Isuzu KB P190. Manual — part 222

ENGINE MECHANICAL 6A – 83

6. Remove the bearing cap.

7. Compare the width of the Plastigage attached to either the

crankshaft or the bearing against the scale printed on the

Plastigage container.

If the measured value exceeds the specified limit, perform

the following additional steps.

1. Use a micrometer to measure the crankpin outside

diameter.

2. Use an inside dial indicator to measure the bearing

inside diameter.

If the crank pin and bearing clearance exceeds the

specified limit, the crankshaft and/or the bearing must

be replaced.

Crankpin and Bearing Clearance

mm (in)

Standard

Limit

4JA1T (L),

4JA1TC

0.029-0.066

(0.0011-0.0026)

0.100 (0.0039)

4JH1TC

0.029-0.083

(0.0011-0.0033)

0.100 (0.0039)

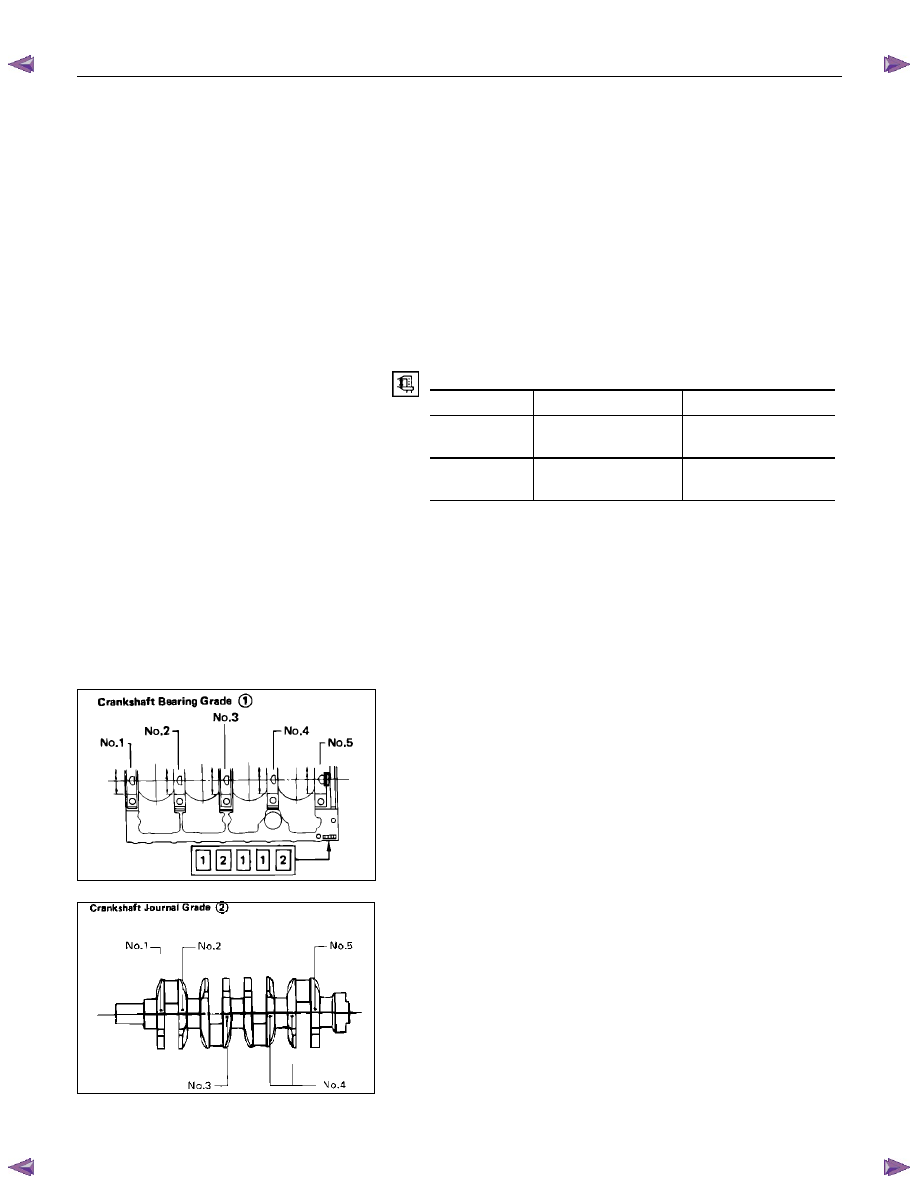

CRANKSHAFT BEARING SELECTION

Crankshaft bearing selection is based on the measured

diameters of the crankshaft journals and the bearing inserts.

Match the crankshaft bearing housing grade marks and the

crankshaft journal grade marks in the table below to determine

the correct crankshaft bearing size.

Crankshaft Bearing Housing Grade Mark

Position

Crankshaft bearing housing grade marks 1, 2 or 3 are stamped

on the rear right hand side of the cylinder body.

Crankshaft Journal Grade Mark Position

The crankshaft journal grade marks (1 or -, 2 or --, 3 or ---) are

stamped on each crankshaft journal web.

The crankshaft journal and bearing clearance must be the

same for each position after installation of the crankshaft and

the crankshaft bearings.

NOTE:

The crankshaft journal mark No. 4 is stamped on

crankshaft No. 4 journal web front side or rear side.

015LX060

015RY00016

6A – 84 ENGINE MECHANICAL

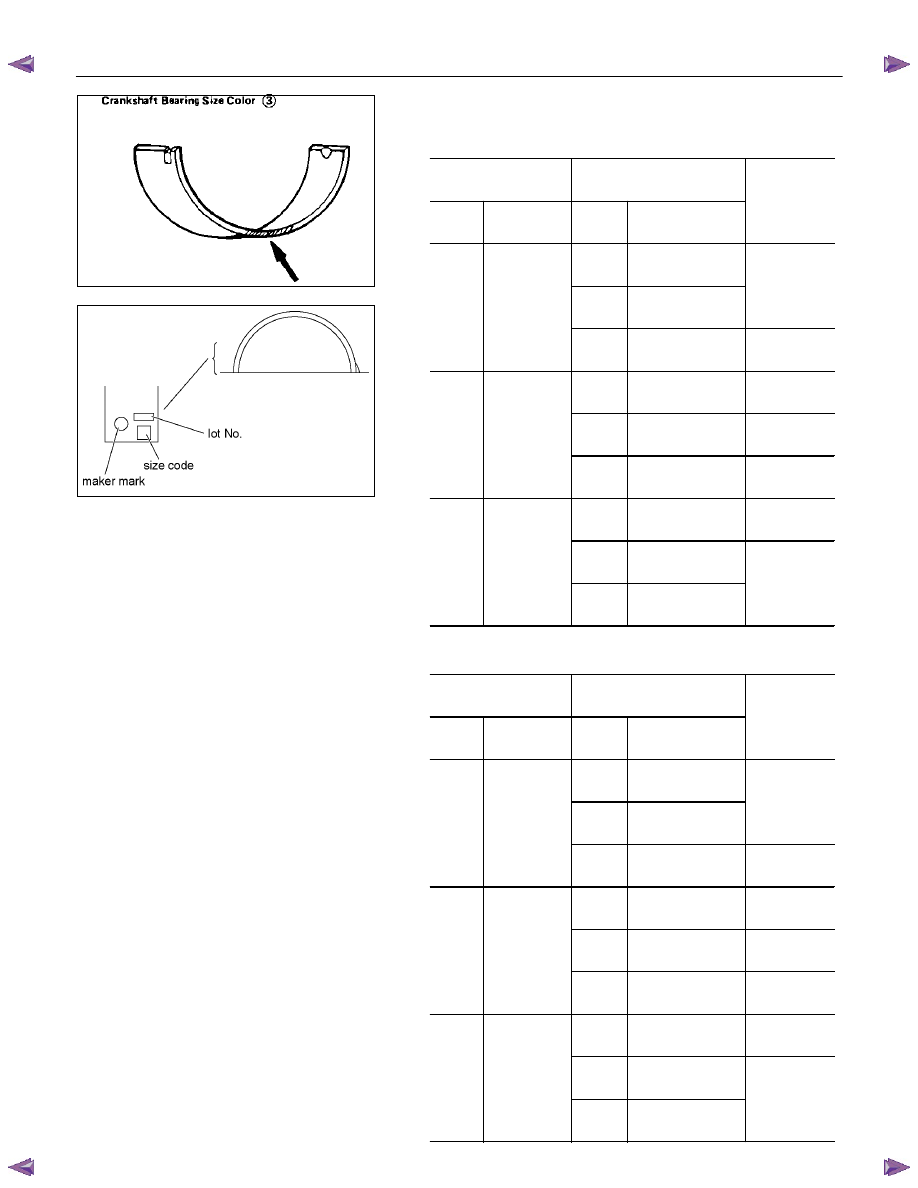

015RY00017

RTW46ASH002501

REFERENCE

4JA1T(L), 4JA1TC

mm (in)

Crankshaft

Bearing Housing

Crankshaft Journal

Grade

Mark

Diamaeter

Grade

Mark

Diamaeter

Crankshaft

Bearing

Size Code

1 or

-

59.927-59.932

(2.3593-23.595)

2 or

- -

59.922-59.927

(2.3591-2.3539)

Brown or 4

1

63.992-

64.000

(2.5194-

2.5197)

3 or

- - -

59.917-59.922

(2.3589-2.3591)

Yellow or 5

1 or

-

59.927-59.932

(2.3593-2.3595)

Black or 2

2 or

- -

59.922-59.927

(2.3591-2.3593)

Blue or 3

2

63.983-

63.992

(2.5190-

2.5194)

3 or

- - -

59.917-59.922

(2.3589-2.3591)

Brown or 4

1 or

-

59.927-59.932

(2.3593-2.3595)

Green or 1

2 or

- -

59.922-59.927

(2.3591-2.3593)

3

63.975-

63.983

(2.5187-

2.5190)

3 or

- - -

59.917-59.922

(2.3598-2.3591)

Black or 2

4JH1TC mm

(in)

Crankshaft

Bearing Housing

Crankshaft Journal

Grade

Mark

Diamaeter

Grade

Mark

Diamaeter

Crankshaft

Bearing

Size Code

1 or

-

69.927-69.932

(2.7530-2.7532)

2 or

- -

69.922-69.927

(2.7528-2.7530)

4

1

73.992-

74.000

(2.9131-

2.9134)

3 or

- - -

69.917-69.922

(2.7556-2.7528)

5

1 or

-

69.927-69.932

(2.7530-2.7532)

2

2 or

- -

69.922-69.927

(2.7528-2.7530)

3

2

73.983-

73.992

(2.9127-

2.9131)

3 or

- - -

69.917-69.922

(2.7556-2.7528)

4

1 or

-

69.927-69.932

(2.7530-2.7532)

1

2 or

- -

69.922-69.927

(2.7528-2.7530)

3

73.975-

73.983

(2.9124-

2.9127)

3 or

- - -

69.917-69.922

(2.7526-2.7528)

2

ENGINE MECHANICAL 6A – 85

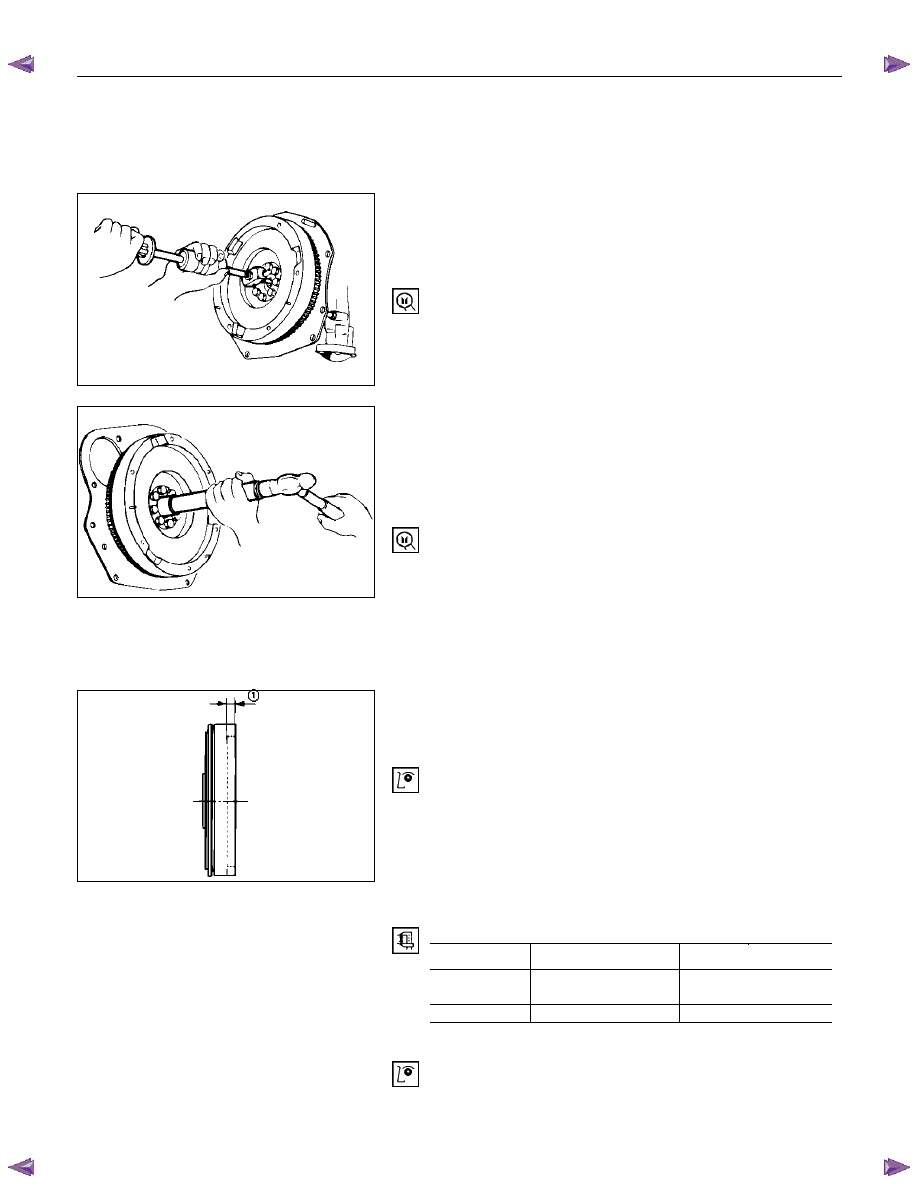

CRANKSHAFT PILOT BEARING

Check the crankshaft pilot bearing for excessive wear and

damage and replace it if necessary.

Crankshaft Pilot Bearing Replacement

Crankshaft Pilot Bearing Removal

Use the pilot bearing remover to remove the crankshaft pilot

bearing.

Pilot Bearing Remover: 5-8840-2000-0

Sliding Hammer: 5-8840-0019-0

Crankshaft Pilot Bearing Installation

1. Place the crankshaft pilot bearing right angle across the

crankshaft bearing installation hole.

2. Tap around the edges of the crankshaft pilot bearing outer

races with a brass hammer to drive the bearing into the

crankshaft bearing installation hole.

Pilot Bearing Installer: 5-8522-0024-0

NOTE:

Strike only the crankshaft pilot bearing outer race with

the hammer. Do not strike the bearing inner race.

Bearing damage and reduced bearing service life will

result.

FLYWHEEL AND RING GEAR

Flywheel

1. Inspect the flywheel friction surface for excessive wear and

heat cracks.

2. Measure the flywheel friction surface depth.

If the measured value is within the specified limit, the

flywheel may be reground.

If the measured value exceeds the specified limit, the

flywheel must be replaced.

Flywheel Friction Surface Depth (1)

mm (in)

Standard

Limit

4JA1T (L),

4JA1TC

20 (0.7874)

21 (0.8267)

4JH1TC

18 (0.7087)

19 (0.7480)

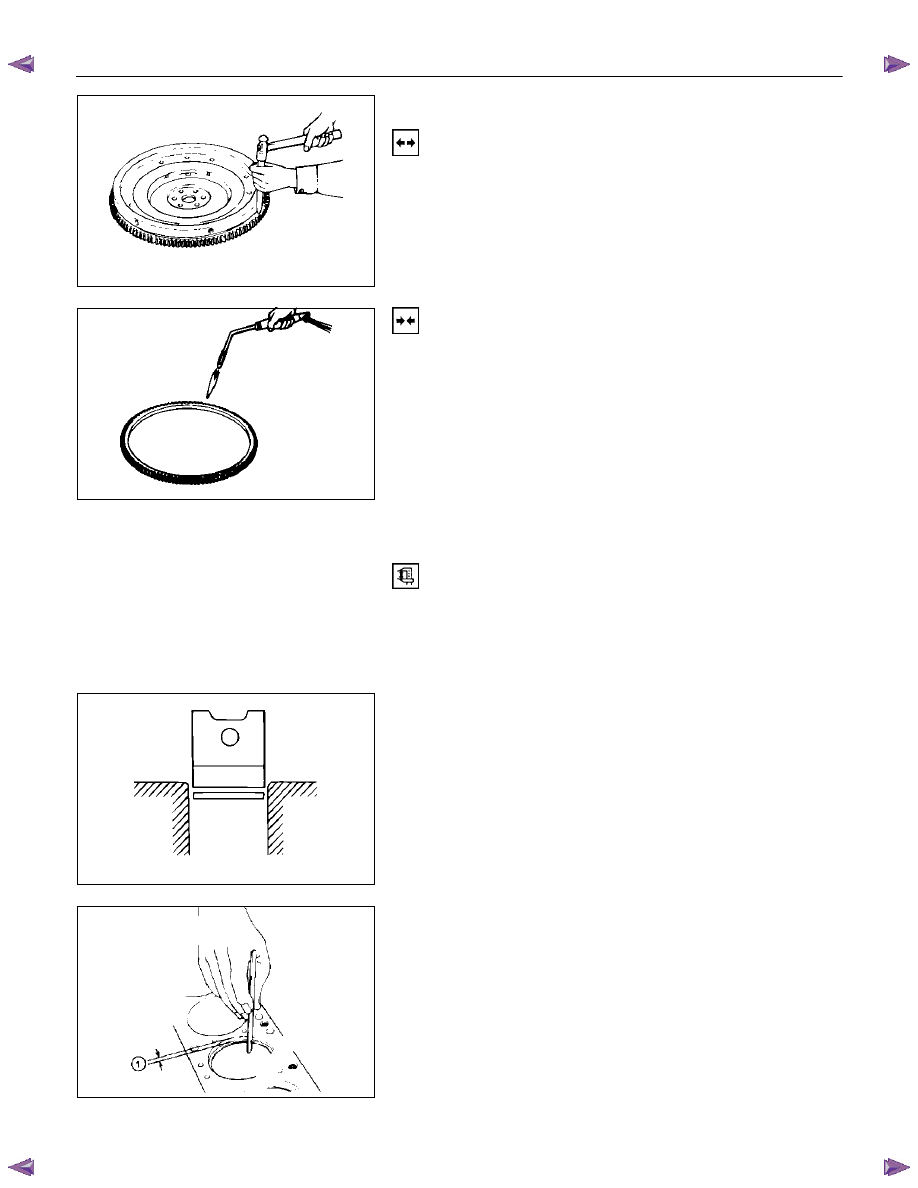

Ring Gear

Inspect the ring gear.

If the ring gear teeth are broken or excessively worn, the ring

gear must be replaced.

015RY00010

015RY00019

015RY00018

6A – 86 ENGINE MECHANICAL

Ring Gear Replacement

Ring Gear Removal

Strike around the edges of the ring gear with a hammer and

chisel to remove it.

Ring Gear Installation

1. Heat the ring gear evenly with a gas burner to invite

thermal expansion.

Do not allow the temperature of the gas burner to exceed

200

°

C (390

°

F).

2. Install the ring gear when it is sufficiently heated.

The ring gear must be installed with the chamfer facing the

clutch.

PISTON

Piston Grade Selection and Cylinder Bore

Measurement

Refer to the Section "Cylinder Body", Item "Cylinder Liner Bore

Measurement" for details on piston grade selection and

cylinder liner bore measurement.

Piston Ring Gap

1. Insert the piston ring horizontally (in the position it would

assume if it were installed to the piston) into the cylinder

liner.

2. Push the piston ring into the cylinder bore until it reaches

the measuring point 1 or 2 where the cylinder liner bore is

the smallest.

Do not allow the piston ring to slant to one side or the

other. It must be perfectly horizontal.

Measuring Point 1 10 mm (0.4 in)

or

Measuring Point 2 120 mm (4.7 in)

020LX008

020LX009

015LX023

015RY00020

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст