Isuzu KB P190. Manual — part 201

TROUBLESHOOTING 6 – 19

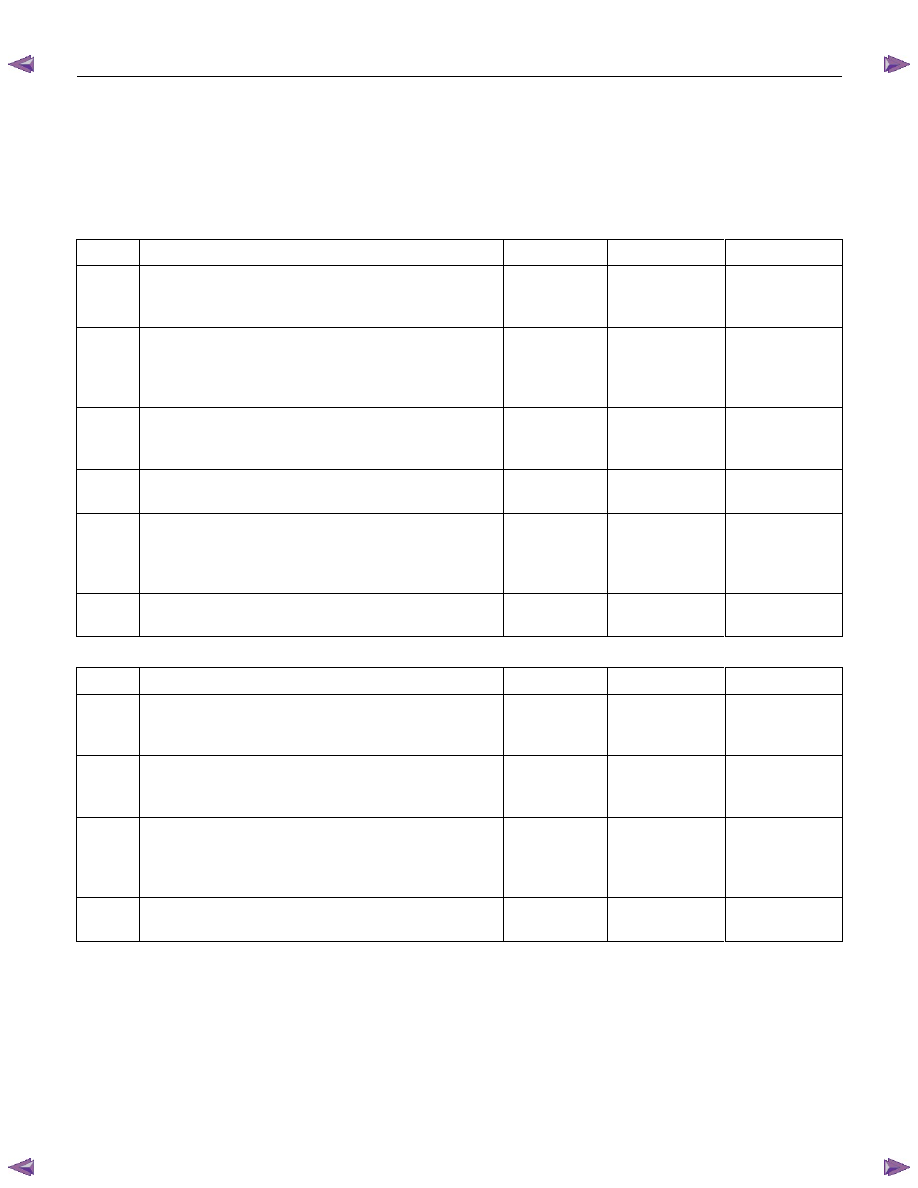

15. Starter Motor Problem

Visual/physical check the following items before diagnosis.

The battery terminals connection condition.

The ground connection condition.

The starter motor or the battery fastener condition.

The battery fluid level and specific gravity.

15-1 Starter motor pinion engages to ring gear but engine does not turn over

Step Action Value(s)

Yes

No

1 Was

“

Visual/Physical Check" performed.

—

Go to Step 2

Go to

visual/physical

check

2

Check the contact condition between the brush and

the commutator.

Was the brush and the commutator contact

intermittent?

—

Replace

the

brush or repair

the

commutator. Go

to

Step 3

3

Were the brush and the commutator contact faces

dirty?

—

Clean contact

face Go

to

Step 4

4

Was the pinion clutch slipped?

—

Replace

the

pinion clutch

Go to Step 5

5

Inspect the armature field coil.

Was there an open circuit or a short circuit in the

armature field coil?

—

Repair

or

replace the

armature field

coil. Go

to

Step 6

6

Are any DTC stored?

—

Go

to

indicated

DTC. Solved

15-2 Incorrect pinion and ring gear engagement

Step Action Value(s)

Yes

No

1 Was

“

Visual/Physical Check" performed.

—

Go to Step 2

Go to

visual/physical

check

2

Inspect the pinion and the ring gear teeth.

Were the pinion and/or the ring gear teeth worn or

broken?

—

Replace the

wron parts.

Go to Step 3

3

Inspect the pinion gear return movement.

Was the pinion gear return movement incorrect?

—

Adjust

or

replace the

movement

parts. Go

to

Step 4

4

Are any DTC stored?

—

Go

to

indicated

DTC. Solved

6 – 20 TROUBLESHOOTING

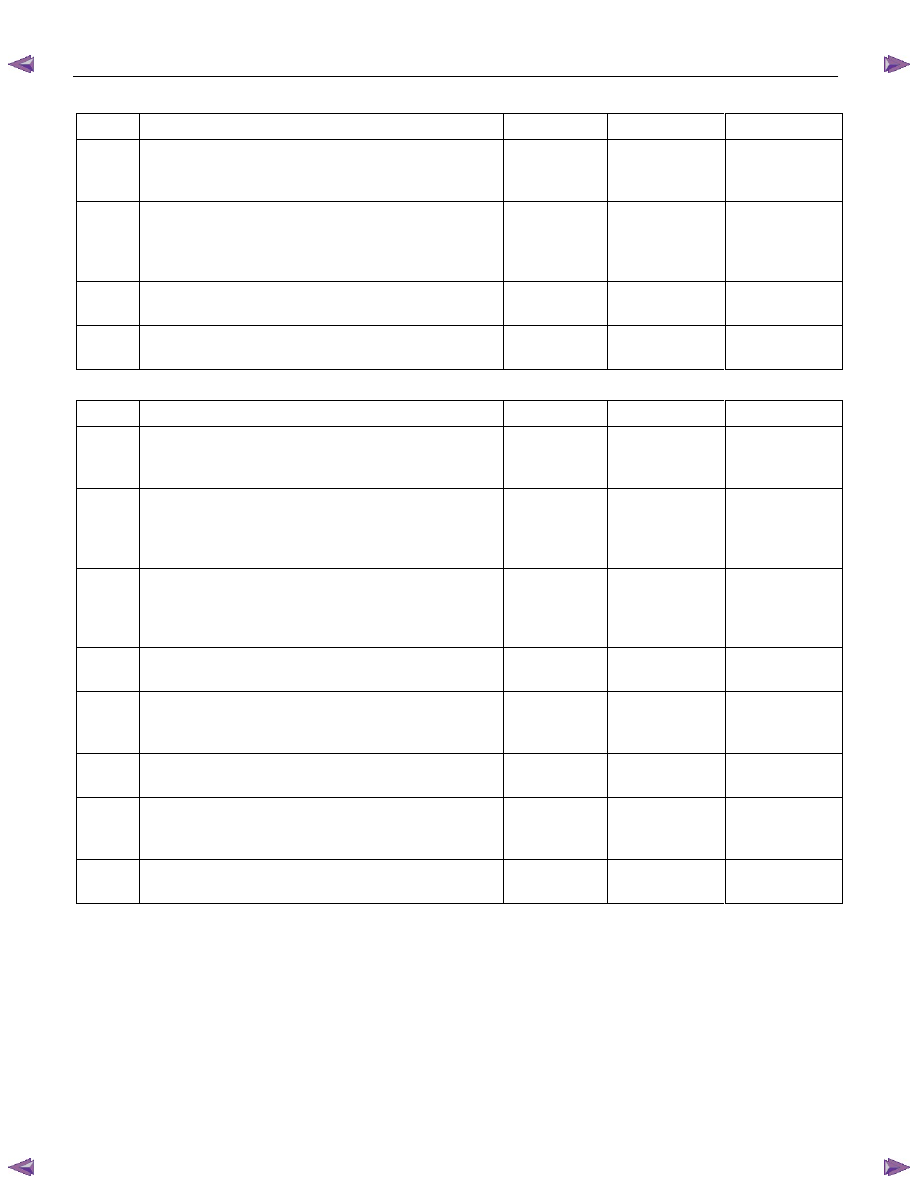

15-3 Starter motor continues to run after the starter switch is turned off

Step Action Value(s)

Yes

No

1 Was

“

Visual/Physical Check" performed.

—

Go to Step 2

Go to

visual/physical

check

2

Inspect the magnetic switch contact point.

Was the contact point seized?

—

Repair

or

replace the

magnetic

switch. Go

to

Step 3

3

Inspect the starter switch.

Was the starter switch defective?

—

Replace

the

starter switch.

Go to Step 4

4

Are any DTC stored?

—

Go

to

indicated

DTC. Solved

15-4 Excessive commutator sparking

Step Action Value(s)

Yes

No

1 Was

“

Visual/Physical Check" performed.

—

Go to Step 2

Go to

visual/physical

check

2

Inspect the contact condition between the brush and

the commutator.

Was the brush and the commutator contact

intermittent?

—

Replace

the

brush or repair

the

commutator. Go

to

Step 3

3

Was there the slag accumulation on the contact

face?

—

Clean

the

contact face or

replace the

brush. Go

to

Step 4

4

Was the brush holder loose?

—

Repair

the

brush holder

Go to Step 5

5

Inspect the commutator.

Was there excessive wear or pitting?

—

Repair

or

replace the

commutator. Go

to

Step 6

6

Was there loose the solder on the commutator?

—

Clean

and

repair Go

to

Step 7

7

Inspect the armature shaft.

Was the run-out of armature shaft outside the

standard value due to worn bearing ?

—

Replace the

bearing Go

to

Step 8

8

Are any DTC stored?

—

Go

to

indicated

DTC. Solved

SECTION 6A

ENGINE MECHANICAL

TABLE OF CONTENTS

PAGE

Standard Bolts. . . . . . . . . . . . . . . . . . . . . . . . . . ... 6A - 8

Special Parts Fixing Nuts and Bolts . . . . . . . . . . . . . . . . . . 6A - 9

Recommended Liquid Gasket . . . . . . . . . . . . . . . . . . . . . .. 6A - 22

LOCTITE Application Procedure . . . . . . . . . . . . . . . . . . . . .. 6A - 23

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A - 24

Model Identification . . . . . . . . . . . . . . . . . . . . . . . . ... 6A - 24

Air Cleaner. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6A - 24

Lubricating System. . . . . . . . . . . . . . . . . . . . . . . . . 6A - 24

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A - 25

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6A - 27

Valve Clearance Adjustment. . . . . . . . . . . . . . . . . . . . . . 6A - 31

Compression Pressure Measurement . . . . . . . . . . . . . . . . . . 6A - 32

General Description . . . . . . . . . . . . . . . . . . . . . . . . . .. 6A- 36

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . .. 6A- 37

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6A- 37

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6A- 40

Coolant Replenishment . . . . . . . . . . . . . . . . . . . . . . . 6A- 41

Engine Warm-Up . . . . . . . . . . . . . . . . . . . . . . . . . 6A- 41

Engine Repair Kit. . . . . . . . . . . . . . . . . . . . . . . . . . ... 6A- 42

Engine Overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A- 43

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6A- 43

External Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A- 43

ENGINE MECHANICAL 6A – 1

Main Data and Specifications. . . . . . . . . . . . . . . . . . . . . ... 6A -

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . ... 6A -

6A – 2 ENGINE MECHANICAL

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 6A- 47

Internal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6A- 47

Major Components . . . . . . . . . . . . . . . . . . . . . . . . 6A- 47

Minor Components . . . . . . . . . . . . . . . . . . . . . . . . 6A- 56

Rocker Arm Shaft and Rocker Arm . . . . . . . . . . . . . . . ... 6A- 56

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . .. 6A- 57

Piston and Connecting Rod . . . . . . . . . . . . . . . . . . ... 6A- 59

Inspection and Repair . . . . . . . . . . . . . . . . . . . . . . . ... 6A- 61

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A- 61

Rocker Arm Shaft and Rocker Arm. . . . . . . . . . . . . . . . . ... 6A- 68

Cylinder Body . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A- 69

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A- 77

Crankshaft and Bearing. . . . . . . . . . . . . . . . . . . . . . . 6A- 79

Crankshaft Bearing Selection . . . . . . . . . . . . . . . . . . . ... 6A- 83

Crankshaft Pilot Bearing . . . . . . . . . . . . . . . . . . . . . ... 6A- 85

Flywheel and Ring Gear. . . . . . . . . . . . . . . . . . . . . . . 6A- 85

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6A- 86

Cylinder Head Gasket Selection . . . . . . . . . . . . . . . . . . ... 6A- 88

Connecting Rod. . . . . . . . . . . . . . . . . . . . . . . . . .. 6A- 90

Idler Gear Shaft and Idler Gear . . . . . . . . . . . . . . . . . . . . 6A- 91

Timing Gear Case Cover. . . . . . . . . . . . . . . . . . . . . . 6A- 91

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A- 93

Internal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6A- 93

Minor Component . . . . . . . . . . . . . . . . . . . . . . . ... 6A- 93

Rocker Arm Shaft and Rocker Arm . . . . . . . . . . . . . . . ... 6A- 93

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . .. 6A- 94

Piston and Connecting Rod . . . . . . . . . . . . . . . . . . ... 6A- 96

Positive Crankcase Ventilation (PCV) Valve . . . . . . . . . . . . . 6A- 99

Major Component . . . . . . . . . . . . . . . . . . . . . . . ... 6A- 101

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6A- 118

External Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A- 118

Lubrication System . . . . . . . . . . . . . . . . . . . . . . . . . ... 6A- 126

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст