Isuzu KB P190. Manual — part 16

1-30 HEATER AND AIR CONDITIONING

ON-VEHICLE SERVICE

PRECAUTIONS FOR REPLACEMENT OR

REPAIR OF AIR CONDITIONING PARTS

There are certain procedures, practices and precautions that

should be followed when servicing air conditioning systems:

• Keep your work area clean.

• Always wear safety goggle and protective gloves when

working on refrigerant systems.

• Beware of the danger of carbon monoxide fumes caused by

running the engine.

• Beware of discharged refrigerant in enclosed or improperly

ventilated garages.

• Always disconnect the negative battery cable and discharge

and recover the refrigerant whenever repairing the air

conditioning system.

• When discharging and recovering the refrigerant, do not

allow refrigerant to discharge too fast; it will draw

compressor oil out of the system.

• Keep moisture and contaminants out of the system. When

disconnecting or removing any lines or parts, use plugs or

caps to close the fittings immediately.

Never remove the caps or plugs until the lines or parts are

reconnected or installed.

• When disconnecting or reconnecting the lines, use two

wrenches to support the line fitting, to prevent from twisting

or other damage.

• Always install new O-rings whenever a connection is

disassembled.

• Before connecting any hoses or lines, apply new specified

compressor oil to the O-rings.

• When removing and replacing any parts which require

discharging the refrigerant circuit, the operations described

in this section must be performed in the following sequence:

1) Using the ACR

4

(HFC-134a Refrigerant Recovery/

Recycling/Recharging/System) or equivalent to

thoroughly discharge and recover the refrigerant.

ACR

4

(115V 60Hz) : 5-8840-0629-0 (J-39500-A)

ACR

4

(220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4

(220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

2) Remove and replace the defective part.

3) After evacuation, charge the air conditioning system and

check for leaks.

HEATER AND AIR CONDITIONING 1-31

REPAIR OF REFRIGERANT LEAKS

Refrigerant Line Connections

RTW410SH000101

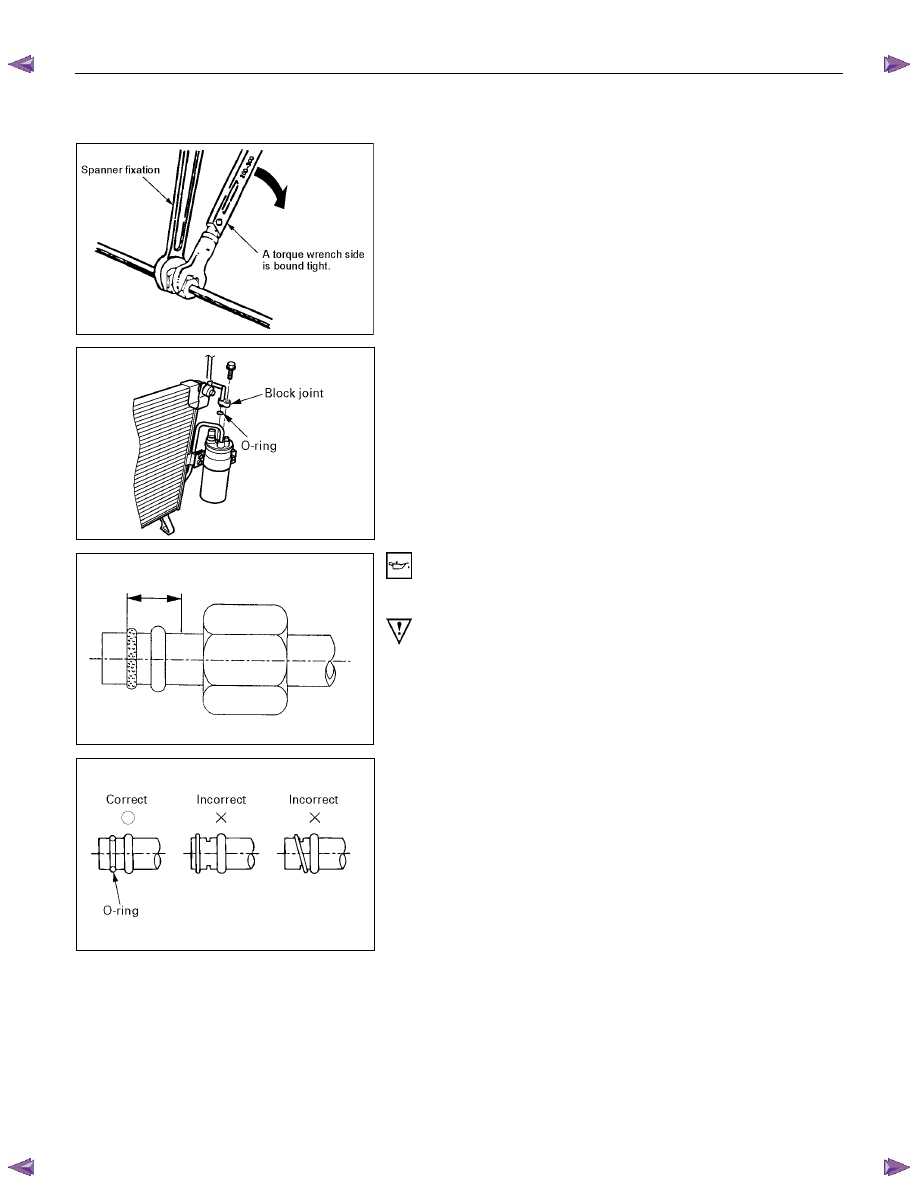

Install new O-ring, if required. When disconnecting or

connecting lines, use two wrenches to prevent the connecting

portion from twisting or becoming damaged.

When connecting the refrigerant line at the block joint, securely

insert the projecting portion of the joint portion into the

connecting hole on the unit side and secure with a bolt.

Apply specified compressor oil to the O-rings prior to

connecting.

CAUTION:

Compressor (PAG) oil to be used varies according to

compressor model. Be sure to apply oil specified for the

model of compressor.

O-rings must be closely aligned with raised portion of

refrigerant line.

1-32 HEATER AND AIR CONDITIONING

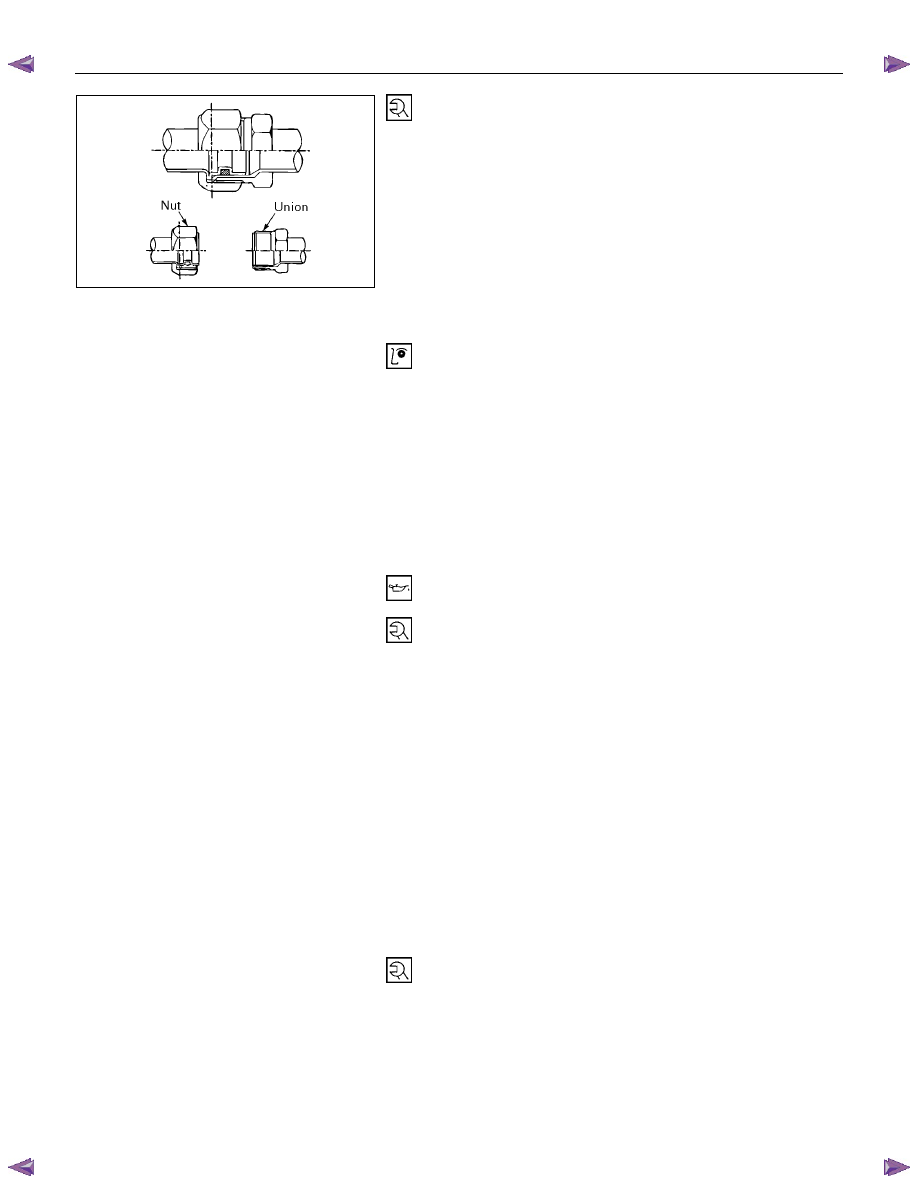

Insert nut into union. First tighten nut by hand as much as

possible. Then, tighten nut to specified torque.

(Refer to "Special Parts Fixing Nuts and Bolts" in this section)

LEAK AT REFRIGERANT LINE

CONNECTIONS

1) Check the torque on the refrigerant line fitting and, if too

loose, tighten to the specified torque.

• Use two wrenches to prevent twisting and damage to the

Line.

• Do not over tighten.

2) Perform a leak test on the refrigerant line fitting.

3) If the leak is still present, discharge and recover the

refrigerant from the system.

4) Replace the O-rings.

• O-rings cannot be reused. Always replace with new

ones.

• Be sure to apply specified compressor oil to the new O-

rings.

5) Retighten the refrigerant line fitting to the specified torque.

• Use two wrenches to prevent twisting and damage to the

line.

6) Evacuate, charge and retest the system.

LEAK IN THE HOSE

If the compressor inlet or outlet hose is leaking, the entire hose

must be replaced. Refrigerant hose must not be cut or spliced

for repair.

1) Locate the leak.

2) Discharge and recover the refrigerant.

3) Remove the hose assembly.

• Cap the open connections at once.

4) Connect the new hose assembly.

• Use two wrenches to prevent twisting or damage to the

hose fitting.

• Tighten the hose fitting to the specified torque.

5) Evacuate, charge and test the system.

COMPRESSOR LEAKS

If leaks are located around the compressor shaft seal or shell,

replace or repair the compressor.

HEATER AND AIR CONDITIONING 1-33

RECOVERY, RECYCLING, EVACUATION

AND CHARGING

Handling Refrigerant-134a (HFC-134a)

Air conditioning systems contain HFC-134a.

This is a chemical mixture, which requires special handling

procedures to avoid personal injury.

• Always wear safety goggles and protective gloves.

• Always work in a well-ventilated area. Do not weld or steam

clean on or near any vehicle-installed air conditioning lines

or components.

• If HFC-134a should come in contact with any part of the

body, flush the exposed area with cold water and

immediately seek medical help.

• If it is necessary to transport or carry any container of HFC-

134a in a vehicle, do not carry it in the passenger

compartment.

• If it is necessary to fill a small HFC-134a container from a

large one, never fill the container completely. Space should

always be allowed above the liquid for expansion.

• Keep HFC-134a containers stored below 40°C (104°F).

WARNING

•••• SHOULD HFC-134a CONTACT YOUR EYE(S), CONSULT

A DOCTOR IMMEDIATELY.

•••• DO NOT RUB THE AFFECTED EYE(S). INSTEAD,

SPLASH QUANTITIES OF FRESH COLD WATER OVER

THE AFFECTED AREA TO GRADUALLY RAISE THE

TEMPERATURE OF THE REFRIGERANT ABOVE THE

FREEZING POINT.

•••• OBTAIN PROPER MEDICAL TREATMENT AS SOON AS

POSSIBLE. SHOULD THE HFC-134a TOUCH THE SKIN,

THE INJURY MUST BE TREATED THE SAME AS SKIN

WHICH HAS BEEN FROSTBITTEN OR FROZEN.

F06R300012

REFRIGERANT RECOVERY

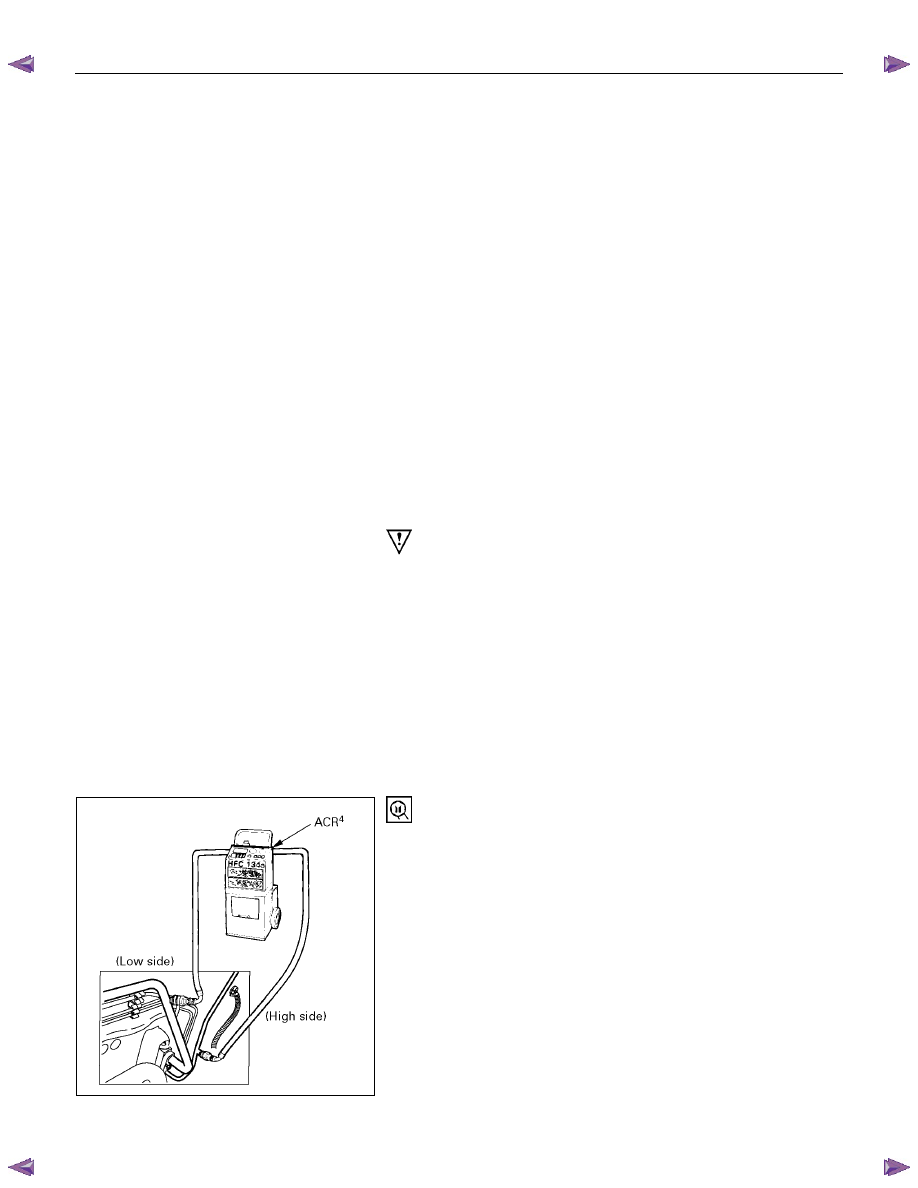

The refrigerant must be discharged and recovered by using

ACR

4

(HFC-134a Refrigerant Recovery/Recycling/Recharging/

System) or equivalent before removing or installing air

conditioning parts.

ACR

4

(115V 60Hz) :5-8840-0629-0 (J-39500-A)

ACR

4

(220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4

(220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

1) Connect the high and low charging hoses of the ACR

4

(or

equivalent) as shown.

2) Recover the refrigerant by following the ACR

4

Manufacturer's Instructions.

3) When a part is removed, put a cap or a plug on the

connecting portion so that dust, dirt or moisture cannot get

into it.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст