Isuzu KB P190. Manual — part 812

Engine Management – V6 – General Information

Page 6C1-1–6

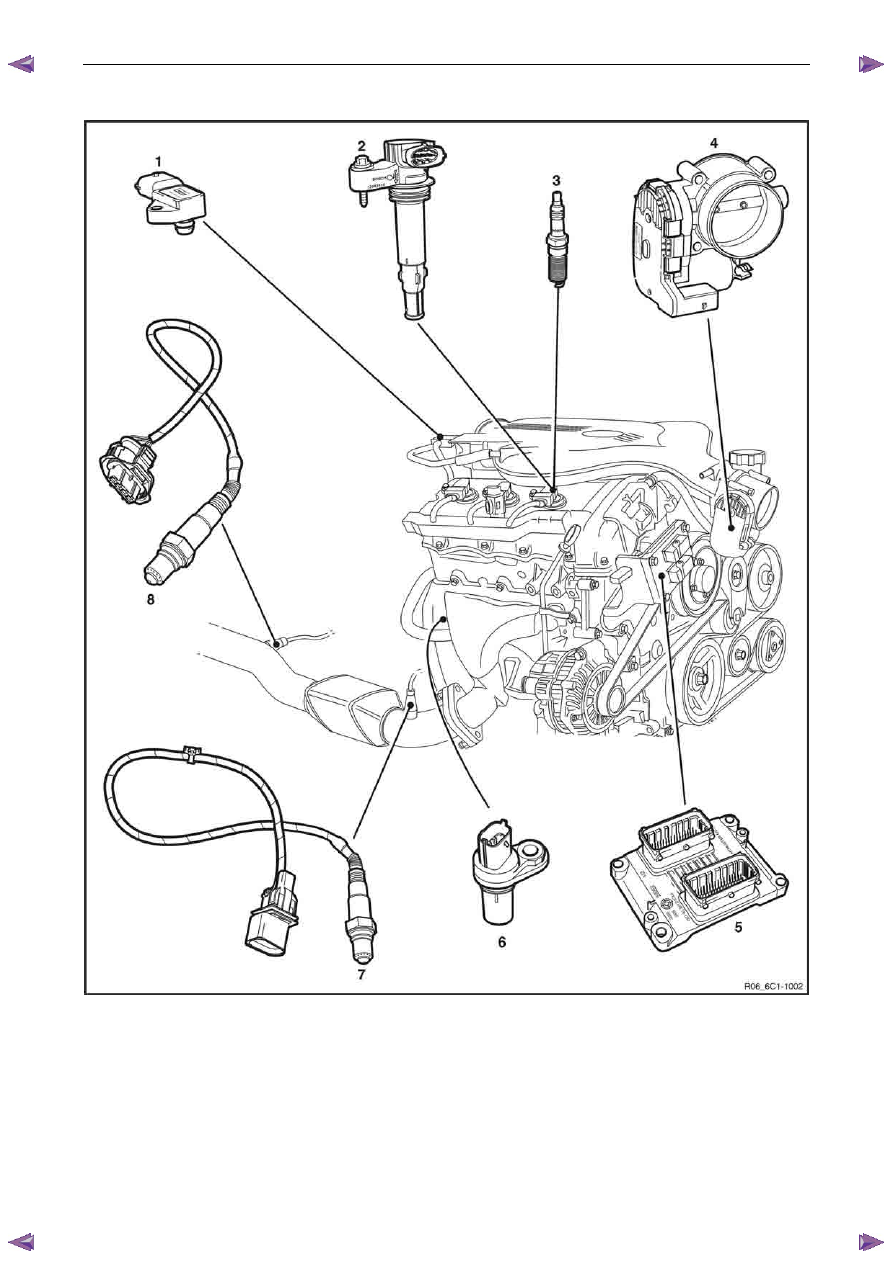

2.3 Engine

Figure 6C1-1 – 3

Legend

1

Barometric Pressure (BARO) Sensor

2

Ignition Coil Assembly (six places)

3

Spark Plug (six places)

4

Throttle Body Assembly

5

Engine Control Module (ECM)

6

Crankshaft Position (CKP) Sensor

7

Heated Oxygen Sensor (HO2S), Pre-Catalyst (two places)

8

Heated Oxygen Sensor (HO2S), Post-Catalyst (two places)

Engine Management – V6 – General Information

Page 6C1-1–7

Figure 6C1-1 – 4

Legend

1

Camshaft Position (CMP) Sensor

2

Fuel Rail Assembly

3

Fuel Injector (six places)

4

Evaporative Canister Purge (EVAP) Valve

5

Engine Coolant Temperature (ECT) Sensor

6

Engine Oil Level / Temperature Sensor

7

Knock (KS) Sensor (two places)

8

Engine Oil Pressure Sensor

Engine Management – V6 – General Information

Page 6C1-1–8

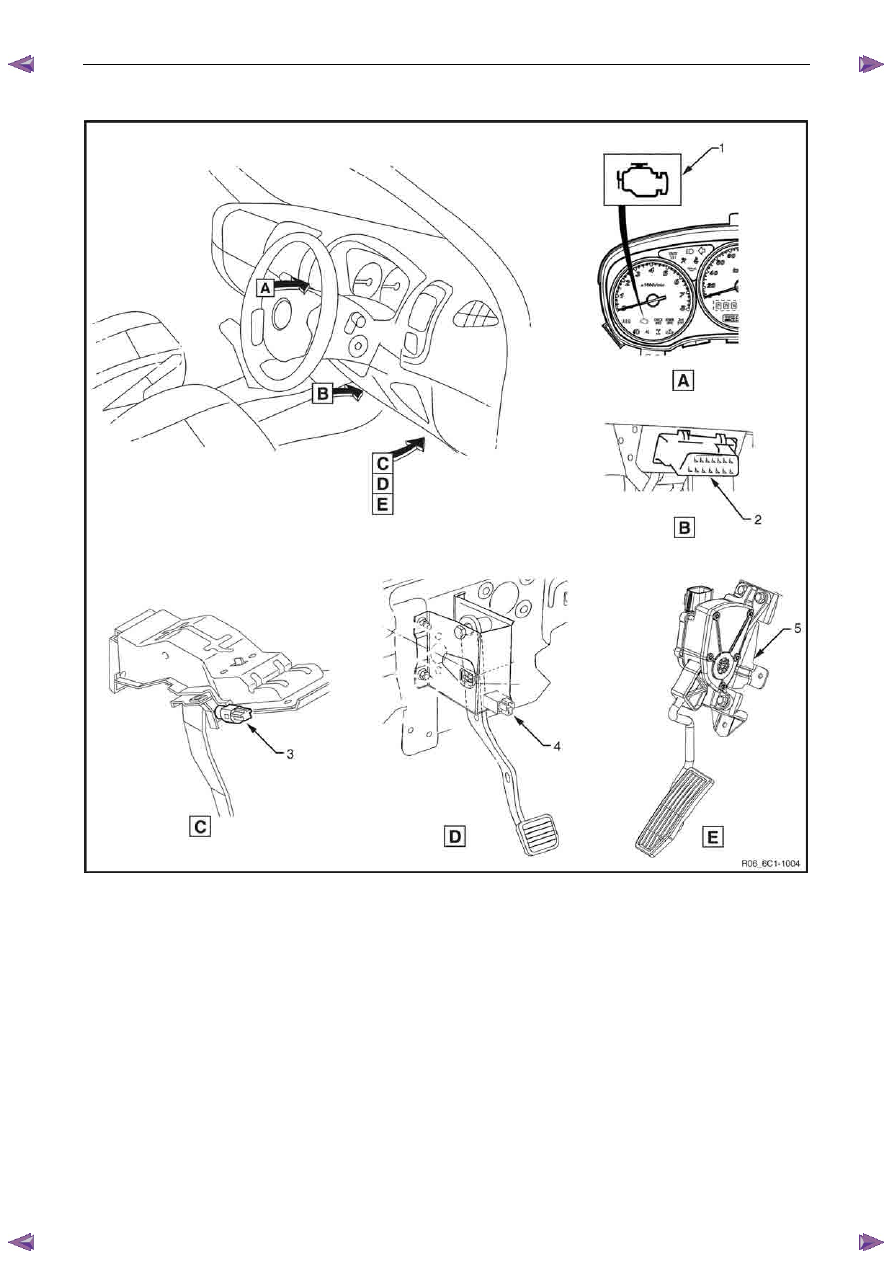

2.4 Interior

Figure 6C1-1 – 5

Legend

1

Malfunction Indicator Lamp (MIL)

2

Data Link Connector (DLC)

3

Brake Pedal Switch Assembly

4

Clutch Pedal Switch Assembly

5

Accelerator Pedal Assembly

Engine Management – V6 – General Information

Page 6C1-1–9

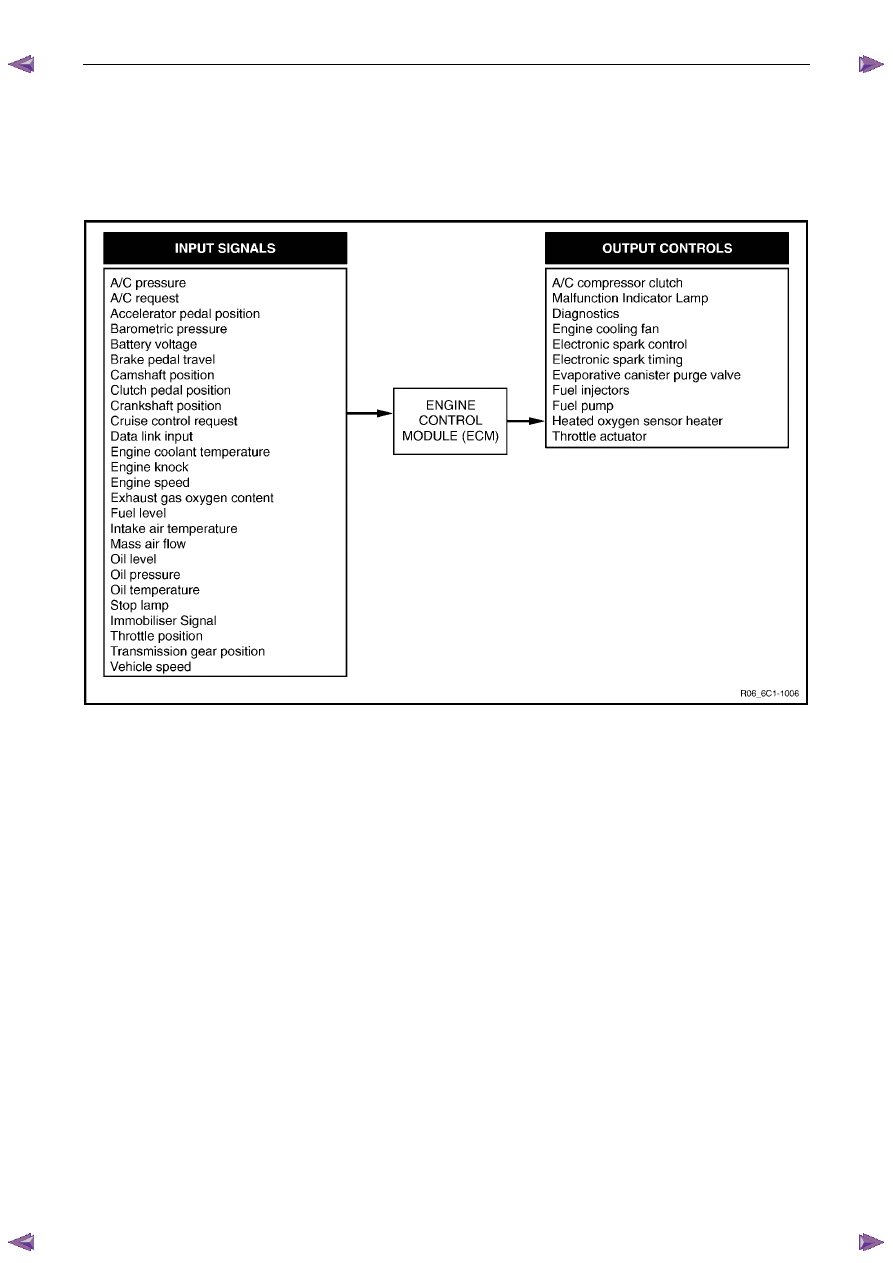

3 System

Operation

The engine control module (ECM) is the control centre of the V6 engine management system. The ECM constantly

monitors and evaluates inputs from various sensors and switches. Based on these inputs, the ECM controls the

operation of the engine management system. Refer to Figure 6C1-1 – 6 for the illustration of the inputs and outputs of

the ECM.

Figure 6C1-1 – 6

3.1

Fuel Delivery System

Fuel System Pressure

When the ignition switch is turned on, the ECM energises the fuel pump circuit and the fuel pump runs and builds up

pressure in the fuel system. The fuel pump will continue to operate if the engine is started or as long as the engine is

cranking or running and the ECM detects crankshaft position (CKP) sensor signal pulses. If the CKP sensor signal

pulses stop, the ECM de-energises the fuel pump circuit within two seconds, which stops the fuel pump operation.

The vehicle is fitted with a modular fuel pump and sender assembly that provides delivery of fuel from the fuel tank and

information on the fuel level. The fuel delivery system is a single line, on-demand design. With the fuel pressure regulator

incorporated into the modular fuel pump and sender assembly, the need for a return pipe from the engine is eliminated.

The electric fuel pump contained in the modular fuel pump and sender assembly provides fuel at a pressure greater than

the regulated pressure which is supplied to the fuel rail. The fuel is then distributed through the fuel rail to six injectors

located directly above each cylinder’s two intake valves.

Having a single line fuel supply system reduces the internal temperature of the fuel tank by not returning hot fuel from the

engine. In reducing the internal temperature of the fuel tank, lower evaporative emissions are achieved.

Unleaded fuel must be used to ensure correct emission parameters and engine operation. Leaded fuel damages the

emission control system and use of leaded fuel can result in loss of emission warranty. Using unleaded fuel will also

minimise any spark plug fouling and extend engine oil life.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст