Isuzu KB P190. Manual — part 1202

7C-30 CLUTCH

RTW57CSH000201

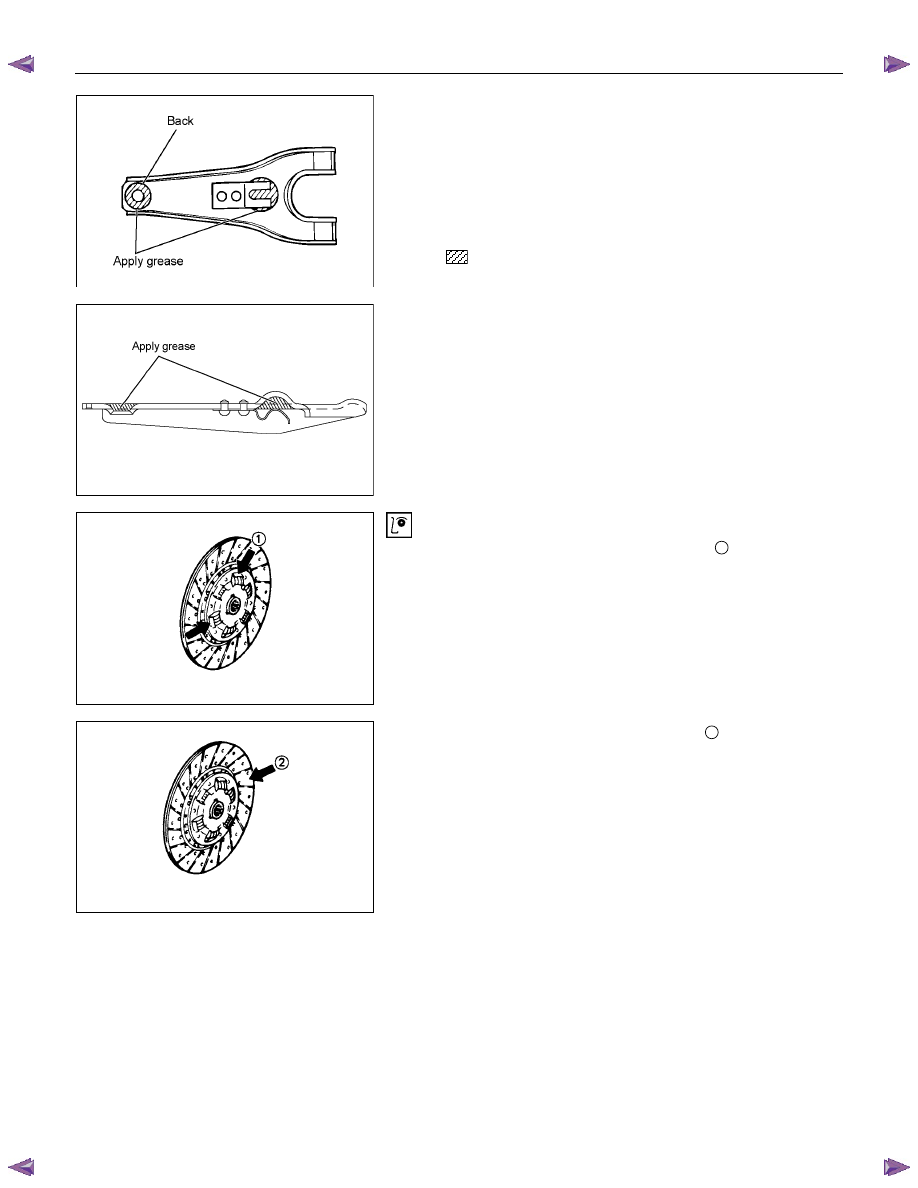

Shift Fork

1. Visually inspect the surfaces of the shift fork making contact

with the release bearing for excessive wear and damage.

2. Remove any minor stepping or abrasion from the release

bearing with an oil stone.

Replace any exhibiting excessive wear or damage.

3. Apply multi-purpose type grease (NLGI No.2 or No.3) to

area.

RTW57CSH000501

DRIVEN PLATE ASSEMBLY

1. Visually inspect the torsion spring

1

for looseness,

breakage, and weakening.

If any of these conditions are discovered, the driven plate

assembly must be replaced.

2. Visually inspect the facing surfaces

2

for cracking and

excessive scorching.

Visually inspect the facing surfaces for the presence of oil

or grease.

If any of these conditions are discovered, the facing must

be cleaned or replaced.

3. Check that the driven plate moves smoothly on the

transmission top gear shaft spline.

Minor ridges on the top gear shaft spline may be removed

with an oil stone.

CLUTCH 7C-31

Driven Plate Warpage

1. Insert the clutch pilot aligner into the driven plate splined

hub.

The clutch pilot aligner must be held perfectly horizontal.

Clutch Pilot Aligner : 5-8525-3001-0

2.

Set a dial indicator to the driven plate outside

circumference.

3. Slowly turn the driven plate.

Read the dial indicator as you turn the driven plate.

If the measured value exceeds the specified limit, the driven

plate assembly and/or the facing must be replaced.

Driven Plate Warpage

mm(in)

Standard

Limit

0.7 (0.028)

1.0 (0.039)

Driven Plate Splined Hub Spline Wear

1. Clean the driven plate splined hub.

2. Install the driven plate to the transmission top gear shaft

spline.

3. Set a surface gauge to the driven plate outside

circumference.

4. Slowly turn the driven plate counterclockwise.

Measure the spline rotation play as you turn the driven

plate.

If the measured value exceeds the specified limit, the driven

plate assembly must be replaced.

Driven Plate Splined Hub Spline Wear

mm(in)

Standard

Limit

0.5 (0.020)

1.0 (0.039)

Rivet Head Depression

Use a depth gauge or a straight edge with steel rule to

measure the rivet head depression

1

from the facing surface

2

.

Be sure to measure the rivet head depression on both sides of

the driven plate.

If the measured value is less than the specified limit, the facing

must be replaced.

Rivet Head Depression

mm(in)

Standard

Fly wheel side

P/Plate side

Limit

4J

series

1.35-1.95

(0.053-0.077)

1.65-2.25

(0.065-0.089)

0.2

(0.008)

C24SE

1.65-2.25

(0.065-0.089)

1.65-2.25

(0.065-0.089)

0.2

(0.008)

4JJ1

(High Output)

1.40-2.00

(0.055-0.079)

1.70-2.30

(0.067-0.091)

0.2

(0.008)

7C-32 CLUTCH

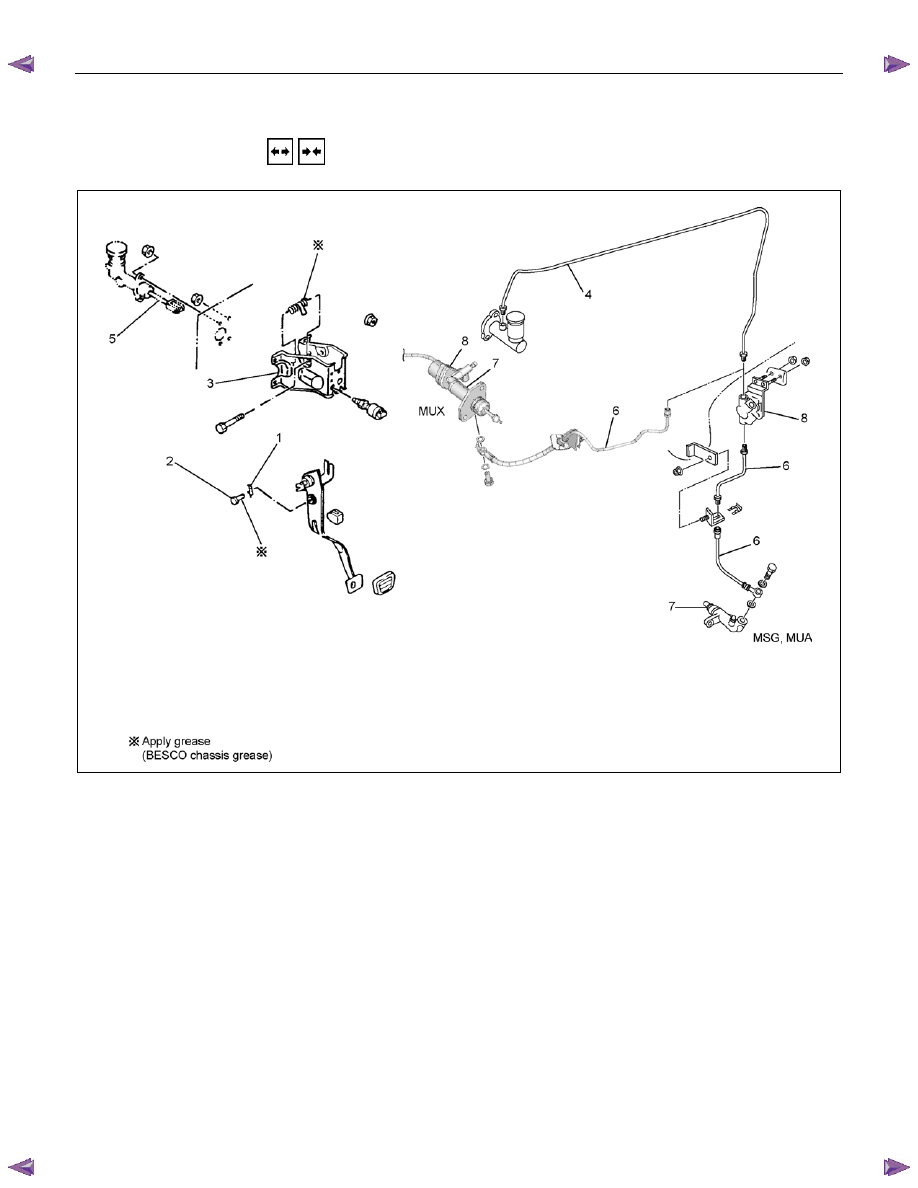

CLUTCH CONTROL

REMOVAL AND INSTALLATION

RTW77CLF000601

Removal Steps

1.

Pin

2. Jaw joint pin

3. Pedal assembly

4. Oil line

5. Master cylinder assembly

6. Oil line

7. Slave cylinder assembly

8. Damper cylinder assembly

Installation Steps

8. Damper cylinder assembly

7. Slave cylinder assembly

6. Oil line

5. Master cylinder assembly

4. Oil line

3. Pedal assembly

2. Jaw joint pin

1.

Pin

CLUTCH 7C-33

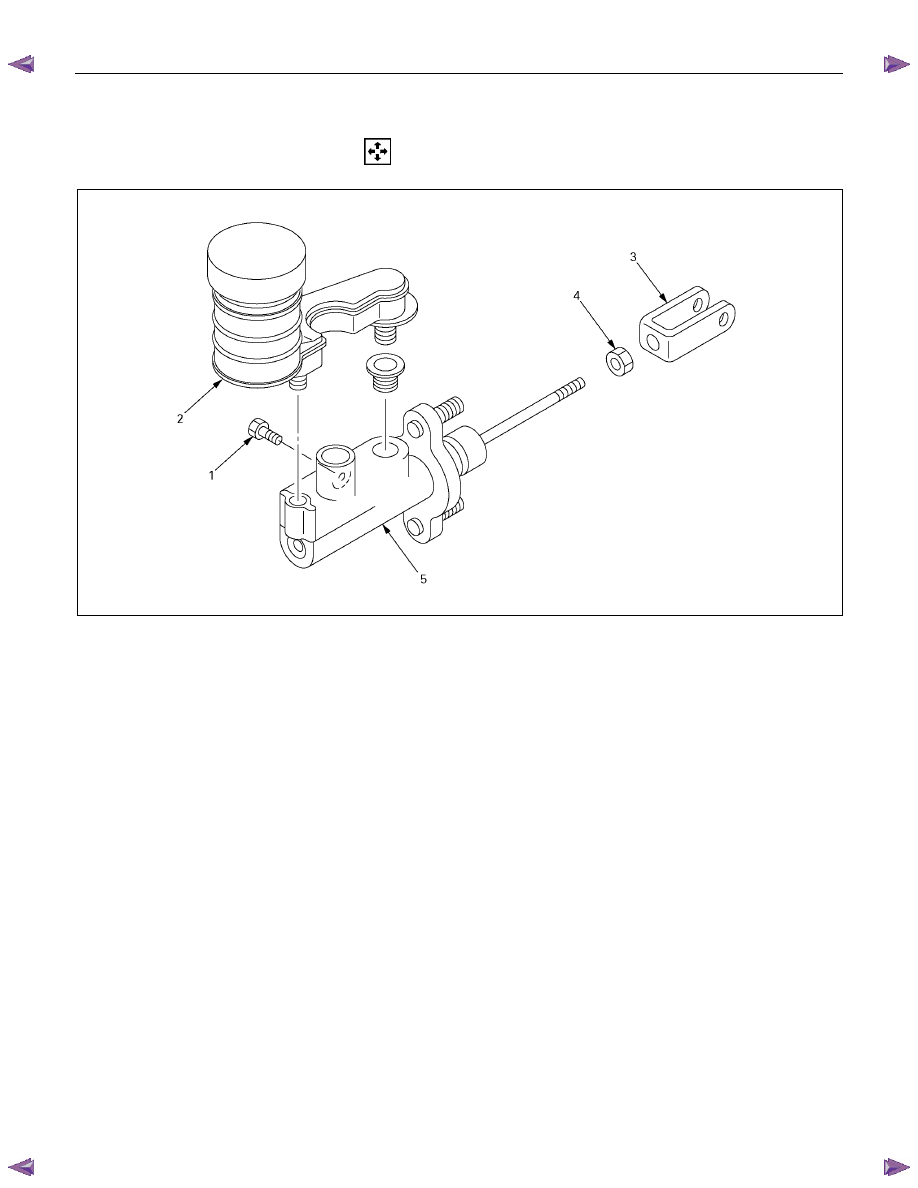

MASTER CYLINDER

DISASSEMBLY

Disassembly Steps

1. Bolt : reservoir tank

2. Reservoir tank

3.

Yoke

4. Lock nut

5. Body sub assembly

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст