Isuzu KB P190. Manual — part 800

Engine Cooling – V6 Engine

Page 6B1–65

E n g i n e C o o l i n g F a n

Rotational Speed (with 13

± 0.26 volts negative polarity duty signal applied)

– Stage 1 (25% Duty) . . . . . . 1,100

± 110 rpm

(3

± 0.3A)

– Stage 2 (25% Duty) . . . . . . 1,600

± 160 rpm

(7

± 0.7A)

– Stage 3 (25% Duty) . . . . . . 2,100

± 210 rpm

(15

± 1.5A)

– Stage 4 (25% Duty) . . . . . . 2,400

± 240 rpm

(22

± 2.2A)

Number of Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5

Fan – Design . . . . . . . . . . . . . . . . . Asymmetrical spaced, curved blades

Material . . . . . . . . . . . . . . . . . . . . ...Nylon Glass, Mineral reinforced

Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..500 mm

Fan Motor – Type . . . . . . . . . . . . . . . . . . . . . . . . . . Brushless

Fan Motor – Power . . . . . . . . . . . . . . . . . . . . . . . . . . . 400W

Fan Motor – Input signal . . . . . . . . . . . . . . . . . . . . . . . . 100Hz

Housing . . . . . . . . . . . . . . ..Semi-sealed, zinc-coated steel with drain hole

Direction of Rotation . . . . . . . . . .Counter clockwise (as viewed from drivers seat)

Engine Cooling – V6 Engine

Page 6B1–66

6

Torque Wrench Specifications

N.m

Coolant Outlet housing to Engine Outlet Attaching Bolts. . . . . . . ... 10

Coolant Pump to Front Cover Attaching Bolts . . . . . . . . . . . ... 10

Coolant Pump Pulley Attaching Bolts . . . . . . . . . . . . . . . 12

Coolant Inlet Pipe to Thermostat Housing Attaching Bolt . . . . . . . .. 23

Fan Motor Assembly to Shroud Attaching Screws . . . . . . . . . . .. 5

Heater Pipe Assembly to Thermostat Housing Attaching Bolts . . . . . . 10

Heater Pipe Assembly to Cylinder Head Attaching Bolt . . . . . . . . 35

Thermostat Housing to Engine Block Attaching Bolts. . . . . . . . . 10

Rear Engine Harness . . . . . . . . . . . . . . . . . . . . . 15

Engine Harness Ground Terminal . . . . . . . . . . . . . . . . . 12

Coolant Inlet Pipe To Engine Block Bolt . . . . . . . . . . . . . . 25

Transmission Cooler Lines Bracket . . . . . . . . . . . . . . . .. 23

Engine Cooling – V6 Engine

Page 6B1–67

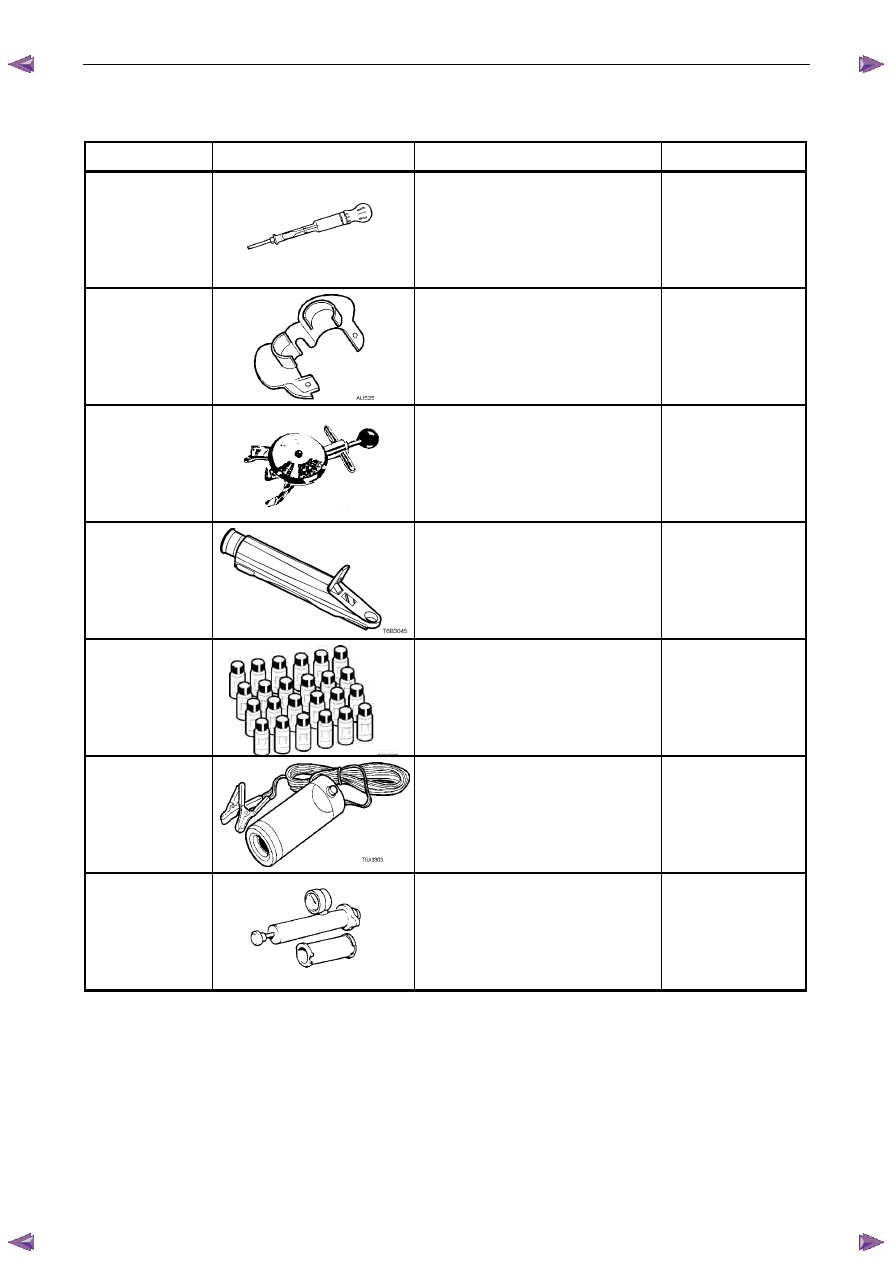

7 Special

Tools

Tool number

Illustration

Description

Classification

AU505

Coolant Tester

Used for testing the coolant

concentration level.

Previously released.

Mandatory

AU525

Quick Connect Release Tool

Used to release the quick connect

fittings on automatic transmission fluid

cooler lines at the radiator end, when

fitted.

Previously released.

Mandatory

BT3373–F

Belt Tension Gauge

Used when checking drive and

accessory belt tension and

adjustments.

Previously released.

Desirable

J 26568

Refractometer

Used for testing coolant concentration

level.

Previously released, as AU 435.

Mandatory

J28431–B

Fluid Dye

Available in 24 x 1-ounce bottles.

Used in conjunction with a black light

such as J42220 to locate the source

of various fluid leaks.

Previously released.

Desirable

J42220

Black Light, Leak Detection Lamp

Used with dye, J28431–B to locate the

source of various vehicle fluid leaks.

Previously released.

Desirable

N/A

Cooling System Pressure Tester

Previously released.

Commercially available.

Mandatory

Fuel System – V6

Page 6C – 1

6C

Fuel System – V6

A T T E N T I O N

Before performing any service operation or other procedure described in this Section, refer to 1.1 WARNING,

CAUTION and NOTES for correct workshop practices with regard to safety and/or property damage.

1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Service Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 3

1.1

WARNING, CAUTION and NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Definition of WARNING, CAUTION and NOTE Statements. . . . . . . . . . . . . . . . . . . . . 4

WARNING defined . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CAUTION defined . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 4

NOTE defined. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2

System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..5

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fuel Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 6

Single Turbine Fuel Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6

Fuel Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3

System Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8

3.1

Fuel Pump Flow Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2

Fuel Pressure Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Gauge Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 8

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9

3.3

Fuel Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 10

3.4

Fuel System Depressurisation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Repressurise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4

Service Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...13

4.1

Fuel Lines And Quick Connect Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 13

Leak Test and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2

Fuel Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 15

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Reinstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 16

4.3

Fuel Tank and Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 17

4.4

Fuel Tank Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5

Modular Fuel Pump and Sender Assembly . . . . . . . . . . . . . . . . . . . . . . . . . ... 23

Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Fuel Level Sender Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 26

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 26

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст