Isuzu KB P190. Manual — part 678

Engine Mechanical – V6

Page 6A1–233

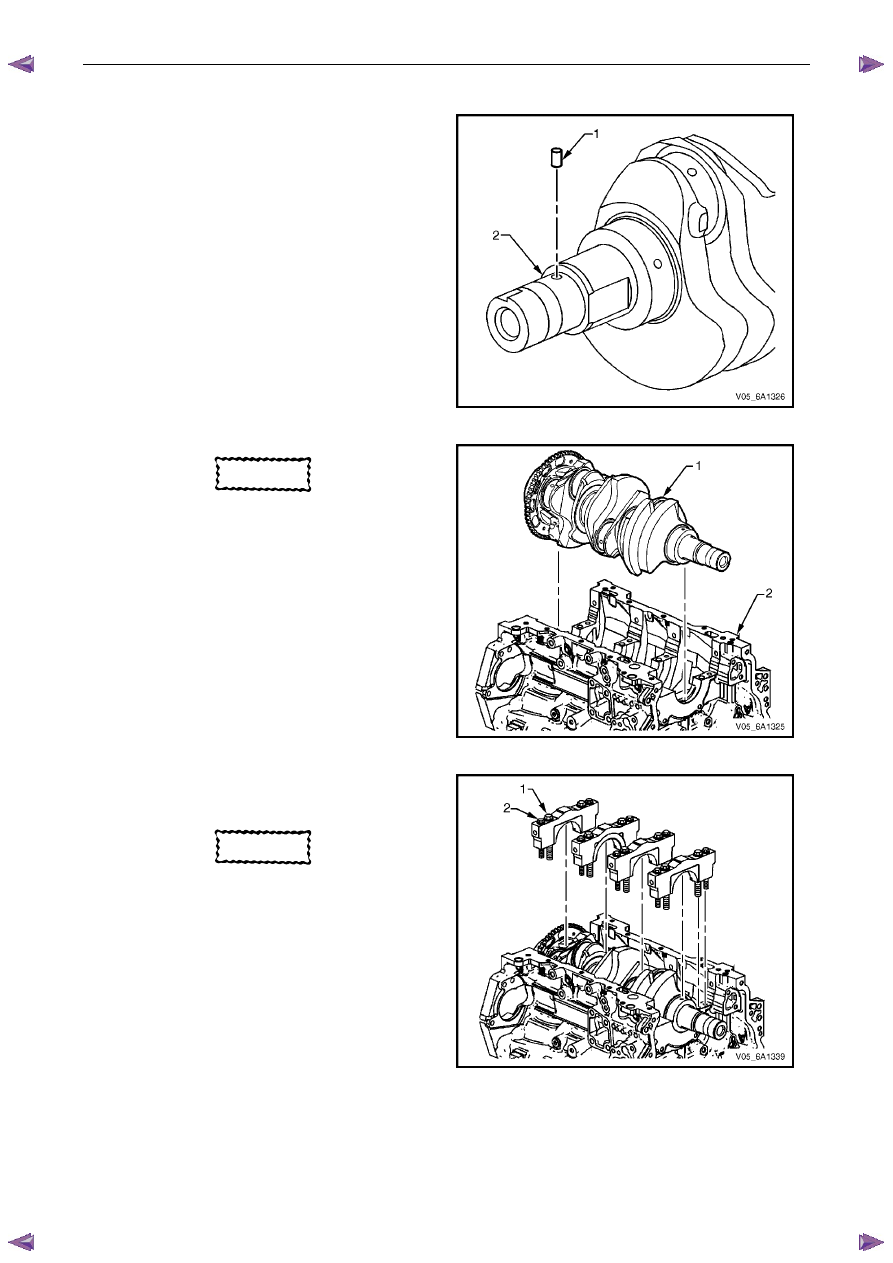

Crankshaft Final Installation Procedure

1

If removed, install the crankshaft sprocket drive

pin (1). Lightly tap the pin in place with a small soft

face, bronze/plastic, hammer until it bottoms in the

hole.

Figure 6A1 – 432

CAUTION

Ensure the crankshaft position sensor has

been removed from the cylinder block prior

to loading the crankshaft, as damage to the

sensor may occur.

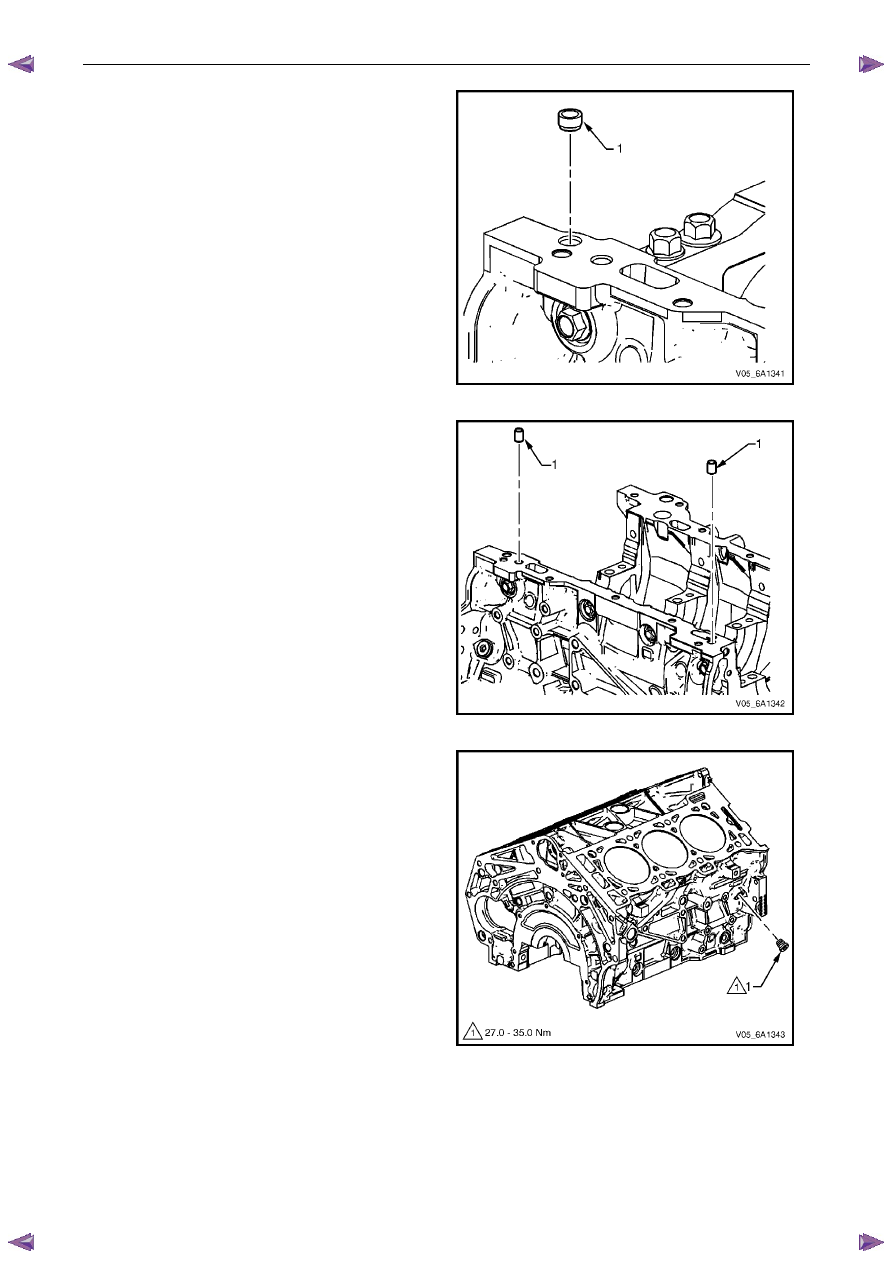

2

Apply a liberal amount of clean engine oil to the upper

and lower bearing surfaces.

3

Gently lower the crankshaft (1) into position in the

cylinder block (2).

Figure 6A1 – 433

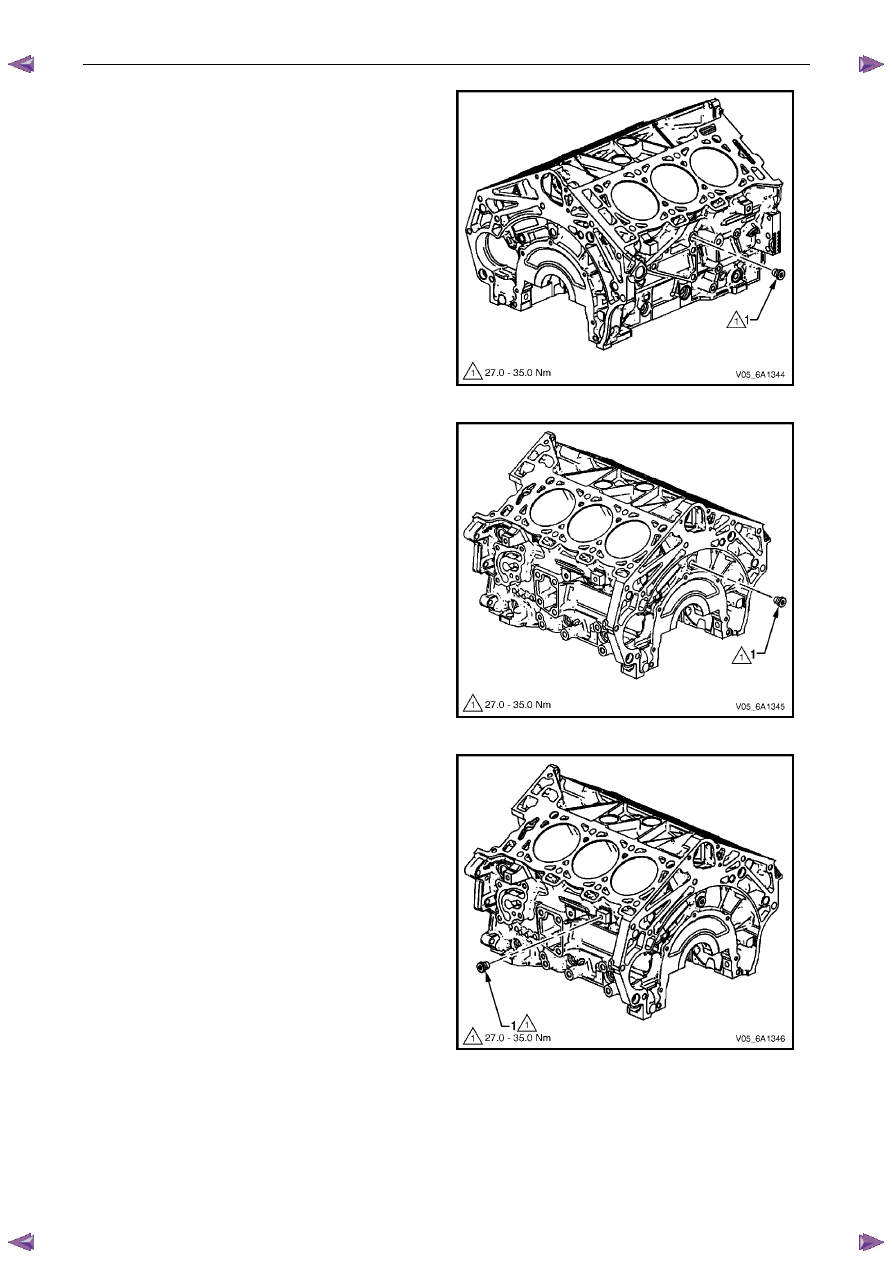

4

Install the crankshaft main bearing caps.

5

Loosely install the original inner main cap bolts (1).

CAUTION

The outer crankshaft bearing cap bolts (2)

are yield tightened during assembly and

must be replaced prior to reassembly. Outer

crankshaft bearing cap bolts that are not

replaced will not torque to the correct clamp

load and can lead to serious engine damage.

6

Loosely install the new outer main bearing cap

bolts (2).

7

Gently tap the crankshaft main bearing caps with a

soft-faced hammer to help seat the caps.

Figure 6A1 – 434

Engine Mechanical – V6

Page 6A1–234

8

Loosely install new short / inner side main cap

bolts (4).

CAUTION

• The short / inner side main cap bolts

originally have a sealant on the flange of

the bolt head. New bolts must be used. If

new bolts are not used, oil can leak from

the crankcase past the bolts.

• The long / outer side main cap bolts

originally have a sealant on the flange of

the bolt head. New bolts must be used. If

new bolts are not used, oil can leak from

the crankcase past the bolts.

9

Loosely install the new long / outer side main cap

bolts (3).

10

Tighten the main caps bolts to the correct torque

specification, and in the following sequence.

Crankshaft main bearing cap inboard

attaching bolt torque specification:

Stage 1 . . . . . . .20.0 Nm

Stage

2 . . . . . . . . .80°

Crankshaft main bearing cap outboard

attaching bolt torque specification:

Stage 1 . . . . . . .15.0 Nm

Stage

2 . . . . . . . ...110°

Crankshaft main bearing cap side

attaching bolt torque specification:

Stage 1 . . . . . . .30.0 Nm

Stage

2 . . . . . . . . .60°

Figure 6A1 – 435

11

Ensure the crankshaft turns without binding or noise.

12

Install the remaining components in the reverse order to removal, refer to the appropriate Section.

4.7 Cylinder

Block

Disassemble

1

Remove oil jet bolt (1) attaching the oil jet (2), three

places.

Figure 6A1 – 436

Engine Mechanical – V6

Page 6A1–235

2

Remove the right-hand front oil pan rail oil gallery

expansion plug (1).

Figure 6A1 – 437

3

Remove the cylinder block-to-oil pan alignment

dowels (1).

Figure 6A1 – 438

4

Remove the right-hand side M14 oil gallery threaded

plug (1).

Figure 6A1 – 439

Engine Mechanical – V6

Page 6A1–236

5

Remove the right-hand side M14 coolant drain

threaded plug (1).

Figure 6A1 – 440

6

Remove the rear M14 oil gallery threaded plug (1).

Figure 6A1 – 441

7

Remove the left-hand side M14 coolant drain

threaded plug (1).

Figure 6A1 – 442

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст