Isuzu KB P190. Manual — part 831

Engine Management – V6 – Diagnostics

Page 6C1-2–46

6.5

Alcohol / Contaminants in Fuel

Diagnosis

Description

Water contamination in the fuel system may cause driveability conditions such as hesitation, stalling, no start, or

misfires in one or more cylinders. Water may collect near a single fuel injector at the lowest point in the fuel rail, and

cause a misfire in that cylinder. If the fuel system is contaminated with water, inspect the fuel system components for

rust, or deterioration.

Alcohol (e.g. Ethanol) concentrations more than 10% in the fuel can be detrimental to fuel system components. Alcohol

contamination may cause fuel system corrosion, deterioration of rubber components, and subsequent fuel filter

restriction. Fuel contaminated with alcohol may cause driveability conditions such as hesitation, lack of power, stalling,

or no start. Some types of alcohol are more detrimental to fuel system components than others.

Alcohol in Fuel Testing Procedure

N O T E

The procedures detailed are not intended to be

accurate but rather, indicative of a contamination

situation.

The fuel sample should be drawn from the bottom of the tank so that any water present in the tank will be detected. The

sample should be bright and clear. If alcohol contamination is suspected, then use the following procedure to test the

fuel quality.

•

Using a 100 ml graduated cylinder with 1 ml marks, fill the cylinder with fuel to the 90 ml mark.

•

Add 10 ml of water to bring the total fluid volume to 100 ml and install a stopper.

•

Shake the cylinder vigorously for 10 – 15 seconds.

•

Carefully loosen the stopper to release the pressure.

•

Re-install the stopper and shake the cylinder vigorously again for 10 – 15 seconds.

•

Put the cylinder on a level surface for approximately 5 minutes to allow adequate liquid separation.

If alcohol is present in the fuel, the volume of the lower layer, that now contains both alcohol and water, will be more

than 10 ml. For example, if the volume of the lower layer is increased to 15 ml, this indicates at least 5 percent alcohol in

the fuel. The actual amount of alcohol may be somewhat more because this procedure does not extract all of the

alcohol from the fuel. To obtain an accurate determination of the amount of alcohol contamination in a given fuel sample,

then professional analysis should be sought.

Particulate Contaminants in Fuel Testing Procedure

The fuel sample should be drawn from the bottom of the tank so that any contaminants present in the tank will be

detected. The sample should be bright and clear. If the sample appears cloudy or contaminated with water as indicated

by a water layer at the bottom of the sample, use the following procedure to diagnose the fuel.

•

Using an approved fuel container, draw approximately 0.5 litre of fuel.

•

Place the cylinder on a level surface for approximately 5 minutes to allow settling of the particulate contamination.

Particulate contamination will show up in various shapes and colours. Sand will typically be identified by a white or light

brown crystals. Rubber will appear as black and irregular particles. If particles are found, clean the entire fuel system

thoroughly. Refer to 6C Fuel System – V6.

6.6

Crankshaft Position (CKP) System

Variation Learn Procedure

Description

The crankshaft position system variation learn feature is carried out automatically on the HFV6 engine under decel with

fuel cut. The road speed and duration of the self-learn process varies with different vehicle equipment levels such as

transmission, final drive ratio etc.

The variation learn procedure cannot be over-written, nor can it be accessed with Tech 2.

Engine Management – V6 – Diagnostics

Page 6C1-2–47

6.7

Throttle Body Relearn

A throttle body relearn procedure is performed in one of two ways:

•

Engine Control Module initiated throttle body relearn, or

•

Tech 2 initiated throttle body relearn.

Engine Control Module Throttle Body Relearn

The engine control module (ECM) will automatically perform a throttle body relearn procedure if either of the following

conditions exist:

•

The battery has been disconnected, or

•

The ignition switch is in the ON position for greater than 29 seconds, and the following conditions are met:

−

Engine speed is less than 40 rpm,

−

Vehicle speed is 0 km/h,

−

Engine coolant temperature is 5 – 60°C,

−

Intake air temperature is 5 – 60°C,

−

Accelerator pedal position sensor angle is less than 14.9%, and

−

Ignition voltage is greater than 10 V.

Tech 2 Throttle Body Relearn

To perform a throttle body relearn using Tech 2, complete the following procedure:

N O T E

Tech 2 will not initiate a throttle body relearn if

the engine is running.

1

Connect Tech 2 to the data link connector (DLC) and turn the ignition on.

2

On Tech 2 select Engine / Programming / Throttle Body Relearn.

3

When Tech 2 displays ‘Do you really want to Reset?’, press the ‘Yes’ soft key.

4

When Tech 2 displays ‘Programming Completed’, and the electronic throttle control value displayed by Tech 2 is

‘11’, press the ‘Confirm’ soft key to return to the Tech 2 Programming screen.

5

The throttle body relearn is now complete.

6.8

Electronic Ignition (EI) System Diagnosis

Circuit Description

The engine control module (ECM) controls the ignition coils by pulsing the ignition control (IC) circuits, which triggers an

ignition coil and fires the spark plug. The ECM controls the sequencing and the timing of each ignition coil. The ignition

system consist of the following components:

•

The six ignition coils

•

The crankshaft position (CKP) sensor

•

The four camshaft position (CMP) sensors

•

The ECM

The ignition coils use the following circuits:

•

An IC circuit

•

An ignition 1 voltage circuit

•

Two ground circuits

Engine Management – V6 – Diagnostics

Page 6C1-2–48

Additional Information

•

Use the J 35616-B Connector Test Adapter Kit for any test that requires probing the ECM harness connector or a

component harness connector.

•

Inspect the ignition coils for aftermarket devices. An aftermarket device connected to the ignition coil circuits, may

cause a condition with the ignition coils.

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

To assist diagnosis, refer to 3 Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

4

The ignition coils for each bank are fused separately. If a fuse opens or the ignition 1 voltage circuit opens

between the fuse and the splice, all the ignition coils for one bank of the engine would be inoperative. If the ground

circuit opens at the engine block, the ignition coils would be inoperative for one bank of the engine.

5

This step tests for an open or a high resistance in the ignition 1 voltage circuit of the ignition coil. If the DMM does

not display near battery voltage there is an open or a high resistance in the circuit.

6

This step determines if the ground circuit is open. If the circuit is open, the ignition coils would be inoperative for

one bank of the engine.

7

This step determines if the ignition 1 voltage circuit is shorted to ground. If the fuse is open, the ignition coils would

be inoperative for one bank of the engine.

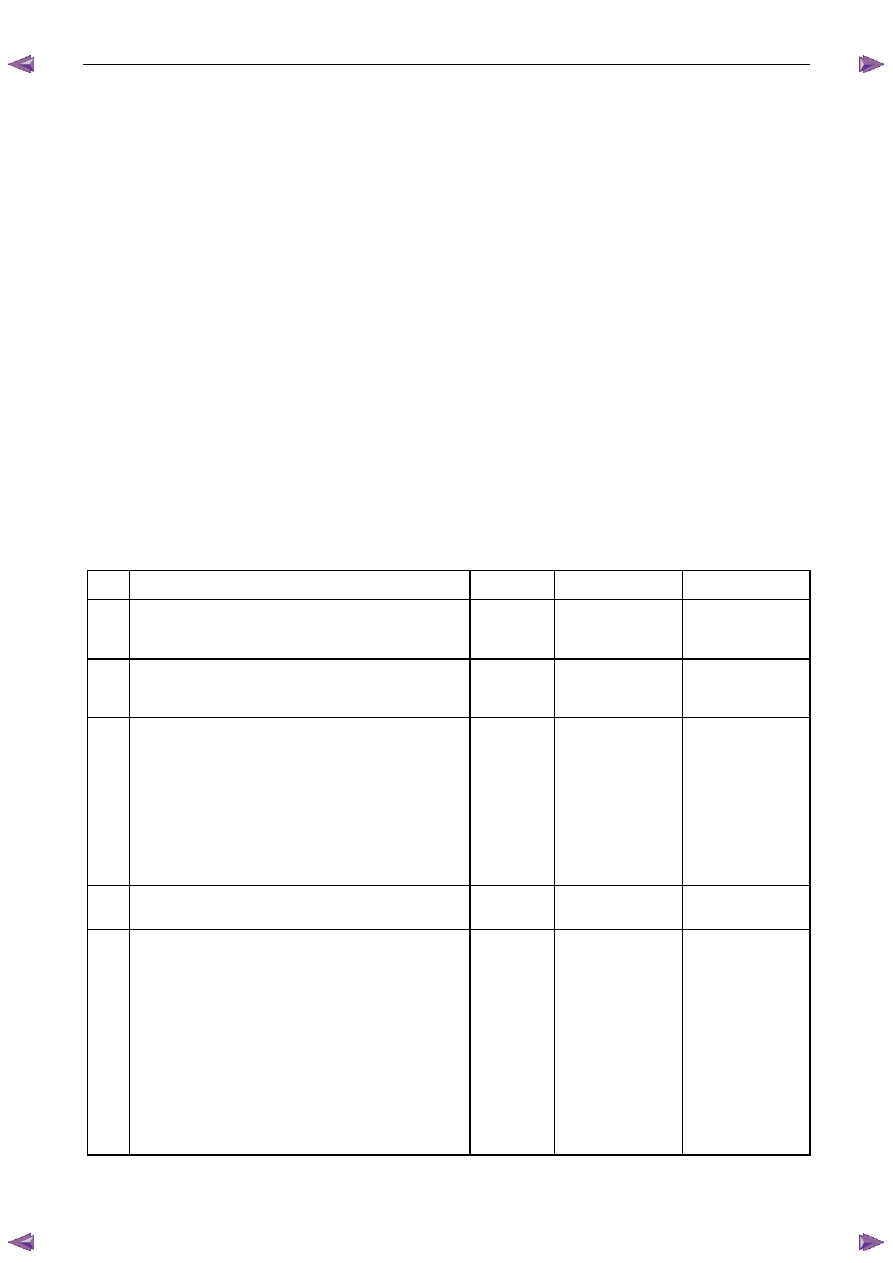

Diagnostic Table

Step Action Value(s)

Yes

No

1

Has the Diagnostic System Check been performed?

—

Go to Step 2

Refer to

4.4 Diagnostic

System Check

2

Were you sent here from DTC P0300 or P0301-P0306?

—

Go to Step 3

Go to DTC P0300 or

DTC P0301 –

P0306

3

1

Start the engine.

2

Allow the engine to reach operating temperature.

3

Operate the engine at 2,000 rpm.

4

Monitor all of the Misfire Current Counters with a

scan tool. There are a total of 6 counters,

1 counter per cylinder.

Are any of the Misfire Current Counters incrementing?

—

Go to Step 4

Go to

5.2 Intermittent

Fault Conditions

4

Are all the misfire counters incrementing for one bank

of the engine?

—

Go to Step 7

Go to Step 5

5

1 Ignition

OFF.

2

Disconnect the appropriate ignition coil.

3

Ignition ON, engine OFF.

4

Connect a test lamp between the battery voltage

circuit of the ignition coil and a good ground.

5

Measure the voltage between the probe of the

test lamp and a good ground with a DMM. Refer

to 8A Electrical - Body and Chassis for the

procedure to measure voltage drop.

Is the voltage at the specified value?

B+

Go to Step 6

Go to Step 9

Engine Management – V6 – Diagnostics

Page 6C1-2–49

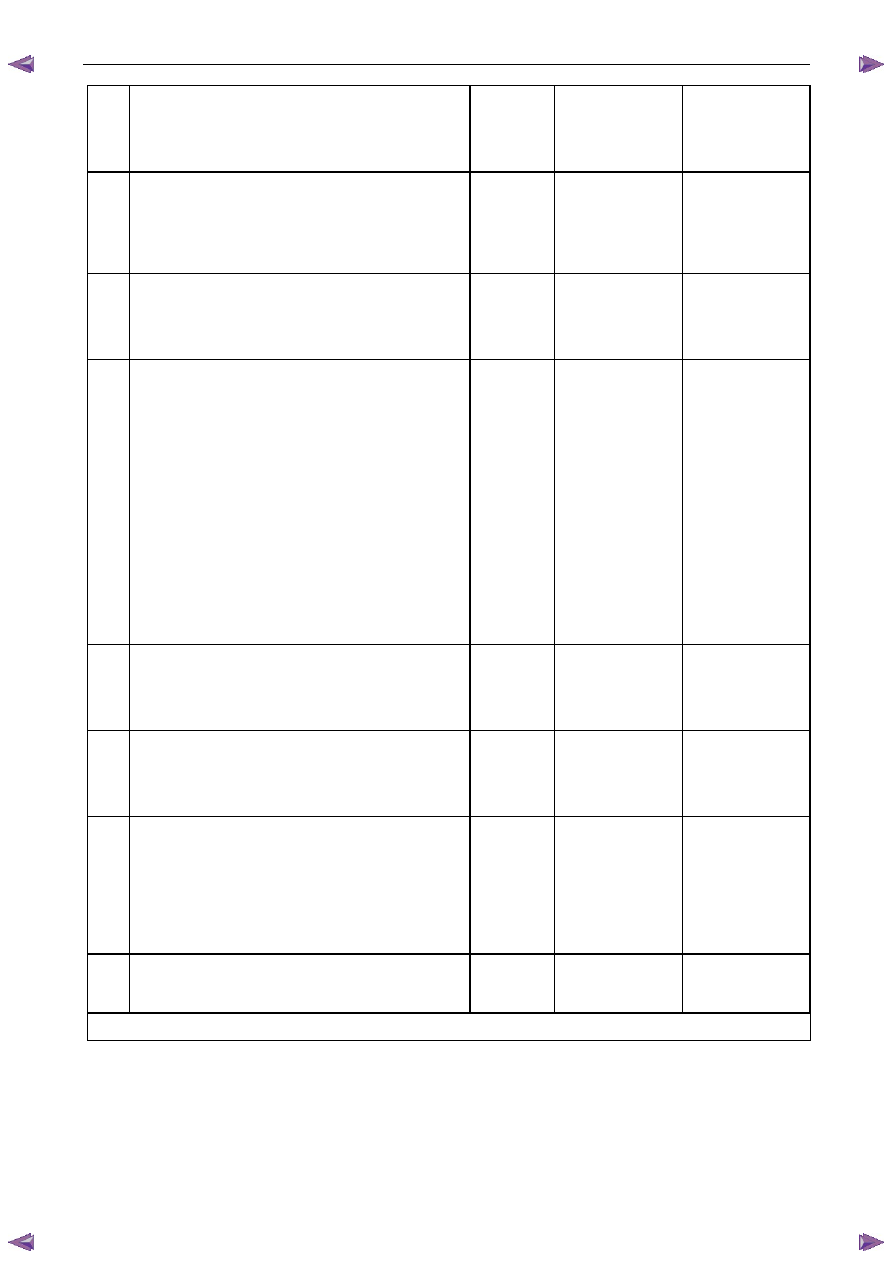

6

1

Connect the test lamp between the battery

voltage circuit of the ignition coil and to each

ground circuit of the ignition coil.

Does the test lamp illuminate at each ground circuit?

—

Go to Step 8

Go to Step 10

7

1

Test the battery voltage circuit for an open or high

resistance at the splice of the affected bank of

ignition coils. Refer to 8A Electrical - Body and

Chassis for circuit testing procedures.

Did you find and correct the condition?

—

Go to Step 12

Go to Step 10

8

1

Test for an intermittent and for a poor connection

at the ignition coil. Refer to 8A Electrical - Body

and Chassis for circuit testing procedures.

Did you find and correct the condition?

—

Go to Step 12

Go to Step 11

9

N O T E

The battery voltage circuit is shared with

other components. Disconnecting a

component on the shared battery voltage

circuit may isolate a shorted component.

Review the electrical schematic and

diagnose the shared circuits and

components.

1

Repair a short to ground, an open or high

resistance in the ignition 1 voltage circuit. Refer to

Refer to 8A Electrical - Body and Chassis for

wiring repair procedures.

2

Replace the fuse as necessary.

Did you complete the repair?

—

Go to Step 12

—

10

1

Repair the open or high resistance in the ground

circuit. Refer to 8A Electrical - Body and Chassis

for wiring repair procedures.

Did you complete the repair?

—

Go to Step 12

—

11

1

Replace the ignition coil. Refer to 2.15 Ignition

Coils, in 6C1-3 Engine Management – V6 –

Service Operations.

Did you complete the replacement?

—

Go to Step 12

—

12

1

Connect all disconnected components.

2

Use Tech 2 to clear the DTC/s.

3

Start the engine.

4

Observe the Capture Info with Tech 2.

Do any of the misfire counters increment?

—

Go to Step 2

Go to Step 13

13

1

Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

—

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст