Isuzu KB P190. Manual — part 740

Engine Mechanical – V6

Page 6A1–183

Page 6A1–183

Inspect

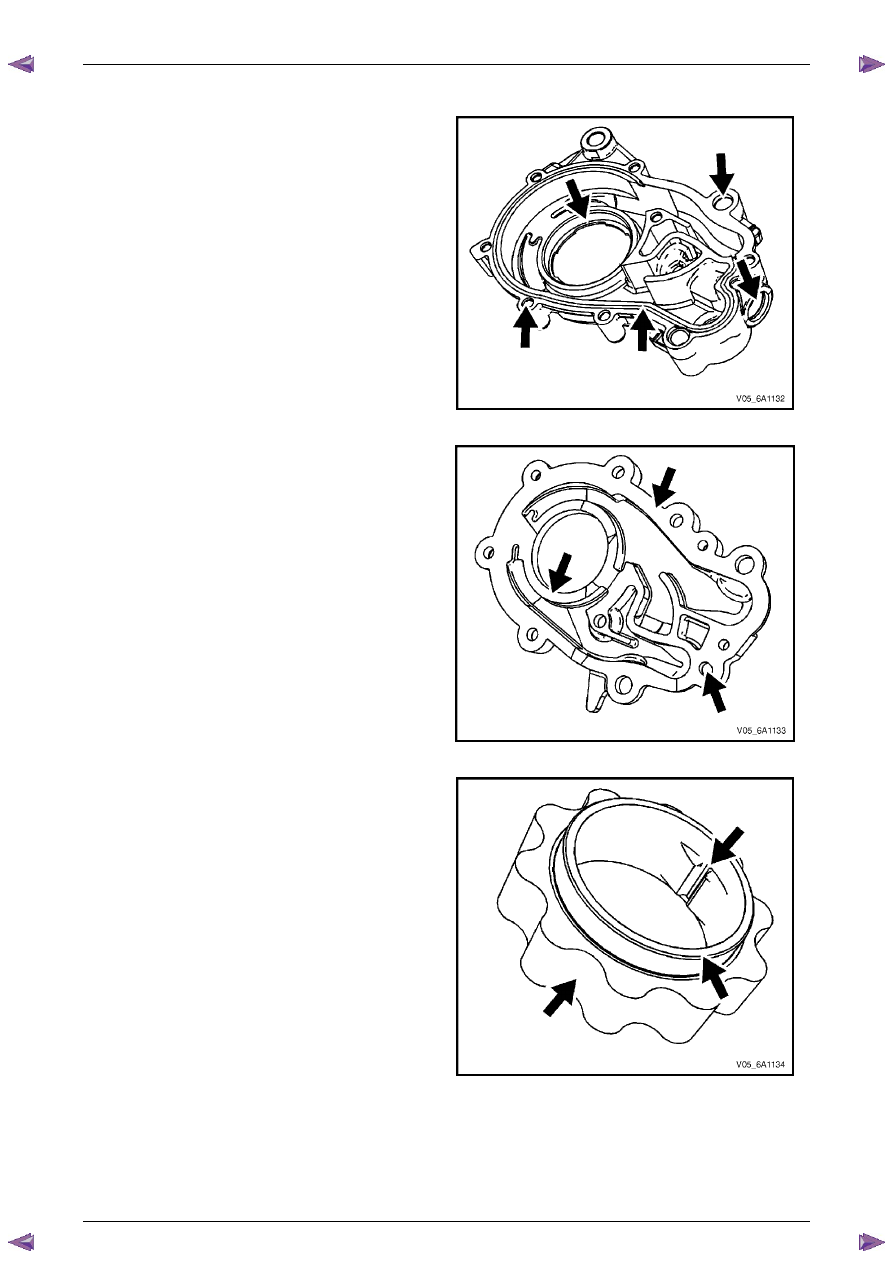

1

Inspect the oil pump housing for damage.

Figure 6A1 – 291

2

Inspect the oil pump cover for damage.

Figure 6A1 – 292

3

Inspect the inner drive gear for damage. If inner

surface damage is found, ensure the crankshaft is

also inspected.

Figure 6A1 – 293

Engine Mechanical – V6

Page 6A1–184

Page 6A1–184

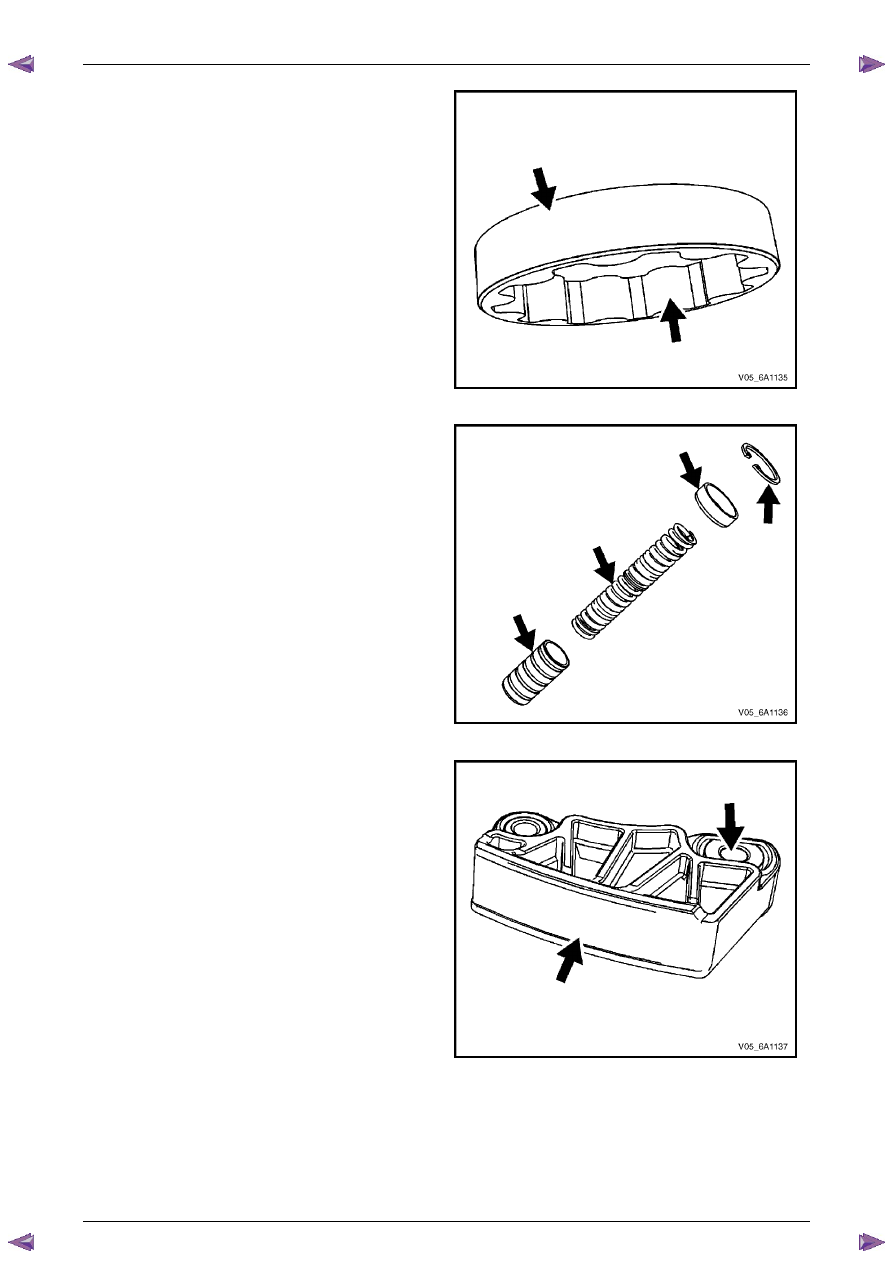

4

Inspect the outer driven gear for damage.

Figure 6A1 – 294

5

Inspect the oil pump relief valve components for

debris or damage.

Figure 6A1 – 295

6

Inspect the primary camshaft chain lower guide for

damage. If replacement of the primary camshaft chain

lower guide is required, replace the entire oil pump

assembly as the primary camshaft chain lower guide

is not serviceable separately.

7

If debris or damage is present within the oil pump,

further inspection of all of the engine components is

required.

Figure 6A1 – 296

Engine Mechanical – V6

Page 6A1–185

Page 6A1–185

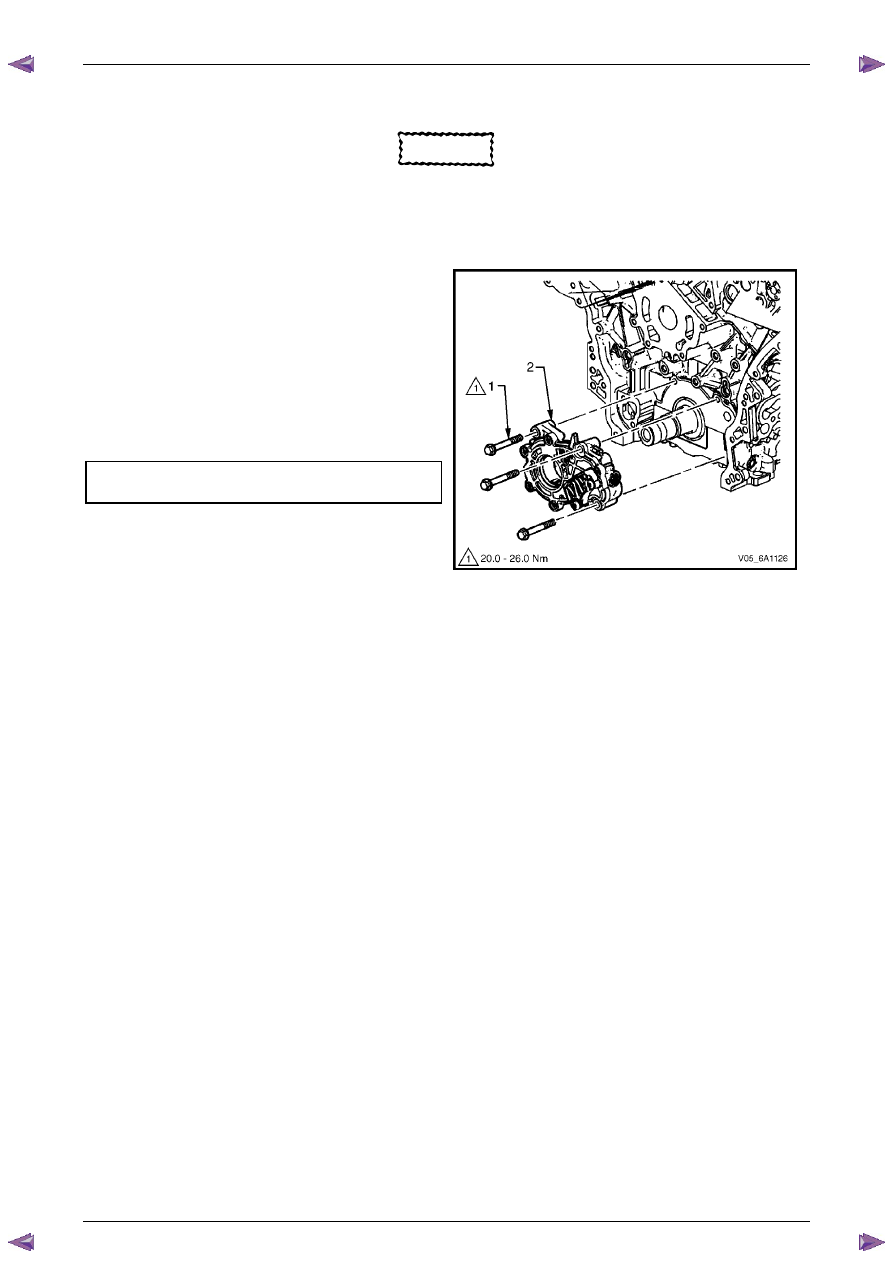

Reassemble

CAUTION

As there are no serviceable components

within the oil pump, a disassembled oil pump

must be replaced.

Reinstall

1

Align the oil pump gerotor with the crankshaft flats

and fit the oil pump assembly to the engine block.

2

Align the pump body (2) with the mounting holes in

the cylinder block.

3

Install the oil pump bolt (1), three places, and tighten

to the correct torque specification.

4

Install the primary timing chain, refer to

3.16 Timing

Chains, Tensioners, Shoes and Guides

.

Oil pump attaching bolt torque

specification . . . . . . . . . . . 20.0 – 26.0 Nm

Figure 6A1 – 297

Engine Mechanical – V6

Page 6A1–186

Page 6A1–186

3.18 Camshaft Sprocket – Excluding MY06

Update

CAUTION

Setting the camshaft timing is required

whenever the camshaft drive system is

disturbed to ensure the relationship between

any chain and sprocket is not lost. Even when

only one sprocket is involved, multiple

crankshaft rotations will not produce

conditions where correct timing can be

confirmed.

If required, follow the Left-hand Secondary

Camshaft Chain Components reinstallation

procedure to reset the camshaft timing.

Remove

Right-hand Side

1

Remove the right-hand camshaft cover, refer to

3.12 Camshaft Cover

.

2

Remove the camshaft position sensors, refer to

Section 6C1-3 Engine Management – Service Operations

.

3

Remove the camshaft position actuator solenoids, refer to

Section 6C1-3 Engine Management – V6 – Service

Operations

.

4

Remove the crankshaft balancer assembly, refer to

3.13 Crankshaft Balancer Assembly

.

5

Install the crankshaft rotation socket Tool No.

EN-46111 onto the crankshaft.

6

Rotate the crankshaft until the camshafts are in a

neutral low tension position. The camshaft flats will be

parallel with the camshaft cover rail (1).

Figure 6A1 – 298

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст