Isuzu KB P190. Manual — part 797

Engine Cooling – V6 Engine

Page 6B1–53

N O T E

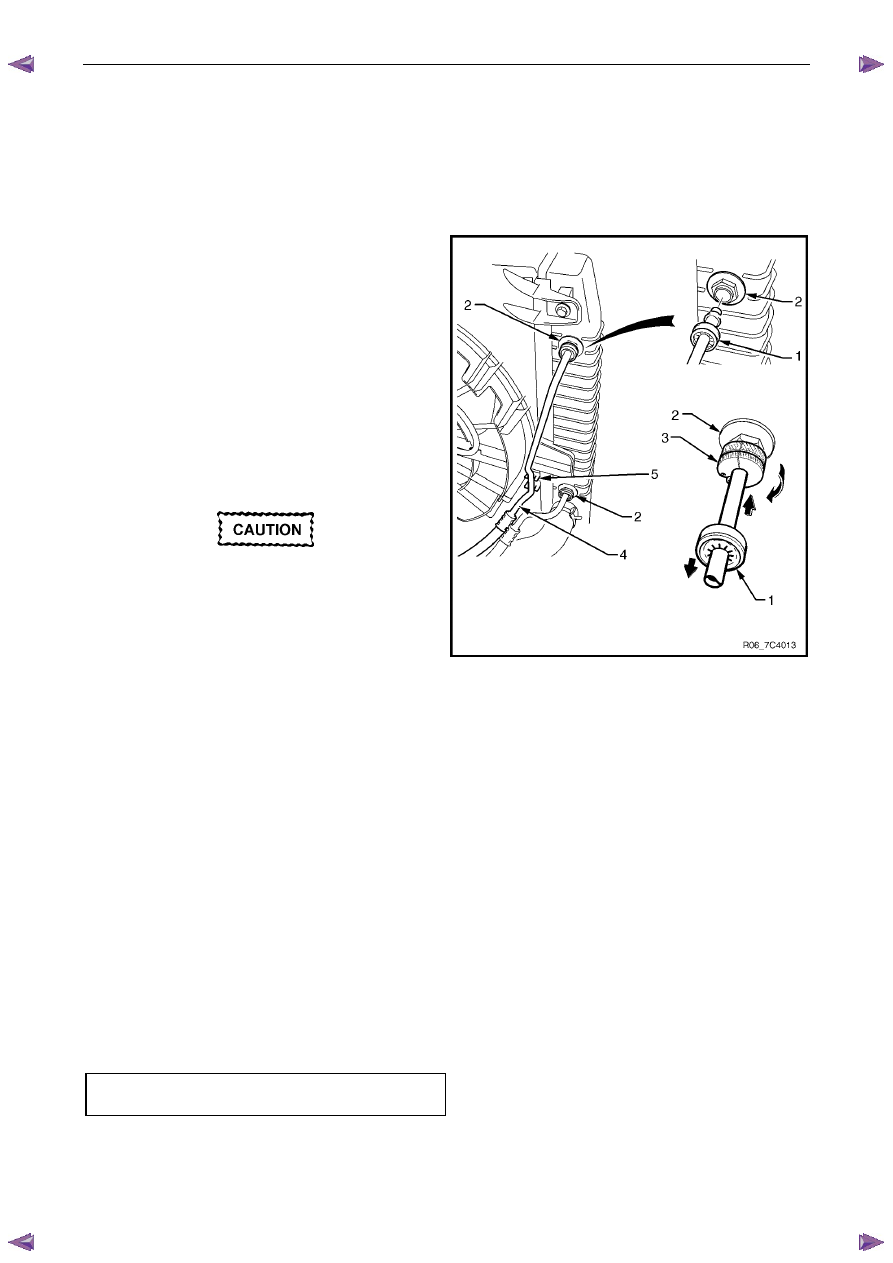

Should the spring clip or the O-ring seal in the

quick connect fitting be damaged during the line

removal process, then the complete fitting must

be replaced.

Reinstall

1

Remove the plugs installed in the transmission cooler

line and hose openings and wipe all exposed parts

with a clean shop rag.

•

Smear clean automatic transmission fluid on

each cooler line end, then push into the radiator

quick connect fittings. As a security check gently

pull on the connector to ensure correct

engagement.

•

As a security check, push and clip each

verification disc into place over the quick-

connect fittings. If difficulty is experienced,

repeat the installation process until the

verification disc can be clipped into place over

the radiator quick-connect fitting.

If the verifier disc does not clip into place,

the quick-connect fitting is not engaged,

rectify this before proceeding.

•

Snap the outlet cooler line (4) in the clip (5) of

the radiator fan shroud

•

At the transmission end, again clean the line

ends and proceed as detailed in step 2. As a

further security check ensure that each

verification disc can be pushed into place over

the quick connect fitting. If difficulty is

experienced, then the line has not been

completely installed. Remove and repeat the

installation process again until the verification

disc can be clipped into place over the

transmission quick connect fitting

•

Ensure that all line clamps are fitted correctly

and that the lines and hoses are correctly routed

and free of obstructions

•

Tighten the screw attaching the cooler lines

bracket to the correct torque specifications

•

If required, top up the transmission fluid level

(cold)

•

Start the engine and check for any fluid leak at

the fittings. If a leak is found, stop the engine

and rectify the leak

Figure 6B1 – 61

Transmission cooler lines bracket

attaching screw torque specification . . . . ..23.0 Nm

Engine Cooling – V6 Engine

Page 6B1–54

3.15 Radiator

Remove

Refer to 3.1 Service Notes in this Section, for

important safety items.

1

Allow engine to cool to ambient temperature (less than 50

° C), then remove coolant filler cap.

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 00

Warnings, Cautions and Notes, before

removing the ground lead.

2

Disconnect the battery ground lead. Refer to 8A – Electrical Body & Chassis.

3

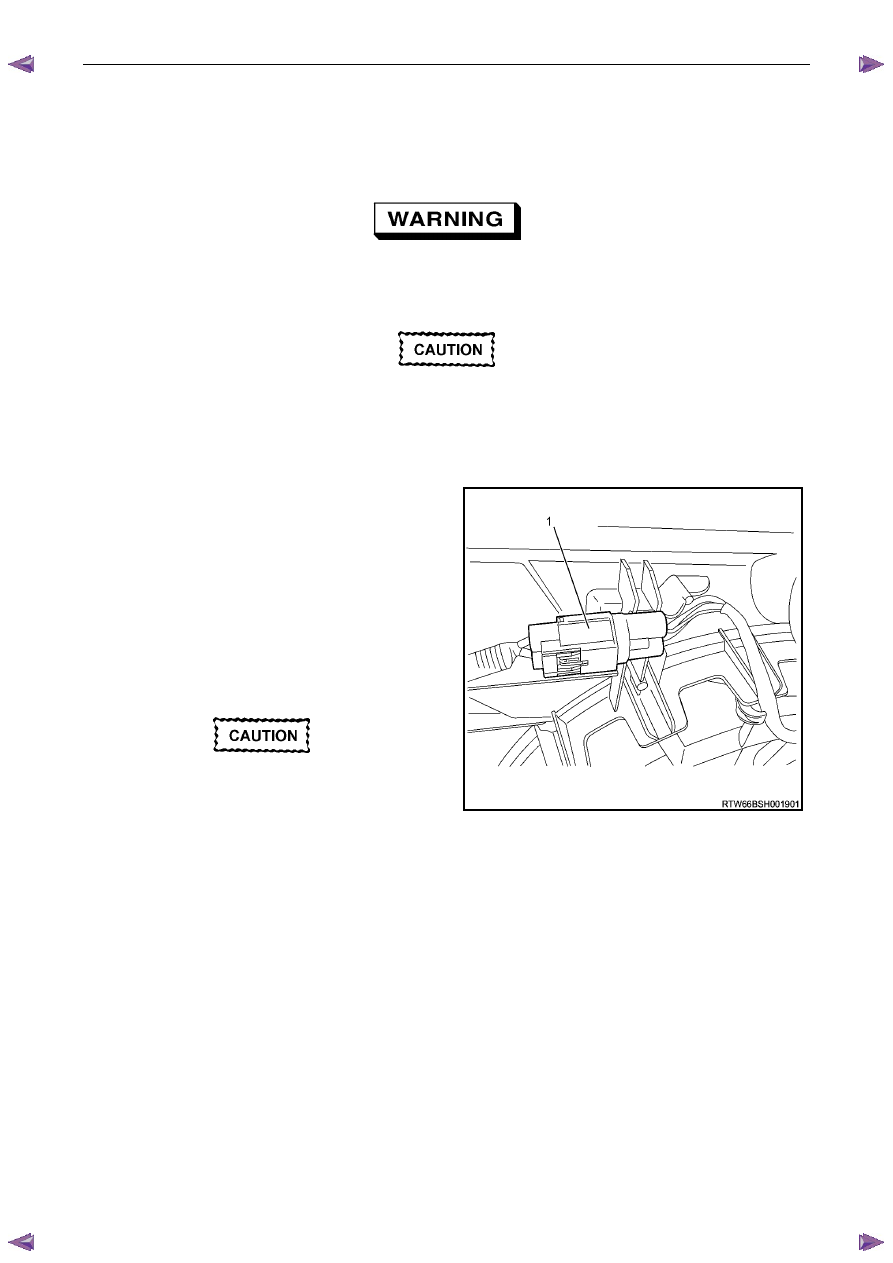

Depress the tang on the main wiring harness to the

cooling fan motor wiring harness connector (1) and

separate the connector.

4

Remove the radiator cooling fan and shroud

assembly. Refer to 3.13 Cooling Fan and Shroud

Assembly in this Section.

5

Drain the coolant from the system. Refer to 3.3

Draining and Filling Cooling System in this

Section.

Refer to ‘

‘

‘

‘ Environmental Issues ’

’

’

’ in 3.1

Service Notes, before draining the

coolant.

Figure 6B1 – 62

Engine Cooling – V6 Engine

Page 6B1–55

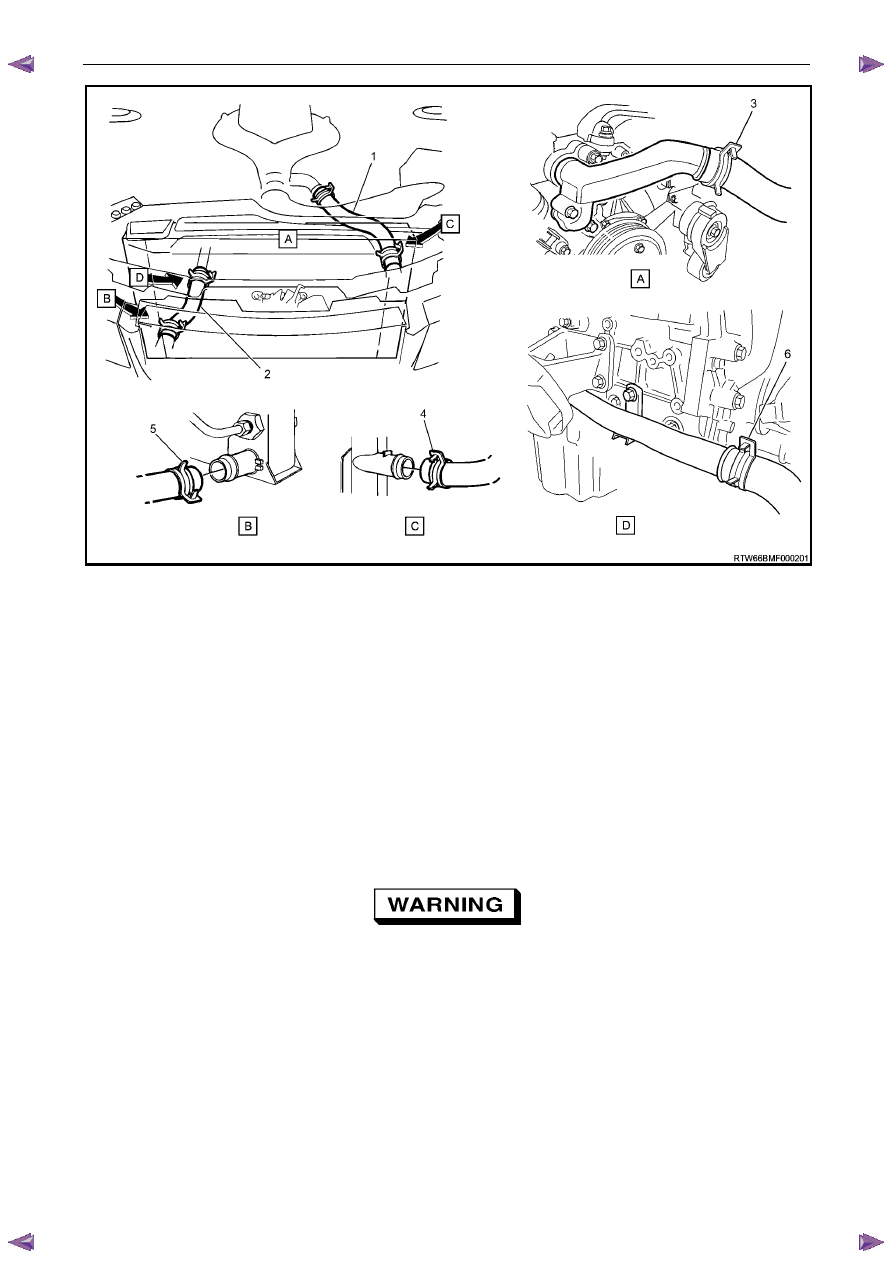

Figure 6B1 – 63

Legend

1

Radiator Hose – Upper

2

Radiator Hose – Lower

3

Hose Clamp – Upper Hose to Engine Outlet Housing

4

Hose Clamp – Upper Hose to Radiator Inlet

5

Hose Clamp – Lower Hose to Radiator Outlet

6

Hose Clamp – Lower Hose to Engine Coolant Inlet Pipe

6

Remove radiator upper hose (1) from radiator connection.

7

Remove radiator lower hose (2) from radiator connection.

8

Remove the two rubber insert mounting brackets supporting the top of the radiator.

9

Remove the two lower attaching bolts (either side) and the rubber mounts.

10

Remove the radiator from the vehicle.

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

Engine Cooling – V6 Engine

Page 6B1–56

Reinstall

Installation of the radiator is the reverse of removal procedures, noting the following points:

1

Before installing radiator, inspect core to ensure that there is no foreign matter in core fins. Clean out between core

fins with compressed air, blowing from rear to front.

2

If the vehicle is fitted with an automatic transmission, remove plugs from the removed cooling pipe ends and the

two quick connect fittings.

3

After wiping cooler line ends and smearing clean automatic transmission fluid over each flared line end, push into

the quick connect fitting to engage. As a security check, tug on each line to ensure correct engagement.

4

Check the transmission fluid level. Refer to the following references as required:

•

7C4 Automatic Transmission

•

4L60E On-vehicle Servicing

5

Install the following hoses:

a.

Lower radiator hose, securing with the hose clamp.

b.

Upper radiator hose, securing with the hose clamp.

6

Install the radiator cooling fan and shroud assembly. Refer to 3.13Cooling Fan and Shroud Assembly in this

Section. Ensure that electrical connectors and the transmission cooler lines are seated correctly in the integral

retainer clips before install upper radiator shroud.

7

Refill cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

8

Check for coolant leaks. Refer to 3.7 Pressure Testing in this Section.

9

Reconnect battery ground lead. Refer to 8A Electrical Body & Chassis.

10

Check cooling fan operation. Refer to 6C1-2 Engine Management Diagnostics. Also check for correct rotational

direction of cooling fan.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст