Isuzu Rodeo UE. Manual — part 173

6E1–63

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

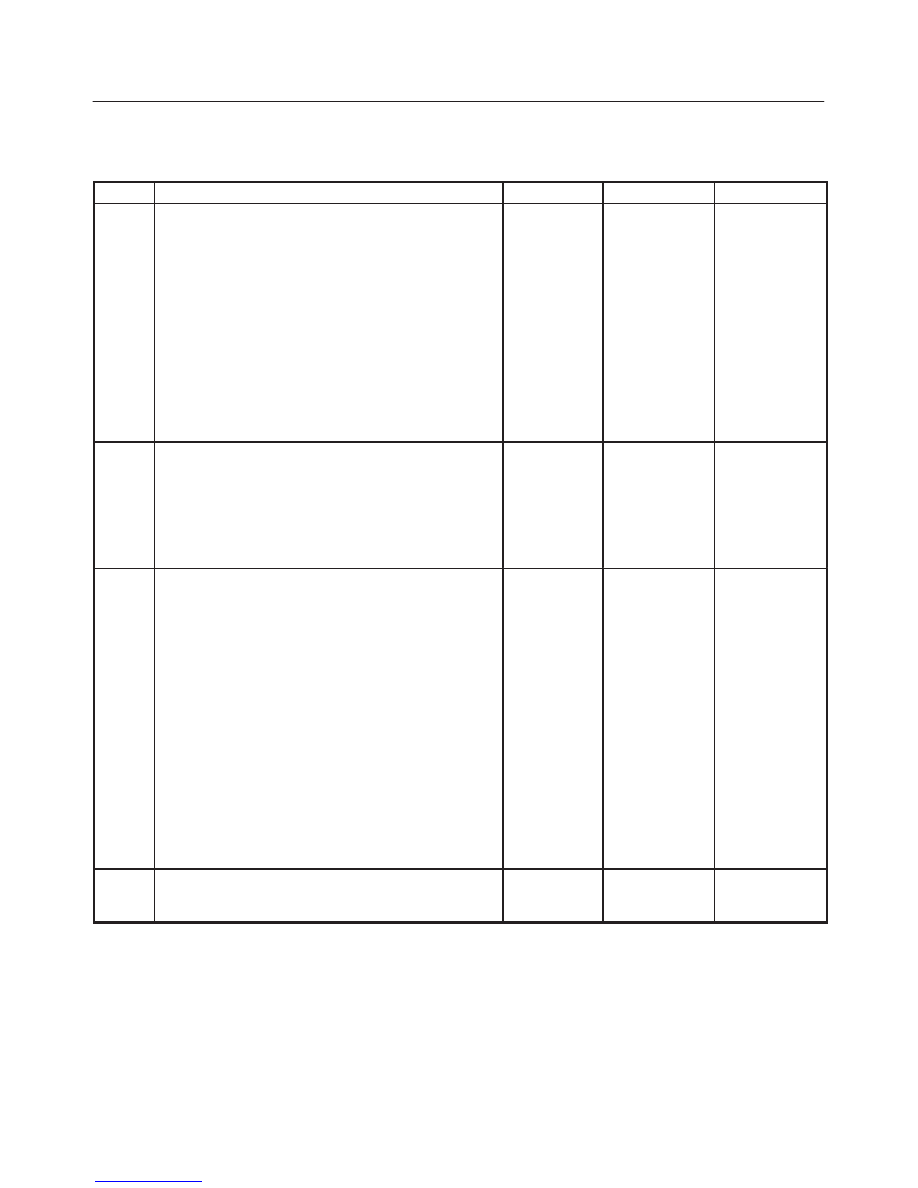

Injector Coil Test Procedure (Steps 1–6) And Injector Balance Test Procedure

(Steps 7–11)

(Cont'd)

Step

No

Yes

Value(s)

Action

5

1. Set the injector switch box to injector #1.

2. Press the ”Push to Start Test” button on the fuel

injector tester.

3. Observe the voltage reading on the DVM.

IMPORTANT: The voltage reading may rise during the

test.

4. Record the lowest voltage observed after the first

second of the test.

5. Set the injector switch box to the next injector and

repeat steps 2, 3, and 4.

Did any fuel injector have an erratic voltage reading

(large fluctuations in voltage that did not stabilize) or a

voltage reading above the specified value?

9.5 V

Go to

Step 4

Go to

Step 6

6

1. Identify the highest voltage reading recorded (other

than those above 9.5 V).

2. Subtract the voltage reading of each injector from

the highest voltage selected in step 1. Repeat until

you have a subtracted value for each injector.

For any injector, is the subtracted value in step 2

greater than the specified value?

0.6 V

Go to

Step 4

Go to

Step 7

7

CAUTION: In order to reduce the risk of fire and

personal injury, wrap a shop towel around the

fuel pressure connection. The towel will absorb

any fuel leakage that occurs during the

connection of the fuel pressure gauge. Place the

towel in an approved container when the

connection of the fuel pressure gauge is

complete.

1. Connect the J 34730–1 Fuel Pressure Gauge to the

fuel pressure test port.

2. Energize the fuel pump using the Tech 2.

3. Place the bleed hose of the fuel pressure gauge into

an approved gasoline container.

4. Bleed the air out of the fuel pressure gauge.

5. With the fuel pump running, observe the reading on

the fuel pressure gauge.

Is the fuel pressure within the specified values?

296 kPa– 376

kPa (43–55

psi)

Go to

Step 8

Go to

Fuel

System

Diagnosis

8

Turn the fuel pump OFF.

Does the fuel pressure remain constant?

—

Go to

Step 9

Go to

Fuel

System

Diagnosis

6E1–64

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

Injector Coil Test Procedure (Steps 1–6) And Injector Balance Test Procedure

(Steps 7–11)

(Cont'd)

Step

No

Yes

Value(s)

Action

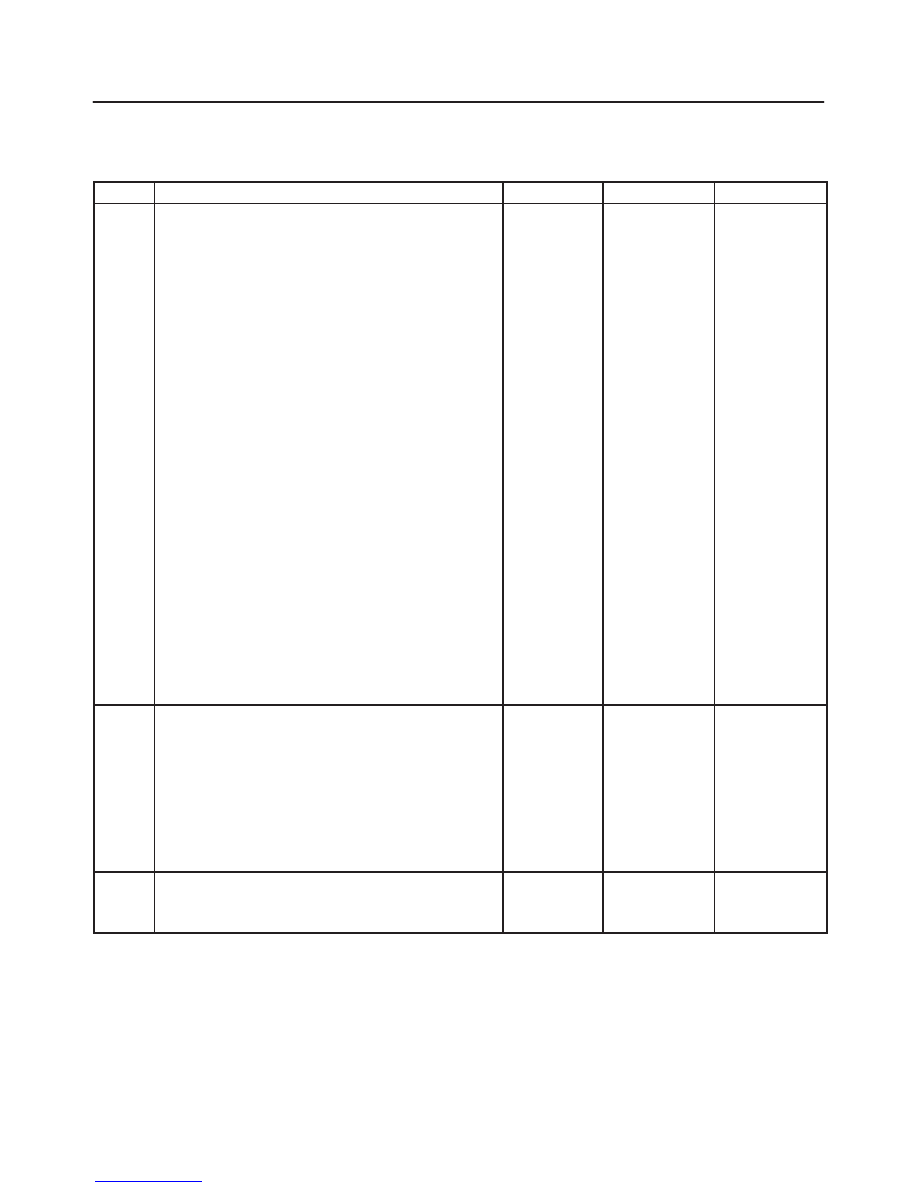

9

1. Connect the J 39021–5V Fuel Injector Tester and

J39021–90 Injector Switch Box to the fuel injector

harness connector.

2. Set the amperage supply selector switch on the fuel

injector tester to the ”Balance Test” 0.5–2.5 amp

position.

3. Using the Tech 2 turn the fuel pump ON then OFF in

order to pressurize the fuel system.

4. Record the fuel pressure indicated by the fuel

pressure gauge after the fuel pressure stabilizes.

This is the first pressure reading.

5. Energize the fuel injector by depressing the Push to

Start Test button on the fuel injector tester.

6. Record the fuel pressure indicated by the fuel

pressure gauge after the fuel pressure gauge

needle has stopped moving. This is the second

pressure reading.

7. Repeat steps 1 through 6 for each fuel injector.

8. Subtract the second pressure reading from the first

pressure reading for one fuel injector. The result is

the pressure drop value.

9. Obtain a pressure drop value for each fuel injector.

10.Add all of the individual pressure drop values. This

is the total pressure drop.

11. Divide the total pressure drop by the number of fuel

injectors. This is the average pressure drop.

Does any fuel injector have a pressure drop value that

is either higher than the average pressure drop or lower

than the average pressure drop by the specified value?

10 kPa (1.5

psi)

Go to

Step 10

Go to

OBD

System

Check

10

Re–test any fuel injector that does not meet the

specification. Refer to the procedure in step 11.

NOTE: Do not repeat any portion of this test before

running the engine in order to prevent the engine from

flooding.

Does any fuel injector still have a pressure drop value

that is either higher than the average pressure drop or

lower than the average pressure drop by the specified

value?

10 kPa (1.5

psi)

Go to

Step 11

Go to

Symptoms

11

Replace the faulty fuel injector(s). Refer to Fuel

Injector.

Is the action complete?

—

Verify repair

—

6E1–65

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

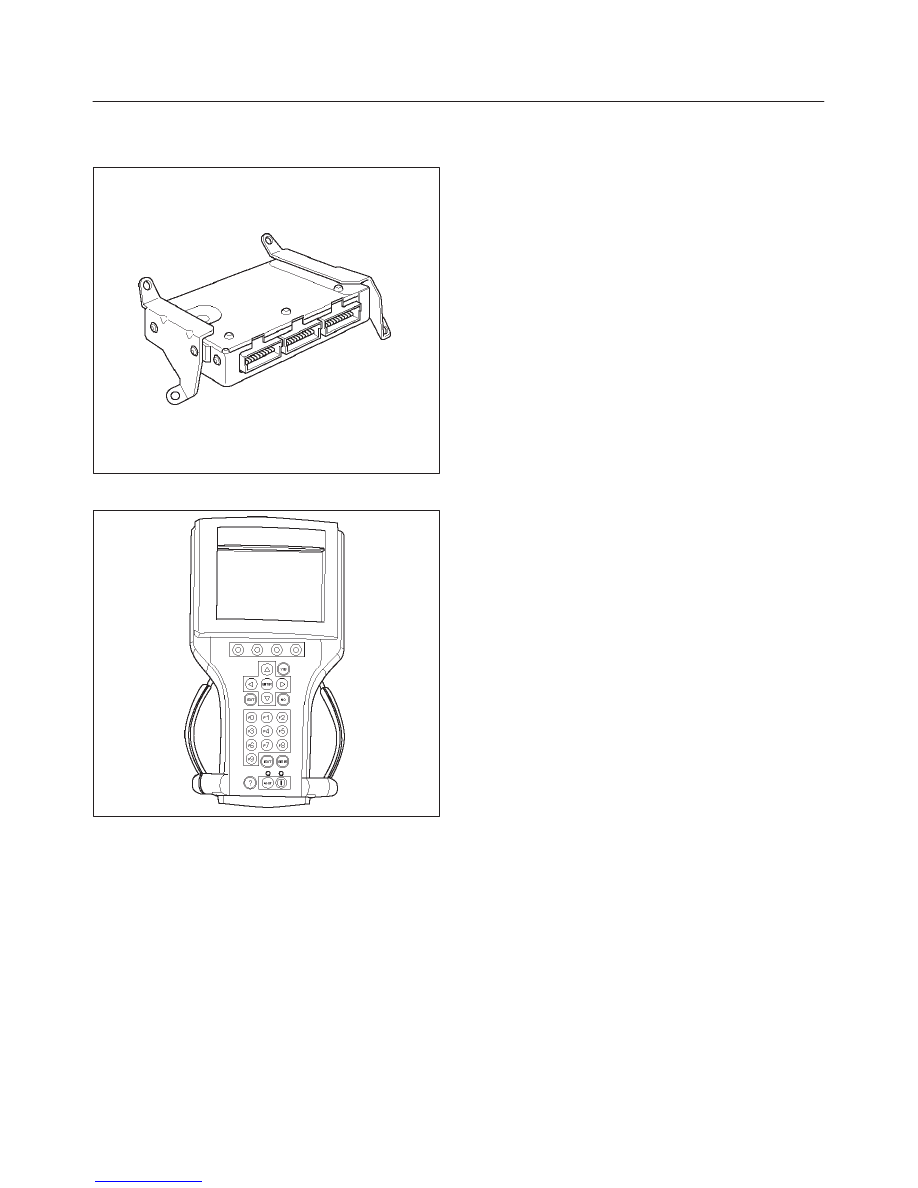

POWERTRAIN CONTROL MODULE

(PCM) DIAGNOSIS

014RX002

To read and clear diagnostic trouble codes, use a Tech 2.

901RX031

IMPORTANT:

Use of a Tech 2 is recommended to clear

diagnostic trouble codes from the PCM memory.

Diagnostic trouble codes can also be cleared by turning

the ignition OFF and disconnecting the battery power

from the PCM for 30 seconds. Turning off the ignition and

disconnecting the battery power from the PCM will cause

all diagnostic information in the PCM memory to be

cleared. Therefore, all the diagnostic tests will have to be

re–run.

Since the PCM can have a failure which may affect only

one circuit, following the diagnostic procedures in this

section will determine which circuit has a problem and

where it is.

If a diagnostic chart indicates that the PCM connections

or the PCM is the cause of a problem, and the PCM is

replaced, but this does not correct the problem, one of the

following may be the reason:

f

There is a problem with the PCM terminal

connections. The terminals may have to be removed

from the connector in order to check them properly.

f

EEPROM program is not correct for the application.

Incorrect components or reprogramming the PCM

with the wrong EEPROM program may cause a

malfunction and may or may not set a DTC.

f

The problem is intermittent. This means that the

problem is not present at the time the system is being

checked. In this case, make a careful physical

inspection of all components and wiring associated

with the affected system and refer to the Symptoms

portion of the manual.

f

There is a shorted solenoid, relay coil, or harness.

Solenoids and relays are turned ON and OFF by the

PCM using internal electronic switches called drivers.

A shorted solenoid, relay coil, or harness will not

damage the PCM but will cause the solenoid or relay

to be inoperative.

MULTIPLE PCM INFORMATION

SENSOR DTCs SET

Circuit Description

The powertrain control module (PCM) monitors various

sensors to determine the engine operating conditions.

The PCM controls fuel delivery, spark advance, and

emission control device operation based on the sensor

inputs.

The PCM provides a sensor ground to all of the sensors.

The PCM applies 5 volts through a pull–up resistor, and

determines the status of the following sensors by

monitoring the voltage present between the 5–volt supply

and the resistor:

f

The Fuel Tank Vapor Pressure Sensor

f

The throttle position (TP) sensor

f

The manifold absolute pressure (MAP) sensor

The PCM provides the following sensors with a 5–volt

reference and a sensor ground signal:

f

The Linear exhaust gas recirculation (EGR) valve

f

The A/C Pressure Sensor

The PCM monitors the separate feedback signals from

these sensors in order to determine their operating

status.

Diagnostic Aids

Be sure to inspect PCM and engine grounds for being se-

cure and clean.

A short to voltage in one of the sensor input circuits may

cause one or more of the following DTCs to be set:

f

P0108/P1106

f

P0113/P1111

f

P0118/P1115

f

P0123/P1121

f

P0463

If a sensor input circuit has been shorted to voltage, en-

sure that the sensor is not damaged. A damaged sensor

6E1–66

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

will continue to indicate a high or low voltage after the af-

fected circuit has been repaired. If the sensor has been

damaged, replace it.

An open in the sensor ground circuit between the PCM

and the splice will cause one or more of the following

DTCs to be set:

f

P0108/P1106

f

P0113/P1111

f

P0118/P1115

f

P0123/P01121

f

P0453/P0463

A short to ground in the 5–volt reference A circuit will

cause one or more of the following DTCs to be set:

f

P0107/P1107

f

P0122/P1122

f

P0112/P1112

f

P0117/P1114

f

P0454/P0462

f

P0405

f

P0532

Check for the following conditions:

f

Poor connection at PCM. Inspect the harness

connectors for backed–out terminals, improper

mating, broken locks, improperly formed or damaged

terminals, and a poor terminal–to–wire connection.

f

Damaged harness. Inspect the wiring harness for

damage. If the harness is not damaged, observe an

affected sensor’s displayed value on the Tech 2 with

the ignition ON and the engine OFF while you move

the connectors and the wiring harnesses related to

the following sensors:

f

IAT

f

ECT

f

TP

f

MAP

f

EGR

f

Fuel Tank Vapor Pressure Sensor

f

A/C Pressure Sensor

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст