Isuzu KB P190. Manual — part 221

ENGINE MECHANICAL 6A – 79

CRANKSHAFT AND BEARING

Inspect the surface of the crankshaft journals and crankpins for

excessive wear and damage.

Inspect the oil seal fitting surfaces for excessive wear and

damage.

Inspect the oil ports for obstructions.

NOTE:

To increase crankshaft strength, tufftriding (Nitrizing

Treatment) has been applied. Because of this, it is not

possible to regrind the crankshaft surfaces.

Therefore, under size bearing are not available.

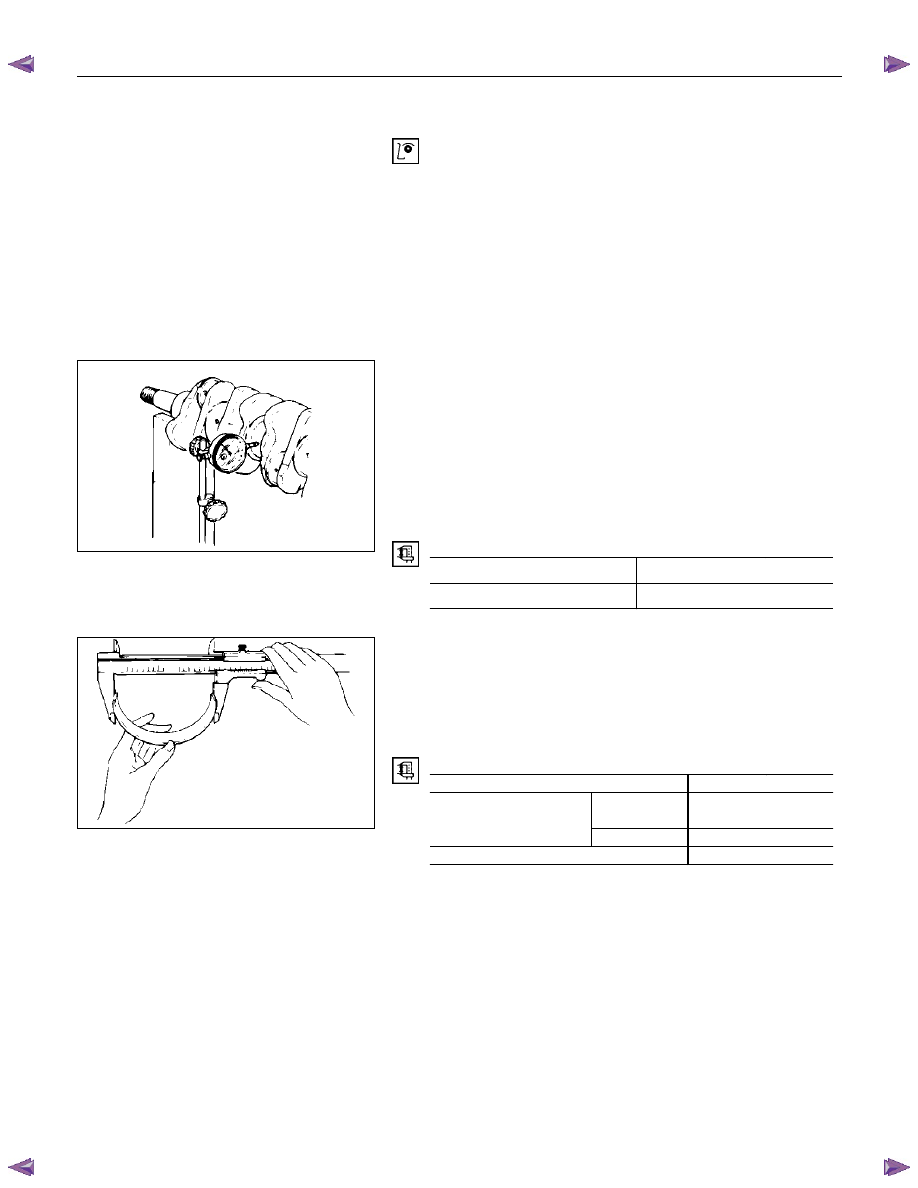

Crankshaft Run-Out

1. Set a dial indicator to the center of the crankshaft journal.

2. Gently turn the crankshaft in the normal direction of

rotation.

Read the dial indicator as you turn the crankshaft.

If the measured value exceeds the specified limit, the

crankshaft must be replaced.

Crankshaft Run-Out

mm (in)

Standard Limit

0.05 (0.002) or less

0.08 (0.003)

Bearing Spread

Use a vernier caliper to measure the bearing spread.

If the measured value is less than the specified limit, the

bearing must be replaced.

Bearing Spread

mm

(in)

Limit

4JA1T (L),

4JA1TC

64.5 (2.54)

Creankshaft Bearing

4JH1TC 74.5

(2.93)

Connecting Rod Bearing

56.5 (2.22)

015LX061

015RY00007

6A – 80 ENGINE MECHANICAL

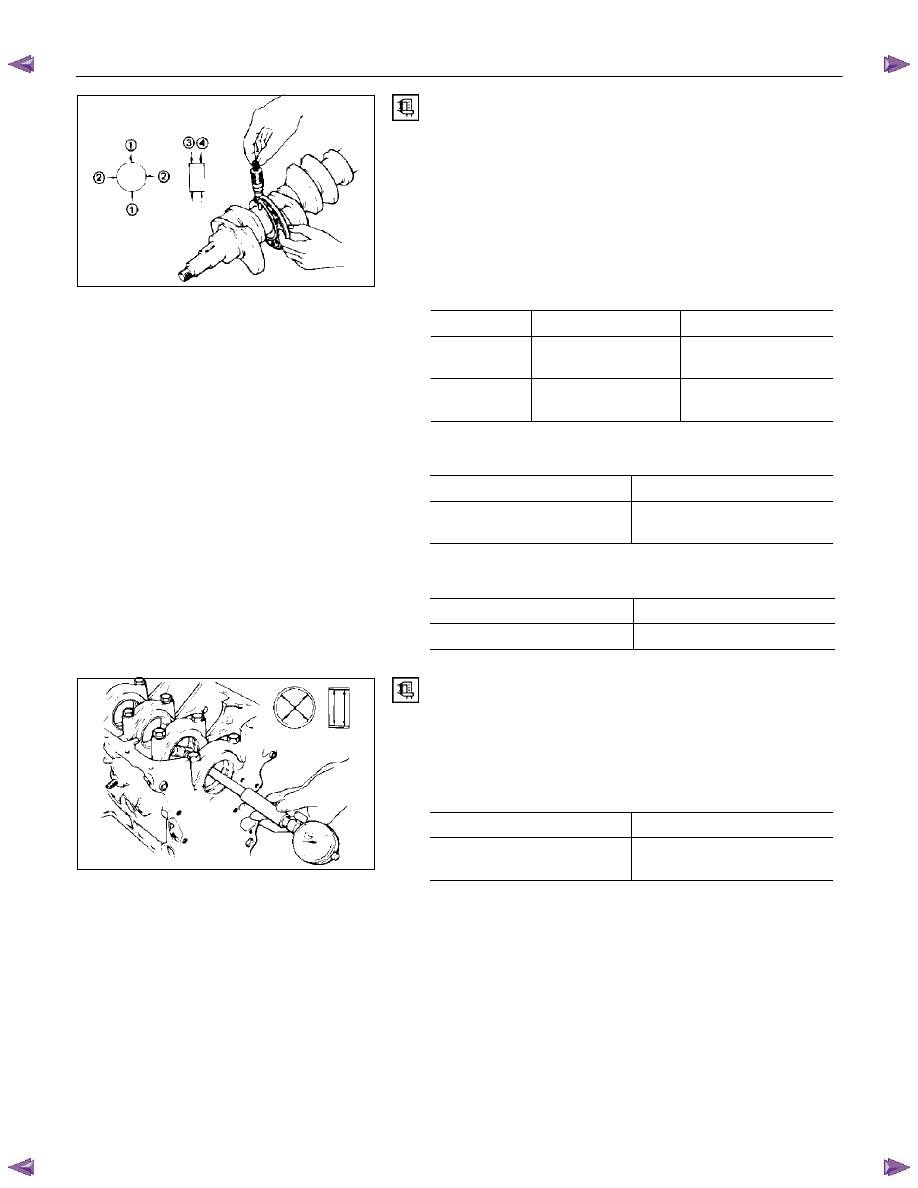

Crankshaft Journal and Crankpin Diameter

1. Use a micrometer to measure the crankshaft journal

diameter across points 1 - 1 and 2 - 2.

2. Use the micrometer to measure the crankshaft journal

diameter at the two points (3 and 4).

3. Repeat Steps 1 and 2 to measure the crankpin diameter.

If the measured values are less than the specified limit, the

crankshaft must be replaced.

Crankshaft Journal and Diameter

mm (in)

Standard

Limit

4JA1T (L),

4JA1TC

59.921-59.928

(2.3591-2.3594)

59.91 (2.3586)

4JH1TC

69.917-69.932

(2.7526-2.7532)

69.91(2.7524)

Crankpin Diameter

mm

(in)

Standard

Limit

52.915 - 52.930

(2.0833 - 2.0839)

52.90 (2.083)

Crankshaft Journal and Crankpin Uneven Wear

mm

(in)

Standard

Limit

0.05 (0.002) or less

0.08 (0.003)

Crankshaft Journal and Crankpin Diameter

If the clearance between the measured bearing inside diameter

and the crankshaft journal diameter exceeds the specified limit,

the bearing and/or the crankshaft must be replaced.

Crankshaft Journal and Bearing Clearance

mm (in)

Standard

Limit

0.032 - 0.077

(0.0013 - 0.0030)

0.110 (0.0043)

015RY00008

015RY00009

ENGINE MECHANICAL 6A – 81

Connecting Rod Bearing Inside Diameter

1. Install the bearing to the connecting rod big end.

2. Tighten the bearing cap to the two step of anglar tightening

method.

Connecting Rod Bearing Cap Bolt Torque

N·m (kg·m/Ib ft)

4JA1T (L),

4JA1TC

78-88 (8.0/57 – 9.0/65)

1st step ; 29.0–29.2 (3.00/22.0–3.01/22.2)

4JH1TC

2nd step ; 45

°

-60

°

3. Use an inside dial indicator to measure the connecting rod

bearing inside diameter.

Crankpin and Bearing Clearance

If the clearance between the measured bearing inside diameter

and the crankpin exceeds the specified limit, the bearing

and/or the crankshaft must be replaced.

Crankpin and Bearing Clearance

mm (in)

Standard

Limit

4JA1T (L),

4JA1TC

0.029-0.066

(0.0011-0.0026)

0.100(0.0039)

4JH1TC

0.029-0.083

(0.0011-0.033)

0.100 (0.0039)

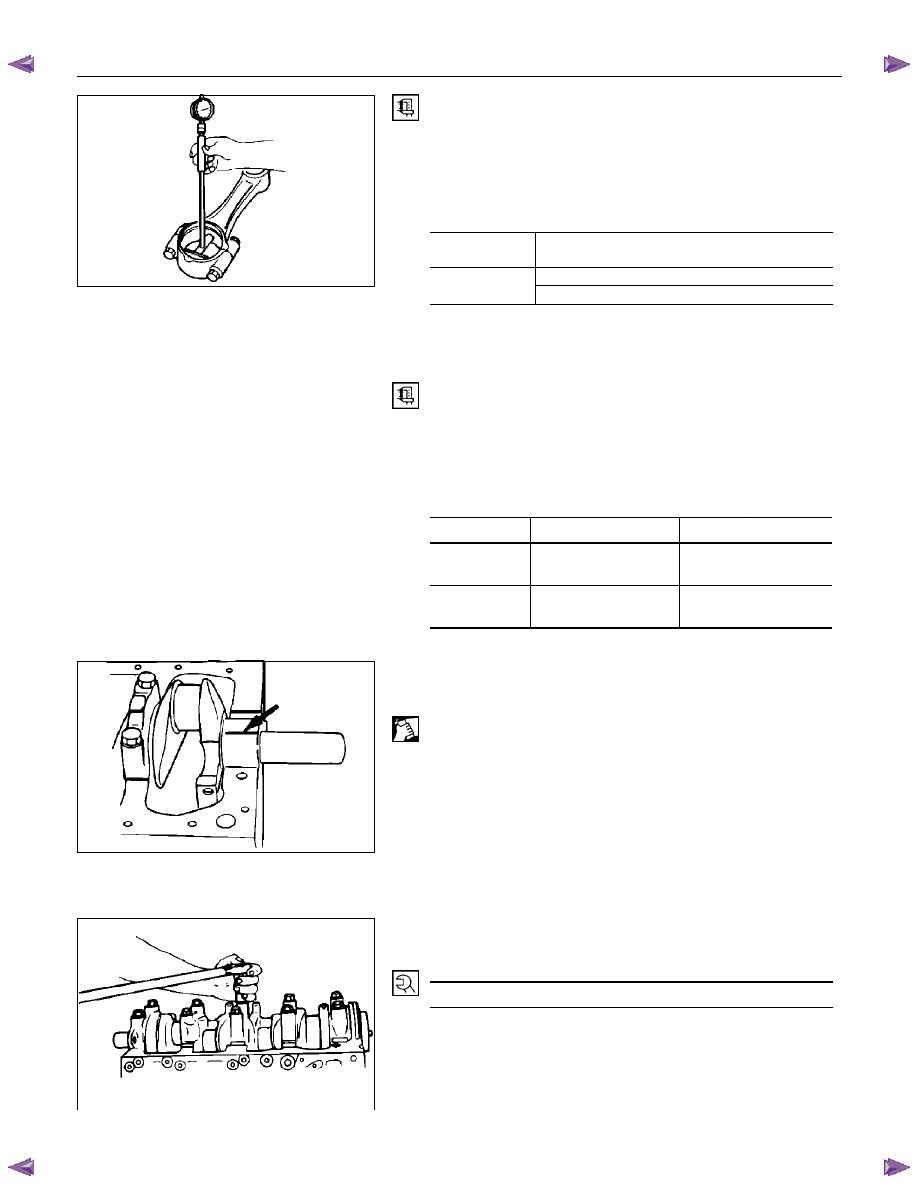

Clearance Measurements (With Plastigage)

Crankshaft Journal and Bearing Clearance

1. Clean the cylinder body, the journal bearing fitting surface,

the bearing caps, and the bearings.

2. Install the bearings to the cylinder body.

3. Carefully place the crankshaft on the bearings.

4. Rotate the crankshaft approximately 30

°

to seat the

bearing.

5. Place the Plastigage (arrow) over the crankshaft journal

across the full width of the bearing.

6. Install the bearing caps with the bearing.

7. Tighten the bearing caps to the specified torque.

Crankshaft Bearing Cap Bolt Torque

mm (in)

167 (17/123)

Do not allow the crankshaft to turn during bearing cap

installation and tightening.

8. Remove the bearing cap.

015RY00012

015RY00013

015RY00011

6A – 82 ENGINE MECHANICAL

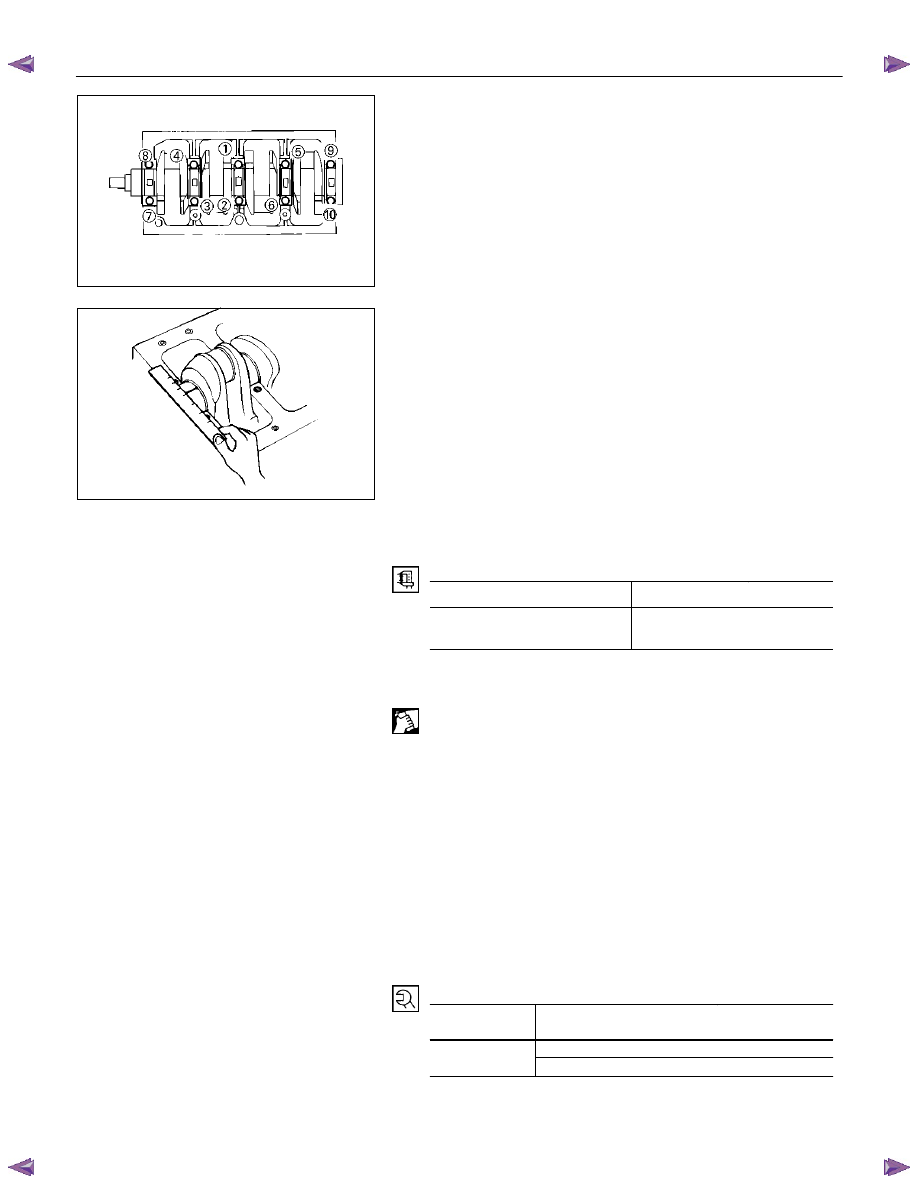

9. Compare the width of the Plastigage attached to either the

crankshaft or the bearing against the scale printed on the

Plastigage container.

If the measured value exceeds the limit, perform the

following additional steps.

1. Use a micrometer to measure the crankshaft outside

diameter.

2. Use an inside dial indicator to measure the bearing

inside diameter.

If the crankshaft journal and bearing clearance

exceeds the limit, the crankshaft and/or the bearing

must be replaced.

Crankshaft Journal and Bearing Clearance

mm (in)

Standard

Limit

0.032 - 0.077

(0.0013 - 0.0030)

0.110 (0.0043)

Crankpin and Bearing Clearance

1. Clean the crankshaft, the connecting rod, the bearing cap,

and the bearings.

2. Install the bearing to the connecting rod and the bearing

cap.

Do not allow the crankshaft to move when installing the

bearing cap.

3. Prevent the connecting rod from moving.

4. Attach the Plastigage to the crankpin.

Apply engine oil to the Plastigage to keep it from falling.

5. Install the bearing cap and tighten it to the two step of

anglar tihtening method.

Do not allow the connecting rod to move when installing

and tightening the bearing cap.

Connecting Rod Bearing Cap Bolt Torque

N·m (kg·m/Ib ft)

4JA1T (L),

4JA1TC

78-88 (8.0/57 – 9.0/65)

1st step ; 29.0–29.2 (3.00/22.0–3.01/22.2)

4JH1TC

2nd step ; 45

°

-60

°

015LX129

015LX060

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст