Isuzu KB P190. Manual — part 133

4C1-28 FRONT WHEEL DRIVE

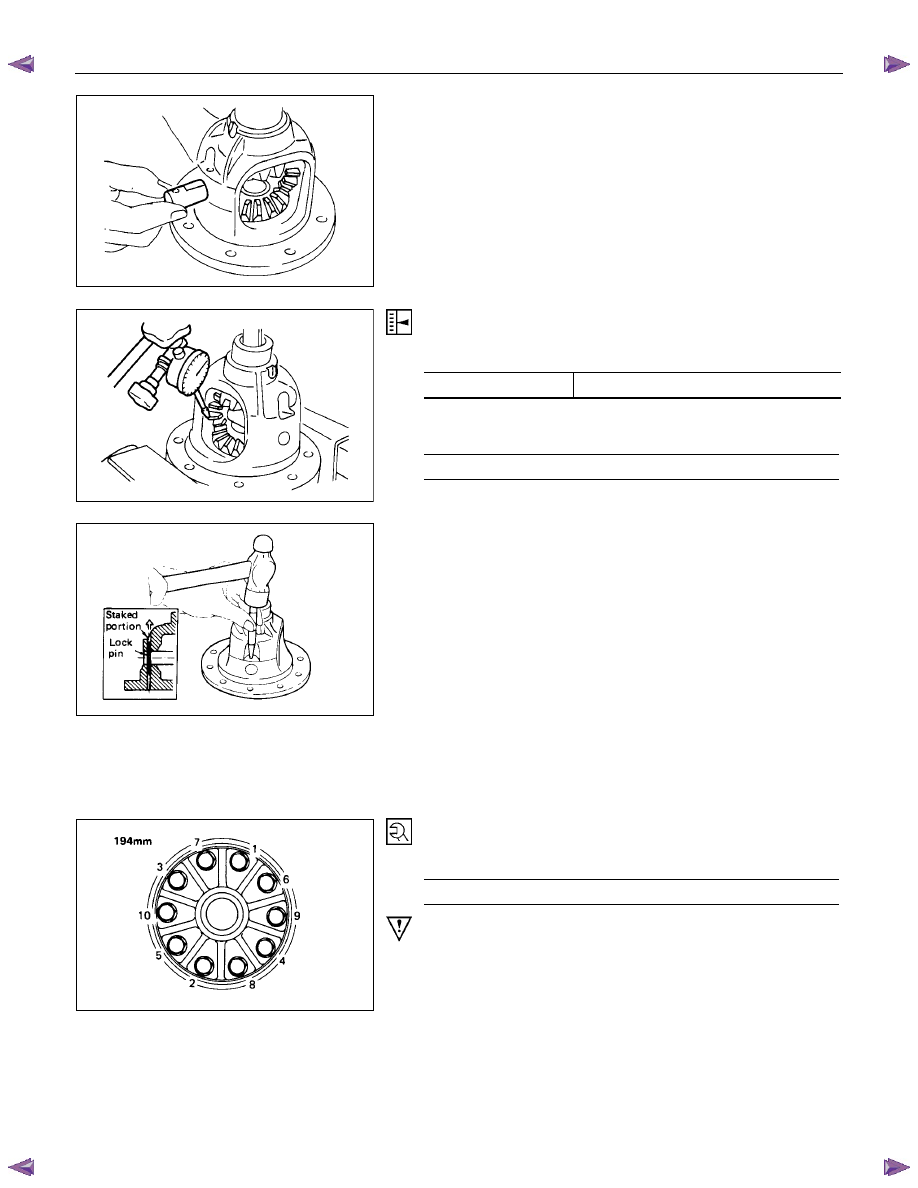

5. Cross Pin

(1) Be sure to install the cross pin so that it is in alignment with

the lock pin hole in the differential cage.

(2) Adjust the backlash between the side gear and the pinion

gear.

mm(in)

Backlash

0.10 - 0.20 (0.004 - 0.008)

Thickness of thrust washers available

mm(in)

1.00, 1.05, 1.10 (0.039, 0.041, 0.043)

6. Lock Pin

After lock pin installation, stake the cage to prevent discharge

of the lock pin.

7. Ring Gear

When installing the ring gear, apply LOCTITE 271 or

equivalent to the threaded hole and bolt.

8. Bolt

Tighten the bolts in diagonal sequence as illustrated.

Bolt Torque

N

⋅m (kgf⋅m/lb⋅ft)

108 (11.0/80)

Note :

Discard used bolts and install new ones.

Note that all bolts have a left hand thread.

FRONT WHEEL DRIVE 4C1-29

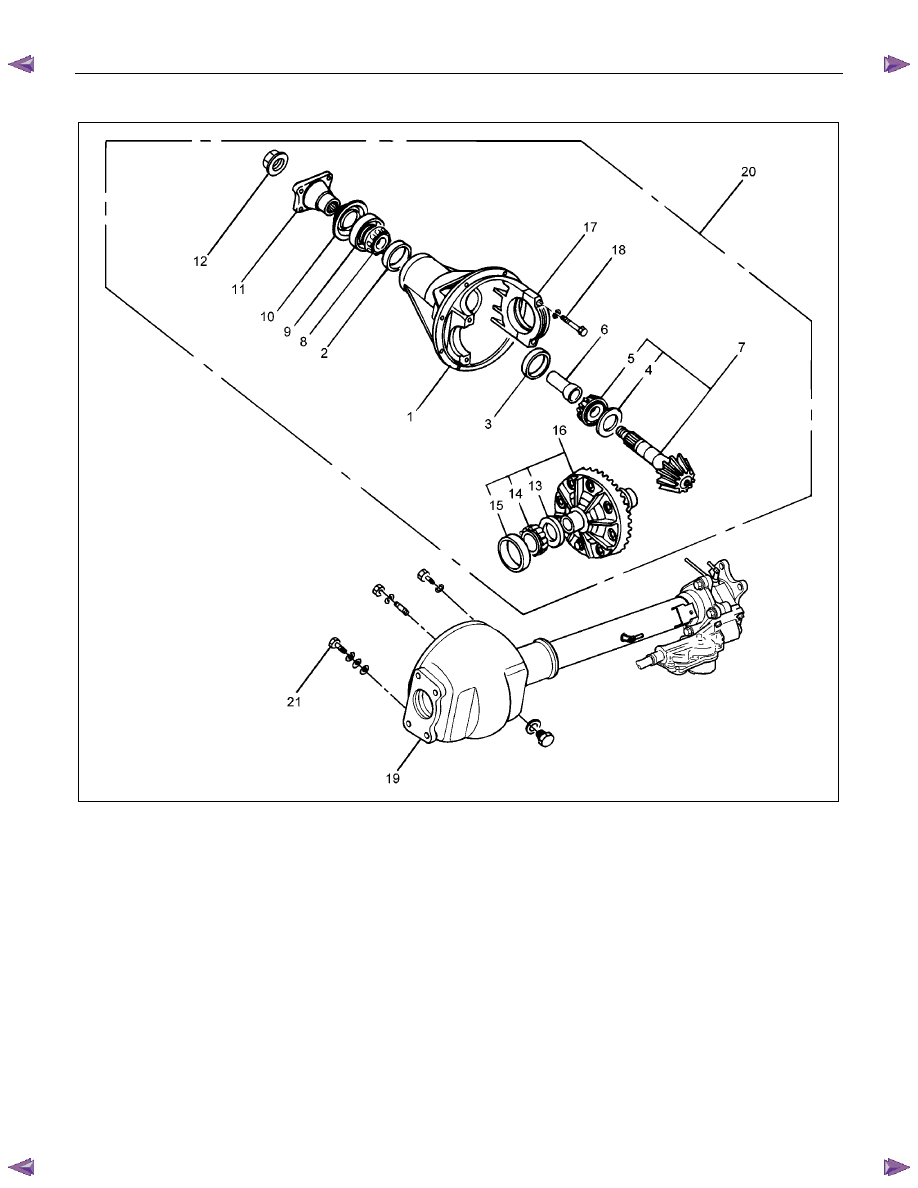

Major Components

RTW54CLF000201

Reassembly Steps

1.

Diff.

carrier

▲ 2. Outer bearing outer race

▲ 3. Inner bearing outer race

▲ 4. Adjust shim

▲ 5. Inner bearing

▲ 6. Collapsible spacer

7.

Pinion

gear

8.

Outer

bearing

▲ 9. Oil seal

10.

Dust

cover

11.

Flange

▲12. Flange nut

▲13. Adjust shim

▲14. Side bearing

15. Bearing outer race

16. Diff. cage assembly

▲17. Bearing cap

▲18. Bolt

19.

Axle

case

▲20. Differential assembly

21.

Bolt

4C1-30 FRONT WHEEL DRIVE

Important Operations

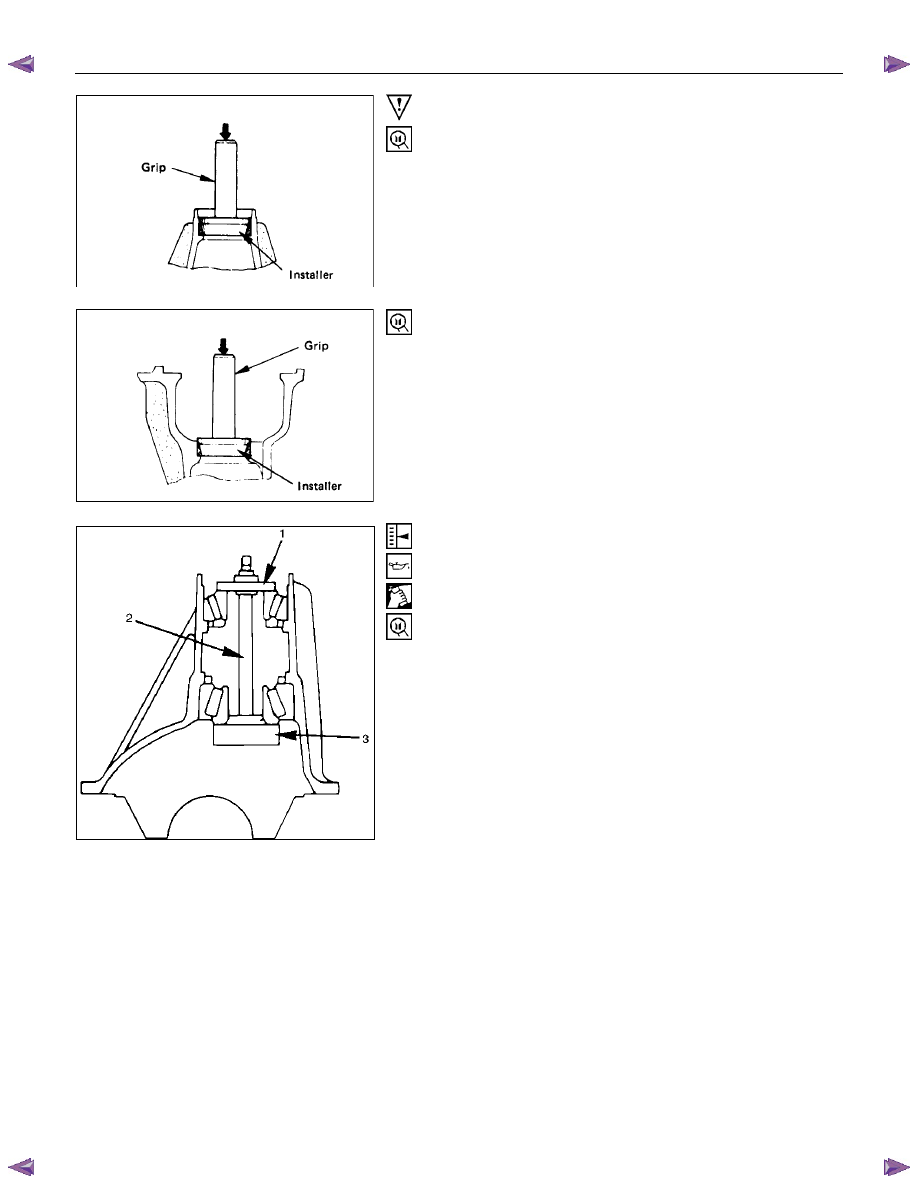

2. Outer Bearing Outer Race

Installer : 9-8522-1141-0

Grip :

5-8840-0007-0

3. Inner Bearing Outer Race

Installer : 9-8522-1274-0

Grip :

5-8840-0007-0

4. Adjust Shim

Adjustment of drive pinion mounting distance

(1) Apply gear oil to the inner and outer drive pinion bearing.

Clean the pinion setting gage set.

Then install the gage set together with the inner and outer

bearings.

1. Pilot

: 5-8840-2085-0

2. Nut and bolt : 5-8840-2089-0

3. Gage plate : 5-8840-2087-0

FRONT WHEEL DRIVE 4C1-31

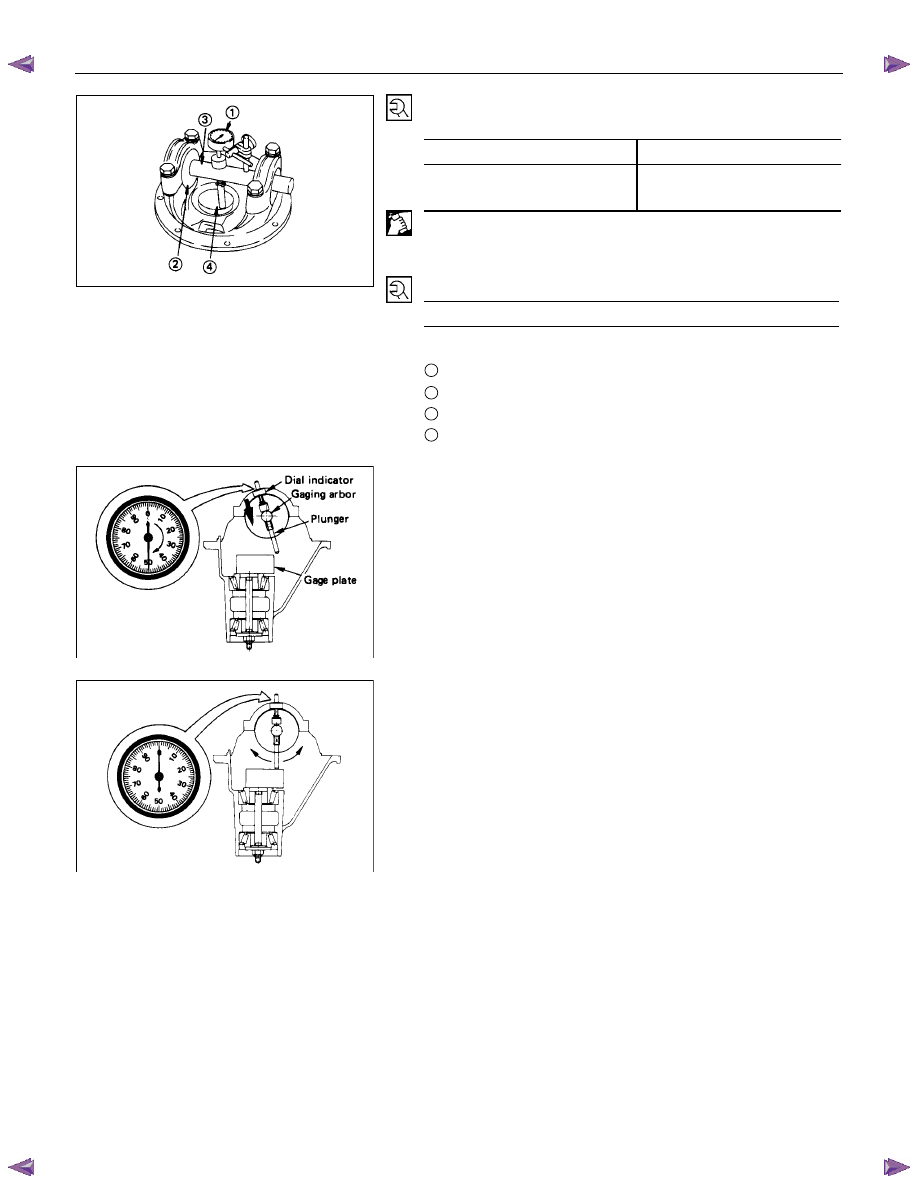

Tighten the nut to the specified torque.

N

⋅m (kgf⋅m/lb⋅in)

New bearing

2.3 (0.23/20)

Used bearing

0.98 - 1.18

(0.10 – 0.12/9 – 10)

(2) Clean the side bearing bores. Install the dial indicator with

the discs and Arbor. Install and tighten the bearing caps to

the specified torque.

Torque N

⋅m (kgf⋅m/lb⋅ft)

98 (10.0/72)

1

Dial indicator : 5-8840-0126-0

2

Disc (2 pcs.) : 5-8840-2088-0

3

Arbor

: 5-8840-0128-0

4

Gage plate : 5-8840-2087-0

(3) Set the dial indicator to “0”. Place it on the mounting post of

the gaging arbor with the contact button touching the

indicator pad. Force the dial indicator downward until the

needle has made a half turn clockwise. Tighten down the

dial indicator in this position.

(4) Position the plunger on the gage plate. Move the gaging

arbor slowly back and forth and locate the position at which

the dial indicator shows the greatest deflection. At this

point, once again set the dial indicator to “0”.

Repeat the procedure to verify the “0” setting.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст