Isuzu KB P190. Manual — part 830

Engine Management – V6 – Diagnostics

Page 6C1-2–42

6.3

Fuel Injector Balance Test

To avoid irregular fuel pressure readings, do

not perform this procedure if the engine

coolant temperature is greater than 94

°°°° C.

Fuel Injector Balance Test – With Tech 2

1

Check the engine coolant temperature is less than 94

°C.

2

Perform the fuel injector coil test and replace any fuel injectors that are not functioning correctly before proceeding.

Refer to 6.2

Fuel Injector Coil Test.

3

Perform the fuel system pressure check and ensure the fuel system is functioning correctly before proceeding with

the fuel injector balance test. Refer to 6C Fuel System – V6.

4

While the fuel pressure gauge is still connected to the fuel pressure test point, pressurise the fuel system. Refer to

6C Fuel System – V6.

5

When the fuel pressure reading stabilises, record the fuel pressure reading indicated by the fuel pressure gauge.

N O T E

The fuel pressure reading taken in Step 5 is

known as the first pressure reading.

6

Connect Tech 2 to the data link connector (DLC) and turn the ignition on.

7

On Tech 2 select Engine / V6 Engine / Actuator Test / Fuel Injector Balance.

8

Follow the Tech 2 prompts, recording the fuel pressure gauge reading for each injector.

N O T E

The fuel pressure readings taken in Step 8 are

known as the second pressure reading

9

Perform the Fuel Injector Pressure Drop Calculation in this Section.

Fuel Injector Balance Test – Without Tech 2

1

Check the engine coolant temperature is less than 94

°C.

2

Perform the fuel injector coil test and replace any fuel injectors that are not functioning correctly before proceeding.

Refer to 6.2 Fuel Injector Coil Test.

3

Perform the fuel system pressure check and ensure the fuel system is functioning correctly before proceeding with

the fuel injector balance test. Refer to 6C Fuel System – V6.

4

While the fuel pressure gauge is still connected to the fuel pressure test point, pressurise the fuel system. Refer to

6C Fuel System – V6.

5

When the fuel pressure reading stabilises, record the fuel pressure reading indicated by the fuel pressure gauge.

N O T E

The fuel pressure reading taken in Step 5 is

known as the first pressure reading.

Engine Management – V6 – Diagnostics

Page 6C1-2–43

6

Remove the upper intake manifold assembly, refer to 6A1 Engine Mechanical – V6.

N O T E

After removing the upper intake manifold, plug

the lower manifold opening to prevent dirt and

other contaminants from entering.

7

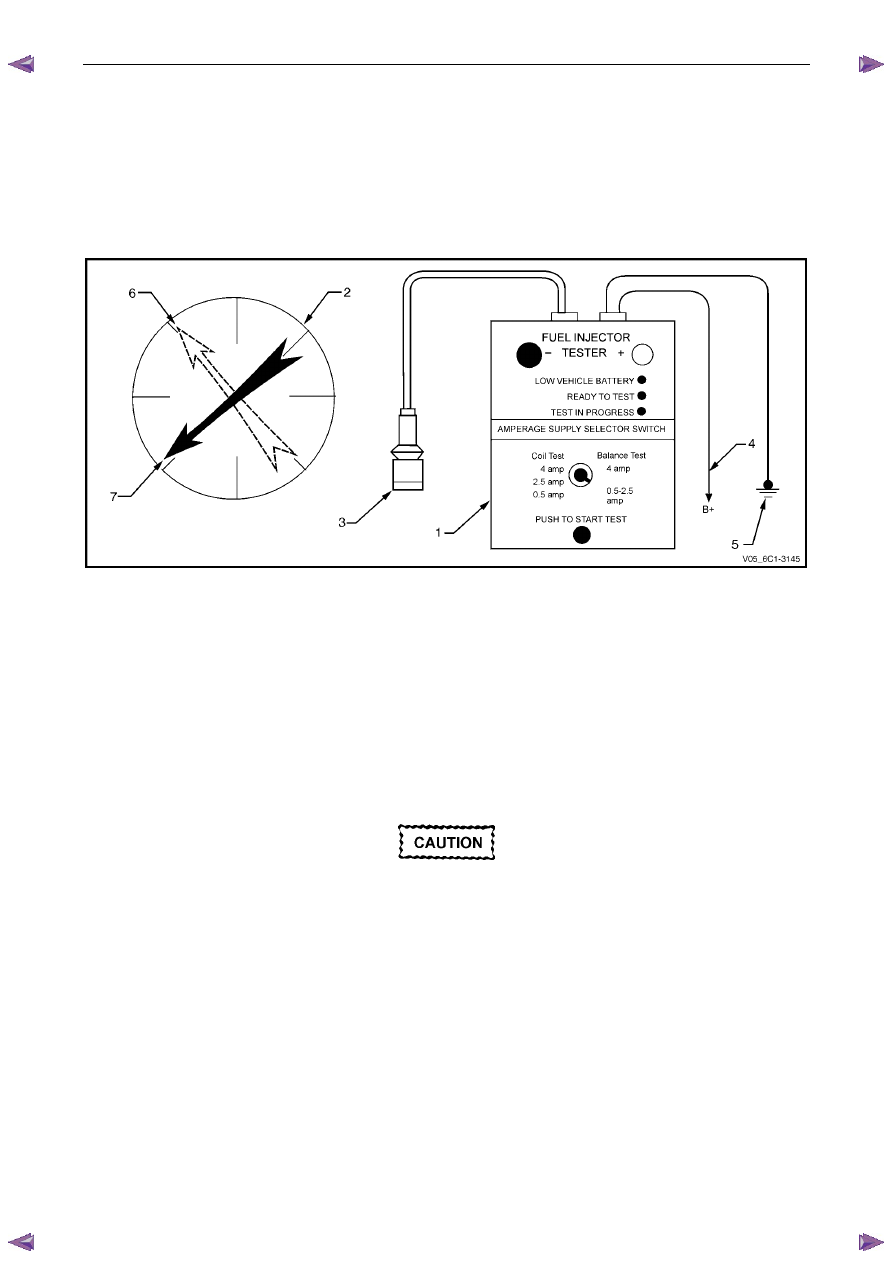

Connect Tool No. J 39021 Fuel Injector Tester (1), and Tool No. J 44602 (3) to the fuel injector connector. Refer to

Figure 6C1-2 – 14.

Figure 6C1-2 – 14

Legend

1

Fuel Injector Tester – Special Tool J39021

2

Fuel Pressure Gauge – Special Tool SD28018

3

Fuel Injector Harness Adapter – Special Tool J44602

4

To Battery Positive Terminal

5 Battery

Earth

6

First Pressure Reading

7

Second Pressure Reading

8

Connect the fuel injector tester battery positive lead (4) and battery negative lead (5) to the battery, refer to Figure

6C1-2 – 14.

9

Set the amperage supply selector of the fuel injector tester to the Balance Test 0.5 – 2.5 A position.

As the fuel pressure tends to increase after

the fuel injector stops fuel delivery, record the

fuel pressure value immediately after the fuel

injector stops fuel delivery. Do not record the

higher fuel pressure value.

10

Press the Push to Start Test Button on the fuel injector tester to activate the fuel injector.

11

Record the fuel pressure reading indicated by the fuel pressure gauge.

N O T E

The fuel pressure readings taken in Step 10 is

known as the second pressure reading

12

Repeat the balance test pressure reading for each fuel injector.

13

Perform the Fuel Injector Pressure Drop Calculation in this Section.

Engine Management – V6 – Diagnostics

Page 6C1-2–44

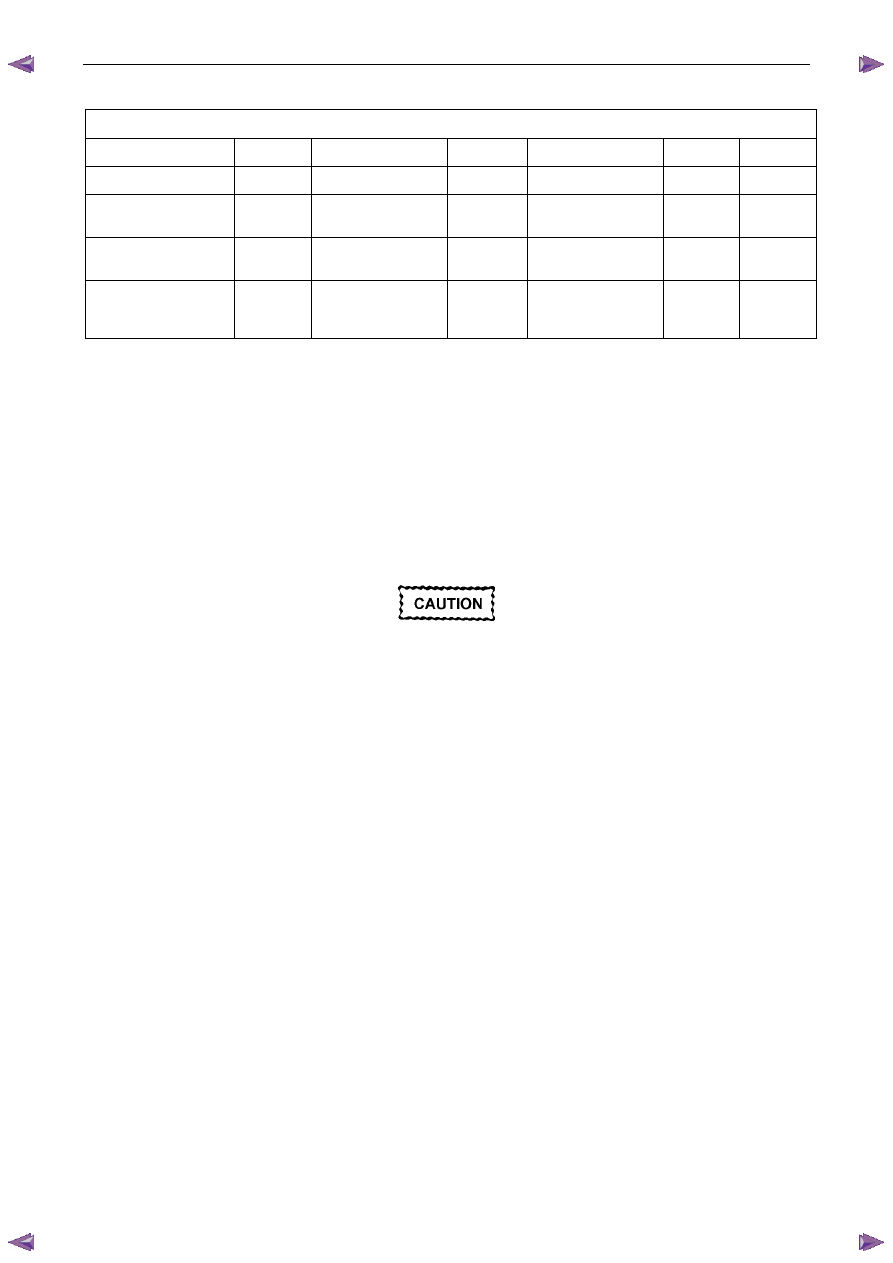

Fuel Injector Pressure Drop Calculation

Fuel Injector Balance Test Example – Typical Values Shown

Cylinder 1

2

3

4

5

6

1st Pressure Reading

360 kPa

360 kPa

360 kPa

360 kPa

360 kPa

360 kPa

2nd Pressure

Reading

155 kPa

131 kPa

155 kPa

200 kPa

146 kPa

150 kPa

Amount of Pressure

Drop

205 kPa

229 kPa

205 kPa

160 kPa

214 kPa

210 kPa

Average Range

194 - 214 kPa

Injector

OK

Replace fuel

injector – too much

pressure drop

Injector

OK

Replace fuel

injector – too little

pressure drop

Injector

OK

Injector

OK

Figure 6C1-2 – 15

1

Subtract the second pressure reading from the first pressure reading to calculate the pressure drop value. Refer to

the table in Figure 6C1-2 – 15, typical results.

2

Calculate the pressure drop value for each fuel injector.

3

Add all the individual pressure drop values of each fuel injector to calculate the total pressure drop.

4

Divide the total pressure drop by the number of fuel injectors to calculate the average pressure drop.

Fuel Injector Pressure Drop Analysis

1

A fuel injector is faulty if its pressure drop value deviates from the average pressure drop by more than 10 kPa.

Do not repeat any portion of the test before

running the engine to prevent the engine from

flooding.

2

Re-test any fuel injector that does not meet the specification.

3

Replace all faulty fuel injectors, refer to 2.13 Fuel Rail Assembly, in 6C1-3 Engine Management – V6 – Service

Operations.

6.4

Fuel Injector Leak Down Test

1

Turn the ignition switch OFF.

N O T E

After removing the upper intake manifold, plug

the lower manifold opening to prevent dirt and

other contaminants from entering.

2

Remove the upper intake manifold assembly, refer to 6A1 Engine Mechanical – V6.

Engine Management – V6 – Diagnostics

Page 6C1-2–45

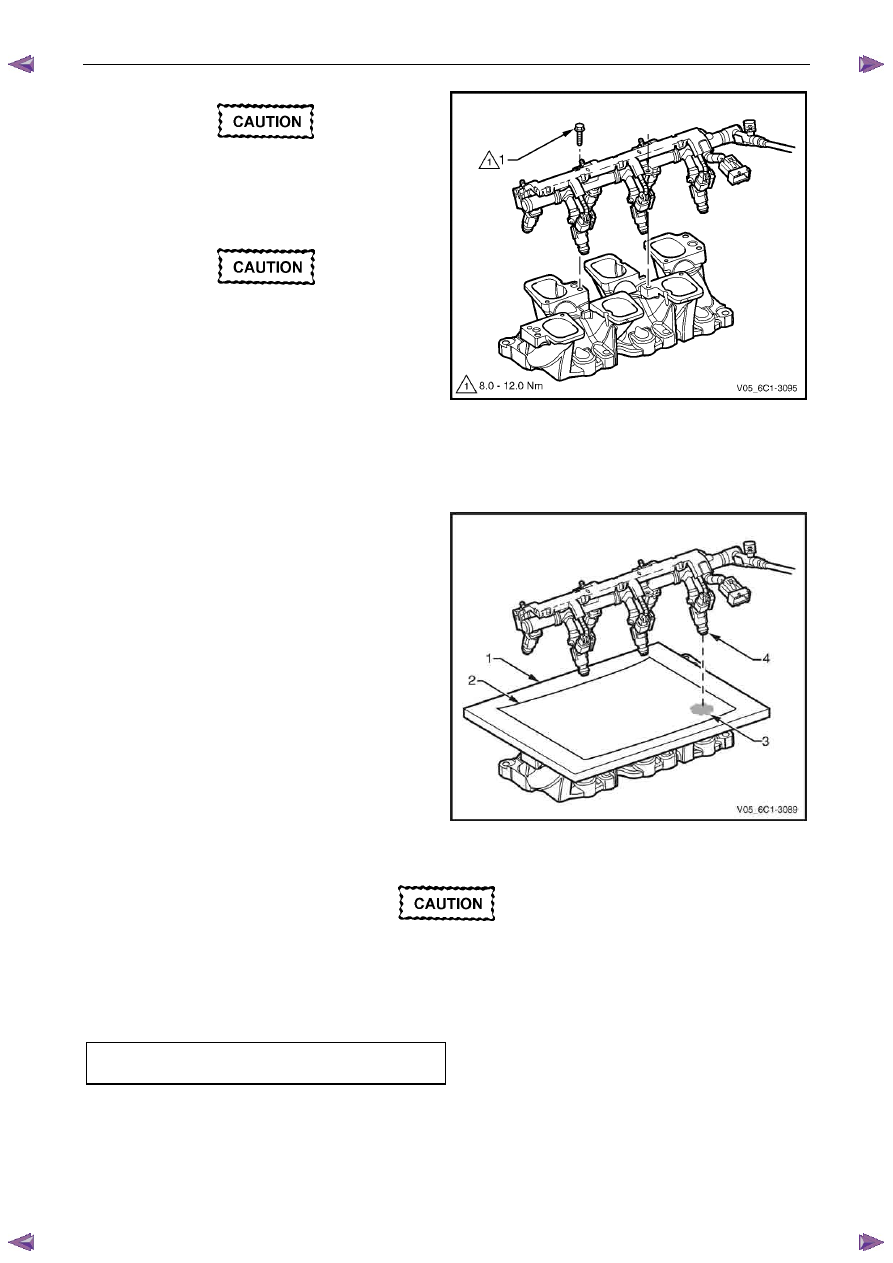

Clean around the area where the fuel

injectors enter the lower intake manifold.

3

Remove the bolt (1), three places, attaching the fuel

rail to the lower intake manifold.

Care must be taken when removing the fuel

rail and injector assembly to prevent damage

to the injector spray tips and injector harness

connector terminals.

Support the fuel rail and injector assembly

after removal.

4

Lift up and support the fuel rail and injector assembly.

N O T E

Do not disconnect the fuel feed hose from the

fuel rail.

Figure 6C1-2 – 16

5

Place a board (1) with a sheet of clean paper (2),

preferably white, onto the lower intake manifold.

6

Using Tech 2, enable the fuel pump to pressurise the

fuel system.

7

Whilst the fuel system is pressurised, check the

following:

•

Signs of fuel stains on the paper (3).

•

Signs of weeping at the fuel injector spray

tips (4).

8

If any of the above conditions are present, replace the

leaking fuel injector/s, refer to 2.13 Fuel Rail

Assembly, in 6C1-3 Engine Management – V6 –

Service Operations.

9

Carefully reinstall the fuel rail and injector assembly.

Figure 6C1-2 – 17

Ensure the fuel injectors are correctly seated

in the lower intake manifold, and the fuel rail

attaching brackets are correctly located prior

to tightening the attaching bolts.

10

Tighten the fuel rail bolts to the correct torque specification.

Fuel rail attaching bolt

torque specification . . . . . . . . ..8.0 – 12.0 Nm

11

Reinstall the upper intake manifold assembly, refer to 6A1 Engine Mechanical – V6.

12

Inspect the fuel rail and quick connect fitting for leaks, refer to 6C Fuel System – V6.

13

Road test the vehicle and check for correct operation.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст