Isuzu KB P190. Manual — part 679

Engine Mechanical – V6

Page 6A1–237

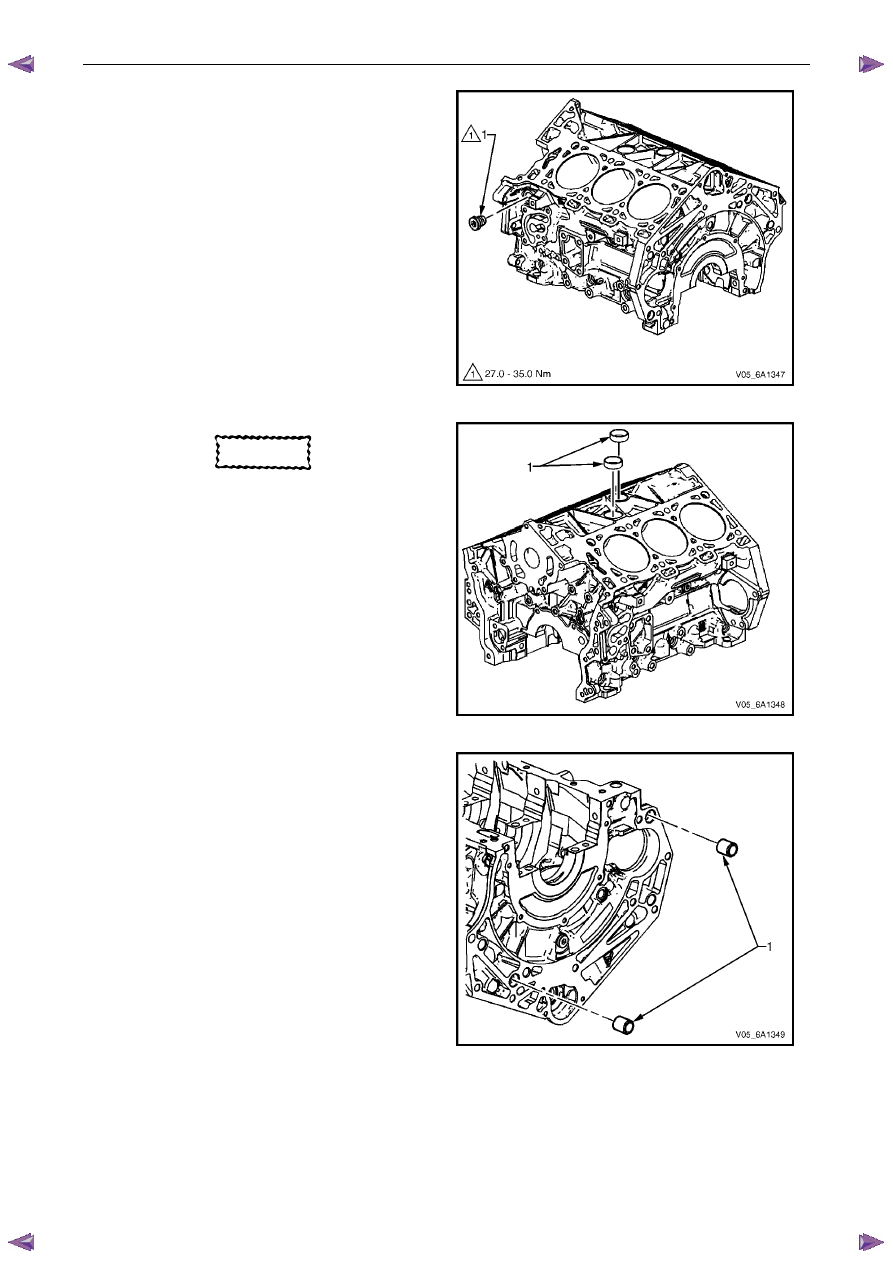

8

Remove the left-hand side M20 oil gallery threaded

plug (1).

Figure 6A1 – 443

CAUTION

Do not force coolant expansion plugs

downwards during removal procedure as the

cylinder block will be damaged.

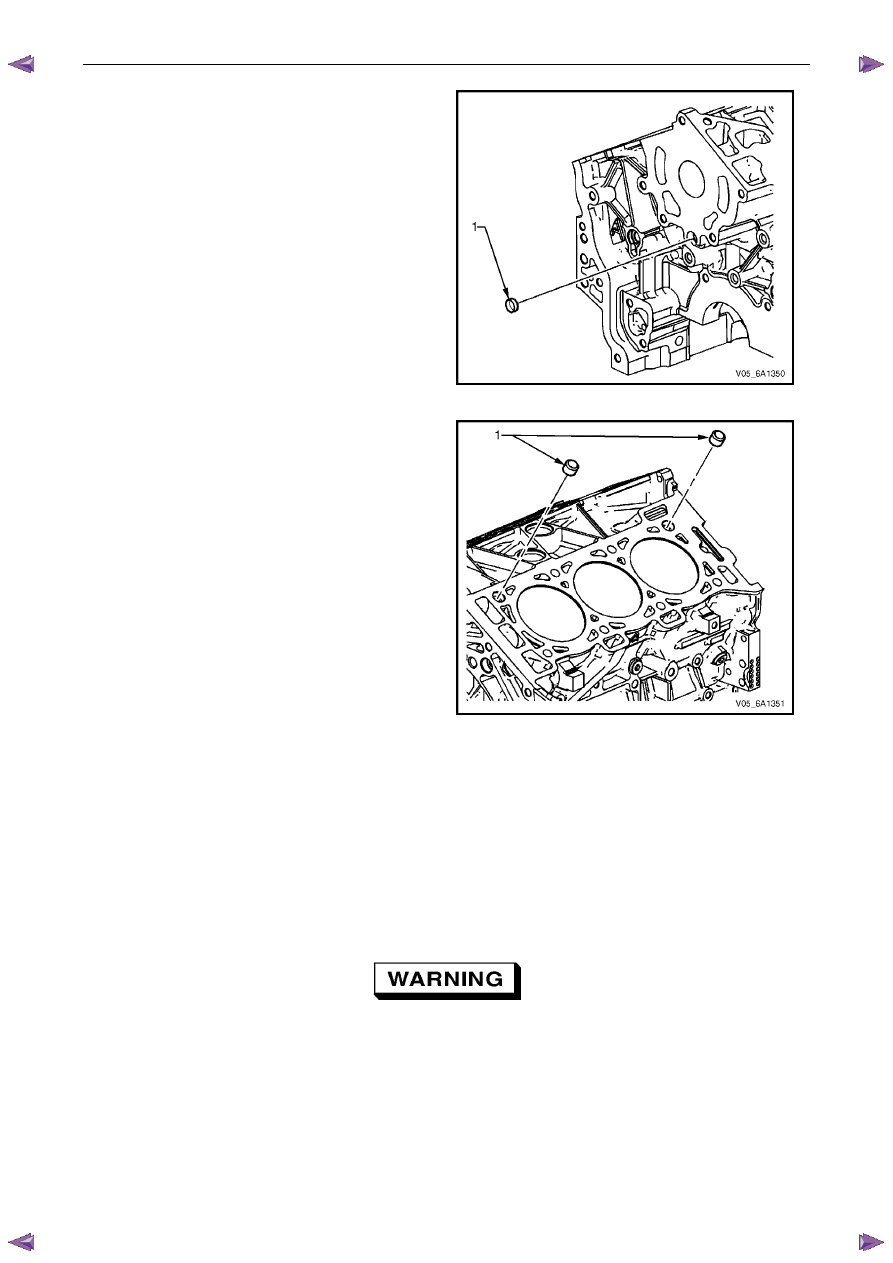

9

Remove the coolant expansion plugs (1).

Figure 6A1 – 444

10

Remove the cylinder block-to-transmission alignment

dowels (1).

Figure 6A1 – 445

Engine Mechanical – V6

Page 6A1–238

11

Remove the front oil gallery expansion plug (1).

Figure 6A1 – 446

12

Remove the cylinder block-to-cylinder head alignment

dowels (1).

Figure 6A1 – 447

Clean

1

Remove all thread sealant, gasket material or sealant using a commercially available plastic or wood scraper.

2

Clean all the following areas with a suitable solvent:

•

sealing surfaces,

•

cooling passages,

•

oil passages, and

•

bearing journals.

3

Clean all threaded and through holes with a suitable solvent.

Safety glasses must be worn when using

compressed air.

4

Dry the engine block with compressed air.

Engine Mechanical – V6

Page 6A1–239

Inspect

Visual Inspection

N O T E

The following procedure assumes the engine has

been disassembled and cleaned, as described

above.

1

Inspect the crankshaft bearing journals for damage or spun bearings. The crankshaft bearing journals are not

repairable and if damage is found, the cylinder block assembly must be replaced.

2

Inspect the primary camshaft chain tensioner mounting surface on the engine block for burrs or any defects that

would affect the sealing of the new primary camshaft chain tensioner gasket.

3

Inspect all sealing and mating surfaces for damage, repair or replace the cylinder block assembly if required.

4

Inspect all threaded and through holes for damage or excessive debris.

5

Inspect all bolts for damage, if damaged replace with new bolts only.

6

Inspect the cylinder walls for cracks or damage. The cylinder sleeves are not serviced separately, if the cylinders

are damaged the cylinder block assembly must be replaced.

7

Inspect the engine block for cracks. Do not repair any cracks. If cracks are found, the cylinder block assembly must

be replaced. Repair any damaged threaded holes, refer to 4.9

Thread Repair Specifications.

Measuring Cylinder Bore Diameter

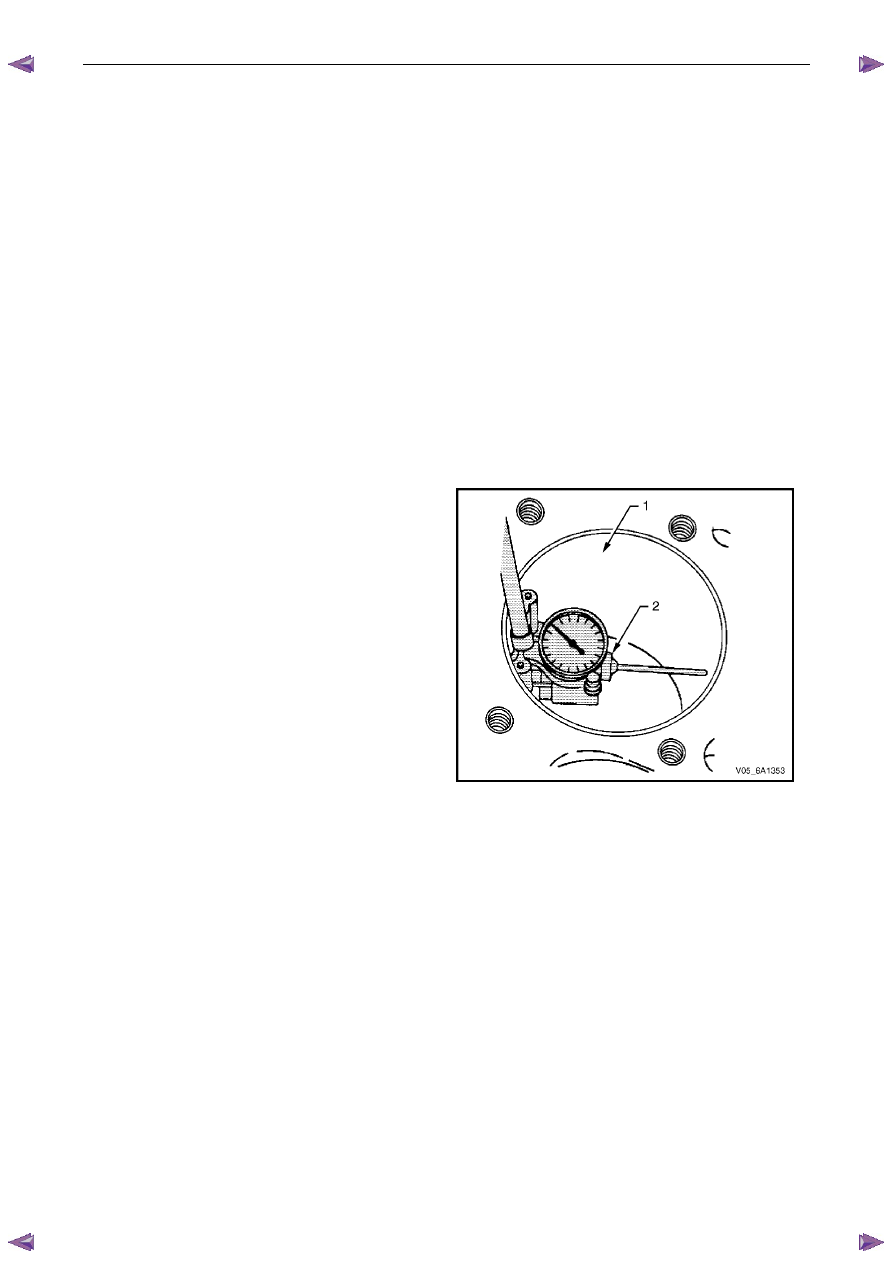

1

Measure the cylinder bore diameter 37 mm from the

deck face (1) using a commercially available bore

gauge or Tool No. J-8087 (2).

2

Record the results and compare with the dimensions

listed in the specifications, refer to 5

Specifications.

N O T E

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of

oversized pistons and rings are available for

service. If the cylinder bore diameter exceeds

specification by more than 0.25 mm, the

cylinder block must be replaced.

Figure 6A1 – 448

Measuring Cylinder Bore Taper

1

Measure the cylinder bore along the thrust surfaces, perpendicular to the crankshaft centreline, at 10 mm below the

deck surface and record the measurement.

2

Measure the cylinder bore along the thrust surfaces, perpendicular to the crankshaft centreline, at 100 mm below

the deck surface and record the measurement.

3

Calculate the difference between the two measurements. The result will be the cylinder taper.

4

Compare the results with the dimensions listed in the specifications, refer to 5

Specifications.

N O T E

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of oversized

pistons and rings are available for service. If the

cylinder bore diameter exceeds specification by

more than 0.25 mm, the cylinder block must be

replaced.

Measuring Cylinder Bore Out-of-Round

1

Measure both the thrust and non-thrust cylinder diameter at 10 mm below the deck. Record your measurements.

Engine Mechanical – V6

Page 6A1–240

2

Calculate the difference between the two measurements. The result will indicate out-of-round at the upper end of

the cylinder.

3

Measure both the thrust and non-thrust cylinder diameter at 100 mm below the deck surface. Record your

measurements.

4

Calculate the difference between the two measurements. The result will indicate out-of-round at the lower end of

the cylinder.

5

Compare your results with the dimensions listed in the specifications, refer to 5

Specifications.

N O T E

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of oversized

pistons and rings are available for service. If the

cylinder bore diameter exceeds specification by

more than 0.25 mm, the cylinder block must be

replaced.

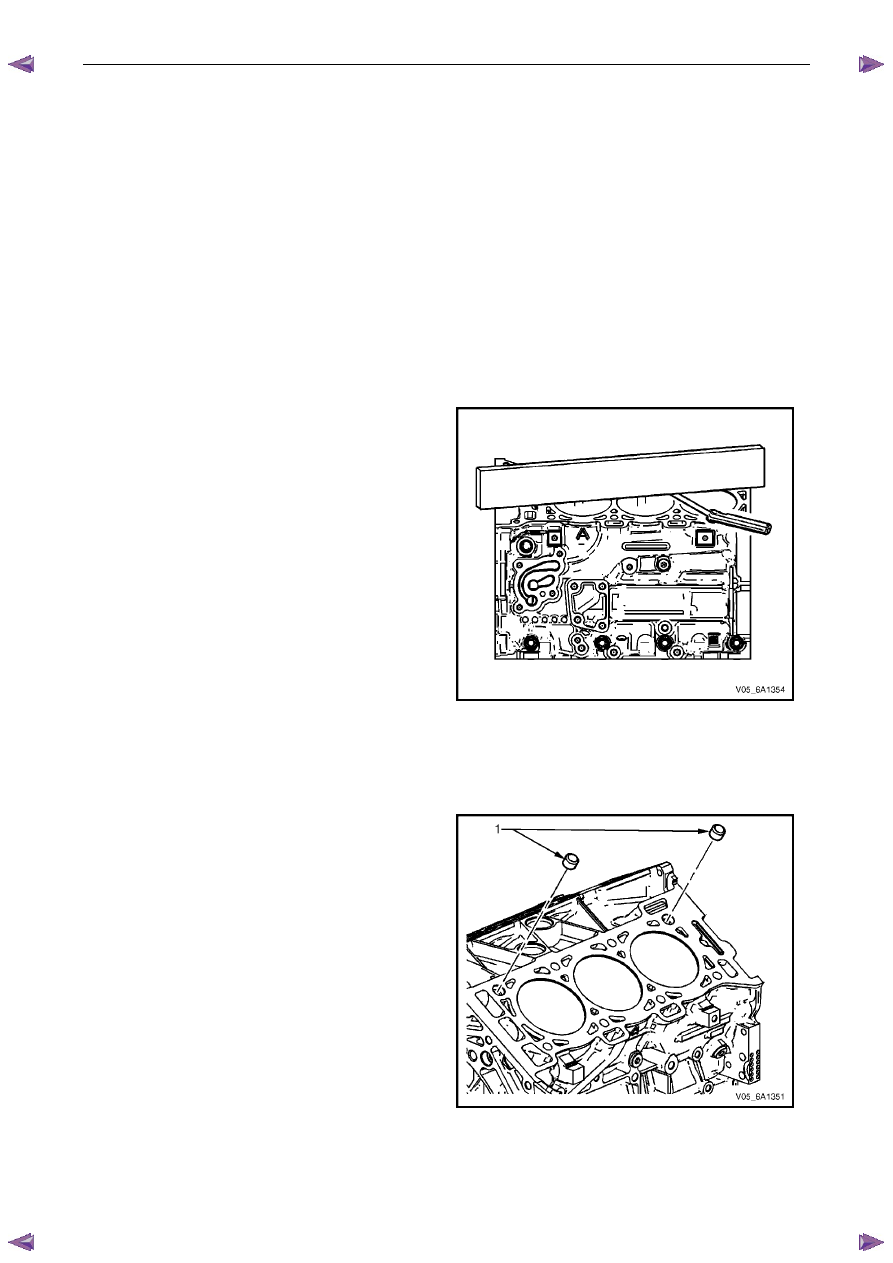

Deck Flatness Inspection

1

Ensure the engine block decks are clean and free of

gasket material.

2

Inspect the surface for any imperfections or scratches

that could inhibit correct cylinder head gasket sealing.

3

Place a straight-edge diagonally across the cylinder

block deck face surface.

4

Measure the clearance between the straight-edge

and the cylinder block deck face using a feeler gauge

at 4 points along the straight-edge.

5

If the warpage is less than 0.05 mm, the cylinder

block deck surface does not require resurfacing.

6

If the warpage is between 0.05 ±0.20 mm or any

imperfections or scratches that could inhibit correct

cylinder head gasket sealing are present, the cylinder

block deck surface requires resurfacing.

7

If resurfacing is required the maximum amount that

can be removed is 0.25 mm.

8

If the cylinder block deck surface requires more than

0.25 mm material removal the block must be

replaced.

Figure 6A1 – 449

Reassemble

1

Install the cylinder block-to-cylinder head alignment

dowels (1).

Figure 6A1 – 450

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст