Isuzu KB P190. Manual — part 739

Engine Mechanical – V6

Page 6A1–179

Page 6A1–179

27

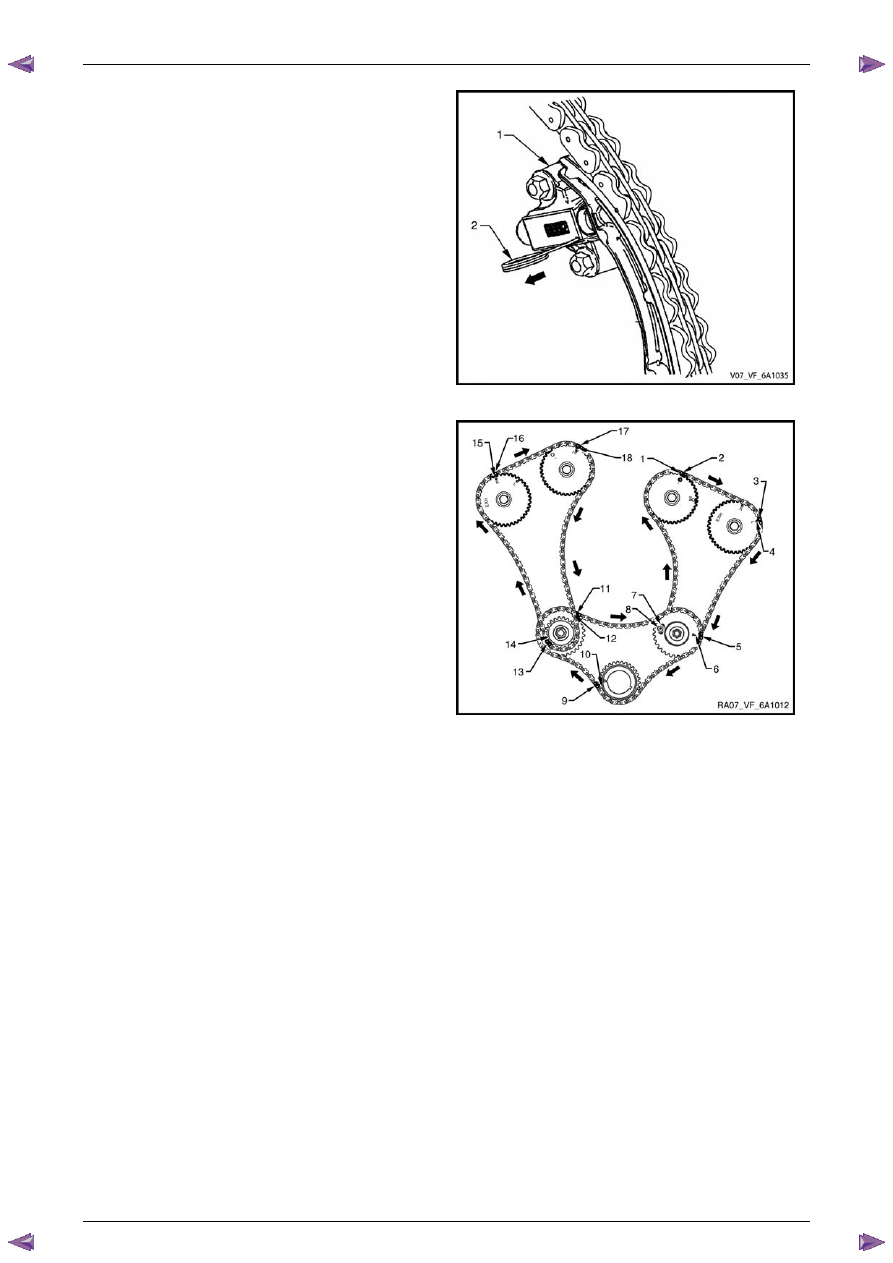

Release the right-hand timing chain tensioner (1) by

pulling out Tool No. EN 46112 (2) and unlocking the

tensioner plunger.

Figure 6A1 – 284

28

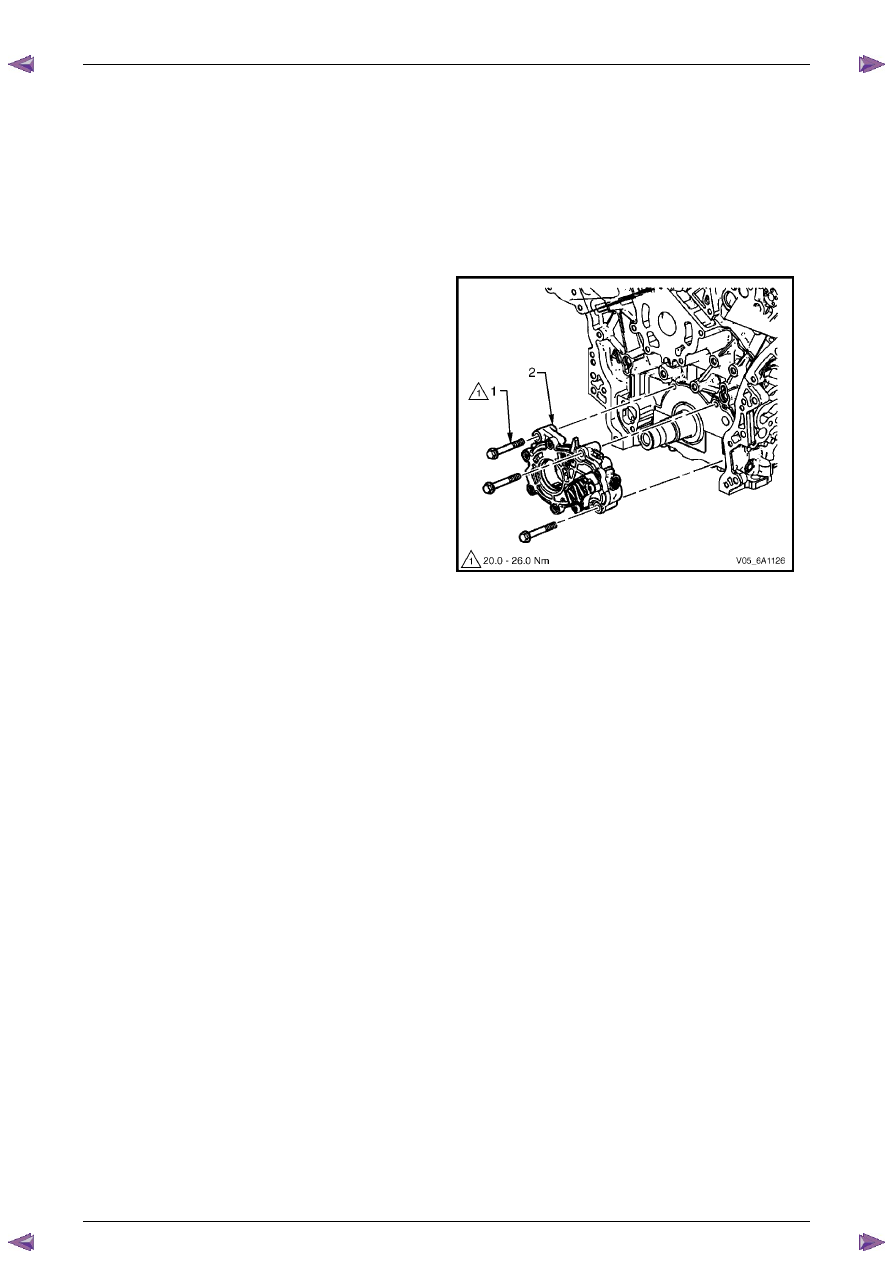

Verify all primary and secondary timing chain timing

mark alignments (1 to 18).

29

Remove Tool No. EN 46105–1 and EN 46105-2 from

the left and right-hand cylinder head camshafts.

30

Reinstall the spark plugs. Refer to

Section 6C1-3

Engine Management – V6 – Service Operations

.

31

Reinstall the engine front cover assembly, refer to

3.15 Front Cover Assembly

.

Figure 6A1 – 285

Engine Mechanical – V6

Page 6A1–180

Page 6A1–180

3.17 Oil Pump Assembly

Remove

N O T E

Do not remove the left-hand bank idler sprocket.

1

Remove the primary timing chain and crankshaft sprocket, refer to

3.16 Timing Chains, Tensioners, Shoes and

Guides

.

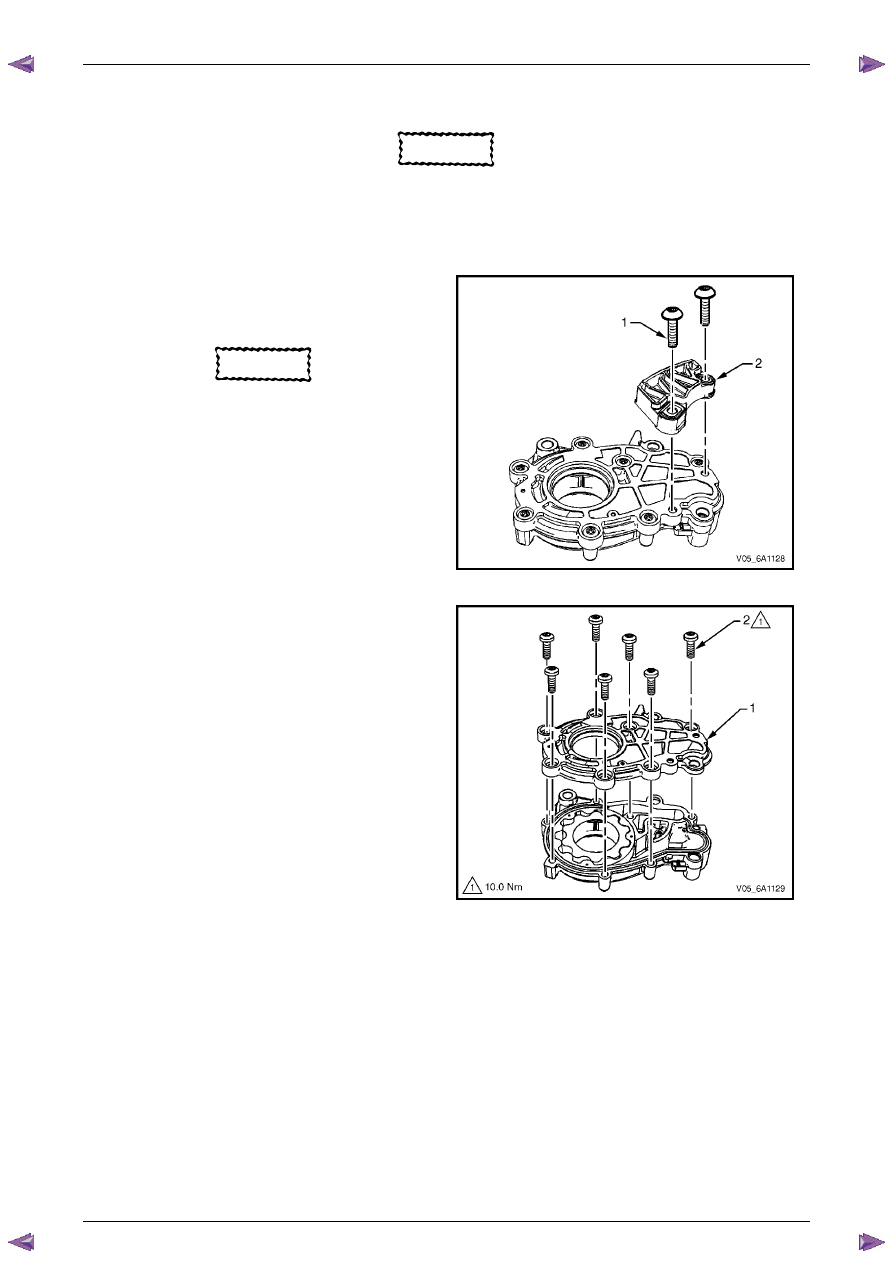

2

Remove the three bolts (1) attaching the oil pump (2).

3

Remove the oil pump assembly.

Figure 6A1 – 286

Engine Mechanical – V6

Page 6A1–181

Page 6A1–181

Disassemble

CAUTION

There are no serviceable components within

the oil pump. Disassemble the pump only to

diagnose an oil related concern. A

disassembled oil pump must not be reused: it

must be replaced.

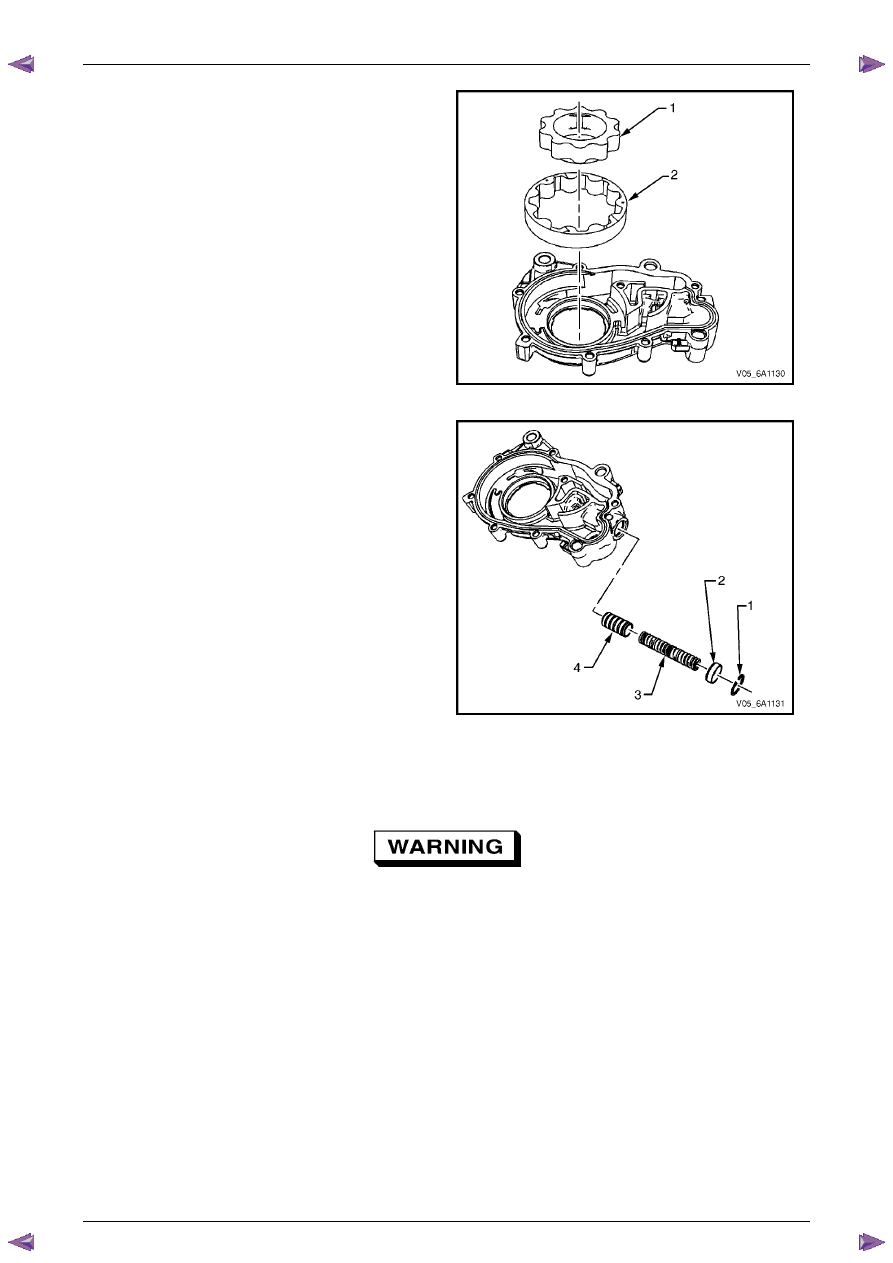

1

Remove the two bolts (1) attaching the primary timing

chain lower guide (2) and remove the guide.

CAUTION

The primary timing chain lower guide is not

serviced separately and is part of the oil

pump assembly. If it is removed from the

pump assembly, the guide and the pump

must be replaced.

Figure 6A1 – 287

2

Remove the seven bolts (2) attaching the oil pump

cover to the oil pump housing (1) and remove the

cover from the housing.

Figure 6A1 – 288

Engine Mechanical – V6

Page 6A1–182

Page 6A1–182

3

Remove the inner gerotor ring (1).

4

Remove the outer gerotor ring (2).

Figure 6A1 – 289

5

Remove the clip (1), retaining the oil relief valve cap

(2).

6

Remove the cap, spring (3) and plunger (4) from the

oil pump housing.

Figure 6A1 – 290

Clean

1

Clean the oil pump components with non-corrosive solvent.

Safety glasses must be worn when using

compressed air.

2

Dry the oil pump components with compressed air.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст