Isuzu KB P190. Manual — part 672

Engine Mechanical – V6

Page 6A1–209

d

If the endplay exceeds the specified limits, measure the width of the crankpin end of the connecting rod, refer

to 5

Specifications.

e

If the connecting rod width is significantly smaller than specified and severe wear is present on the side of the

connecting rod, replace the connecting rod.

f

If the connecting rod width is within specification and excessive scoring is present on the crankshaft journals,

replace the crankshaft.

CAUTION

Do not use a stamp, punch or any other

method that may distort or stress the

connecting rod and cap. Extensive engine

damage may result from a connecting rod that

is distorted or stressed.

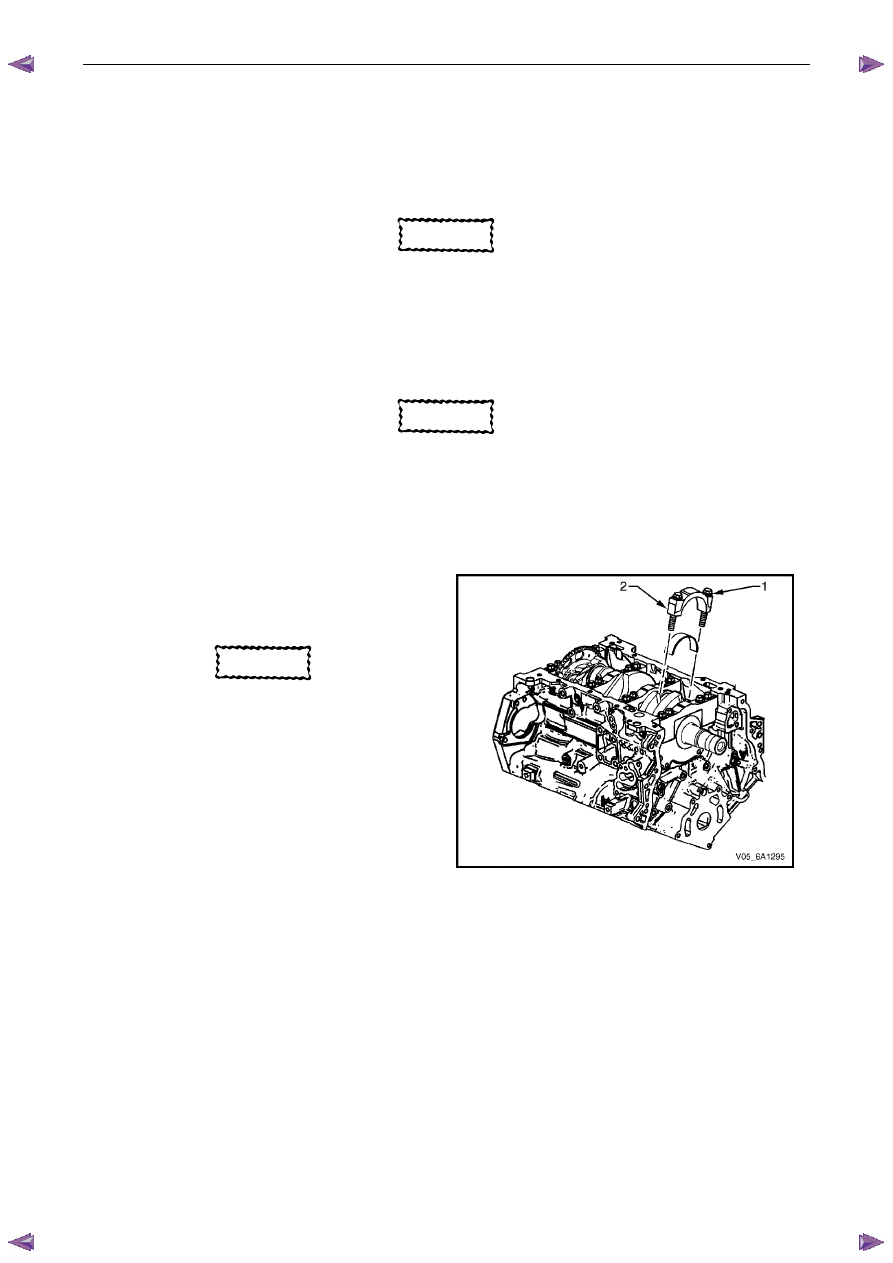

8

Mark the cylinder number on the connecting rod and the connecting rod cap with a paint stick or permanent marker.

CAUTION

Powdered metal connecting rods have rod

bolts which yield when tighten to the

specified torque. If the bolts are loosened or

removed they must be replaced. Rod bolts

that are not replaced will not torque to the

correct clamp load and can lead to serious

engine damage.

9

Remove the connecting rod bolts (1), loosening

progressively from side to side.

CAUTION

The connecting rod caps must remain with

the original connecting rod.

10

Remove the connecting rod cap (2).

Figure 6A1 – 375

Engine Mechanical – V6

Page 6A1–210

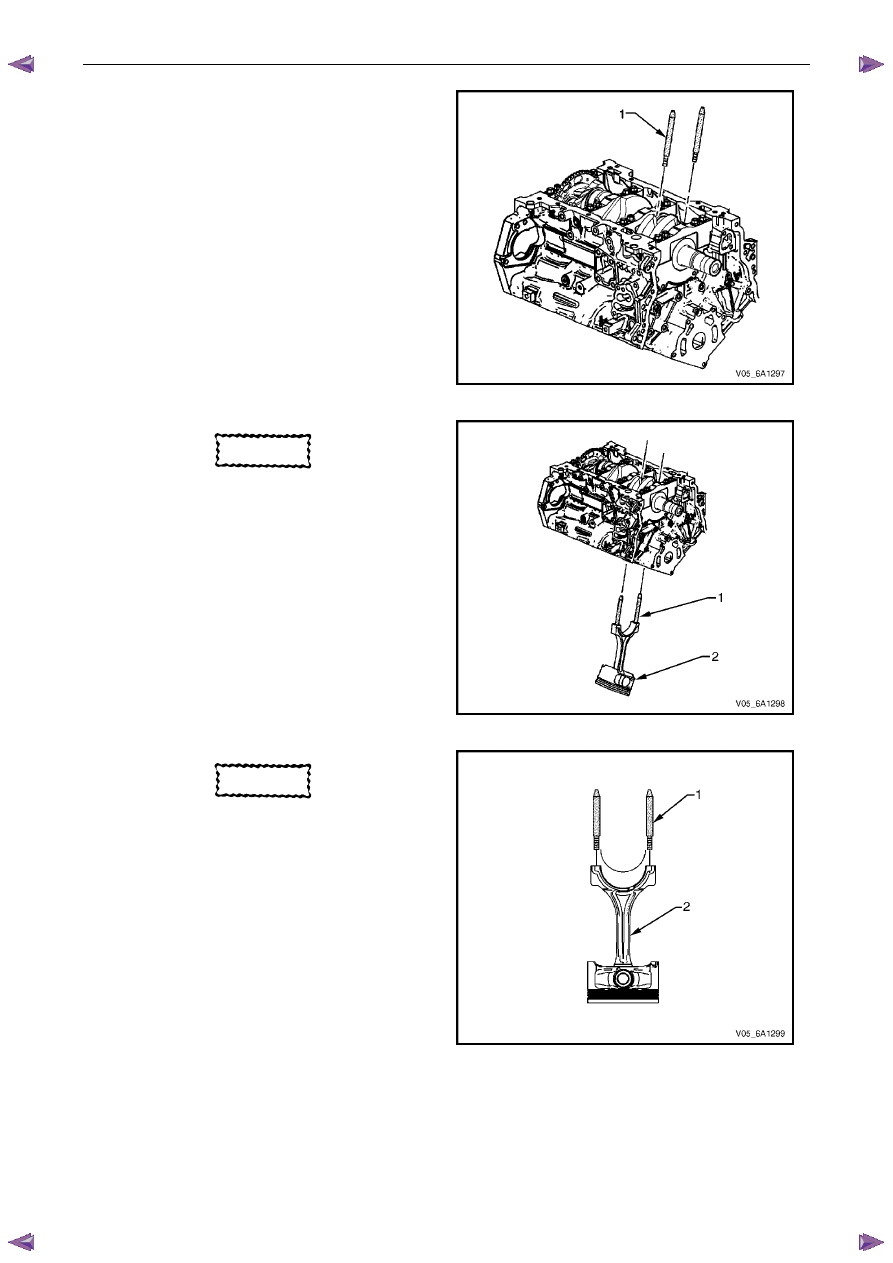

11

Install connecting rod guide pin set, Tool No.

EN-46121 (1) to the connecting rod bolt holes.

Figure 6A1 – 376

CAUTION

Do not damage the crankshaft journal,

cylinder wall and piston cooling jets when

removing the connecting rod and piston

assembly.

12

Using connecting rod guide pin set, Tool No.

EN-46121 (1), push the connecting rod and piston

assembly (2) through the top of the cylinder.

Figure 6A1 – 377

CAUTION

When dismantled, ensure the connecting

rod, connecting rod cap, piston and

bearings are organised in their original

position and location. This will also aid

engine mechanical diagnosis.

13

Remove connecting rod guide pin set, Tool No.

EN-46121 (1) from the connecting rod bolt holes.

14

Remove the upper connecting rod bearing from the

connecting rod (2).

Figure 6A1 – 378

Engine Mechanical – V6

Page 6A1–211

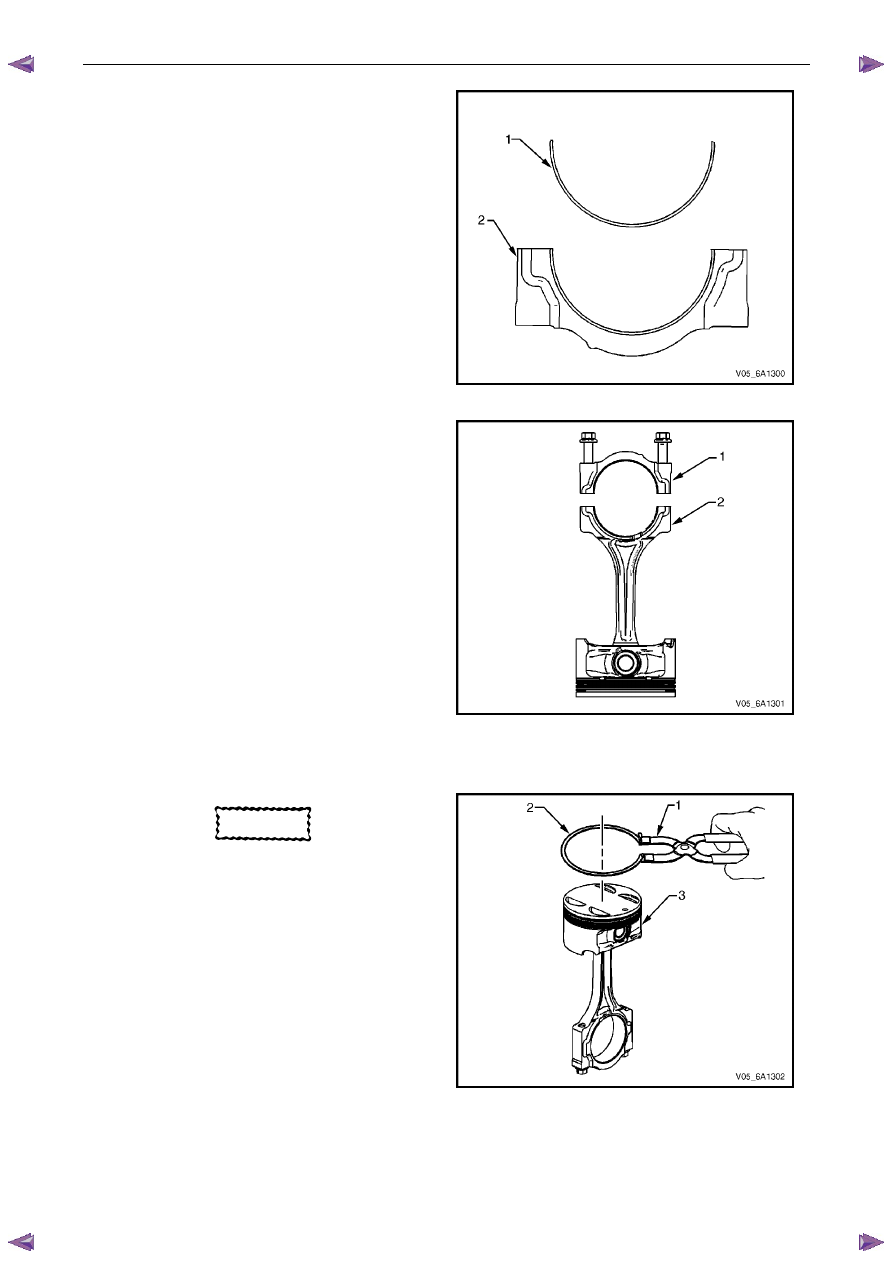

15

Remove the lower connecting rod bearing (1) from

the connecting rod cap (2).

Figure 6A1 – 379

N O T E

The cap and rod are a matched set and must be

kept together.

16

Reattach the connecting rod cap (1) to the connecting

rod (2) to prevent damage to their mating surfaces.

17

Repeat steps 4 to 16 for the remaining piston and

connecting rod assemblies.

Figure 6A1 – 380

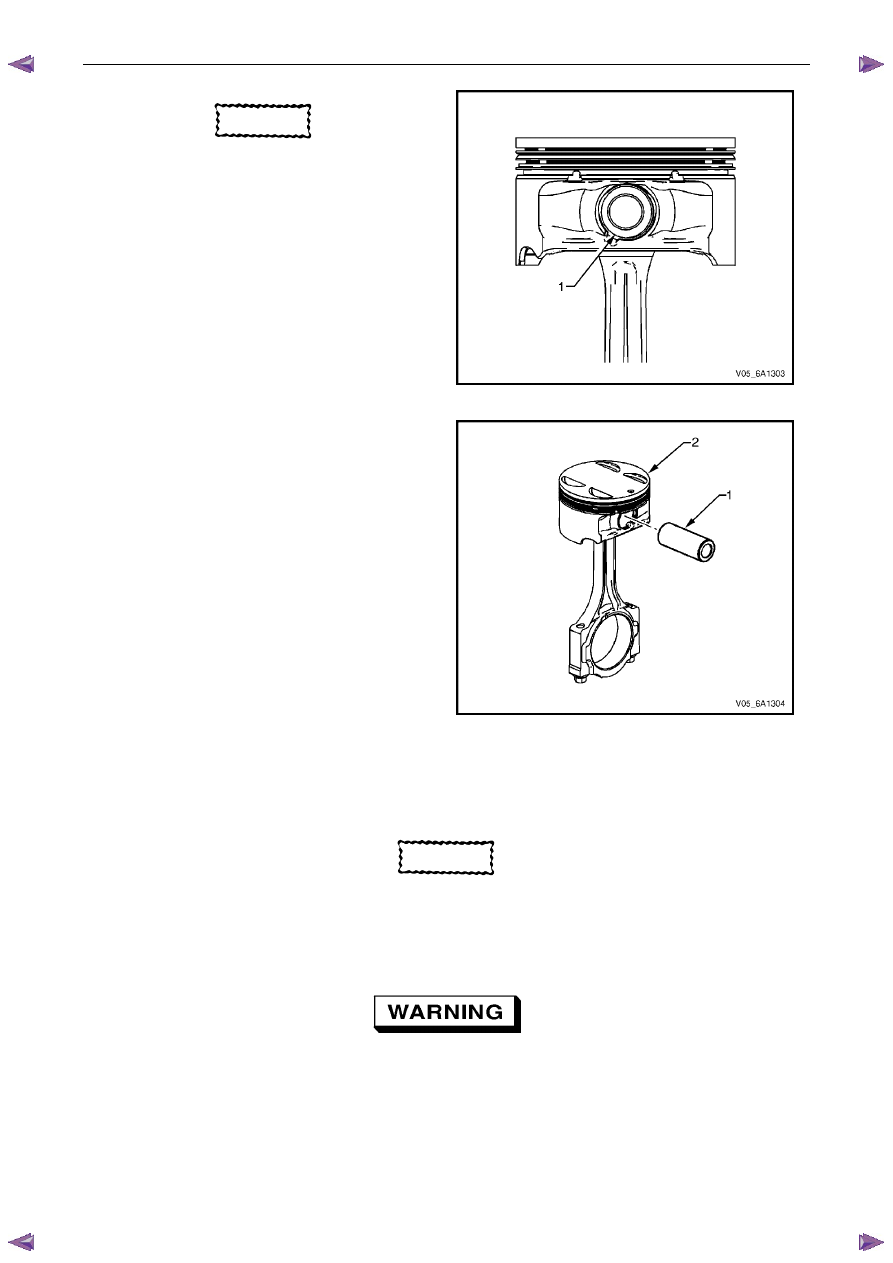

Disassemble

CAUTION

A piston ring expander must be used to

remove and install the piston rings. Only

expand the rings far enough to fit over the

piston lands. If the rings are overexpanded,

the top ring will shatter and the others will

distort.

1

Remove the piston rings (2) using a piston ring

expander (1). Place each ring in a clean shop towel

for storage.

Figure 6A1 – 381

Engine Mechanical – V6

Page 6A1–212

CAUTION

Do not reuse the piston pin retainers.

2

Remove the piston pin retainers by using the removal

access notch (1) in the side of the piston. Discard the

piston pin retainers.

Figure 6A1 – 382

3

Slide the piston pin (1) out of the piston (2). The

piston will disconnect from the connecting rod.

Figure 6A1 – 383

Clean and Inspect

Piston Cleaning Procedure

CAUTION

Do not use a wire brush to clean any part of

the piston.

1

Clean the piston skirts and the pins with a suitable solvent.

2

Clean the piston ring grooves with a groove cleaner. Ensure the oil ring holes and slots are clean.

Safety glasses must be worn when using

compressed air.

3

Dry the piston with compressed air.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст