Isuzu KB P190. Manual — part 928

Powertrain Interface Module – V6

Page 6E1–51

Additional Information

•

Refer to 6 Wiring Diagram and Connector Chart for the following information:

•

PIM connector illustration and terminal assignment, and

•

PIM wiring diagram.

•

For intermittent fault conditions, refer to

Intermittent Fault Conditions.

•

Since fault conditions in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to

8A Electrical - Body and Chassis for information on electrical fault diagnosis.

Conditions for Running the DTC

Conditions for running the DTC are:

•

The ignition is switched on.

•

The ignition voltage is 10.0 – 16.0 V.

Conditions for Setting the DTC

The DTC will set when the PIM detects a low voltage of <0.41 volts for one second.

The DTC will set when the PIM detects a high voltage of >4.59 volts for one second.

Action Taken When the DTC Sets

When the DTC sets, there is no warning lamp displayed on the instrument cluster.

Conditions for Clearing the DTC

The DTC is cleared at the next ignition cycle.

Refer to 4.1

Diagnostic General Descriptions for information on the conditions for clearing DTCs.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

2

This step tests the vertical acceleration sensor using Tech 2.

6

This step tests the ground circuit.

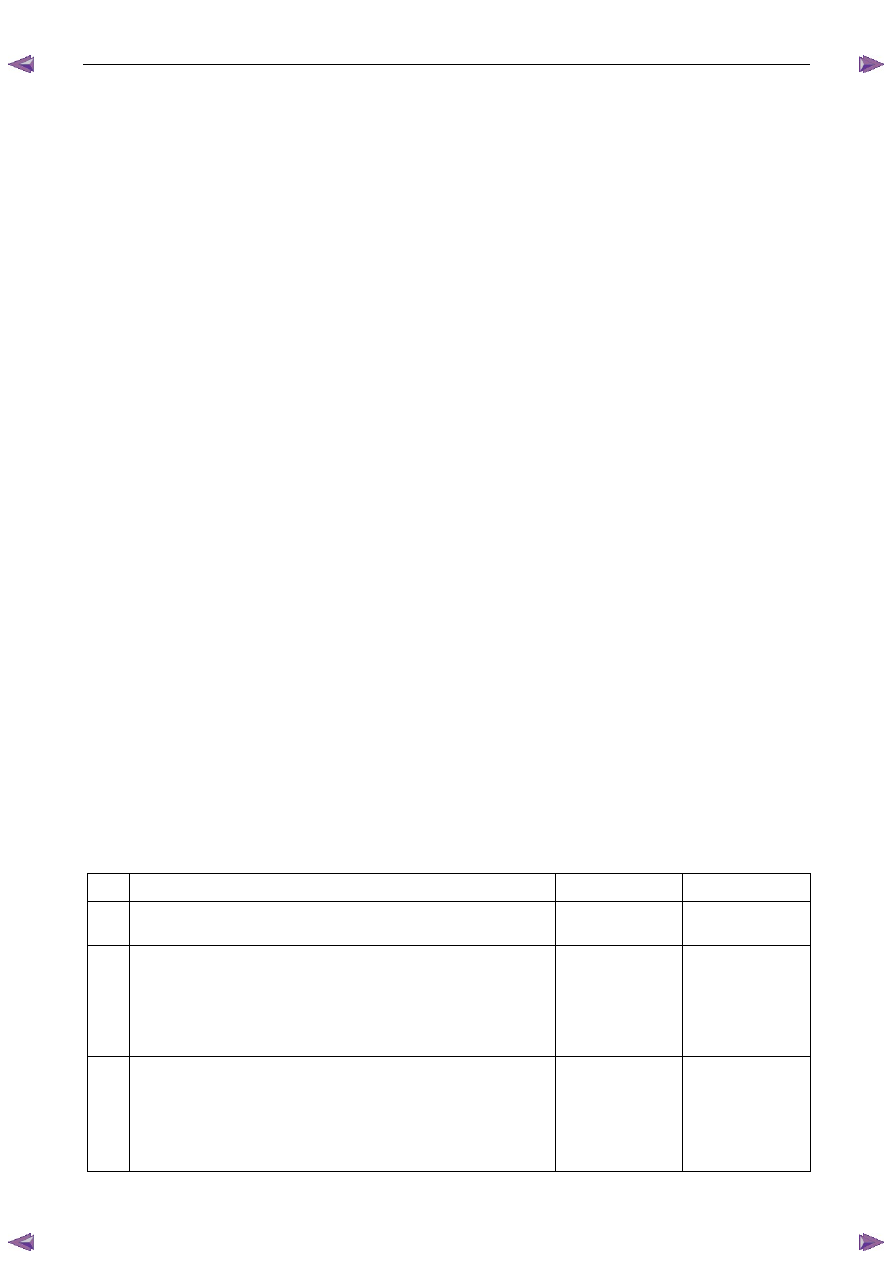

Vertical Acceleration Sensor Diagnostic Table

Step Action

Yes

No

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to additional

information

2

1

Switch off the ignition for 30 seconds.

2

Start the engine.

3

Using Tech 2, select the DTC display function.

Does DTC P0318 fail this ignition cycle?

Go to Step 3

Refer to

Additional

Information in this

DTC

3

1

Switch on the ignition with the engine not running.

2

Using a digital multimeter, measure the voltage between the

VAS reference circuit and a good ground. Refer to 6

Wiring

Diagram and Connector Chart.

Does the multimeter display approximately 5.0 V?

Go to Step 4

Go to Step 7

Powertrain Interface Module – V6

Page 6E1–52

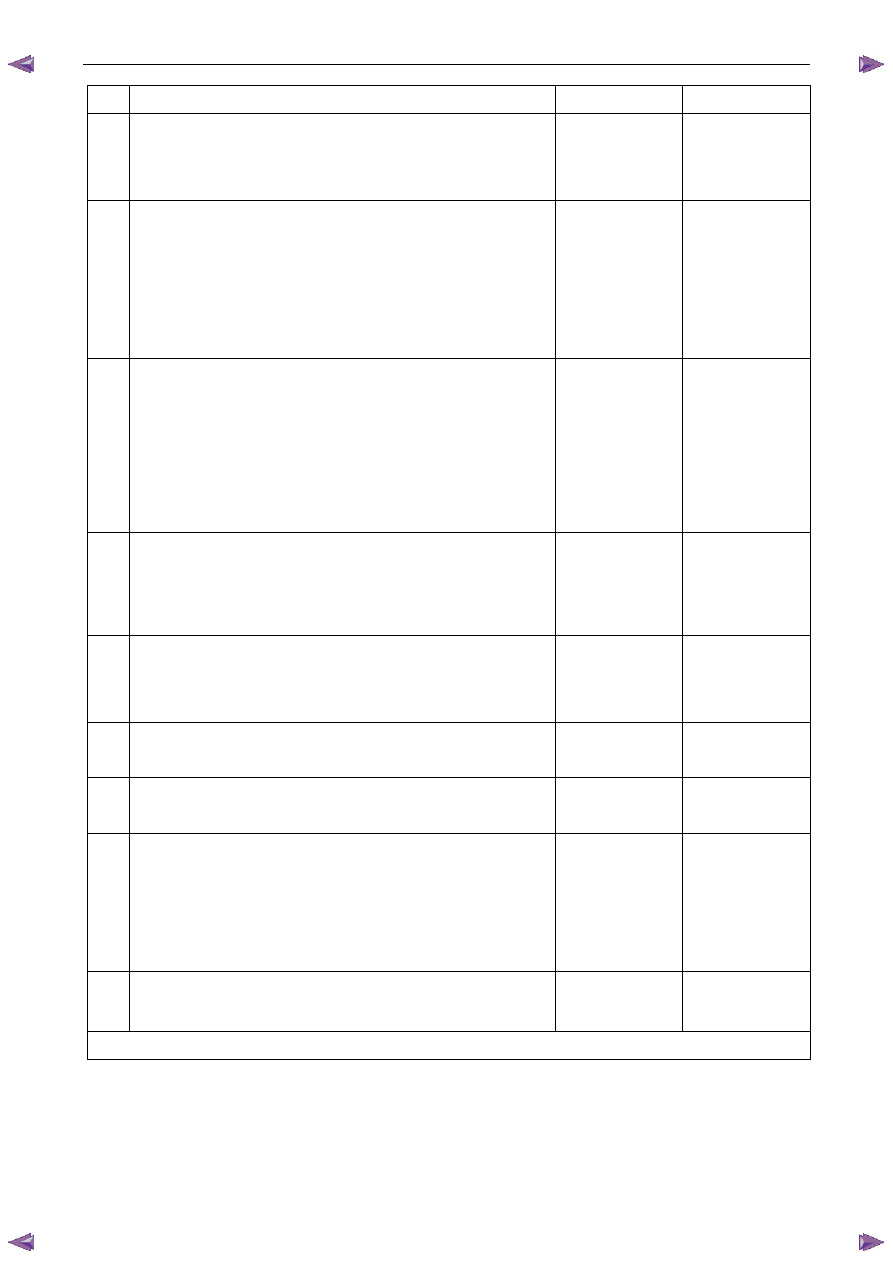

Step Action

Yes

No

4

Using a digital multimeter, measure the resistance between the VAS

earth circuit and a good ground. Refer to 6 Wiring Diagram and

Connector Chart.

Does the multimeter display approximately 5.0

Ω?

Go to Step 5

Go to Step 8

5

1

Remove the VAS from its mounting bracket on the vehicle

chassis.

2

Switch on the ignition with the engine not running.

3

While rapidly moving the sensor in a vertical up and down

motion, Use a digital multimeter to measure the voltage between

the VAS output signal circuit and a good ground.

Does the multimeter display 1.8 – 3.3 V?

Go to Step 6

Go to Step 9

6

Perform the following VAS inspection:

•

Inspect the sensor wiring harness for conditions that may induce

electromagnetic interference. Refer to Intermittent Fault

Conditions in this Section.

•

Inspect the sensor for incorrect sensor installation or incorrect

attaching nut torque value. Refer to 11.3

Vertical

Acceleration Sensor.

Was any fault found and rectified?

Go to Step 11

Go to Step 7

7

Test the VAS signal circuit and 5V reference circuit for a high

resistance, open circuit, short to ground, short to voltage or shorted

together fault condition. Refer to 8A Electrical - Body and Chassis for

information on electrical fault diagnosis.

Was any fault found and rectified?

Go to Step 11

Go to Step 9

8

Repair the open or high resistance fault condition in the VAS ground

circuit. Refer to 8A Electrical - Body and Chassis for information on

electrical repair procedures.

Was the repair completed?

Go to Step 11

—

9

Replace the VAS. Refer to 11.3

Vertical Acceleration Sensor.

Was the repair completed?

Go to Step 11

—

10 Replace the PIM. Refer to 11.2

Powertrain Interface Module.

Was the repair completed?

Go to Step 11

—

11 1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running the DTC.

Does the VAS circuit DTC fail this ignition cycle?

Go to Step 2

Go to Step 13

12 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, check the system for correct operation.

Powertrain Interface Module – V6

Page 6E1–53

9.13 DTC P0500, P0502 or P0503 – Vehicle

Speed Sensor Signal Malfunction

DTC Descriptors

This diagnostic procedure supports the following DTC’s:

•

DTC P0500 – Vehicle speed sensor open circuit, short circuit to battery voltage, short circuit to ground, or

undefined error

•

DTC P0502 – Vehicle speed sensor sensor low voltage

•

DTC P0503 – Vehicle speed sensor intermittant fault

Circuit Description

The PIM applies the ground to the vehicle speed sensor (VSS) low reference circuit.

The VSS in conjunction with the 40X reluctor wheel generates an AC signal voltage. The amplitude and frequency of the

signal generated is proportional to the vehicle speed. The PIM uses this signal from the VSS signal circuit to determine

the vehicle speed.

A VSS DTC sets if the PIM detects a fault condition in the VSS signal circuit.

Conditions for Running the DTC

DTC P0500

Runs continuously once the following condition is met:

•

The ignition is on and the vehicle is stationary.

DTC P0502

Runs continuously once the following condition is met:

•

The first time the ignition is on and the vehicle starts to move from the stationary position.

DTC P0503

Runs continuously once the following condition is met:

•

The ignition is on and the vehicle is mobile.

Conditions for Setting the DTC

DTC P0500

When the PIM reads back the 15 consecutive readings within 0.5 seconds.

DTC P0502

If the reading is >9.1 Km/Hr the DTC will be set.

DTC P0503

The DTC will set when the sensor detects an occurance of 15 times within 0.5 seconds.

Conditions for Clearing DTC

The DTC’s will clear on the next ignition cycle.

Additional Information

•

Refer to 7B1_Manual Transmission.

Powertrain Interface Module – V6

Page 6E1–54

•

For an intermittent fault condition, refer to

Intermittent Fault Conditions in this Section.

•

The VSS in conjunction with the 40X reluctor wheel generates an AC signal voltage. The amplitude and frequency

of the signal generated is proportional to the vehicle speed. The PIM uses this signal from the VSS signal circuit to

determine the vehicle speed.

•

Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 6 Wiring Diagram and Connector Chart in this Section, for the system wiring diagram

and connector charts.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3

The PIM supplies 2.5 V to signal circuit of the VSS circuit to reduce the Electro Magnetic interference (EMI). If the

voltage is not within range, this indicates there is an PIM fault or a PIM circuit fault condition.

4

The PIM supplies 2.5 V to low reference circuit of the VSS circuit to reduce the Electro Magnetic interference (EMI).

If the voltage is not within range, this indicates there is a PIM fault or a PIM circuit fault condition.

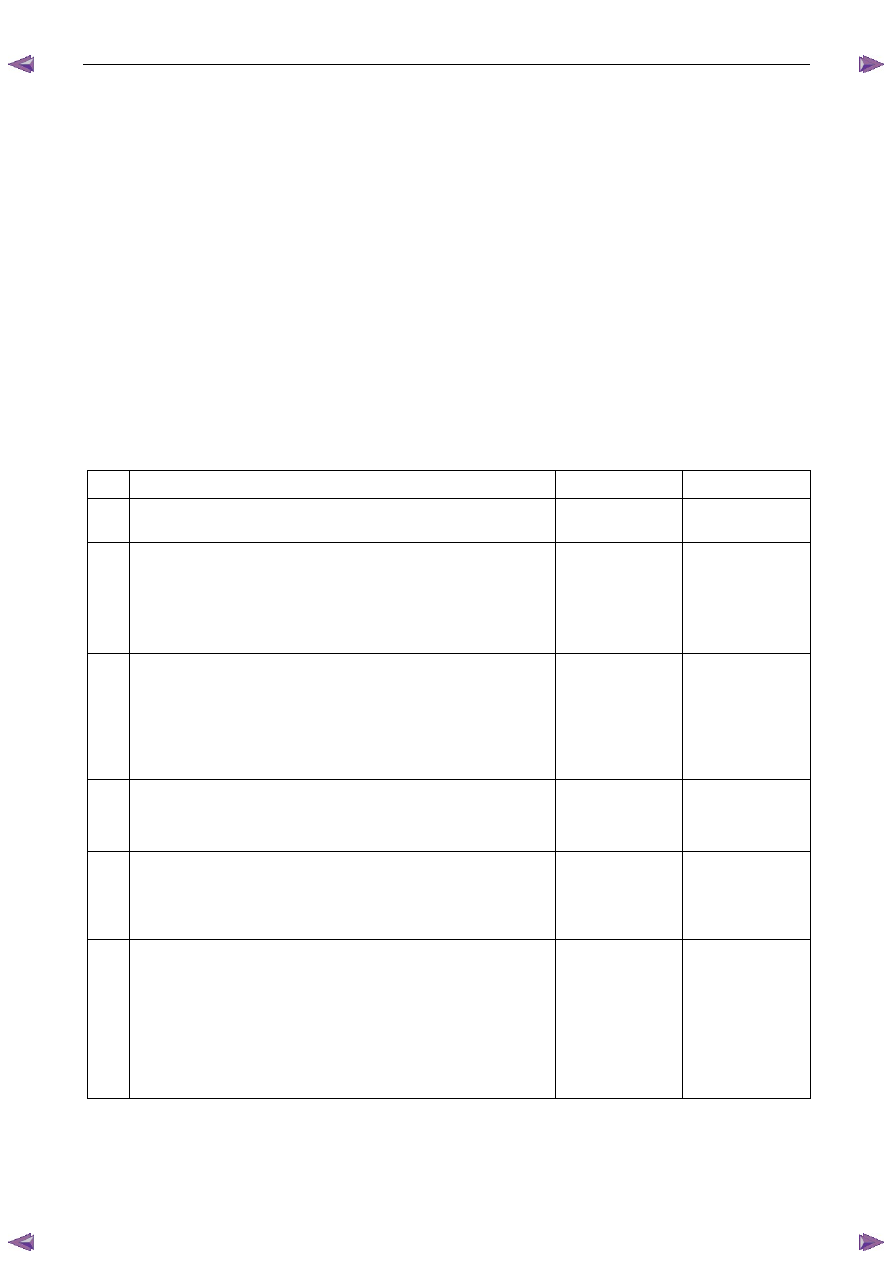

DTC P0335 to P0338 Diagnostic Table

Step Action

Yes

No

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to additional

information

2

1

Switch off the ignition for 30 seconds.

2

Start the engine.

3

Using Tech 2, select the DTC display function.

Does DTC P0500, P0502, P0503 fail this ignition cycle?

Go to Step 3

Refer to

Additional

Information in this

DTC

3

1

Disconnect the VSS connector.

2

Switch on the ignition with the engine not running.

3

Using a digital multimeter, measure the voltage between the

signal circuit of the sensor connector and a good ground.

Does the multimeter display 2 – 3 V?

Go to Step 4

Go to Step 7

4

Using a digital multimeter, measure the voltage between the VSS low

reference circuit and a good ground.

Does the multimeter display 2 – 3 V?

Go to Step 5

Go to Step 7

5

Using a digital multimeter, measure the resistance between the

ground shield circuit of the VSS at the PIM connector and the PIM

housing.

Does the multimeter display approximately 5

Ω?

Go to Step 6

Go to Step 7

6

Perform the following VSS inspection:

•

Inspect the sensor wiring harness for conditions that may induce

electromagnetic interference. Refer to Intermittent Fault

Conditions in this Section.

•

Inspect the sensor for incorrect sensor installation or incorrect

attaching bolt torque value. Refer to 7B1_Manual Transmission.

Was any fault found and rectified?

Go to Step 11

Go to Step 9

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст