Isuzu KB P190. Manual — part 1067

CONSTRUCTION AND FUNCTION 7A1-29

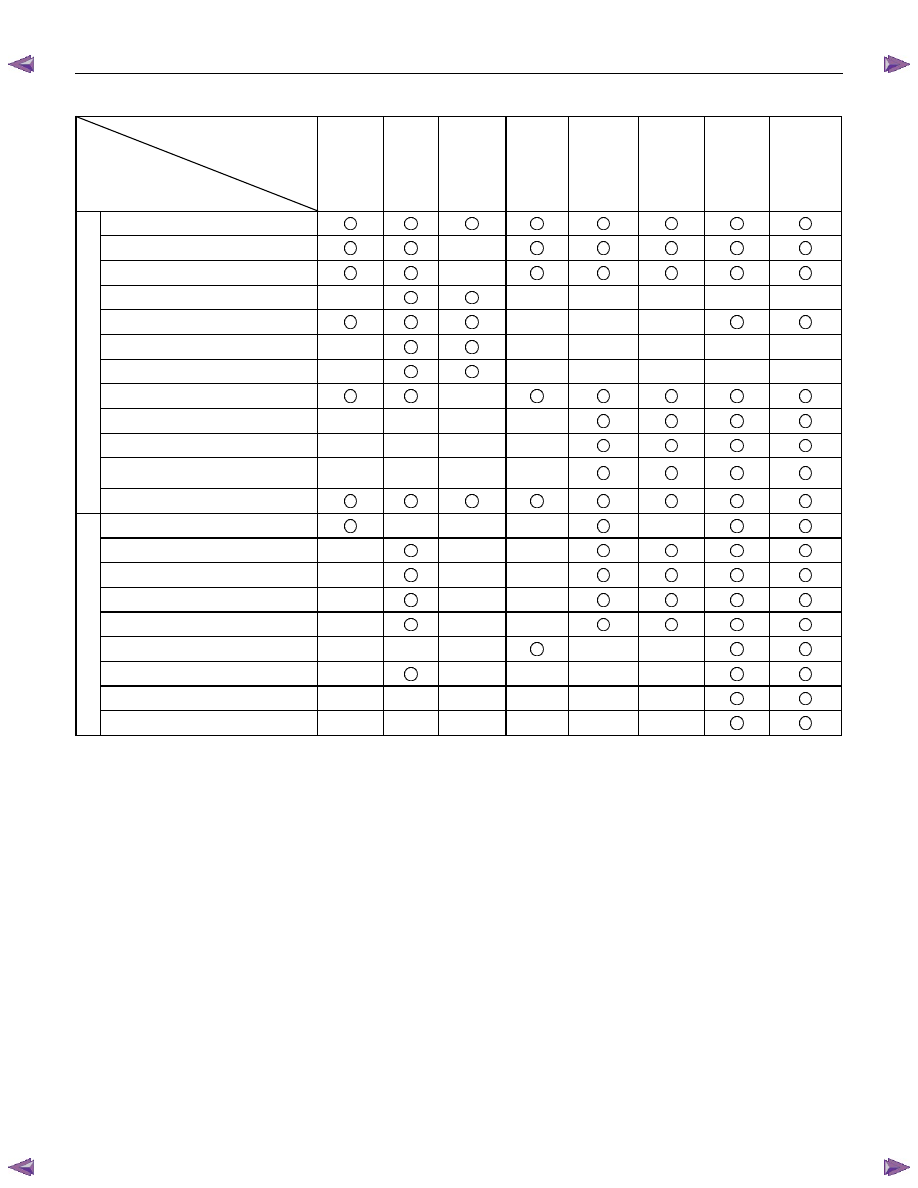

CONTROL ITEM, INPUT AND OUTPUT

Control item

Item

Line

pressure

control

Gear

shift

control

Shift

pattern

selection

Lock-up

control

Direct

electronic

shift

control

(DECS)

Learning

control

Fail-safe

function

Self-

diagnosis

function

Speed sensor

Turbine sensor

Engine speed sensor

Brake switch

Inhibitor switch

Mode select switch

4L switch (4WD Only)

ATF thermo sensor

High clutch oil pressure switch

2-4 brake oil pressure switch

Low & Reverse brake oil pressure

switch

Input

Accelerator Pedal position sensor

Line pressure solenoid

Low clutch solenoid

High clutch solenoid

2-4 brake solenoid

Low & Reverse brake solenoid

Lock-up solenoid

Shift pattern indicator lamp

ATF temperature indicator lamp

O

u

tput

Check trans indicator lamp

7A1-30 CONSTRUCTION AND FUNCTION

LINE PRESSURE CONTROL

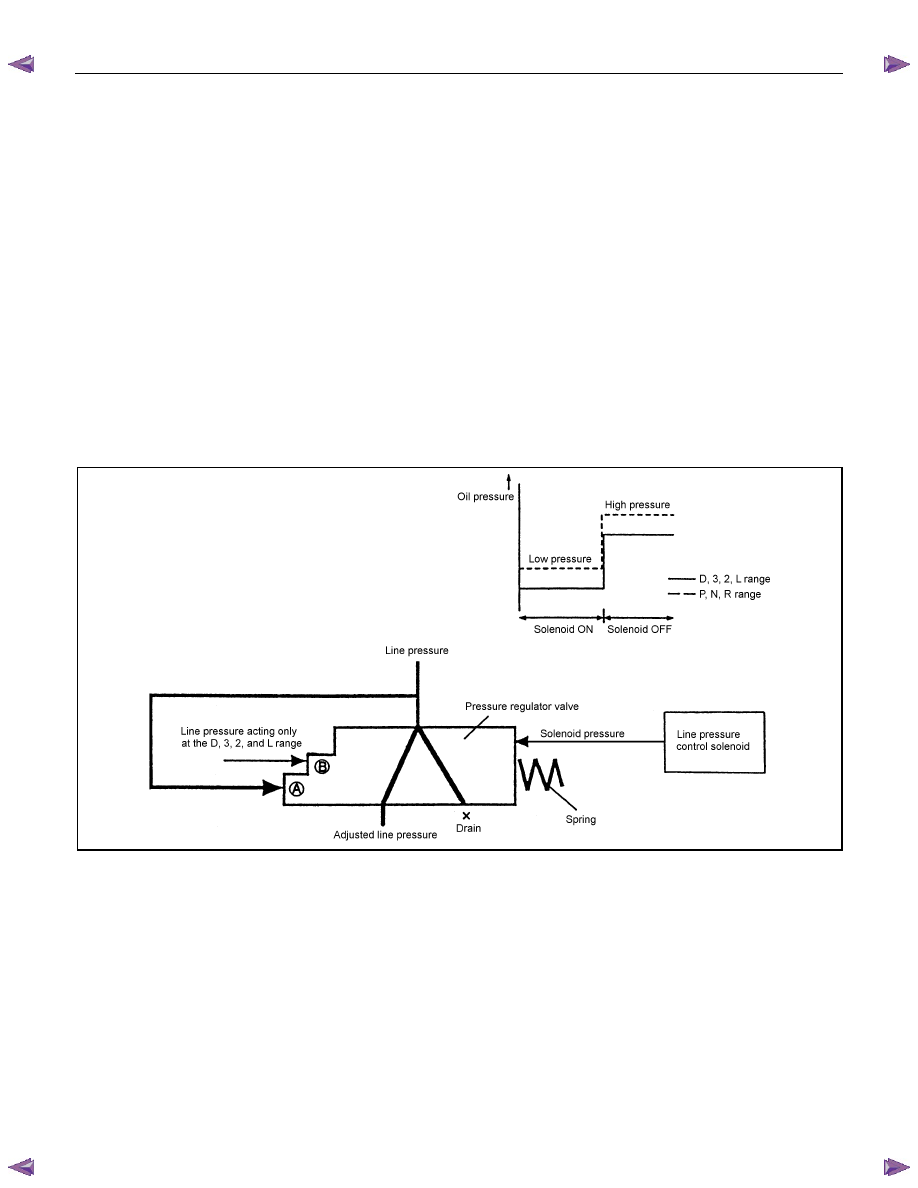

•

The TCM drives the ON/OFF type line pressure solenoid based on the APP opening, vehicle speed,

turbine rotational speed, ATF temperature and shift position signal. The ON/OFF type line pressure

solenoid is actuated, and switches the line pressure to a high or low pressure number appropriate to the

situation.

•

The line pressure generated by the oil pump acts on the point A of the pressure regulator valve. When

the pressure control solenoid is turned ON by the signal from the TCM, the solenoid pressure does not

act. The line pressure is adjusted to match the spring force acting on the right side of the pressure

regulator valve.

•

When the pressure control solenoid is turned OFF, the solenoid pressure acts so that the line pressure is

adjusted to match the spring force acting on the right side of the pressure regulator valve.

•

As a result, the line pressure is adjusted to be low when the pressure control solenoid is ON and to be

high when the pressure control solenoid is OFF.

•

In position D, 3, 2 and L, the line pressure through the oil pressure circuit acts onto the point B of the

pressure regulator valve. The pressure regulator valve moves so as to increase the pressure to be

drained, so that the line pressure is adjusted to be lower than the P, N, and R position by the difference of

area at the point B.

Figure 50. Line Pressure Control

LOCK-UP CONTROL

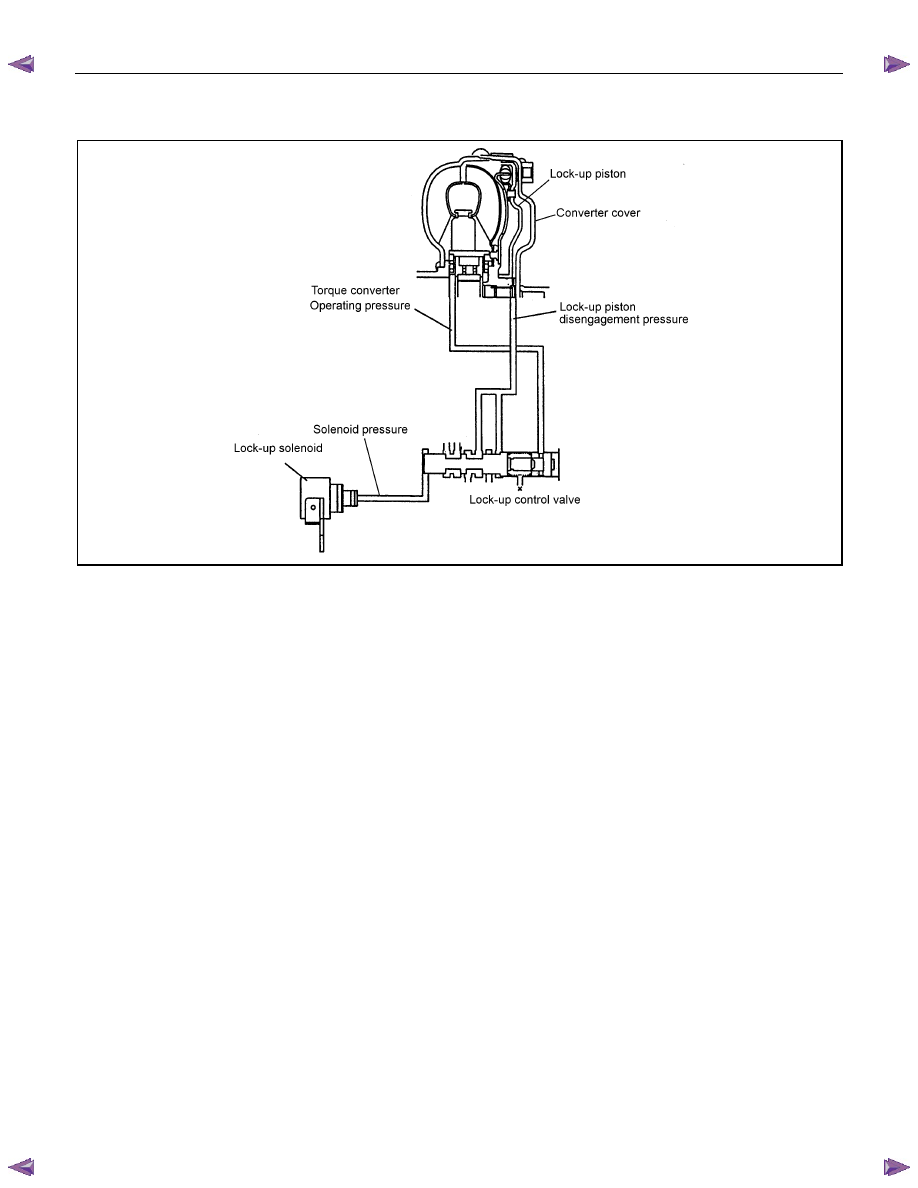

•

The lock-up solenoid adjusts the pressure and controls the lock-up based on the pre-set lock-up point,

according to the vehicle speed, APP opening, engine rotations, turbine rotations and ATF temperature

input signal, based on the signal from the TCM.

•

Smooth lock-up control is employed to engage or disengage the clutch smoothly at the time of lock-up on

or off.

•

When the oil temperature is low (20

°

C or less), lock-up is disengaged even though the vehicle is at the

lock-up speed.

•

The lock-up is disengaged also when the APP is closed.

•

When the TCM determines the lock-up engagement, the DUTY ratio to supply power to the lock-up

solenoid is gradually increased (5% to 95%) and the oil between the lock-up piston and converter cover is

gradually drained.

CONSTRUCTION AND FUNCTION 7A1-31

As a result, the lock-up piston is fitted slowly to the converter cover under pressure securing smooth lock-

up engagement.

Figure 51. Lock-up Control

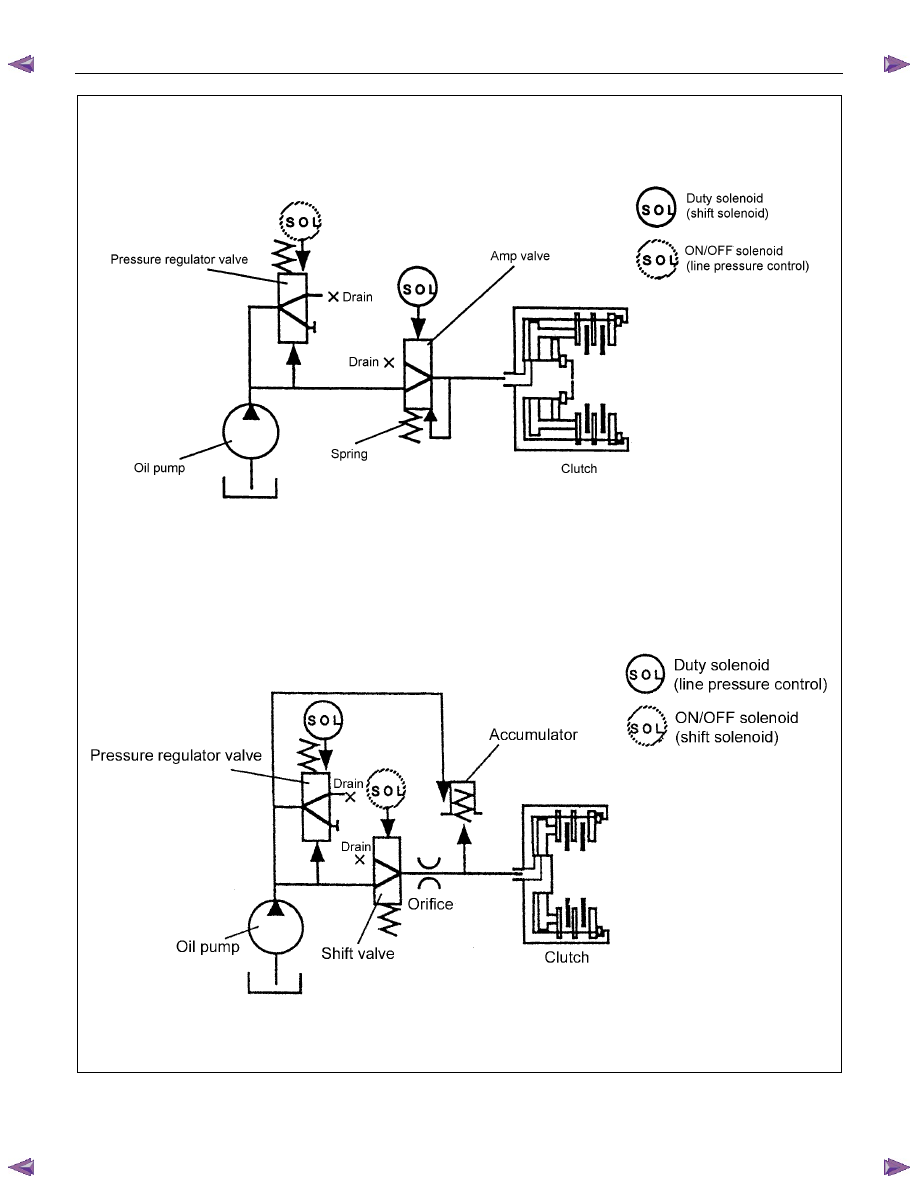

DIRECT ELECTRIC SHIFT CONTROL (DESC)

Feature

•

Based on each switch signal (low & reverse brake pressure, 2-4 brake pressure & high clutch pressure)

and each sensor signal (turbine sensor, speed sensor, engine speed signal & APP position signal), the

duty cycle type solenoid adjusts the clutch pressure to match the engine load and vehicle travel

conditions. Controlling the engagement and disengagement of the clutch and brake pressure is directly

and accurately controlled via TCM, which is different to the previous accumulator type.

Operation

•

Instead of the previous system (on/off type of shift solenoid and shift valve), the combination of the duty

cycle type solenoid and the amplifier (Amp) valve are used to adjust the clutch pressure to match the

engine load and vehicle travel conditions, based on the signal from the TCM. Also, the pressure switch

provided in the oil passage of the control valve transmits the oil pressure condition (at that time) to TCM,

enabling the engagement and disengagement control of the clutch and brake to be directly and finely

carried out.

•

When the gear is shifted from the 2nd to 3rd, 3rd to 4th (O/D), 4th (O/D) to 3rd and 3rd to 2nd, the clutch

pressures on the engagement side and disengagement side are simultaneously controlled.

As a result, engine racing or clutch drag is prevented which enables a smooth and quick shift response.

7A1-32 CONSTRUCTION AND FUNCTION

Direct Electric Shift Control

Previous Model

Figure 52. Direct Electric Shift Control (DESC)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст