Isuzu KB P190. Manual — part 1233

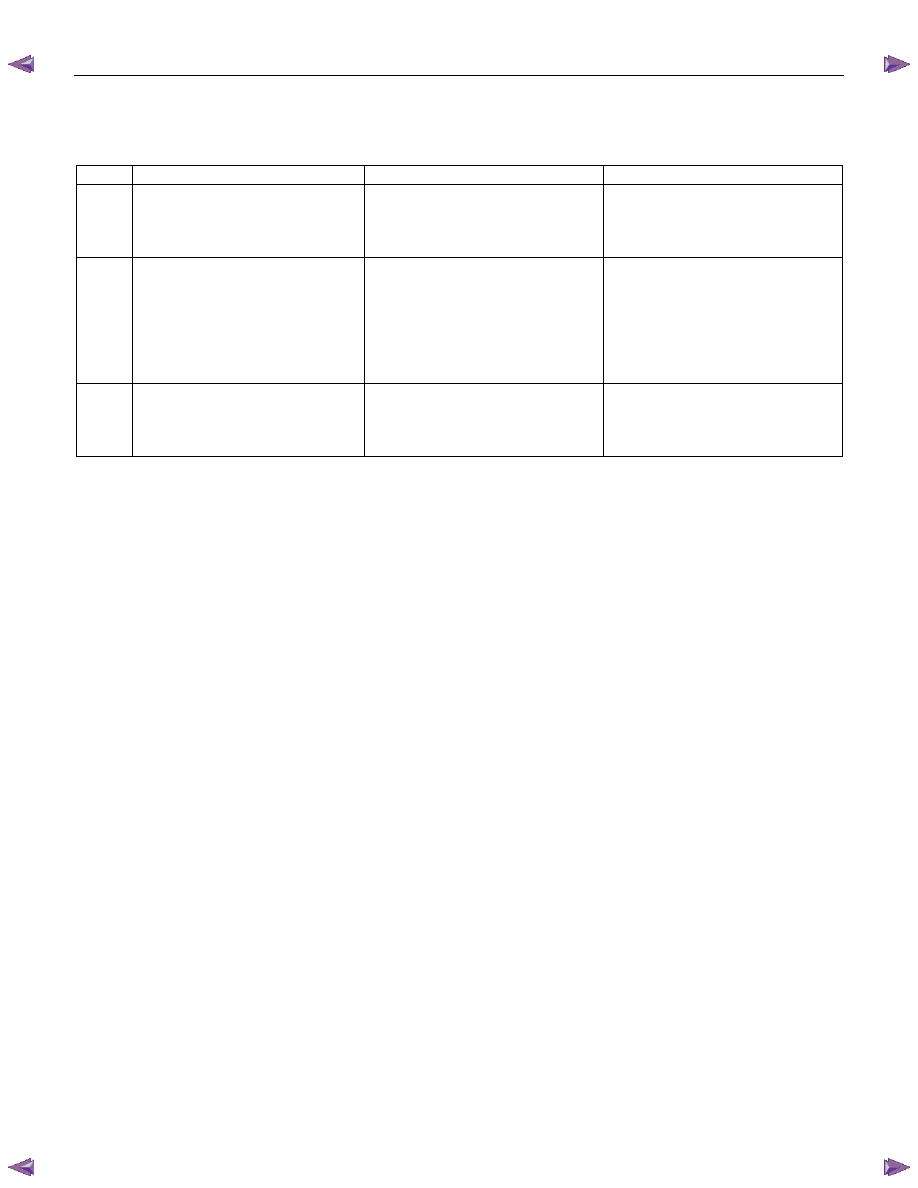

7D1-58 TRANSFER CONTROL SYSTEM

Transfer cannot shift to another position (Except “Check 4WD” failure).

When shifting to another position, indicator (4WD, 4Lo, Check4WD, neutral) does not

respond (Current condition keeping).

Step Action

Yes

No

1

Is the ignition switch ON?

Go to step 2.

Failed indicator and harness

(When lighting).

After repairing, trace this chart

from the beginning.

2

Does the transfer-related

indicators (4WD, 4Lo, Check

4WD, neutral) light up for 2

seconds when the ignition switch

is turned ON?

Go to step 3.

All indicators are burnt out

(Check for GND short circuit

between the indicator and

transfer controller).

Disconnected harness wire.

After repairing, trace this chart

from the beginning.

3

Press the other positions button.

Is the sound of relay heard from

under the seat, and the sound of

a running motor heard?

Failed controller.

After replacing the controller,

trace this chart from the

beginning.

*Failed operation switch. Or

harness for the operation switch

has disconnected or shorted.

* The operation switch is an analog type switch which reads the internal composite resistance value at the time of

operation. If an abnormal value is detected, it is kept at the home position (The position before operating it).

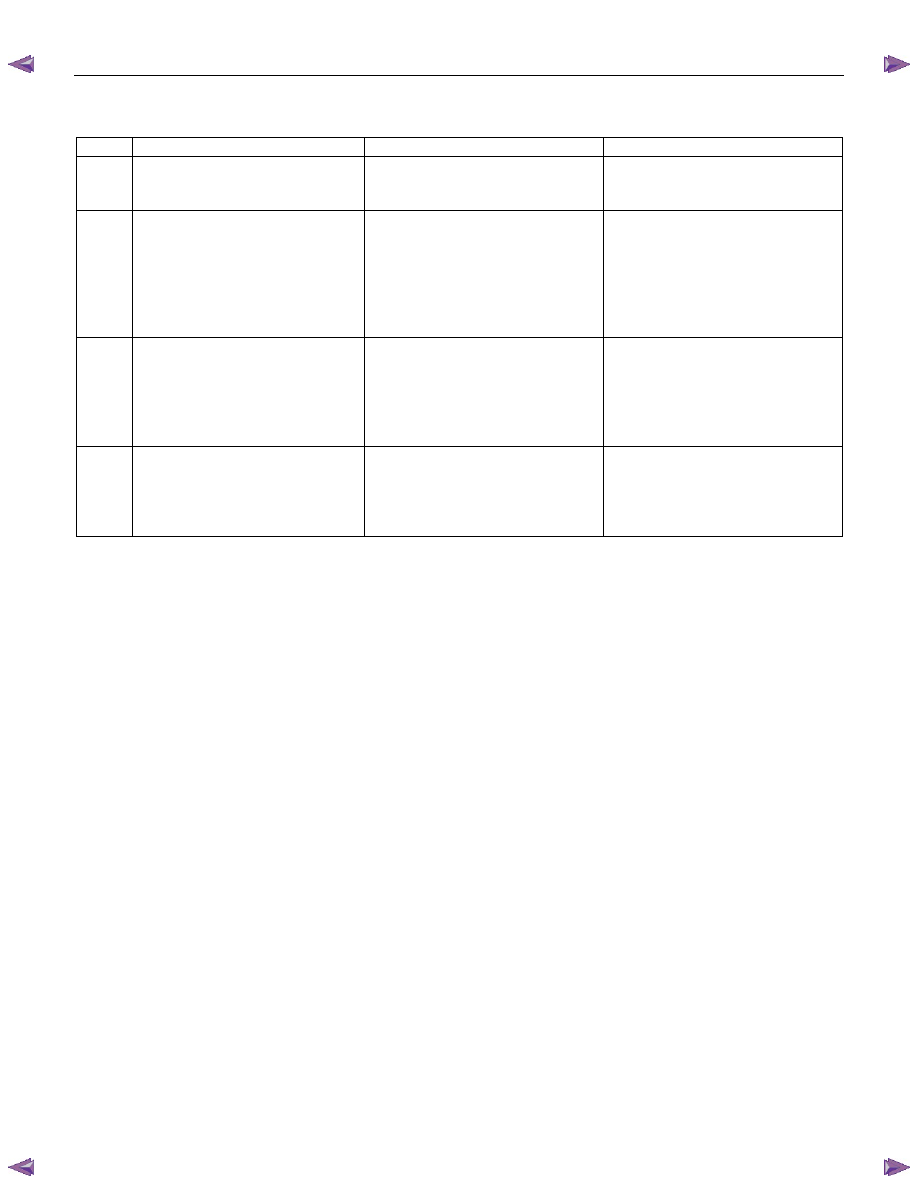

TRANSFER CONTROL SYSTEM 7D1-59

Even after the correction step 2-1(*), the 4WD indicator still blinks at 2Hz when shifting

from 4H to 2H.

Step Action

Yes

No

1

Check all the tires for air

pressure and wear. Is any

trouble detected?

After adjusting the air pressure

and repairing the worn tires, try

the correction step 2-1(*).

Go to step 2.

2

Check the 4WD detection switch

on the transfer case and neutral

detection switch and each

harness. Is a trouble detected?

4WD detection switch is closed

or the GND short of harness.

The neutral detection switch is

closed or the harness GND has

shorted.

Replace or repair and then trace

this chart from the beginning.

Go to step 3.

3

Is there continuity in the harness

between the transfer controller

and axle actuator?

Has a short or disconnection

been detected?

Is the connection incorrect?

Go to step 4.

Body short, disconnection or

incorrect connection of the

harness between the transfer

controller and actuator.

After repairing, trace this chart

from the beginning.

4

Is trouble detected in the axle

detection harness between the

axle actuator and transfer

controller?

GND short of harness

Malfunction of axle actuator.

Refer to the paragraph of axle

disconnect.

After repairing, trace this chart

from the beginning.

*Before determining a trouble (Non-trouble mode)

Note:

Vehicle with manual hub and rigid hub don’t have axle actuator.

When the above-mentioned procedure is followed, check the harness between the axle dummy output terminal and

the axle switch input terminal of the transfer controller, instead of axle actuator.

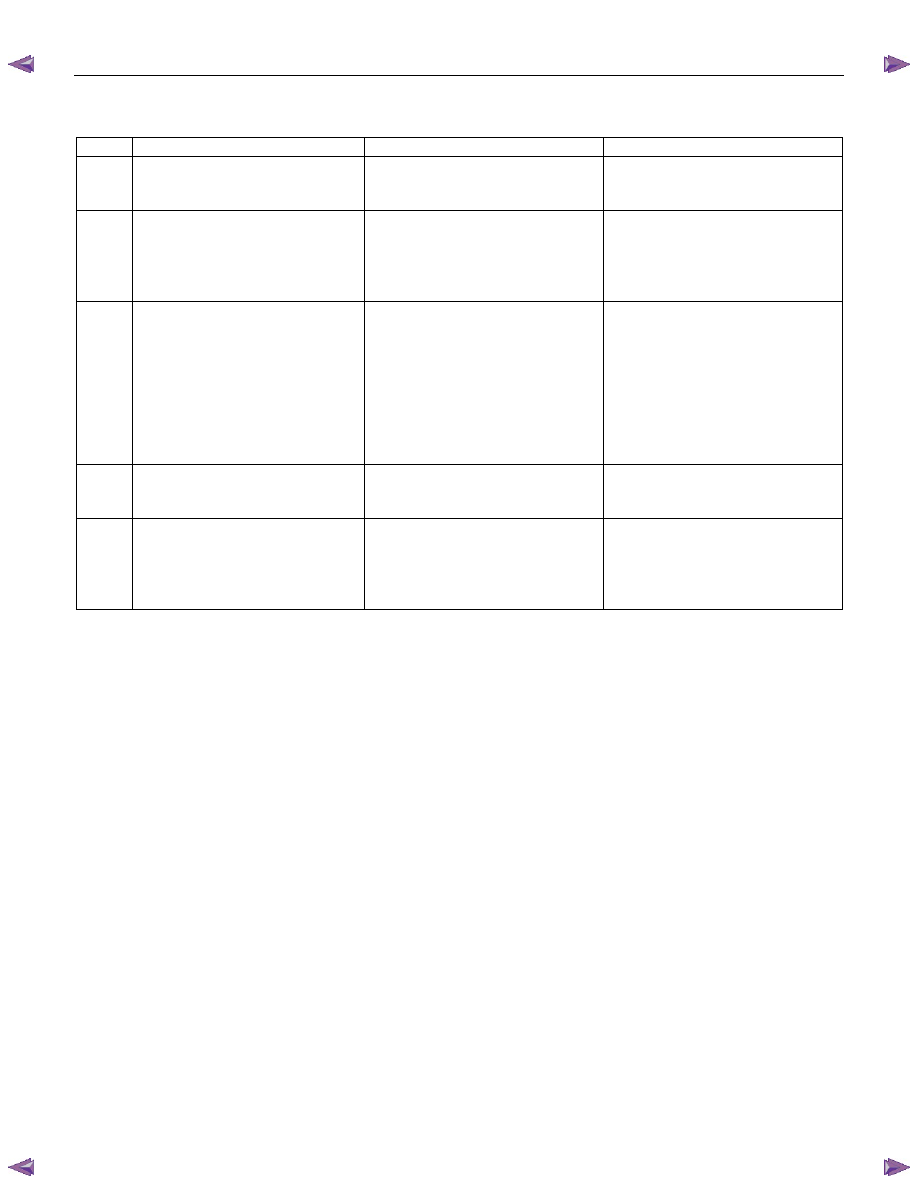

7D1-60 TRANSFER CONTROL SYSTEM

Though the indicator responds when shifting from 4H to 2H(or other position), it returns

to 4H.

Step Action

Yes

No

1

Is the ignition switch ON?

Go to step 2.

Turn the ignition switch ON and

trace this chart from the

beginning.

2

Does the transfer-related

indicators (4WD, 4Lo, Check

4WD, neutral) light up for 2

seconds when the ignition switch

is turned ON?

Go to step 3.

Indicator lamp burnt out.

Disconnected harness wire.

After repairing, trace this chart

from the beginning.

3

After 2 seconds, check if the

Check4WD lamp lights up.

Is the Check4WD lamp OFF?

Go to step 4.

Failed actuator position detection

(limit) switch (LS1, LS2, LS3,

LS4, GND).

Short or disconnection of harness

of this detection switch.

Refer to paragraph of

Check4WD.

After repairing, trace this chart

from the beginning.

4

Press the 2H button.

Is the sound of relay heard from

the transfer controller?

Go to step 5.

Failed controller.

Replace the controller and trace

this chart from the beginning.

5

Is the sound of a running motor

heart?

Failed control system of the

transfer mechanism. Check and

repair and trace this chart from

the beginning.

Failed actuator motor.

Disconnection of controller motor

drive output circuit or GND short.

After repairing, trace this chart

from the beginning.

If the motor does not or cannot run at all (stuck transfer mechanism, disconnected motor, failed drive circuit), the

lamp blinks at 4Hz when the position is shifted to other position by pressing the button for more 10 seconds (20

seconds in case of neutral position).

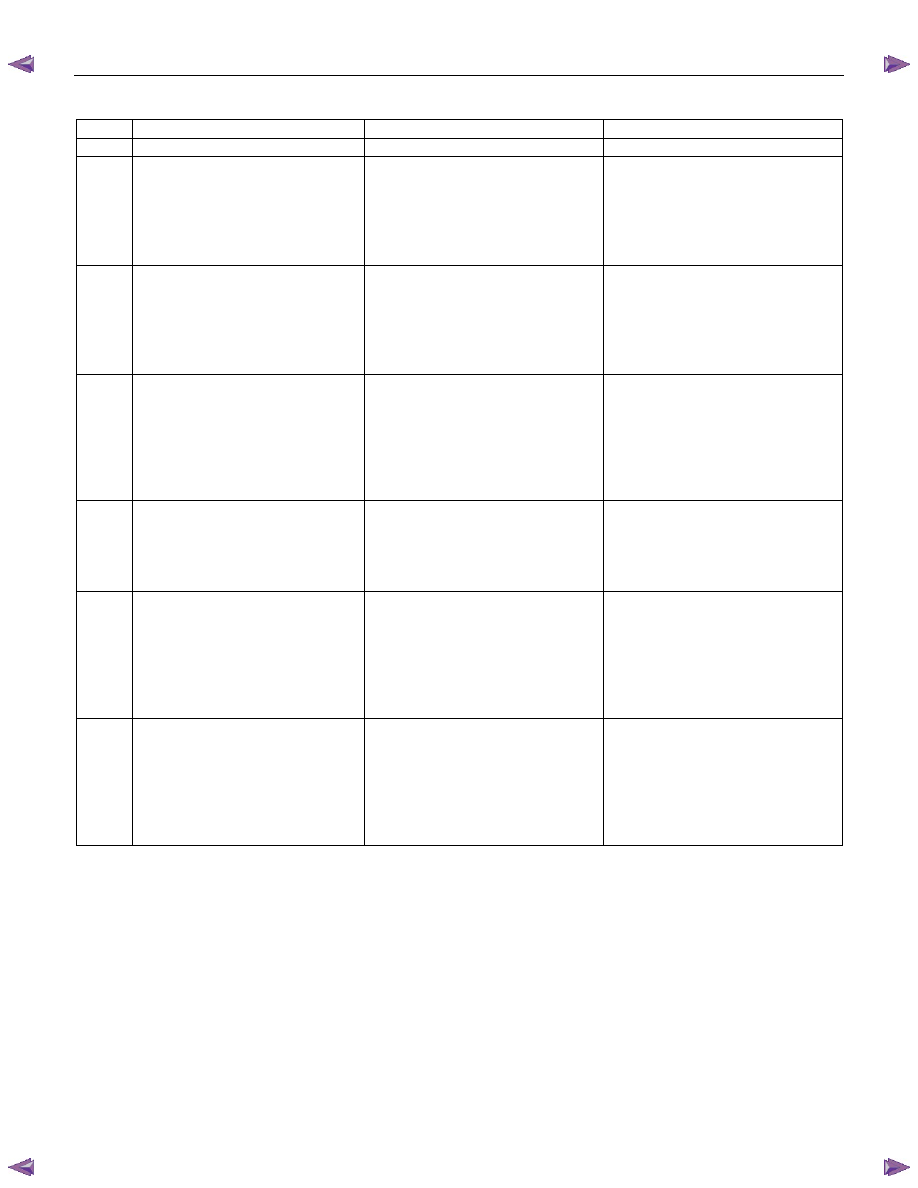

TRANSFER CONTROL SYSTEM 7D1-61

From 4H to 4L; Even after the correction step 3-3(*), 4Lo indicator blinks at 4Hz

Step Action

Yes

No

1

Is the ignition switch ON?

Turn it OFF once.

Go to step 2.

2

Turn ON the ignition switch and

check the valve. Do not start

the engine.

Has the valve check for 2

seconds been completed

normally?

Go to step 3.

Refer to the paragraph about the

indicator when it does not react

when shifted from 2H to 4H.

After taking the remedy, trace this

chart from the beginning.

3

Shift to 2H.

Can be shifted to 2H and then to

4H?

Go to step 4.

Refer to the paragraph about

shifting from 2H to 4H.

In particular, check if not at the

Check4WD condition, return to

this chart and trace it from the

beginning.

4

Set to N position in case of AT

and set to the neutral position in

case of MT and check if the

lamp blinks at 4Hz after

operation.

Failed T/M position switch and

harness (failure of TM1 and TM2

harness and their related

switches shown in the figure).

Incorrect wiring.

Repair as required and trace this

chart from the beginning.

Shift back to 4H and go to step 5.

5

Start the engine and use the

vehicle.

Does the speedometer run at

this time?

Go to step 6.

Failure of speed sensor or

disconnection or short of harness

(for the meter).

After repairing, trace this chart

from the beginning.

6

Check the harness between the

transfer controller and speed

sensor.

(Check the engine rotation

detection harness at the same

time.)

Is any trouble detected?

Failed harness between the

transfer controller and speed

sensor.

After repairing, trace this chart

from the beginning.

(Repair the engine rotation

detection unit, if required.)

Go to step 7.

7

Run the vehicle for several

meters, stop it, meet the

permission requirements for

operation limits.

Did you wait for several seconds

after the requirements were

met?

Failed controller.

Replace the controller and trace

this chart from the beginning.

You did not wait for enough time.

Optimum waiting time is 1 second

or maximum 3 minutes,

depending on the previous

conditions.

Refer to the paragraph about

operation without failure.

*Before determining a trouble (Non-trouble mode)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст