Isuzu KB P190. Manual — part 529

6B-12 ENGINE COOLING

Inspection

Radiator Cap

Measure the valve opening pressure of the pressurizing valve

with a radiator filler cap tester.

Replace the cap if the valve opening pressure is outside the

standard range.

Valve opening pressure kPa (psi) 88.3 – 103.0

(13.5 – 15.7)

Cap tester: 5-8840-0277-0

Adapter: 5-8840-2603-0

Check the condition of the vacuum valve in the center of the

valve seat side of the cap. If considerable rust or dirt is found,

or if the valve seat cannot be moved by hand, clean or replace

the cap.

Valve opening vacuum kPa (psi) 1.9 - 4.9

(0.28 - 0.71)

Radiator Core

1. A bent fin may result in reduced ventilation and overheating

may occur. All bent fins must be straightened. Pay close

attention to the base of the fin when it is being straightened.

2. Remove all dust, bugs and other foreign material.

Flushing the Radiator

Thoroughly wash the inside of the radiator and the engine

coolant passages with cold water and mild detergent. Remove

all sign of scale and rust.

Cooling System Leakage Check

Use a radiator cap tester to force air into the radiator through

the filler neck at the specified pressure of 196 kPa (28.5 psi)

with a cap tester:

• Leakage from the radiator

• Leakage from the coolant pump

• Leakage from the water hoses

• Check the rubber hoses for swelling.

Cap tester: 5-8840-0277-0

Adapter: 5-8840-2603-0

ENGINE COOLING 6B-13

Installation

1. Install radiator assembly, taking care not to damage the

radiator core.

2. Install the radiator assembly.

3. Connect reserve tank hose.

4. Connect radiator inlet hose and outlet hose.

5. Pour engine coolant up to filler neck of radiator, and up to

MAX mark of reserve tank.

Important operation (in case of 100% engine coolant

change) procedure for filling with engine coolant.

• Remove radiator cap.

• Fill with engine coolant to the radiator filler neck.

• Fill with EC to the "MAX" line on the reservoir tank.

• Start the engine with the radiator cap removed and bring to

operating temperature by running engine at 2,500 - 3,000

rpm for 30 minutes.

• By engine coolant temperature gauge reading make sure

that the thermostat is open.

• If air bubbles come up to the radiator filler neck, replenish

with engine coolant. Repeat until the EC level does not drop

any further. Install the radiator cap and stop the engine.

• Replenish engine coolant to the "MAX" line on the reservoir

tank and leave as it is until the engine gets cool.

• After the engine gets cool, start the engine and make sure

there is no water running noise heard from the heater core

while the engine runs at 3000 rpm.

• Should water running noise be heard, repeat the same

procedure from the beginning.

Main Data and Specifications

General Specifications

Cooling system

Engine Coolant forced circulation

Radiator

Tube type corrugated (2 tube in row)

Heat radiation capacity

66.3 kcal/h

Heat radiation area

7.08 m

2

Radiator front area

028 m

2

Radiator dry (weight)

3.1 kg

Radiator cap valve opening pressure

93.3 – 122.7 kpa

Engine coolant capacity

3.4L

Engine coolant pump

Centrifugal type

Thermostat Bypass

type

Engine coolant total capacity

8lit

6B-14 ENGINE COOLING

SPECIAL SERVICE TOOL

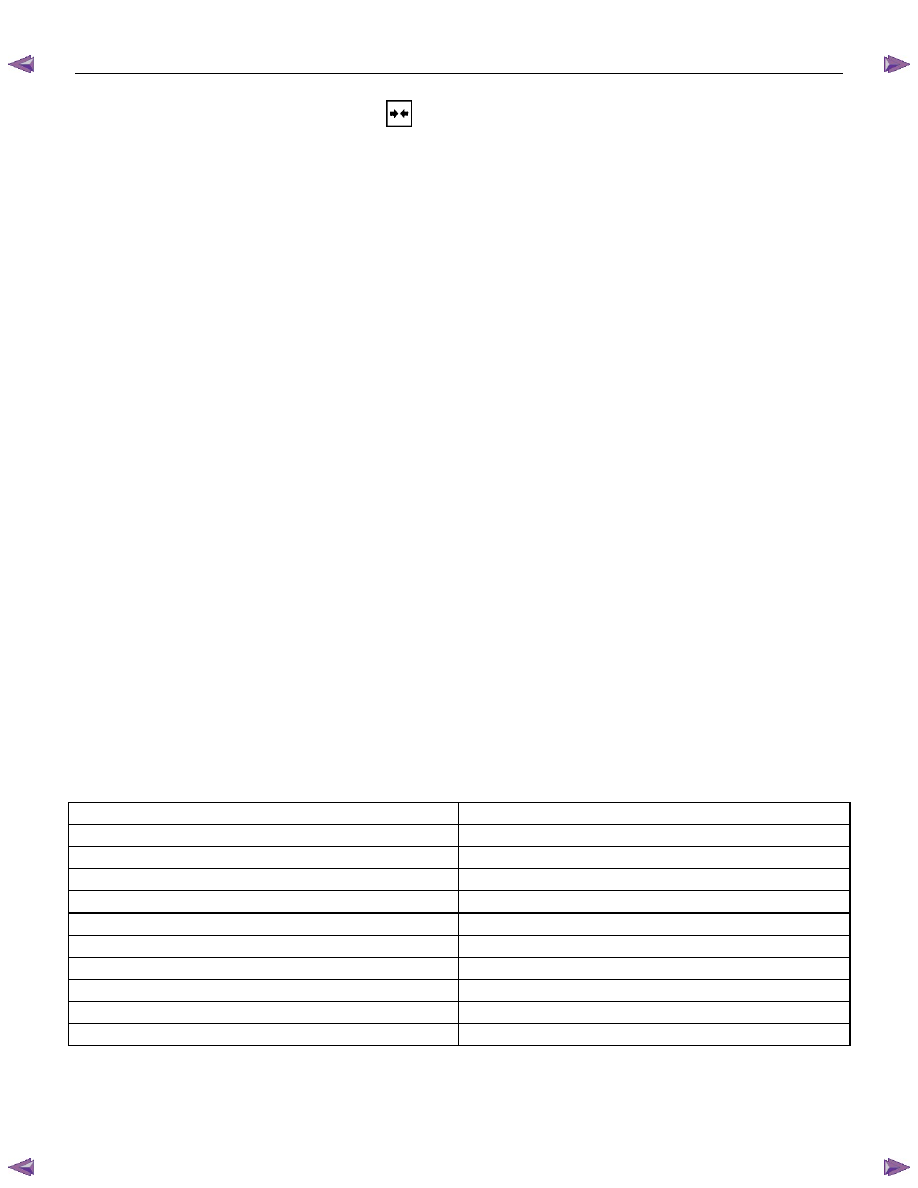

ITEM NO.

ILLUSTRATION

PART NO.

PART NAME

1

5-8840-0277-0

Tester; radiator cap

2

5-8840-2603-0

Adapter; radiator cap

ENGINE FUEL (C24SE) 6C-1

SECTION 6C

ENGINE FUEL (C24SE)

TABLE OF CONTENTS

General Description . . . . . . . . . . . . 6C-2

Service Precaution . . . . . . . . . . . ... 6C-3

Fuel Metering . . . . . . . . . . . . . . . 6C-4

Fuel Filter . . . . . . . . . . . . . . . . 6C-5

Removal . . . . . . . . . . . . . . . ... 6C-5

Inspection. . . . . . . . . . . . . . . 6C-6

Installation. . . . . . . . . . . . . . ... 6C-6

Inspection. . . . . . . . . . . . . . . 6C-6

In-Tank Fuel Filter . . . . . . . . . . . . 6C-6

Fuel Pump Flow Test. . . . . . . . . . 6C-7

Fuel Pump. . . . . . . . . . . . . . . ... 6C-8

Fuel Pump and Associated Parts . . . . .. 6C-8

Removal . . . . . . . . . . . . . . . ... 6C-8

Installation. . . . . . . . . . . . . . ... 6C-9

Fuel Tube / Quick - Connector Fittings . . ... 6C-10

Precautions. . . . . . . . . . . . . . . 6C-10

Cautions During Work. . . . . . . . . .. 6C-10

Removal . . . . . . . . . . . . . . . .. 6C-10

Reuse of Quick-Connector . . . . . . . . 6C-11

Assembling Advice. . . . . . . . . . ... 6C-11

Fuel Pump Relay. . . . . . . . . . . . ... 6C-12

General Description . . . . . . . . . . . 6C-12

Fuel Tank. . . . . . . . . . . . . . . . 6C-13

Fuel Tank and Associated Parts . . . . ... 6C-13

Removal . . . . . . . . . . . . . . . .. 6C-14

Installation . . . . . . . . . . . . . . .. 6C-14

Filler Neck . . . . . . . . . . . . . . . .. 6C-15

Removal . . . . . . . . . . . . . . . .. 6C-15

Installation . . . . . . . . . . . . . . .. 6C-15

Fuel Gauge Unit . . . . . . . . . . . . . 6C-15

Removal and Installation . . . . . . . . 6C-15

Fuel Filler Cap . . . . . . . . . . . . . ... 6C-16

General Description . . . . . . . . . . . 6C-16

Inspection . . . . . . . . . . . . . . ... 6C-16

Main Data and Specifications. . . . . . . 6C-17

Special Tool. . . . . . . . . . . . . . 6C-18

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст