Isuzu KB P190. Manual — part 554

6E–46

ENGINE DRIVEABILITY AND EMISSIONS

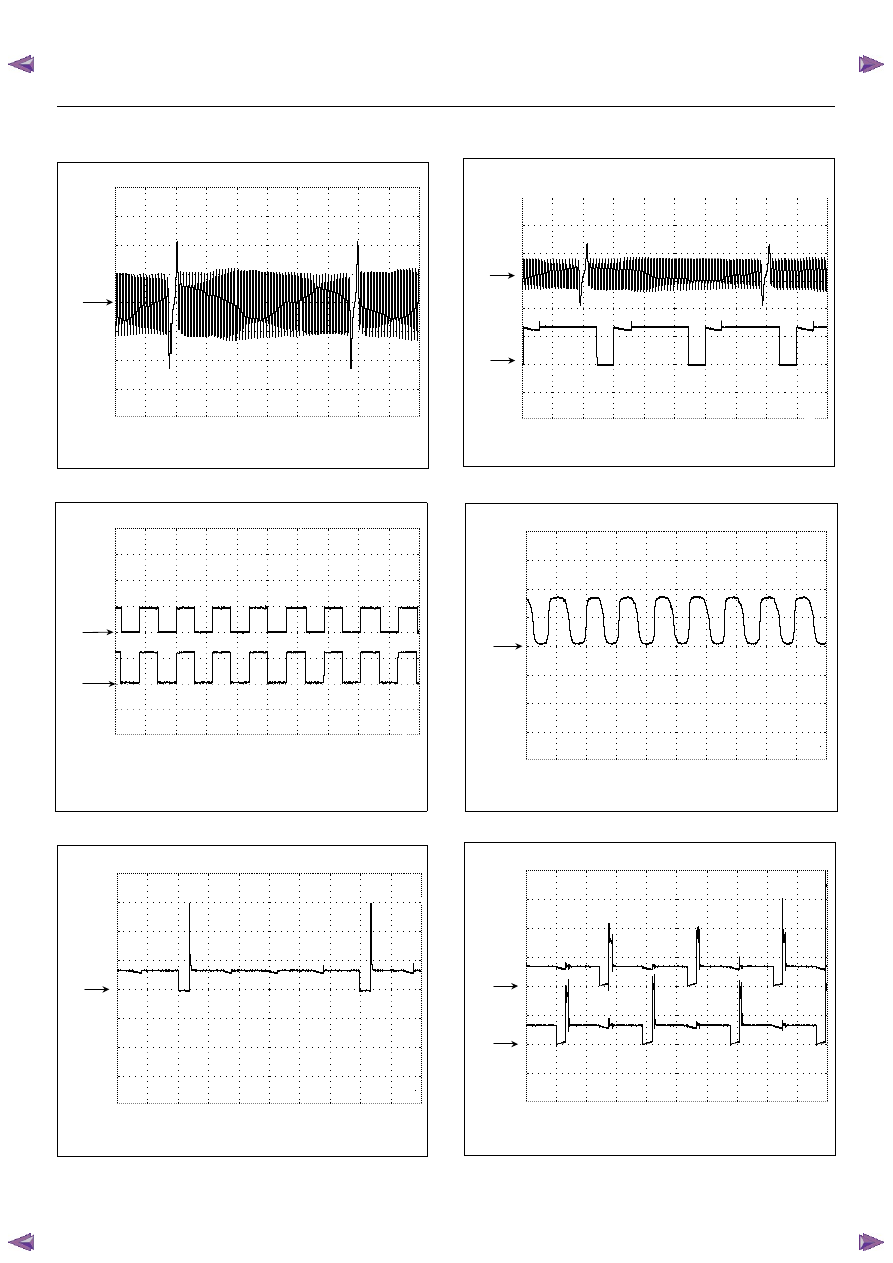

Reference Wave Form

Crankshaft Position (CKP) Sensor Reference Wave Form

0V

Measurement Terminal: J1-21(+) J1-6(-)

Measurement Scale: 10V/div 5ms/div

Measurement Condition: Approximately 2000rpm

Ve h ic le S p e ed S e n so r (V S S ) R e fe re n c e W a ve F o rm

C H 1

0 V

C H 2

0 V

M easurem ent Term inal: CH1: ECM J2-23(+) / CH2: VSS 3(+) GND(-)

Measurem ent Scale: CH1: 10V/div / CH2: 10V/div 50m s/div

Measurem ent Condition: Approxim ately 20km /h

Note: The vehicle is w ithout imm obilizer system,

CH1 signal is same as CH2.

Injector Control Signal Reference Wave Form

0V

Measurement Terminal: J1-9(+) (No.1 Cylinder) GND(-)

Measurement Scale: 20V/div 5ms/div

Measurement Condition: Approximately 2000rpm

Crankshaft Position (CKP) Sensor & Tacho Output Signal

Reference W ave Form

CH1

0V

CH2

0V

Measurement Terminal: CH1: J1-21(+) / CH2: J2-25(+) GND(-)

Measurem ent Scale: CH1: 2V/div / CH2: 10V/div 5m s/div

Measurem ent Condition: Approxim ately 2000rpm

Heated Oxygen Sensor (HO2S) Reference Wave Form

0V

Measurement Terminal: J2-21(+) GND(-)

Measurement Scale: 500mV/div 500ms/div

Measurement Condition: Approximately 2000rpm in Closed Loop

Ignition Coil Control Signal Reference Wave Form

CH1

0V

CH2

0V

Measurement Terminal: CH1: J1-19(+) / CH2: J1-18(+) GND(-)

Measurement Scale: CH1: 20V/div / CH2: 20V/div 10ms

Measurement Condition: Approximately 2000rpm

ENGINE DRIVEABILITY AND EMISSIONS

6E–47

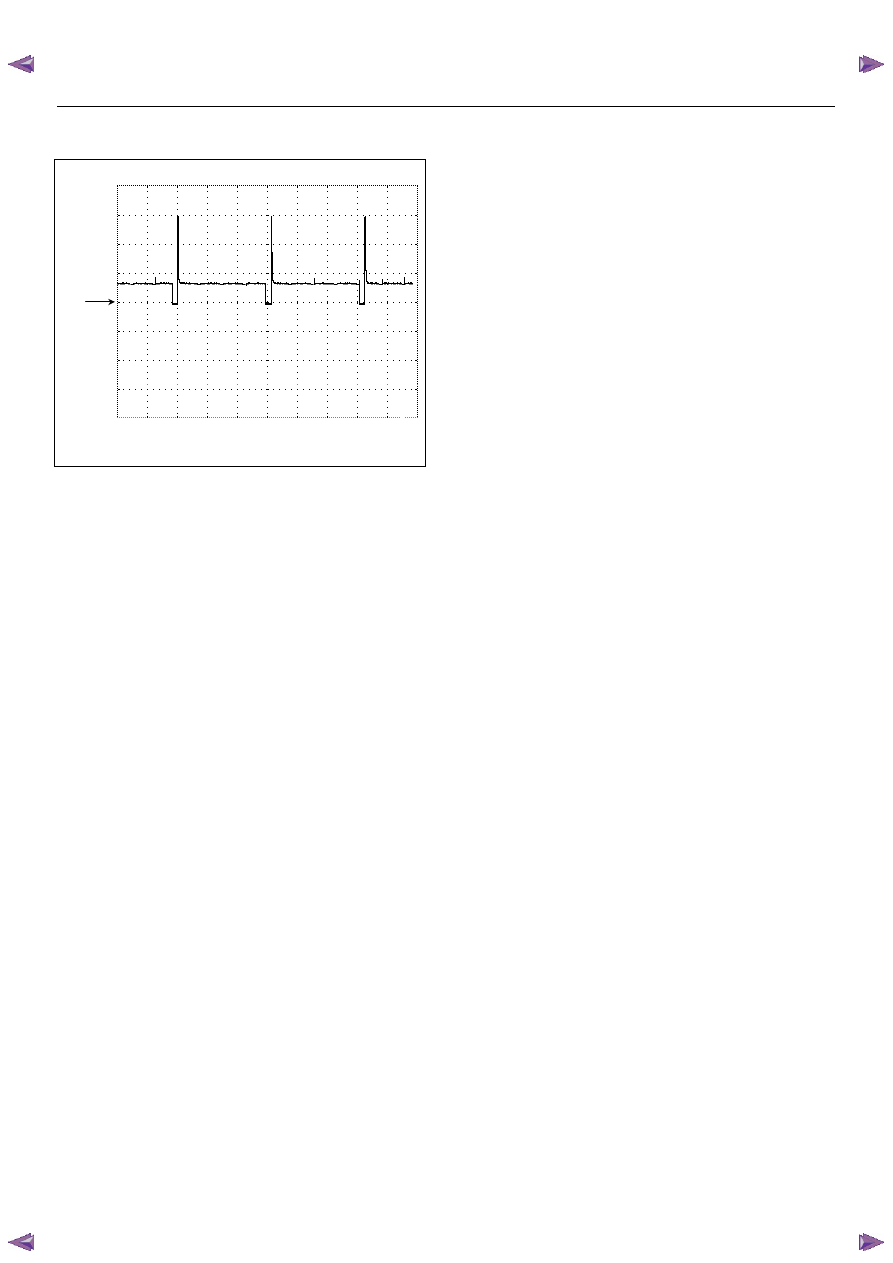

EVAP Canister Purge Solenoid Reference Wave Form

0V

Measurement Terminal: J1-5(+) GND(-)

Measurement Scale: 20V/div 20ms/div

Frequency: Approximately 16Hz

6E–48

ENGINE DRIVEABILITY AND EMISSIONS

GENERAL DESCRIPTION FOR ECM AND

SENSORS

Engine Control Module (ECM)

The engine control module (ECM) is located on the

intake manifold. The ECM controls the following.

• Fuel metering system

• Ignition timing

• On-board diagnostics for electrical functions.

The ECM constantly observes the information from vari-

ous sensors. The ECM controls the systems that affect

vehicle performance. And it performs the diagnostic

function of the system.

The function can recognize operational problems, and

warn to the driver through the check engine lamp, and

store diagnostic trouble code (DTC). DTCs identify the

problem areas to aid the technician in marking repairs.

The input / output devices in the ECM include analog to

digital converts, signal buffers, counters and drivers.

The ECM controls most components with electronic

switches which complete a ground circuit when turned

on.

Inputs (Operating condition read):

• Battery voltage

• Electrical ignition

• Exhaust oxygen content

• Intake manifold pressure

• Intake air temperature

• Engine coolant temperature

• Crankshaft position

• Knock signal

• Throttle position

• Vehicle speed

• Power steering pressure

• Air conditioning request on or off

Outputs (Systems controlled):

• Ignition control

• Fuel control

• Idle air control

• Fuel pump

• EVAP canister purge

• Air conditioning

• Diagnostics functions

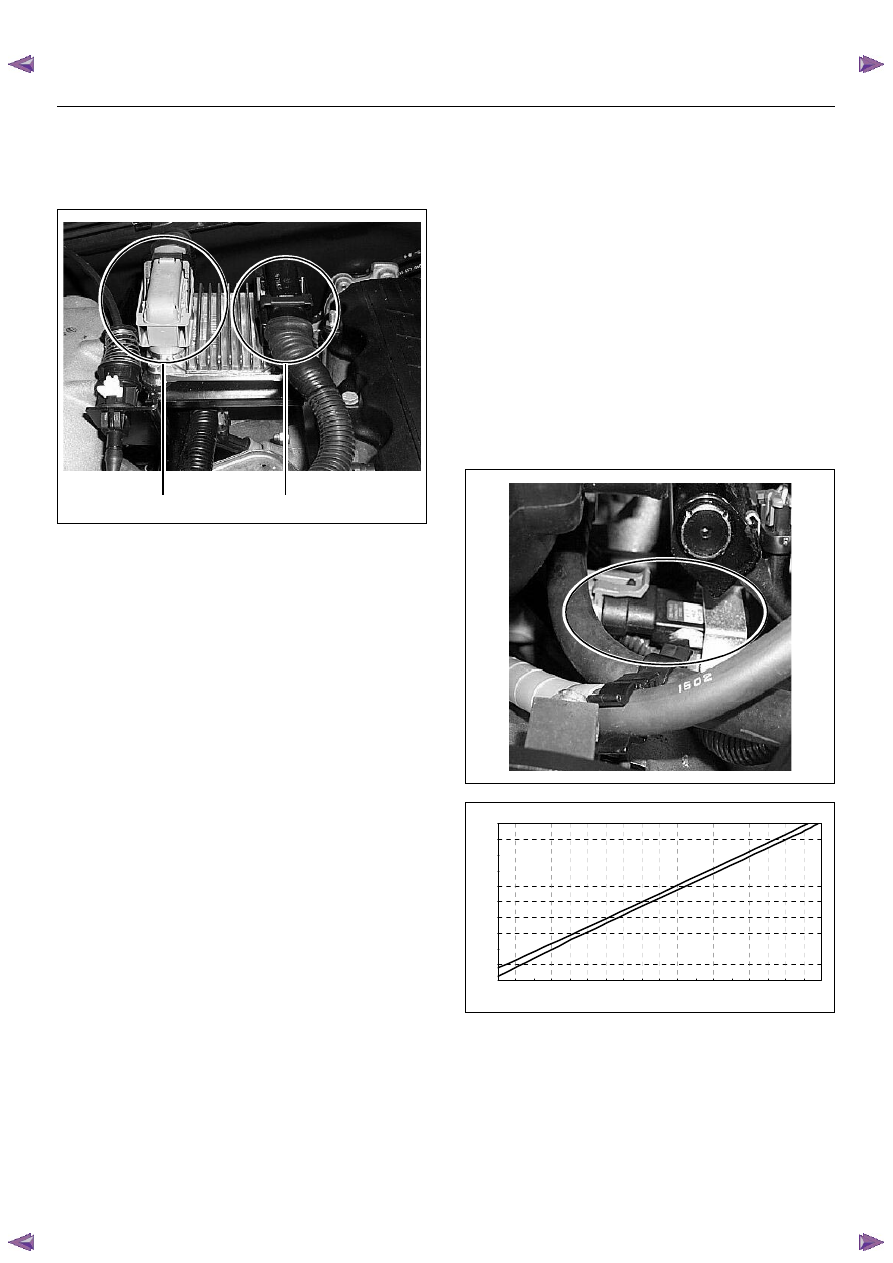

Manifold Absolute Pressure (MAP) Sensor

The MAP sensor is a strain gage. A pressure strains the

resistance on the silicon base. At that time the

resistance value changes. And it changes voltage. In

other words it measures a pressure value. It is installed

to the intake manifold. Output voltage of the MAP

sensor is low as pressure is low.

(1) J1 Port

(2) J2 Port

1

2

C harac t eris t ic of MAP Sens or -R ef erenc e-

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

Mani fol d A bs ol ute P res s ure (K P a) (T ec h2 Readi ng)

O

ut

put

Vol

tage (

V

)

ENGINE DRIVEABILITY AND EMISSIONS

6E–49

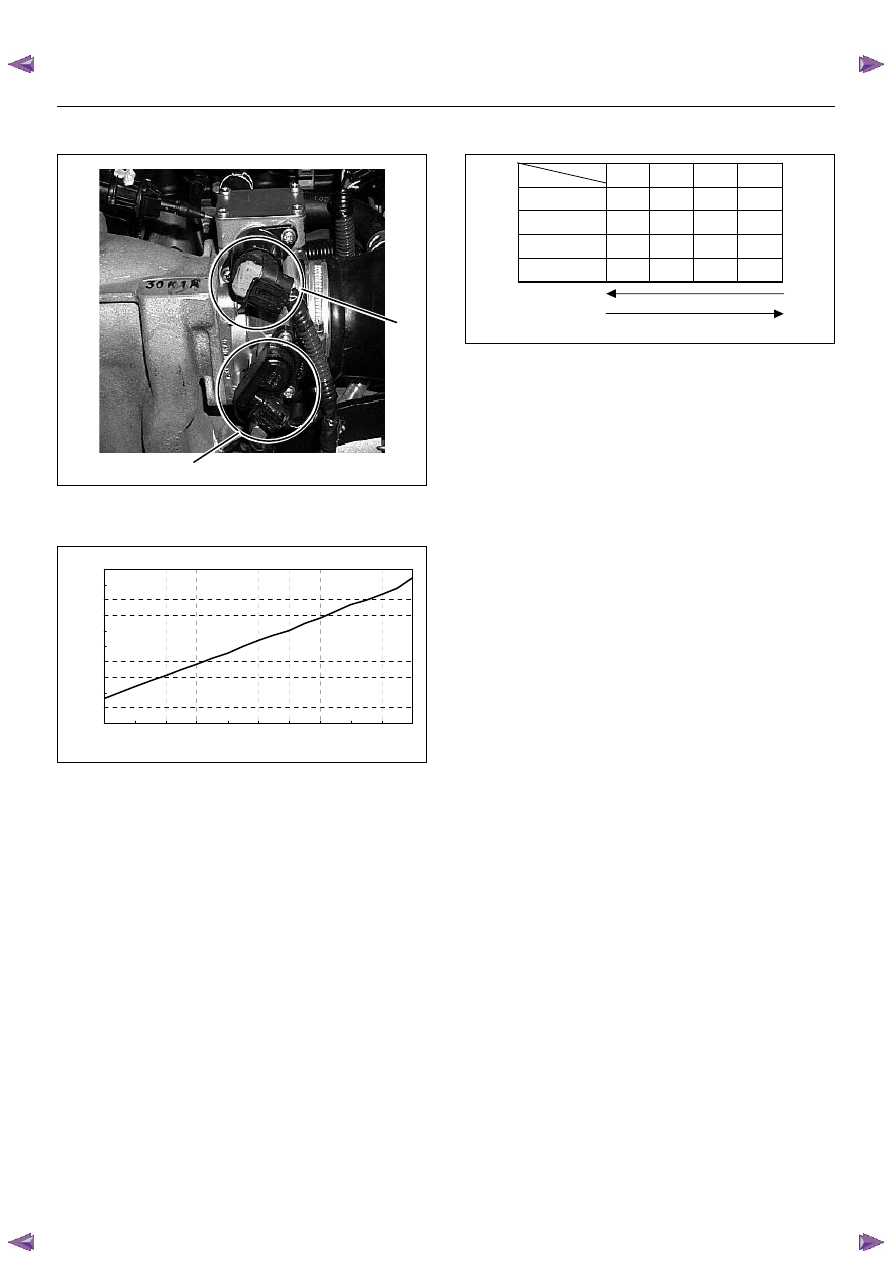

Throttle Position Sensor (TPS)

The TPS is a potentiometer connected to throttle shaft

on the throttle body.

The engine control module (ECM) monitors the voltage

on the signal line and calculates throttle position. As the

throttle valve angle is changed when accelerator pedal

moved. The TPS signal also changed at a moved

throttle valve. As the throttle valve opens, the output

increases so that the output voltage should be high.

The throttle body has a throttle plate to control the

amount of the air delivered to the engine.

Engine coolant is directed through a coolant cavity in

the throttle body to warm the throttle valve and to

prevent icing.

Idle Air Control (IAC) Valve

The idle air control valve (IAC) valve is two directional

and gives 2-way control. With power supply to the coils

controlled steps by the engine control module (ECM),

the IAC valve's pintle is moved to adjust idle speed,

raising it for fast idle when cold or there is extra load

from the air conditioning or power steering.

By moving the pintle in (to decrease air flow) or out (to

increase air flow), a controlled amount of the air can

move around the throttle plate. If the engine speed is

too low, the engine control module (ECM) will retract the

IAC pintle, resulting in more air moving past the throttle

plate to increase the engine speed.

If the engine speed is too high, the engine control

module (ECM) will extend the IAC pintle, allowing less

air to move past the throttle plate, decreasing the

engine speed.

The IAC pintle valve moves in small step called counts.

During idle, the proper position of the IAC pintle is

calculated by the engine control module (ECM) based

on battery voltage, coolant temperature, engine load,

and engine speed.

If the engine speed drops below a specified value, and

the throttle plate is closed, the engine control module

(ECM) senses a near-stall condition. The engine control

module (ECM) will then calculate a new IAC pintle valve

position to prevent stalls.

If the IAC valve is disconnected and reconnected with

the engine running, the idle speed will be wrong. In this

case, the IAC must be reset. The IAC resets when the

key is cycled “On” then “Off”. When servicing the IAC, it

should only be disconnected or connected with the

ignition “Off”.

The position of the IAC pintle valve affects engine start-

up and the idle characteristic of the vehicle.

If the IAC pintle is fully open, too much air will be

allowed into the manifold. This results in high idle

speed, along with possible hard starting and lean air/

fuel ratio.

(1) Throttle Position Sensor

(2) Idle Air Control (IAC) Valve

1

2

C haracterist ic of TPS -R ef erence-

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

0

10

20

30

40

50

60

70

80

90

100

Throt tle Angle (%) (Tech2 R eading)

O

ut

put

Vol

tage (

V

)

Step

Coil

A

B

C

D

Coil A High

(ECM J1-28)

On

On

Coil A Low

(ECM J1-30)

On

On

Coil B High

(ECM J1-13)

On

On

Coil B Low

(ECM J1-29)

On

On

(IAC Valve Close Direction)

(IAC Valve O pen Direction)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст