Isuzu KB P190. Manual — part 850

Engine Management – V6 – Diagnostics

Page 6C1-2–122

P0158, P0159, P0160, P0161, P0221, P0222, P0223, P0300, P0301-P0306, P0443, P0458, P0459, P0496,

P167A, P167B, P2096, P2097, P2098, P2099, P2100, P2101, P2107, P2119, P2122, P2123, P2127, P2128,

P2138, P2176, P2177, P2178, P2179, P2180, P2187, P2188, P2189, P2190, P2195, P2196, P2197, P2198,

P2232, P2235, P2237, P2240, P2243, P2247, P2251, P2254, P2270, P2271, P2272, P2273, P2297, P2298,

P2626, and P2629.

•

The engine speed is 1,040 – 3,000 rpm.

•

The air flow into the engine is between 7.0 – 16.0 g/s and not changing more than 3.0 g/s

•

The engine intake air temperature (IAT) at engine start-up is more than –30° C.

•

The engine is operating for more than 7 minutes.

•

The engine is operating in Closed Loop.

•

The calculated TWC temperature is between 500 – 750° C and steady.

•

The above conditions exist for approximately 17 minutes.

•

DTCs P0420 and P0430 run once a drive cycle. The ECM will attempt to run this diagnostic up to three times a

drive cycle.

Conditions for Setting the DTC

The ECM determines that the catalyst efficiency has degraded below a calibrated threshold for more than 4 seconds.

Action Taken When the DTC Sets

•

The control module activates the malfunction indicator lamp (MIL) on the second consecutive ignition cycle that

the diagnostic runs and fails.

•

The control module records the operating conditions at the time the diagnostic fails. The first time the diagnostic

fails, the control module stores this information in the Failure Records. If the diagnostic reports a failure on the

second consecutive ignition cycle, the control module records the operating conditions at the time of the failure.

The control module writes the operating conditions to the Freeze Frame and updates the Failure Records.

Conditions for Clearing the DTC

The EVAP Purge Solenoid Valve Control Circuit DTCs are Type B DTCs. Refer to 1.4

Diagnostic Trouble Codes in

this Section, for action taken when a Type B DTC sets and conditions for clearing Type B DTCs.

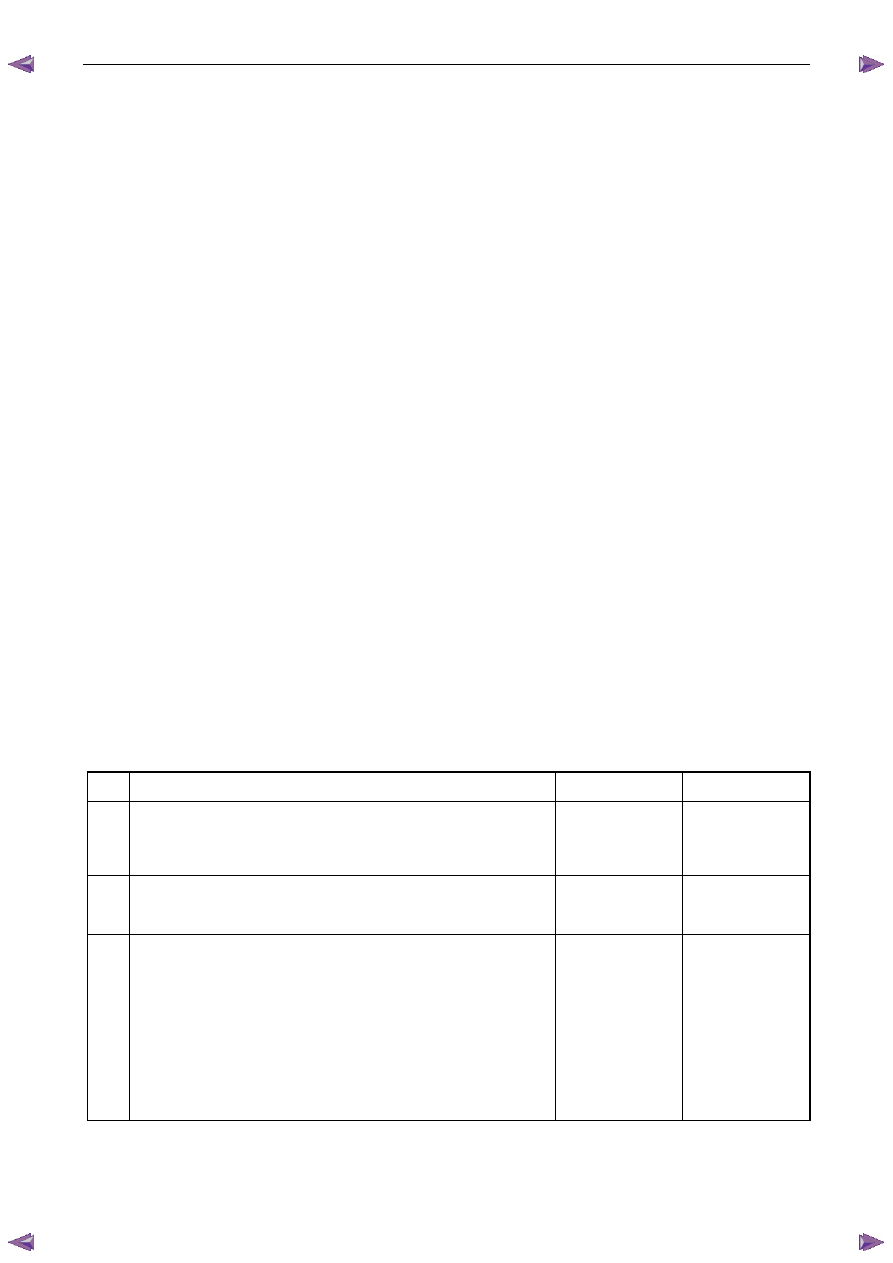

P0420 or P0430 Diagnostic Table

Step Action

Yes

No

1

Has the Diagnostic System Check been completed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

2

Are any other DTCs set?

Go to the

appropriate DTC

Table in this Section

Go to Step 3

3

1

Inspect for the following conditions:

•

The catalytic converter is an original equipment part.

•

Inspect the exhaust system for leaks, damage, loose or

missing hardware in the area from the converter to the

heated oxygen sensor 2.

•

The HO2S 2 is secure and the wiring is not damaged or

contacting the exhaust.

Did you find and correct the condition?

Go to Step 5

Go to Step 4

Engine Management – V6 – Diagnostics

Page 6C1-2–123

Step Action

Yes

No

4

N O T E

Before replacing the 3-way catalytic converter (TWC),

correct any conditions that may have damaged the

converter.

1

Replace the catalytic converter. Refer to the appropriate

procedure in 6F Exhaust System – V6.

Did you complete the replacement?

Go to Step 5

—

5

1

Using Tech 2, clear the DTC/s.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running the DTC.

Does any of the EVAP purge solenoid valve control circuit DTCs fail

this ignition cycle?

Go to Step 2

Go to Step 6

6

Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

7.24 DTC P0443, P0458 or P0459

DTC Descriptors

This diagnostic procedure supports the following DTCs:

•

DTC P0443 – Evaporative Emission Control System Purge Solenoid Circuit Malfunction

•

DTC P0458 – Evaporative Emission Control System Purge Solenoid Circuit Low Voltage

•

DTC P0459 – Evaporative Emission Control System Purge Solenoid Circuit High Voltage

Circuit Description

The Engine control relay applies ignition positive battery voltage to the evaporative emission (EVAP) purge solenoid.

Using a device called a driver, the ECM applies a pulse width modulated (PWM) ground to the EVAP solenoid control

circuit to purge the fuel vapour from the EVAP canister into the intake manifold.

The driver has a feedback circuit that is pulled-up to a voltage. The ECM monitors the driver feedback circuit to

determine if the control circuit is open, shorted to ground or shorted to a positive voltage.

An EVAP purge solenoid valve control circuit DTC sets if the ECM detects the voltage on the EVAP solenoid control

circuit outside the predetermined range when the solenoid is commanded off.

Conditions for Running the DTC

DTC P0443 and P0458

Runs continuously once the following conditions are met:

•

The engine speed is greater than 80 rpm

•

The ignition voltage is 10.0 – 16.0 V.

•

The ECM has commanded the EVAP Purge Solenoid Valve on and off at least once during the ignition cycle.

DTC P0459

Runs continuously once the following conditions are met:

Engine Management – V6 – Diagnostics

Page 6C1-2–124

•

The engine speed is greater than 80 rpm

•

The ignition voltage is 10.0 – 16.0 V.

•

The fuel system is in closed loop.

•

The engine speed is above idle.

•

The engine is at operating temperature.

•

The ECM has commanded the EVAP Purge Solenoid Valve on and off with a duty cycle of greater than 2.5%.

Conditions for Setting the DTC

DTC P0443

The ECM detects the voltage on the EVAP solenoid control circuit is not within the predetermined range when the

solenoid is commanded off.

DTC P0458

The ECM detects the voltage on the EVAP solenoid control circuit is less than 2.6 V when the solenoid is commanded

off.

DTC P0459

The ECM detects the voltage on the EVAP solenoid control circuit is greater than 4.6 V when the solenoid is

commanded on.

Conditions for Clearing the DTC

The EVAP Purge Solenoid Valve Control Circuit DTCs are Type B DTCs. Refer to 1.4

Diagnostic Trouble Codes in

this Section, for action taken when a Type B DTC sets and conditions for clearing Type B DTCs.

Additional Information

•

Refer to 6C1-1 Engine Management – V6 – General Information for details of the EVAP Purge Solenoid Valve

operation.

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 3 Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following number refers to the step number in the diagnostic table:

4

Tests the feedback voltage from the ECM.

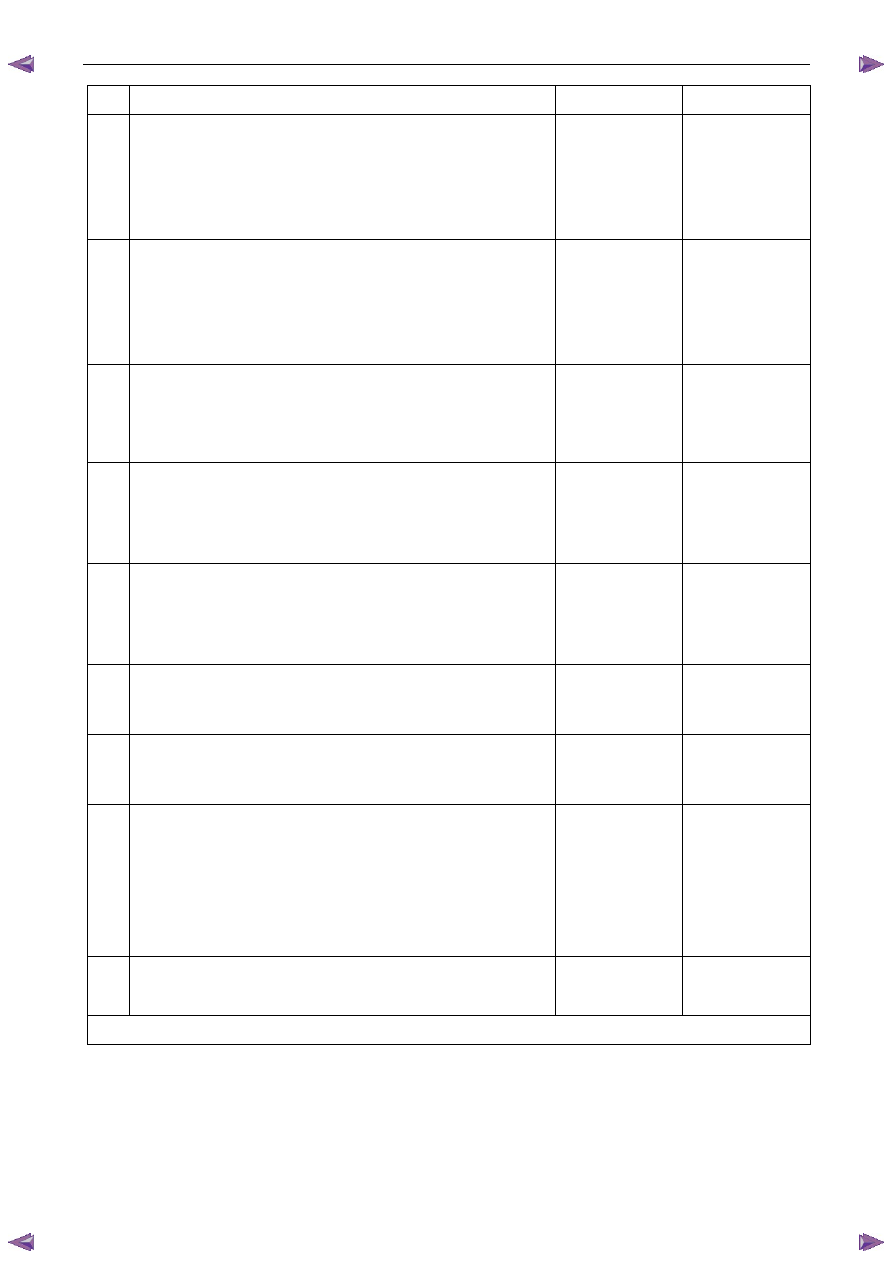

DTC P0443, P0458 or P0459 Diagnostic Table

Step Action

Yes

No

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

Engine Management – V6 – Diagnostics

Page 6C1-2–125

Step Action

Yes

No

2

1

Switch off the ignition for 30 seconds.

2

Allow the engine to reach the normal operating temperature or

operate the vehicle within the conditions for running the DTC.

3

Using Tech 2, select the DTC display function.

Does DTC P0443, P0458 or P0459 fail this ignition cycle?

Go to Step 3

Refer to Additional

Information in this

DTC

3

1

Disconnect the EVAP solenoid valve wiring connector.

2

Switch on the ignition with the engine not running.

3

Connect a test lamp between the EVAP solenoid valve ignition

voltage circuit and the ECM housing.

Does the test lamp illuminate?

Go to Step 4

Go to Step 5

4

1

Switch on the ignition with the engine not running.

2

Using a digital multimeter, measure the voltage between the

EVAP solenoid valve control circuit and the ECM housing.

Does the multimeter display 2.6 – 4.6 V?

Go to Step 7

Go to Step 6

5

Repair the high resistance, open circuit or short to ground fault

condition at the EVAP solenoid valve ignition voltage circuit. Refer to

8A Electrical - Body and Chassis for information on electrical wiring

repair procedures

Was the repair completed?

Go to Step 9

—

6

Test the control circuit of the EVAP solenoid valve for a high

resistance, open circuit, short to ground or short to voltage fault

condition. Refer to 8A Electrical - Body and Chassis for information on

electrical fault diagnosis.

Was any fault found and rectified?

Go to Step 9

Go to Step 8

7

Replace the EVAP solenoid valve. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

Was the repair completed?

Go to Step 9

—

8

Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Was the repair completed?

Go to Step 9

—

9

1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running the DTC.

Does any of the EVAP purge solenoid valve control circuit DTCs fail

this ignition cycle?

Go to Step 2

Go to Step 10

10 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.25 DTC P0460, P0461, P0462 or P0463

DTC Descriptors

This diagnostic procedure supports the following DTCs:

•

DTC P0460 – Fuel Level Sensor Range / Performance

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст