Isuzu KB P190. Manual — part 684

Engine Mechanical – V6

Page 6A1–257

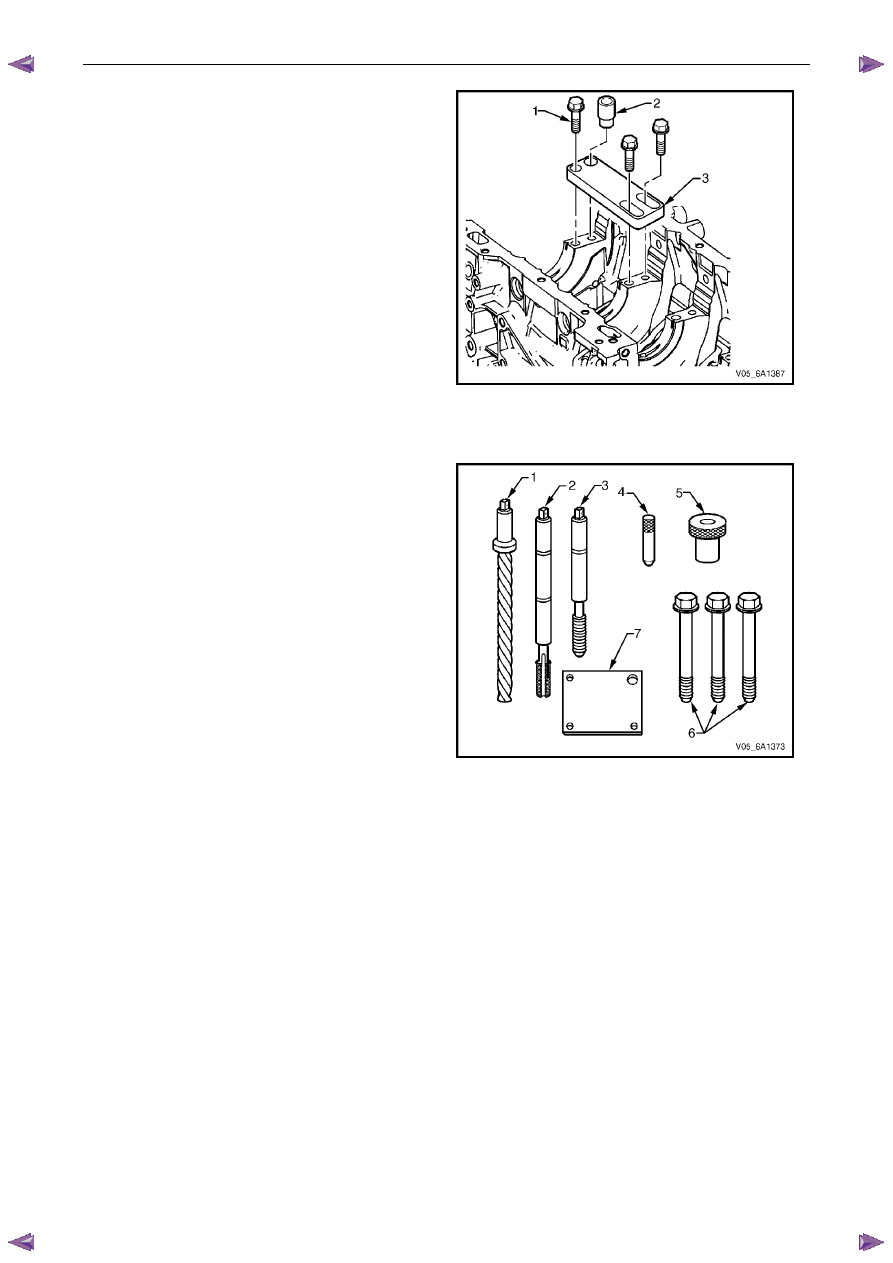

22

Remove the fixture plate bolts (1), bushing (2) and

fixture plate (3).

Figure 6A1 – 497

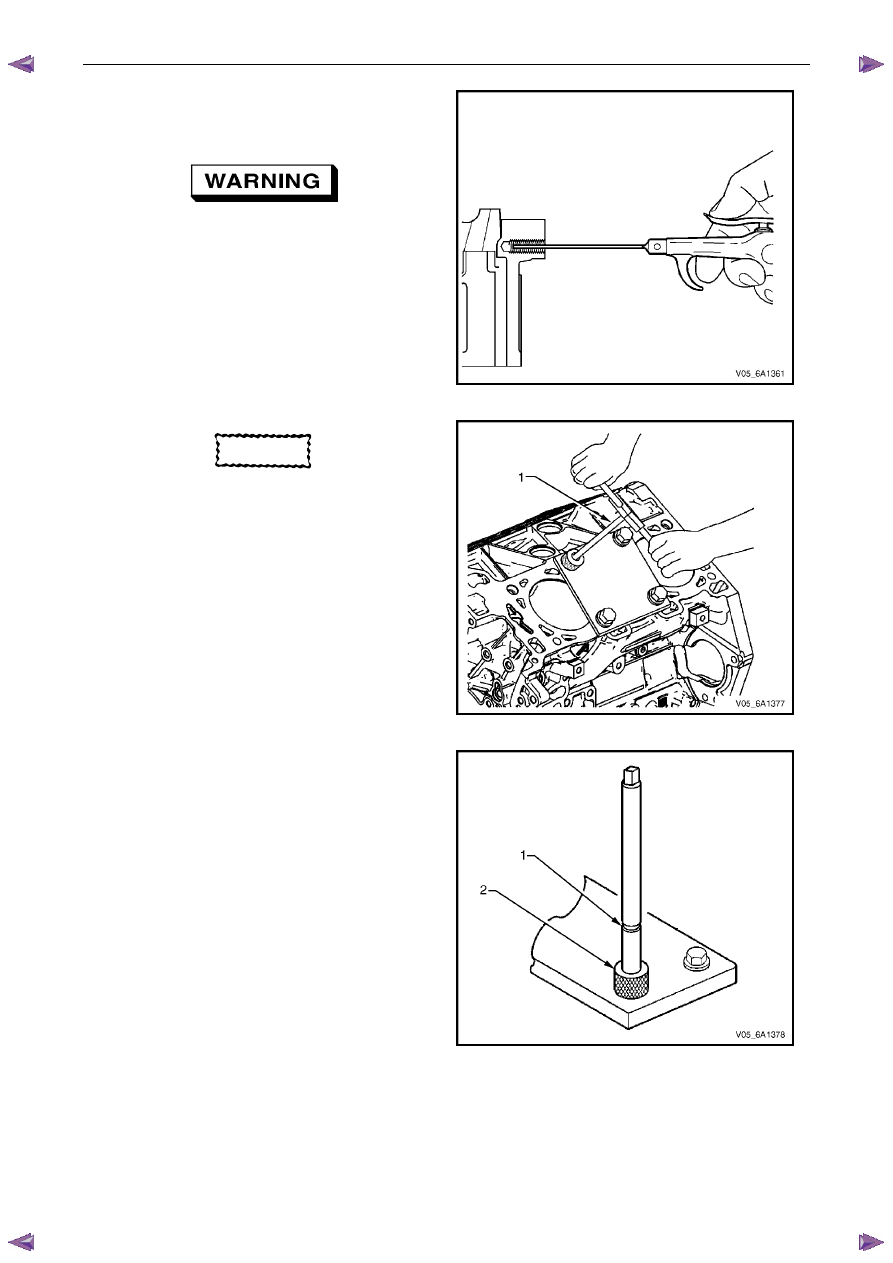

Cylinder Head Bolt Hole Thread Repair

The cylinder head bolt hole thread repair tools are in Tool

No. J 42385-2000 and J 42385-700 which consist of the

following:

•

Drill (1) J 42385-723

•

Tap (2) J 42385-724

•

Installation driver (3) J 42385-725

•

Alignment pin (4) J 42385-303

•

Bushing (5) J 42385-302

•

Bolts (6) J 42385-733

•

Fixture plate (7) J 42385-401

Figure 6A1 – 498

N O T E

• Ensure the fixture plate is installed during the

machining and installation processes of the

insert.

• The use of a cutting type fluid such as

WD 40® or equivalent is recommended when

performing the drilling, counter boring and

tapping procedures.

• When installed to the correct depth, the flange

of the insert will be seated against the counter

bore of the drilled/tapped hole.

Engine Mechanical – V6

Page 6A1–258

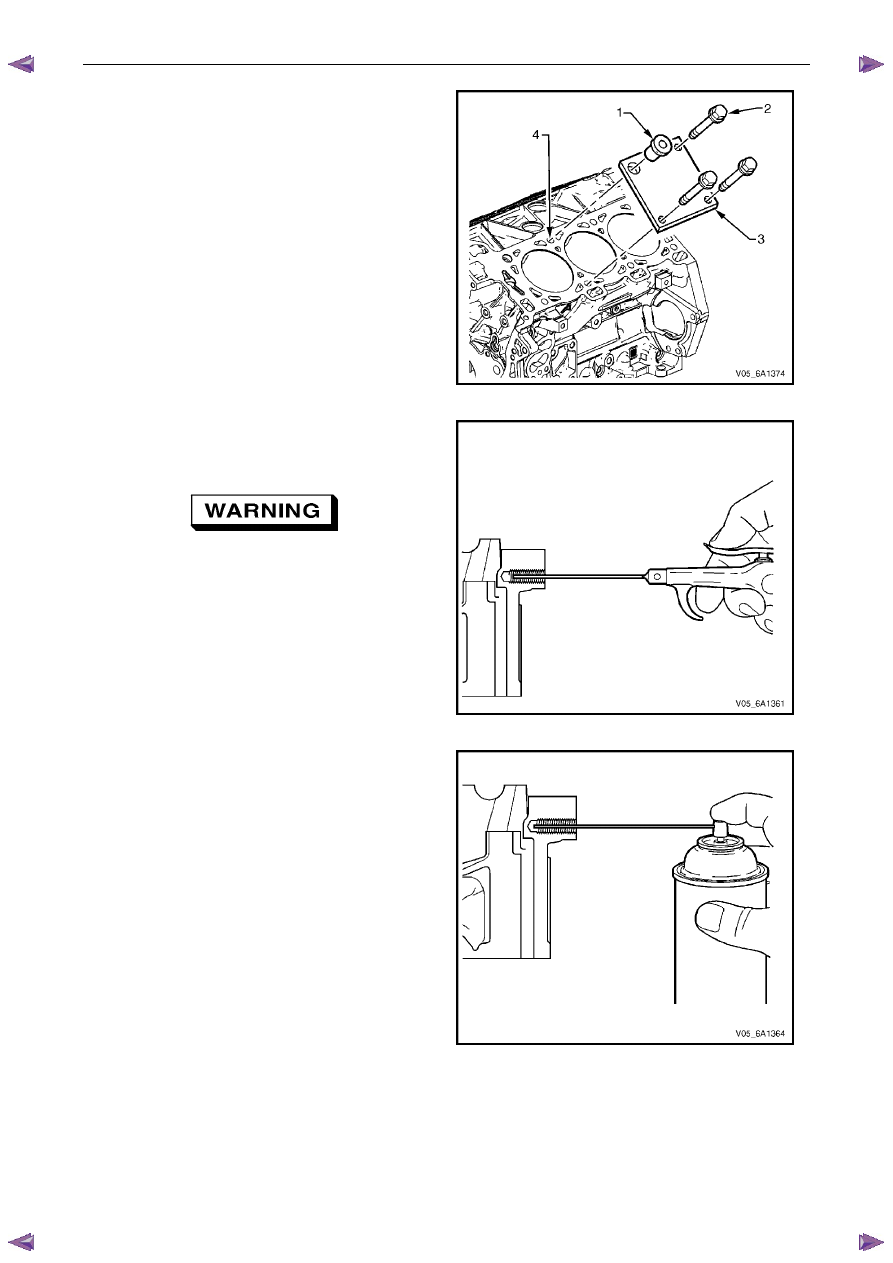

1

Position the fixture plate (3) with the bushing (1)

installed over the cylinder head bolt hole to be

repaired (4).

2

Loosely install the fixture plate bolts (2) into the

remaining cylinder head bolt holes.

Figure 6A1 – 499

3

Position the alignment pin (1) through the bushing

and into the cylinder head bolt hole.

4

With the alignment pin in the desired cylinder head

bolt hole, tighten the fixture retaining bolts (2).

5

Remove the alignment pin.

Figure 6A1 – 500

N O T E

During the drilling process, repeatedly remove

the drill and clean swarf from the hole and the

flutes of the drill.

6

Drill the hole until the stop collar contacts the top of

the drill bushing.

Figure 6A1 – 501

Engine Mechanical – V6

Page 6A1–259

N O T E

All swarf must be removed from the drilled hole

prior to tapping.

Safety glasses must be worn when using

compressed air.

7

Using compressed air, clean out any swarf.

Figure 6A1 – 502

CAUTION

Do not remove the fixture plate during the

machining and installation processes of the

insert.

N O T E

• During the tapping process, repeatedly

remove the tap and clean swarf from the

hole and the flutes of the tap.

• Ensure the tap has created full threads at

least to the depth equal to the insert length.

8

Using a suitable tapping wrench, tap the threads of

the drilled hole by hand only.

Figure 6A1 – 503

9

In order to tap the new threads for the insert to the

correct depth, rotate the tap into the cylinder head

bolt hole until the mark (1) on the tap aligns with the

top of the drill bushing (2).

Figure 6A1 – 504

Engine Mechanical – V6

Page 6A1–260

N O T E

Remove the fixture plate prior to installing the

insert with the installer tool.

10

Remove the bushing (1) and fixture plate bolts (2)

from the cylinder block (4) and remove the fixture

plate (3).

Figure 6A1 – 505

N O T E

All swarf must be removed from the tapped hole

prior to insert installation.

Safety glasses must be worn when using

compressed air.

11

Using compressed air, clean out any swarf.

Figure 6A1 – 506

12

Spray a commercially available thread cleaner into

the tapped hole.

Figure 6A1 – 507

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст