Isuzu KB P190. Manual — part 844

Engine Management – V6 – Diagnostics

Page 6C1-2–98

•

DTC P0268 – Injector 3 Control Circuit High Voltage

•

DTC P0270 – Injector 4 Control Circuit Low Voltage

•

DTC P0271 – Injector 4 Control Circuit High Voltage

•

DTC P0273 – Injector 5 Control Circuit Low Voltage

•

DTC P0274 – Injector 5 Control Circuit High Voltage

•

DTC P0276 – Injector 6 Control Circuit Low Voltage

•

DTC P0277 – Injector 6 Control Circuit High Voltage

Circuit Description

The engine control relay applies ignition positive voltage to the fuel injector ignition circuit. The ECM applies a pulse

width modulated (PWM) ground to the injector control circuit through a device within the ECM called a driver to control

each fuel injector on time.

The driver has a feedback circuit that is pulled-up when the voltage is approximately 3.3 V. The ECM monitors the driver

feedback circuit to determine if the control circuit is open, shorted to ground or shorted to a positive voltage.

A fuel injector control circuit DTC sets if the ECM detects a fault condition in a fuel injector control circuit.

Conditions for Running the DTC

Run continuously once the following conditions are met:

•

the battery voltage is 10.0 – 16.0 V, and

•

engine speed is greater than 80 rpm

Conditions for Setting the DTC

DTC P0201,P0202, P0203, P0204, P0205 or P0206

The ECM detects an open circuit fault condition in a fuel injector circuit.

DTC P0261, P0264, P0267, P0270, P0273 and P0276

The ECM detects a short to ground fault condition in the control circuit a fuel injector.

DTC P0262, P0265, P0268, P0271, P0274 and P0277

The ECM detects a short to voltage fault condition in the control circuit of a fuel injector.

Conditions for Clearing the DTC

The fuel injector control circuit DTCs are Type B DTCs. Refer to 1.4

Diagnostic Trouble Codes in this Section, for

action taken when Type B DTC sets and conditions for clearing Type B DTCs.

Additional Information

•

Refer to 6C1-1 Engine Management – V6 – General Information for details of the fuel injector operation.

•

Using Tech 2, observe the appropriate fuel injector status parameter while wriggle testing related harness and

connectors. Tech 2 reading will change from Ok to Fault if there is an intermittent fault condition in the harness or

connector being tested.

•

Perform the fuel injector coil test to help isolate an intermittent condition. Refer to 6.2

Fuel Injector Coil

Test in this Section.

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 3 Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Engine Management – V6 – Diagnostics

Page 6C1-2–99

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3

Determines if there is a fault condition in the ignition voltage supply circuit. The fuel injectors for each bank of the

engine are fused separately. If all DTCs for a single bank are set, there may be a fault in one of the ignition supply

circuits.

5

Verifies the ECM is sending control voltage to the fuel injector.

6

Tests if the feed back voltage circuit within the ECM is providing the correct voltage.

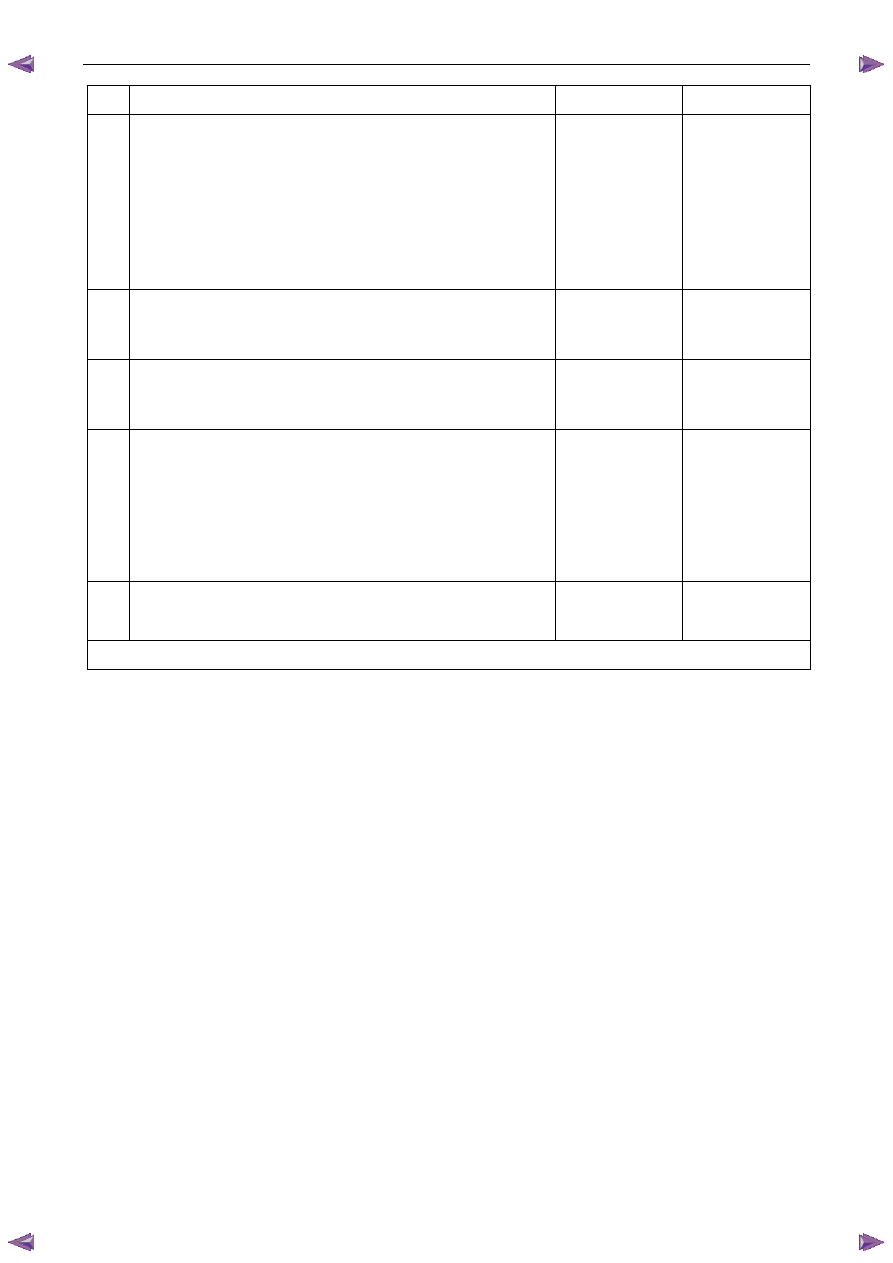

DTC P0201 to P0206, P0261, P0262, P0264, P0265, P0267, P0268, P0270, P0271, P0273,

P0274, P0276 and P0277 Diagnostic Table

Step Action

Yes

No

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

2

1

Switch off the ignition for 30 seconds.

2

Start the engine.

3

Using Tech 2, select the DTC display function.

Does DTC P0201, P0202, P0203, P0204, P0205, P0206, P0261,

P0262, P0264, P0265, P0267, P0268, P0270, P0271, P0273, P0274,

P0276 or P0277 set?

Go to Step 3

Refer to Additional

Information in this

DTC

3

1

Disconnect the fuel injector interconnect harness connector.

Refer to 6C1-3 Engine Management – V6 – Service Operations.

2

Switch on the ignition with the engine not running.

3

Connect a test lamp between the ignition voltage circuit of the

appropriate fuel injector, ECM side of the interconnect

connector, and the ECM housing.

Does the test lamp illuminate?

Go to Step 4

Go to Step 5

4

1

Switch on the ignition with the engine not running.

2

Using a digital multimeter, measure the voltage between the

appropriate fuel injector control circuit, ECM side of the

interconnect connector, and the ECM housing.

Does the multimeter display 2.6 – 4.6 mV?

Go to Step 7

Go to Step 6

5

Repair the open circuit or short to ground fault condition in the ignition

voltage circuit of the appropriate fuel injector. Refer to 8A Electrical -

Body and Chassis for information on electrical wiring repair

procedures.

Was the repair completed?

Go to Step 10

—

6

Test the control circuit of the appropriate fuel injector, between the

interconnect connector and the ECM, for a high resistance, open

circuit, short to ground or short to voltage fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

Was any fault found and rectified?

Go to Step 10

Go to Step 9

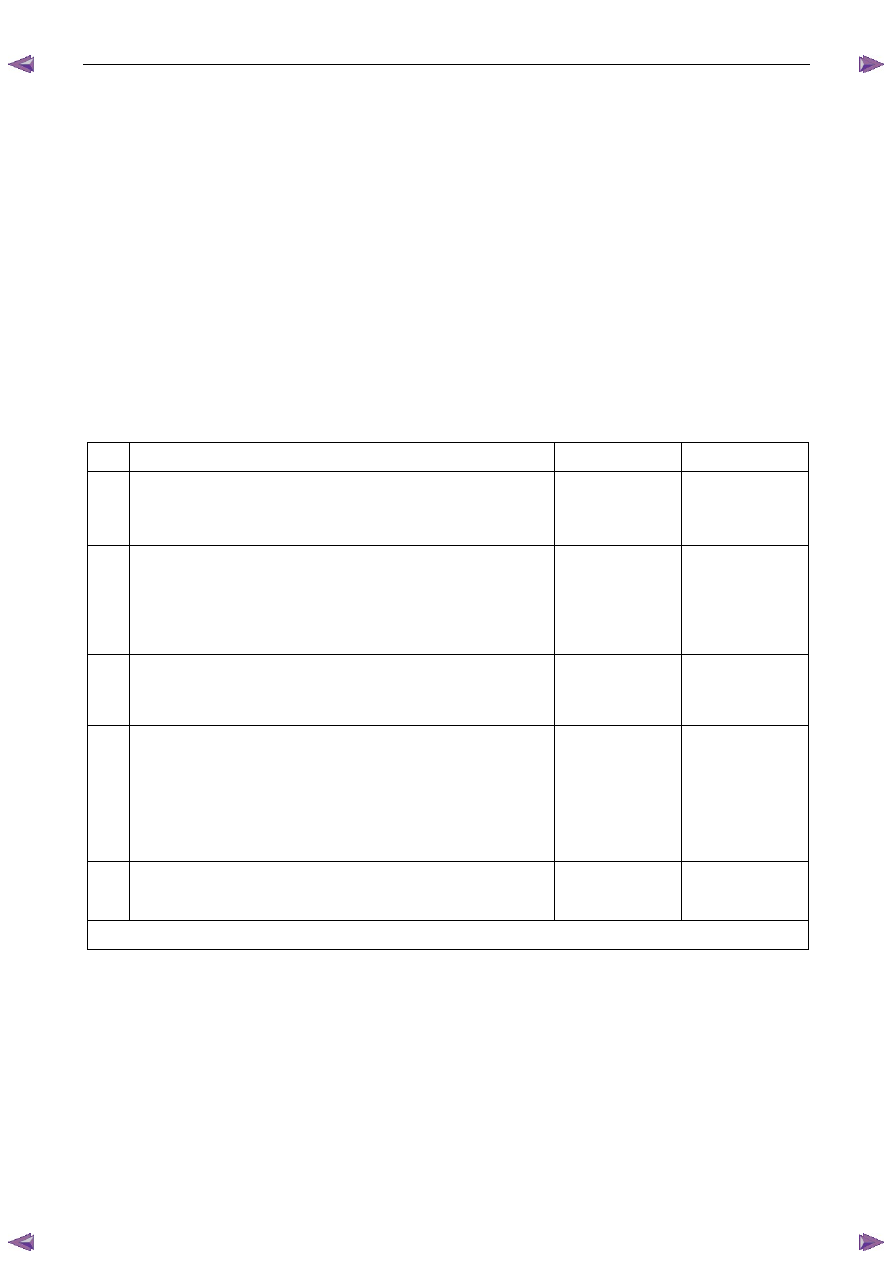

Engine Management – V6 – Diagnostics

Page 6C1-2–100

Step Action

Yes

No

7

1

Remove the upper intake manifold. Refer to 6A1-Engine

Mechanical – V6.

2

Test the control circuit and the ignition voltage circuit of the

appropriate fuel injector, between the interconnect connector

and the appropriate fuel injector connector, for a high

resistance, open circuit, short to ground or short to voltage fault

condition. Refer to 8A Electrical - Body and Chassis for

information on electrical fault diagnosis.

Was any fault found and rectified?

Go to Step 10

Go to Step 8

8

Replace the appropriate fuel injector. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

Was the repair completed?

Go to Step 10

—

9

Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Was the repair completed?

Go to Step 10

—

10 1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running the DTC.

Does any of the fuel injector control circuit DTCs fail this ignition

cycle?

Go to Step 2

Go to Step 11

11 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.15 DTC

P0219

DTC Descriptor

This diagnostic procedure supports DTC P0219 – Engine Overspeed Condition.

Circuit Description

The ECM continually monitors the engines operating environment. A engine over-speed condition DTC sets if the ECM

detects an engine speed in excess of 7200 RPM.

N O T E

An over-speed condition will occur when a low

gear on a manual transmission vehicle has been

selected whilst the vehicle is travelling at high

road speed. This DTC will not set if the engine is

free-revved as the ECM will limit engine speed.

Conditions for Running the DTC

DTC P0219 runs continuously when the following conditions are met:

•

The vehicle is fitted with a manual transmission

•

The engine is running.

•

The ignition voltage is between 10.0 – 16.0 V.

Engine Management – V6 – Diagnostics

Page 6C1-2–101

Conditions for Setting the DTC

The ECM detects an engine speed in excess of 7200 RPM for 1 second or longer.

Conditions for Clearing the DTC

The engine over-speed DTC is a Type C DTC. Refer to 1.4

Diagnostic Trouble Codes in this Section, for action

taken when Type C DTCs set and conditions for clearing Type C DTCs.

Additional Information

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 3

Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

DTC P0219 Diagnostic Table

Step Action

Yes

No

1

Has the diagnostic system check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

2

1

Switch off the ignition for 30 seconds.

2

Operate the vehicle within the conditions for running the DTC.

5

Using Tech 2, select the DTC display function.

Does DTC P0219 fail this ignition cycle?

Go to Step 3

Refer to Additional

Information in this

DTC

3

Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Was the repair completed?

Go to Step 4

—

4

1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running the DTC.

Does DTC P0219 fail this ignition cycle?

Go to Step 2

Go to Step 5

5

Using Tech 2, select the DTC display function.

Are there any DTCs displayed?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.16 DTC

P0300

DTC Descriptor

This diagnostic procedure supports the following DTC:

DTC P0300 Engine Misfire Detected.

Circuit Description

The engine control module (ECM) uses information from the crankshaft position (CKP) sensor and the camshaft position

(CMP) sensors to determine when an engine misfire is occurring. By monitoring variations in the crankshaft rotation

speed for each cylinder, the ECM is able to detect individual misfire events. A misfire rate that is high enough can cause

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст