Isuzu KB P190. Manual — part 508

6A-18 ENGINE MECHANICAL (C24SE)

OPERATIONS ON ENGINE AGGREGATES

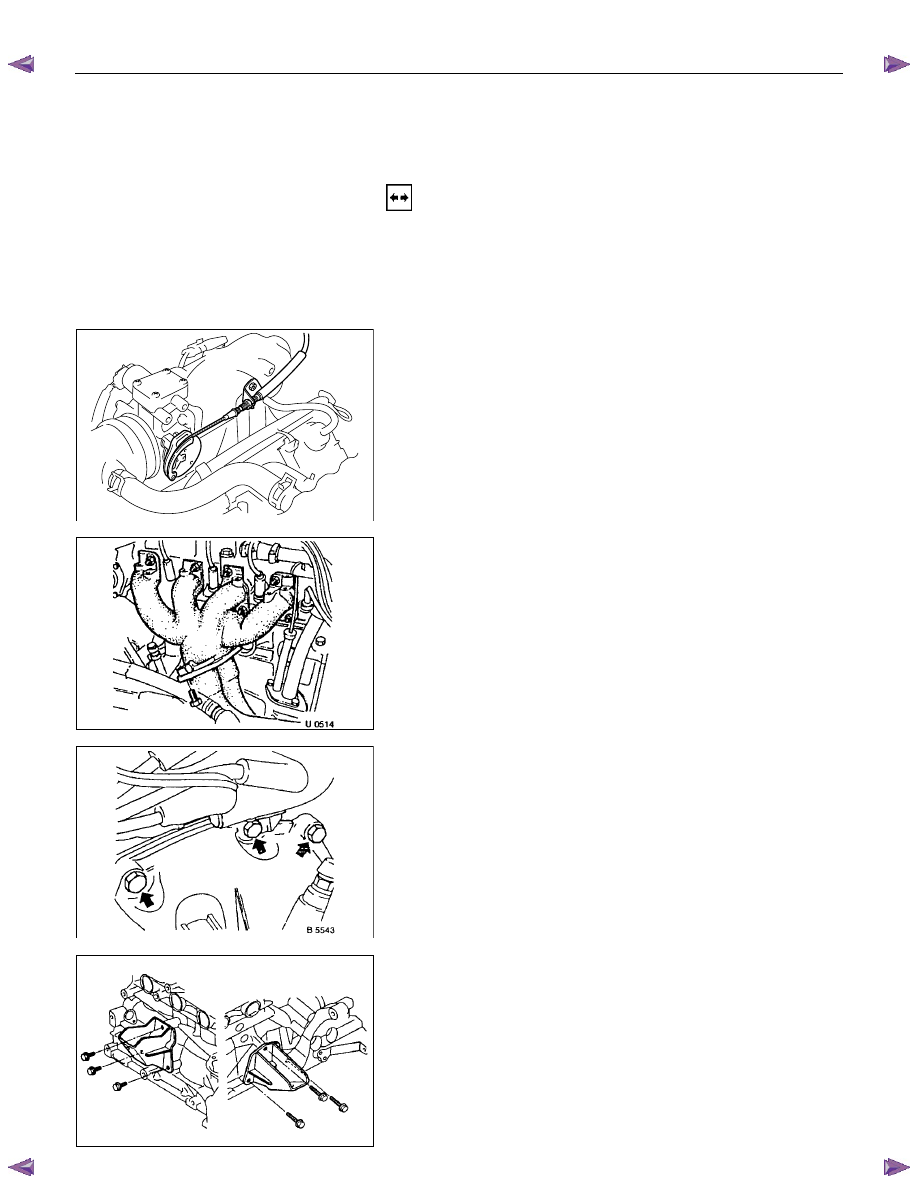

Engine Damping Blocks (Engine Without

Transmission)

Removal

1. Remove bonnet.

2. Remove radiator.

3. Remove air inlet hose.

4. Remove power steering pump drive belt and power

steering pump from engine.

5. Remove all cable connections, hoses and lines from

engine.

6. Remove accelerator cable from inlet pipe.

7. Remove exhaust pipe from manifold.

8. Remove lower nine bolts and transmission from engine

block.

9. Remove clutch slave cylinder and allow to hang free.

10. Remove starter from engine block.

11. Remove upper bolts of left and right engine mounting

from damping blocks.

12. Raise engine slightly.

13. Remove lower bolts of left and right damping blocks.

14. Remove damping blocks.

ENGINE MECHANICAL (C24SE) 6A-19

Attach engine to cable, support transmission with car jack and

remove upper transmission fastening bolt.

Press off engine from transmission and lift out of engine

compartment.

Installation

Lower engine into engine compartment and insert guide

bushings on cylinder block into transmission.

Tighten (Torque)

Transmission to cylinder block (M10)

-45 N

⋅m (4.6 kgf⋅m)

Transmission to cylinder block (M12)

-60 N

⋅m (6.1 kgf⋅m)

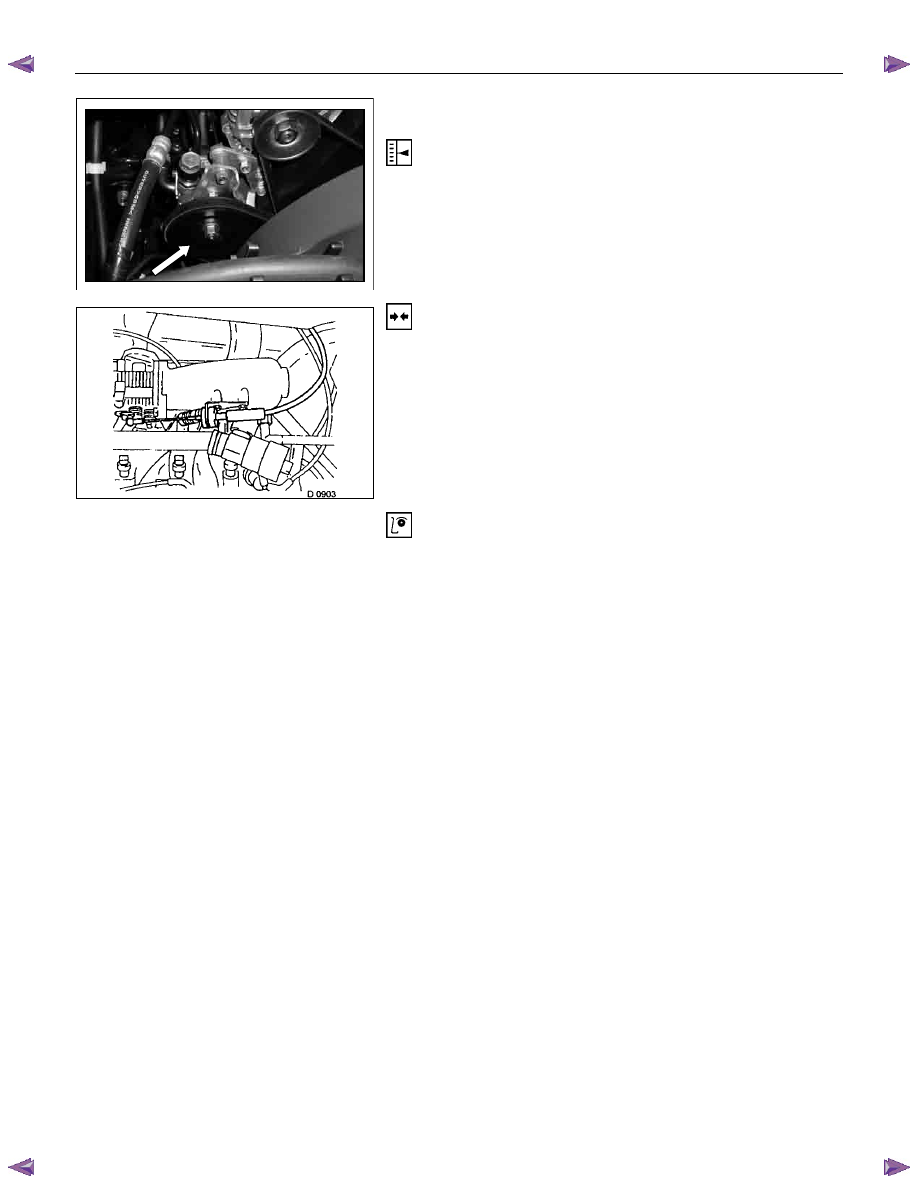

Installation

1. Install engine to vehicle and transmission.

2. Install clutch slave cylinder.

Tighten (Torque)

Transmission to engine block bolts - 76 N

⋅m (7.6 kgf⋅m)

RTW46ASH000401

3. Install left engine damping block to side member.

4. Install left and right engine damping blocks to engine

brackets.

Tighten (Torque)

Engine damper block to side member - 52 N

⋅m (5.3 kgf⋅m)

Engine damper block to engine bracket - 85 N

⋅m (8.7 kgf⋅m)

5. Install exhaust pipe to manifold.

6A-20 ENGINE MECHANICAL (C24SE)

6. Install power steering pump and V-belt.

Adjust

Adjust power steering pump V-belt tension according to the

corresponding operation.

Installation

7. Install radiator according to the corresponding operation.

8. Install air inlet hose.

9. Install all electrical cable connections, hoses and lines to

engine.

10. Install accelerator cable from inlet pipe.

11.

Install bonnet.

Inspection

1. Check engine oil level.

2. Fill up cooling system and bleed according to the

corresponding operation.

ENGINE MECHANICAL (C24SE) 6A-21

Toothed Belt and Timing Check

Removal

1. Remove the belts on the bracket for alternator.

2. Remove the fan.

3. Remove the V-belt for power steering.

4. Remove the V-belt for A/C.

5. Remove the fan belt.

6. Remove the fan shroud.

7. Remove the crankshaft pulley while counterholding on

the fastening bolt of toothed belt drive gear.

8. Remove the toothed belt from cover.

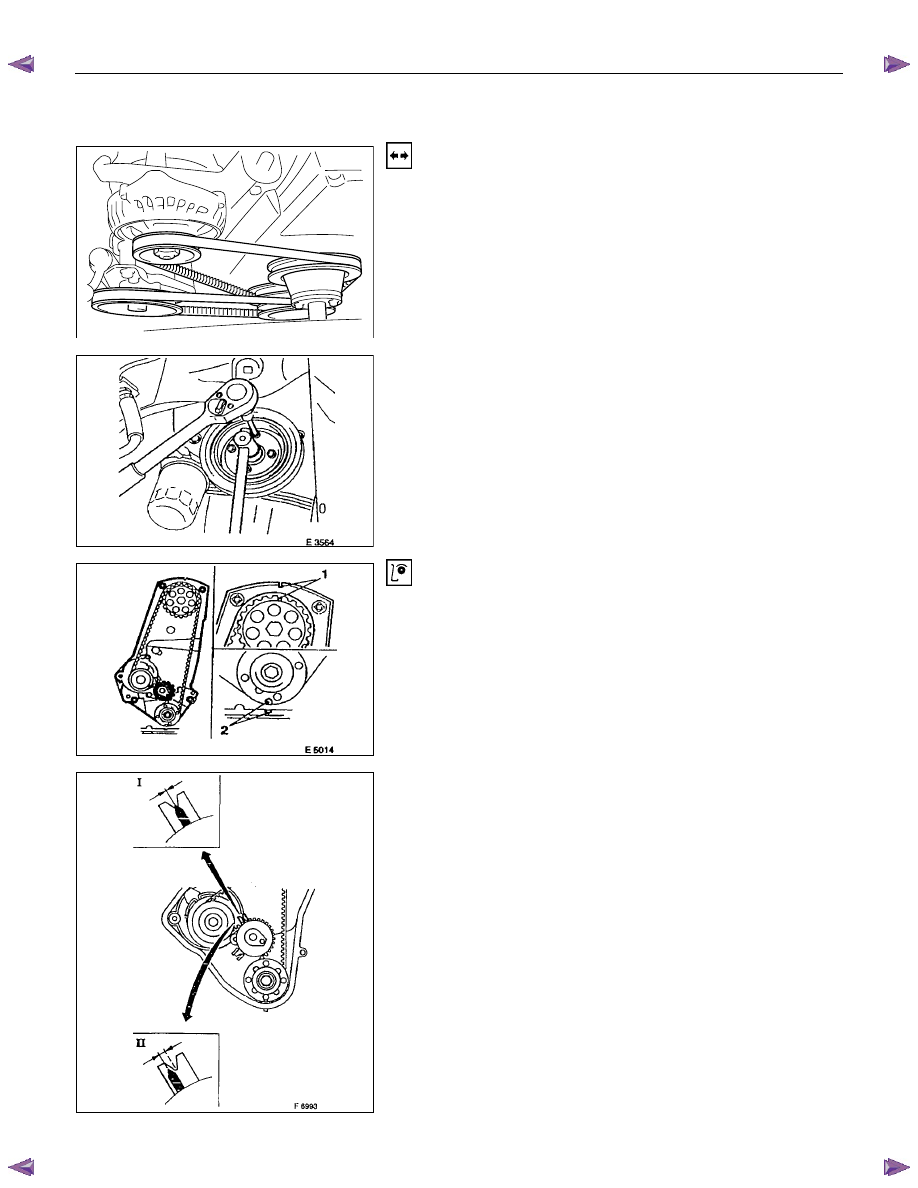

Inspection

1. Turn the crankshaft in the engine rotational direction

mark(2) so that the notch (1) on the camshaft gear aligns

with the mark on toothed belt rear cover.

2. Check the timing belt for worn, cracks or oil adhesion.

3. Check that the cast on the water pump aligns with the

counterpart on cylinder block (arrowed).

4. The tension of a toothed belt is correctly adjusted when

the pointer and the center of the notch are aligned(I).

The tension of a run-in toothed belt (regardless of

mileage covered) is correctly adjusted when the pointer

is positioned approx. 4mm (0.16 in.) to the left of the

center of the notch(II).

Check the condition of the run-in toothed belt for

suitability for reuse. Only toothed belts of the toothed

belt tension rollers must be replaced and the source of oil

contamination must be eliminated.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст