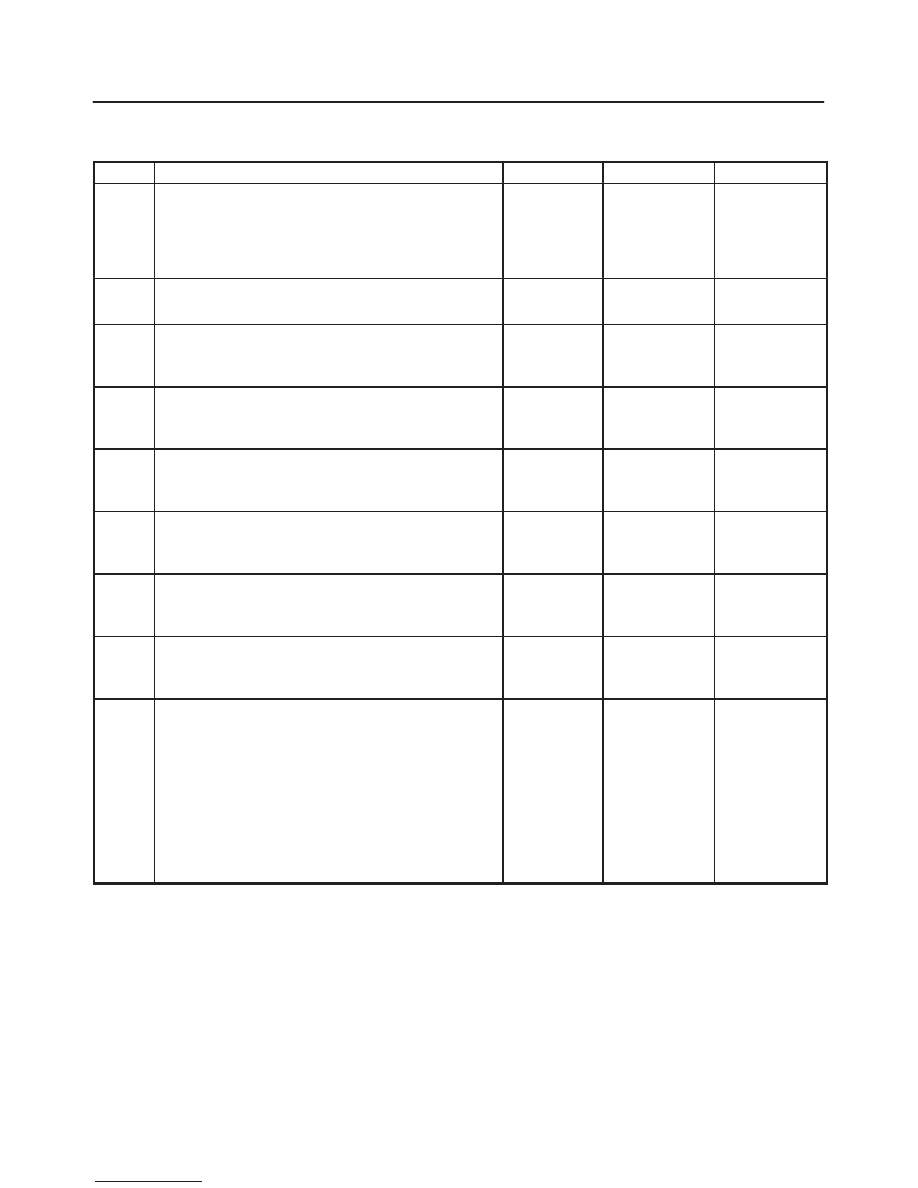

12

1. Disconnect the EGR valve.

2. Measure the voltage between the EGR pintle

position sensor signal circuit at the PCM harness

connector and ground.

Does the voltage measure near the specified value?

0 V

Go to

Step 12

Go to

Step 17

13

Replace the EGR valve.

Is the action complete?

—

Verify repair

—

14

Locate and repair the short to voltage in the MAP

sensor signal circuit.

Is the action complete?

—

Verify repair

—

15

Locate and repair the short to voltage in the TP sensor

signal circuit.

Is the action complete?

—

Verify repair

—

16

Locate and repair the short to voltage in the IAT sensor

signal circuit.

Is the action complete?

—

Verify repair

—

17

Locate and repair the short to voltage in the ECT

sensor signal circuit.

Is the action complete?

—

Verify repair

—

18

Locate and repair the short to voltage in the A/C

Pressure Sensor circuit.

Is the action complete?

—

Verify repair

—

19

Locate and repair the short to voltage in the EGR pintle

position sensor signal circuit.

Is the action complete?

—

Verify repair

—

20

Replace the PCM.

IMPORTANT: The replacement PCM must be

programmed. Refer to On–Vehicle Service in

Powertrain Control Module and Sensors for

procedures.

And also refer to latest service bulletin

Check to see if the Latest software is released or not.

And then Down Load the LATEST PROGRAMMED

SOFTWARE to the replacement PCM.

Is the action complete?

—

Go to

OBD

System

Check

—

6E1–69

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

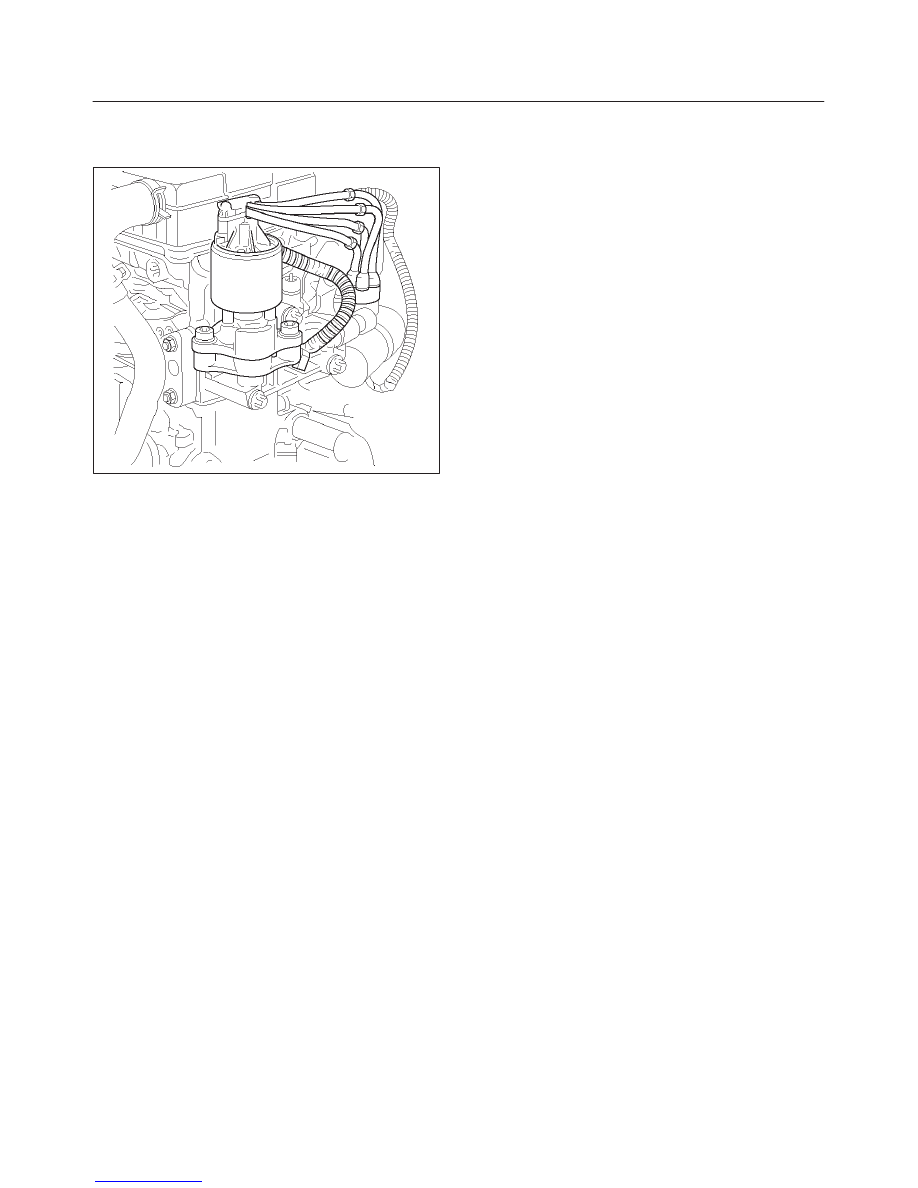

EXHAUST GAS RECIRCULATION

(EGR) DIAGNOSIS

057RX001

An EGR flow check diagnosis of the linear EGR system is

covered by DTC P0401, P0404, and P0405. If EGR

diagnostic trouble code P0401 is encountered, refer to

the DTC charts.

ENGINE Tech 2 DATA DEFINITIONS

AND RANGES

A/C CLUTCH – Tech 2 Displays ON or OFF

Indicates whether the PCM has commanded the A/C

clutch ON. Used in A/C system diagnostics.

A/C REQUEST – Tech 2 Displays YES or NO

Indicates the state of the A/C request input circuit from the

HVAC controls. The PCM uses the A/C request signal to

determine whether A/C compressor operation is being

requested.

AIR/FUEL RATIO – Tech 2 Range 0.0–25.5

Air/fuel ratio indicates the PCM commanded value. In

”Closed Loop”, the air/fuel ratio should normally be

displayed around ”14.2–14.7.” A lower air/fuel ratio

indicates a richer commanded mixture, which may be

seen during power enrichment or TWC protection modes.

A higher air/fuel ratio indicates a leaner commanded

mixture. This can be seen during deceleration fuel mode.

BARO kPa – Tech 2 Range 10–105 kPa/0.00–5.00

Volts

The barometric pressure reading is determined from the

MAP sensor signal monitored during key up and wide

open throttle (WOT) conditions. The barometric pressure

is used to compensate for altitude differences and is

normally displayed around ”61–104” depending on

altitude and barometric pressure.

CMP ACT. COUNTER – Cam Position Activity

DECEL FUEL MODE – Tech 2 Displays ACTIVE or

INACTIVE

”ACTIVE” displayed indicates that the PCM has detected

conditions appropriate to operate in deceleration fuel

mode. The PCM will command the deceleration fuel

mode when it detects a closed throttle position while the

vehicle is traveling over 20 mph. While in the deceleration

fuel mode, the PCM will decrease the amount of fuel

delivered by entering ”Open Loop” and decreasing the

injector pulse width.

DESIRED EGR POS. – Tech 2 Range 0%–100%

Represents the EGR pintle position that the PCM is

commanding.

DESIRED IDLE – Tech 2 Range 0–3187 RPM

The idle speed that the PCM is commanding. The PCM

will compensate for various engine loads based on engine

coolant temperature, to keep the engine at the desired

speed.

ECT – (Engine Coolant Temperature) Tech 2 Range

–40

°

C to 151

°

C (–40

°

F to 304

°

F)

The engine coolant temperature (ECT) is mounted in the

coolant stream and sends engine temperature

information to the PCM. The PCM applies 5 volts to the

ECT sensor circuit. The sensor is a thermistor which

changes internal resistance as the temperature changes.

When the sensor is cold (high resistance), the PCM

monitors a high signal voltage and interprets that as a cold

engine. As the sensor warms (decreasing resistance),

the voltage signal will decrease and the PCM will interpret

the lower voltage as a warm engine.

EGR DUTY CYCLE – Tech 2 Range 0%–100%

Represents the EGR valve driver PWM signal from the

PCM. A duty cycle of 0% indicates that no EGR flow is

being commanded; a 100% duty cycle indicates

maximum EGR flow commanded.

EGR FEEDBACK – Tech 2 Range 0.00–5.00 Volts

Indicates the EGR pintle position sensor signal voltage

being monitored by the PCM. A low voltage indicates a

fully extended pintle (closed valve); a voltage near 5 volts

indicates a retracted pintle (open valve).

EGR TEST COUNT – Tech 2 Range 0–255

Indicates the number of EGR flow test samples collected

during the current ignition cycle. Under normal operation,

only one sample is allowed during an ignition cycle. If the

PCM battery feed has been disconnected or a DTC

P0401 has been cleared, 10 EGR flow test samples will

be allowed during the ignition cycle. This is to allow repair

verification during a single ignition cycle.

ENGINE LOAD – Tech 2 Range 0%–100%

Engine load is calculated by the PCM from engine speed

and MAP sensor readings. Engine load should increase

with an increase in RPM or air flow.

ENGINE RUN TIME – Tech 2 Range 00:00:00–

99:99:99 Hrs:Min:Sec

Indicates the time elapsed since the engine was started.

If the engine is stopped, engine run time will be reset to

00:00:00.

ENGINE SPEED – Range 0–9999 RPM

Engine speed is computed by the PCM from the 58X

reference input. It should remain close to desired idle

under various engine loads with engine idling.

6E1–70

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

EVAP PURGE PWM – Tech 2 Range 0%–100%

Represents the PCM commanded PWM duty cycle of the

EVAP purge solenoid valve. ”0%” displayed indicates no

purge; ”100%” displayed indicates full purge.

EVAP VACUUM SWITCH – Tech 2 Displays PURGE

or NO PURGE

The EVAP purge vacuum switch is a normally closed

switch positioned in the purge line between the canister

and the EVAP purge solenoid. The EVAP purge vacuum

switch will open when vacuum increases to greater than

5 inches of water in the purge line. The EVAP purge

vacuum switch is used by the PCM to monitor EVAP

canister purge solenoid operation and purge system

integrity. The EVAP purge vacuum switch should be

closed to ground with no vacuum present (0% EVAP

purge PWM). With EVAP purge PWM at 25% or greater,

the EVAP purge vacuum switch should be open and

”PURGE” should be indicated.

FUEL PUMP – Tech 2 Displays ON or OFF

Indicates the PCM commanded state of the fuel pump

relay driver circuit.

FUEL TRIM CELL – Tech 2 Range 0–21

The fuel trim cell is dependent upon engine speed and

MAF sensor readings. A plot of RPM vs. MAF is divided

into 22 cells. Fuel trim cell indicates which cell is currently

active.

FUEL TRIM LEARN – Tech 2 Displays NO or YES

When conditions are appropriate for enabling long term

fuel trim corrections, fuel trim learn will display YES. This

indicates that the long term fuel trim is responding to the

short term fuel trim. If the fuel trim learn displays NO, then

long term fuel trim will not respond to changes in short

term fuel trim.

GENERATOR CONTROL – Tech 2 Displays ACTIVE

or INACTIVE.

HO2S BANK 1, SEN. 1 – Tech 2 Range 0–1000 mV

Represents the fuel control exhaust oxygen sensor

output voltage. Should fluctuate constantly within a range

between 10 mV (lean exhaust) and 1000 mV (rich

exhaust) while operating in ”Closed Loop”.

HO2S BANK 1, SEN. 2 – Tech 2 Range 0–1000 mV

Represents the exhaust oxygen sensor output voltage.

Should fluctuate constantly within a range between 10

mV (lean exhaust) and 1000 mV (rich exhaust) while

operating in ”Closed Loop”. This is used along with HO2S

Bank 1, Sensor 3 to determine the catalytic converter

efficiency in the manual transmission models.

HO2S BANK 1, SEN. 1 – Tech 2 Displays NOT

READY or READY

Indicates the status of the exhaust oxygen sensor. The

Tech 2 will indicate that the exhaust oxygen sensor is

ready when the PCM detects a fluctuating HO2S voltage

sufficient to allow ”Closed Loop” operation. This will not

occur unless the exhaust sensor is warmed up.

HO2S WARM UP TIME BANK 1, SEN. 1 – Tech 2

Range 00:00:00–99:99:99 HRS:MIN:SEC

Indicates warm–up time for each HO2S. The HO2S

warm–up time is used for the HO2S heater test. The PCM

will run the heater test only after a cold start (determined

by engine coolant and intake air temperature at the time

of start–up) and only once during an ignition cycle. When

the engine is started the PCM will monitor the HO2S

voltage. When the HO2S voltage indicates a sufficiently

active sensor, the PCM looks at how much time has

elapsed since start–up. If the PCM determines that too

much time was required for the HO2S to become active,

a DTC will set. If the engine was warm when started,

HO2S warm–up will display ”00:00:00.”

IAC POSITION – Tech 2 Range 0–255 Counts

Displays the commanded position of the idle air control

pintle in counts. A larger number of counts means that

more air is being commanded through the idle air

passage. Idle air control should respond fairly quickly to

changes in engine load to maintain desired idle RPM.

IAT (INTAKE AIR TEMPERATURE) – Tech 2 Range

–40

°

C to 151

°

C (–40

°

F to 304

°

F)

The PCM converts the resistance of the intake air

temperature sensor to degrees. Intake air temperature

(IAT) is used by the PCM to adjust fuel delivery and spark

timing according to incoming air density.

IGNITION 1 – Tech 2 Range 0–25.5 Volts

This represents the system voltage measured by the

PCM at its ignition feed.

INJ. PULSE BANK 1 – Tech 2 Range 0–1000 msec.

Indicates the amount of time the PCM is commanding

each injector ON during each engine cycle. A longer

injector pulse width will cause more fuel to be delivered.

Injector pulse width should increase with increased

engine load.

LONG TERM FUEL TRIM BANK 1

The long term fuel trim is derived from the short term fuel

trim values and represents a long term correction of fuel

delivery for the bank in question. A value of 0% indicates

that the fuel delivery requires no compensation to

maintain the PCM commanded air/fuel ratio. A negative

value significantly below 0% indicates that the fuel

system is rich and fuel delivery is being reduced

(decreased injector pulse width). A positive value

significantly greater than 0% indicates that a lean

condition exists and the PCM is compensating by adding

fuel (increased injector pulse width). Because long term

fuel trim tends to follow short term fuel trim, a value in the

negative range due to canister purge at idle should not be

considered unusual. Fuel trim values at maximum

authority may indicate an excessively rich or lean system.

LOOP STATUS – Tech 2 Displays OPEN or CLOSED

”CLOSED” indicates that the PCM is controlling fuel

delivery according to oxygen sensor voltage. In ”OPEN”

the PCM ignores the oxygen sensor voltage and bases

the amount of fuel to be delivered on TP sensor, engine

coolant, and MAF sensor inputs only.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст