Isuzu KB P190. Manual — part 674

Engine Mechanical – V6

Page 6A1–217

Reassemble

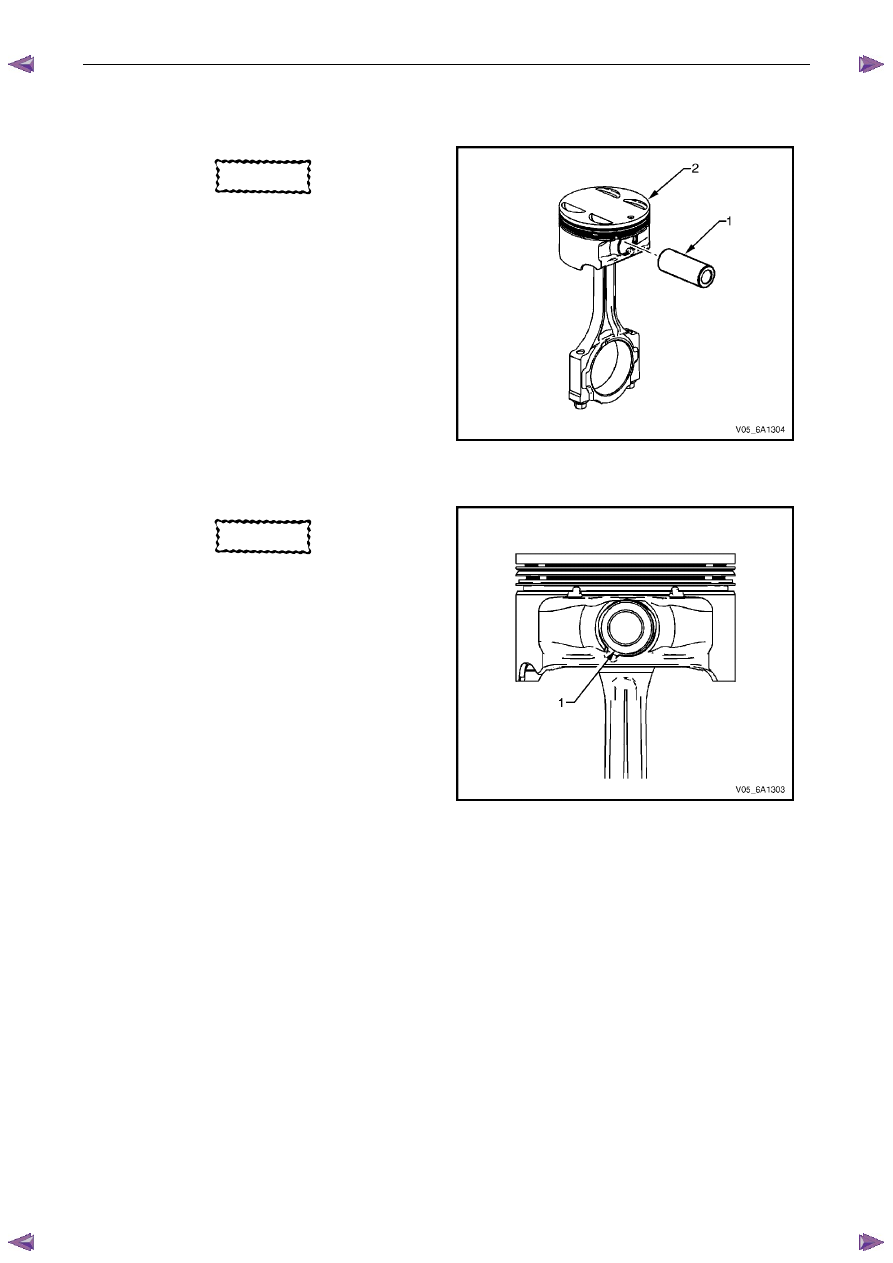

Piston and Piston Pin

CAUTION

The arrow located on top of the piston must

point toward the front of the engine.

N O T E

The connecting rod is non-directional and may

be assembled/reassembled to the piston in

either direction.

1

Lubricate the piston pin (1) bores in the piston (2) and

the connecting rod with clean engine oil.

2

Assemble the piston and piston pin to the connecting

rod. Correctly orient the piston when reusing a

marked connecting rod.

3

Align the piston pin bore with the connecting rod pin

bore.

4

Slide the piston pin into the piston and the connecting

rod.

Figure 6A1 – 395

CAUTION

New piston pin retainers must be used.

Never reuse the piston pin retainers.

5

Install new piston pin retainers (1).

6

Ensure the piston pin retainers are fully seated in their

grooves.

7

Repeat steps 1 to 6 for the remaining pistons.

Figure 6A1 – 396

Engine Mechanical – V6

Page 6A1–218

Piston Ring

N O T E

The ends of the expander must be facing

toward the top of the piston.

1

Correctly orient the oil control ring expander (1)

before installation.

Figure 6A1 – 397

2

Using a piston ring expander, install the oil control

ring assembly using the following procedure:

3

Install the expander ring (3).

4

Install the two oil scraper rings (4). Expand the rings

only enough to clear the piston diameter. Over-

expanding the piston rings will distort or crack the

rings.

5

Install the second (2) and top (1) piston rings as

follows.

Figure 6A1 – 398

6

Using the ring expander (1), install the second piston

ring (2) onto the piston (3). Do not over-expand the

ring. Repeat for the top ring.

Figure 6A1 – 399

Engine Mechanical – V6

Page 6A1–219

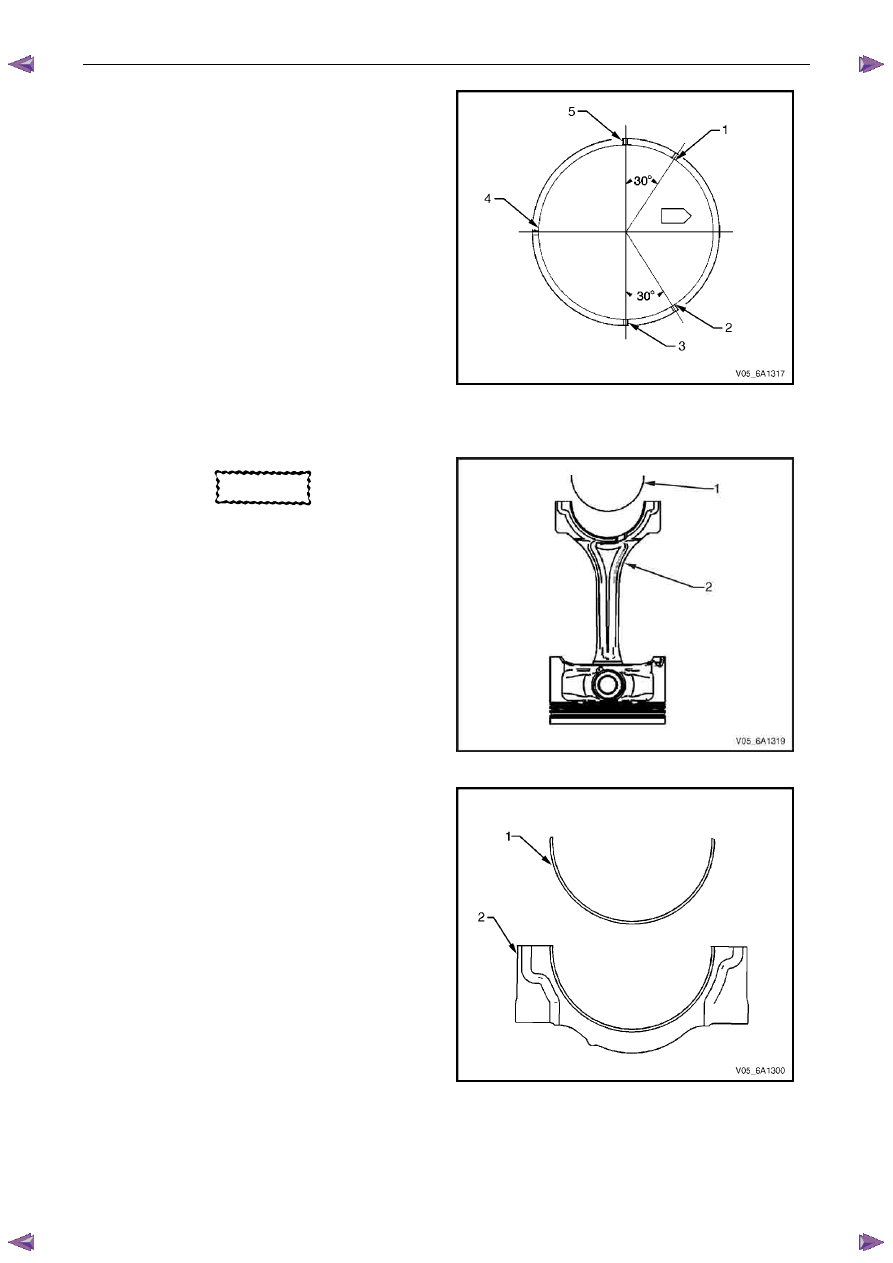

7

Once the rings are installed, set the ring gaps for the

oil control, second and top ring as follows. Use the

piston location arrow for reference.

•

Lower oil control ring position (1).

•

Upper oil control ring position (2).

•

Top ring position (3).

•

Oil control ring expander position (4).

•

Second ring position (5).

Figure 6A1 – 400

Connecting Rod Bearing

CAUTION

If the connecting rod bearings have been

used in a running engine, they must be

replaced with new connecting rod bearings

for reassembly.

1

Clean the connecting rod (2) and the connecting rod

cap bearing bore with a lint-free cloth.

2

Clean the oil from behind the connecting rod bearing

halves.

3

Install a new upper connecting rod bearing (1) into

position. Roll the bearing into position so the lock tang

engages the alignment slot. The bearing must fit flush

in the connecting rod.

Figure 6A1 – 401

4

Install the lower connecting rod bearing (1) into

position in the connecting rod cap (2).

5

Roll the bearing into position so the lock tang

engages the alignment slot. The bearing must fit flush

with the connecting rod cap.

Figure 6A1 – 402

Engine Mechanical – V6

Page 6A1–220

Reinstall

Piston Connecting Rod and Connecting Rod Bearing Installation

CAUTION

The piston is directional and must be

installed in the engine block in the correct

direction. The locating arrow on the top of

each piston must be pointing toward the

front of the engine.

1

Liberally lubricate the cylinder walls, piston rings and

piston skirts with engine oil.

2

Select the correctly numbered piston/connecting rod

assembly for the cylinder. A dot (1) showing correct

piston orientation is located on the top of the piston.

Figure 6A1 – 403

3

Install connecting rod guide pin set, Tool No.

EN-46121 (1) into the connecting rod bolt holes.

Figure 6A1 – 404

4

Compress the piston rings using a commercially

available ring compressor.

CAUTION

Extreme care must be used when installing

the piston and connecting rod to ensure the

rod does not scrape or nick the cylinder

bore, oil jets, or crankshaft surfaces.

5

Using both hands from the top and bottom of the

cylinder, slowly guide the piston (2) and connecting

rod assembly into the cylinder. Do not allow the

connecting rod to contact the cylinder wall.

6

When the ring compressor contacts the deck surface,

gently tap the piston into the cylinder using the handle

end of a dead-blow hammer. Guide the connecting

rod onto the crankshaft bearing journal using

connecting rod guide pin set, Tool No. EN-46121 (1)

while gently tapping the piston into the cylinder with a

soft-blow hammer.

Figure 6A1 – 405

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст