Isuzu KB P190. Manual — part 244

6C – 12 FUEL SYSTEM

Removal

CAUTION: When repair to the fuel system has been

completed, start engine and check the fuel system for

loose connection or leakage. For the fuel system

diagnosis, see Section “Driveability and Emission".

1. Remove fuel tank assembly (9). Refer to “Fuel Tank

Removal" in this section.

2. Disconnect the quick connector (6) of the fuel tube from fuel

gauge unit.

3. Disconnect the quick connector (10) of the evapo tube from

fuel gauge unit.

140R100035

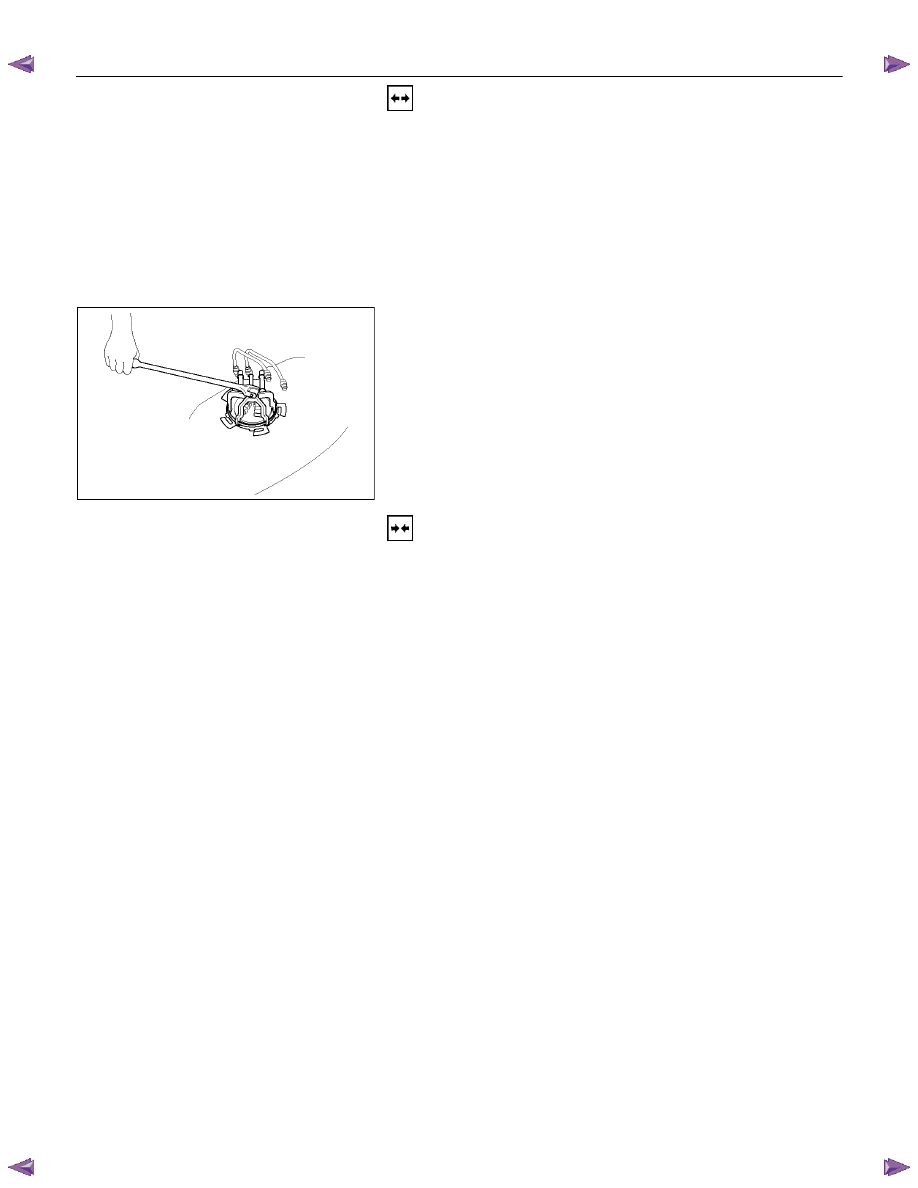

3. Remove the retainer ring (7) from the fuel tank with the

removal tool 5-8840-2602-0.

4. Remove slowly the fuel gauge unit (4) from the fuel tank as

no bend float arm.

NOTE: Cover opening for the fuel gauge unit on fuel tank to

prevent any dust entering.

5. Discard fuel gauge unit seal (8) because it cannot be

reusable.

Installation

1. Clean the seal surface of the fuel tank and the fuel gauge

unit.

NOTE: If there is dust on the seal surface, it becomes cause of

fuel leak.

2. Install the new fuel gauge unit seal (8) to opening of the fuel

tank as along the groove.

3. Install slowly the fuel gauge unit (4) into the fuel tank as no

bend float arm.

4. Set flange of the fuel gauge unit on fuel gauge unit seal as

mating convexity of the fuel gauge unit and reentrant of the

fuel tank.

5. Lock slowly the retainer ring (7) to the fuel tank with the

remover tool 5-8840-2602-0.

6. Connect the quick connector (10) of the evapo tube from

fuel gauge unit.

7. Connect the quick connector (6) of the fuel tube to to gauge

unit.

NOTE: Pull off the left ckecker of the fuel pipe.

NOTE: Refer to “Fuel Tube/Quick Connector Fittings” in this

section when performing any repairs.

FUEL SYSTEM 6C – 13

8. Check leak.

Methed of leak check.

(1) Plug end of quick connector and breather hose (Pull off

the breather hose from fuel tank) and tighten fuel filler

cap until at least one click are heard.

(2) Apply water soap around the fuel gauge unit seal area.

(3) Pressure air into the fuel tank from end of breather pipe

at 5psi (34.3 kPa/2.8kgf/cm

2

) over 15 seconds.

(4) Verify no bubbles around the fuel gauge unit seal area.

9. Install the fuel tank assembly (9).

NOTE: Refer to “Install the fuel tank” in this section.

6C – 14 FUEL SYSTEM

FUEL TUBE / QUICK – CONNECTOR FITTINGS

Precautions

• Do not light a match or create a flame.

• Keep flames away from your work area to prevent

flammable materials from catching fire.

• Disconnect battery ground cable to prevent electrical shorts.

• Pre-treat piping system or associated parts from thermal

damage or from spattering when welding or similar

heat-generating work.

140R100032

Legend

(1) O-ring

(2) Port

(3) Connector

(4) Plastic Tube

Cautions During Work

Do not expose the assembly to battery electrolyte or do not

wipe the assembly with a cloth used to wipe off spilt battery

electrolyte.

Piping that has been splattered with battery electrolyte or

battery electrolyte soaked cloth that was wiped on the piping

cannot be used.

141R100002

Removal

1. Open the fuel cap to relieve the fuel pressure in the tank.

Use compressed air to remove any dirt on the fuel quick

connect fittings prior to disconnecting the fittings.

When disconnecting the fuel pipe, cover the area with a

cloth to prevent fuel from splashing as the fuel pipe may

still have some pressure in it.

FUEL SYSTEM 6C – 15

140R100037

2. For removal of the quick connector, hold the quick

connector in one hand, and pull out the connector with the

other hand while pressing the square relieve button of the

connector, as illustrated.

NOTE: Do not use tools of any kind. Only use bare hands

when disconnecting the connector. Use a lubricant (light oil)

and/or push and pull the connector until the pipe is

disconnected.

140R100028

Cover the connectors that was removed with a plastic bag,

to prevent dust or rain water from entering.

140R100036

Reuse of Quick–Connector

• Replace the port and connector if scratch, dent or crack is

found.

• Remove any dirt build up on the port when installing the

connector. Replace the connector, if there is any forms of

rust, dent, scratch.

• After cleaning the port, insert it straight into the connector

until it clicks. After it clicks, try pulling at 49N (5kgf) it out to

make sure that it is not drawn and is securely locked.

Assembling Advice

By applying engine oil or light oil to the pipe, port makes pipe

assembly easier. The pipe assembly should take place

immediately after applying oil (to prevent dust from sticking to

the pipe surface – which may decrease sealing ability).

Test/Inspection After Assembling

1. Reconnect the battery negative cable.

2. Start the engine and observe the engine idle speed. The

presence of dirt in the fuel system may affect the fuel

injection system.

3. Check for fuel leakage from the connector.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст