Isuzu KB P190. Manual — part 185

BRAKES 5C-41

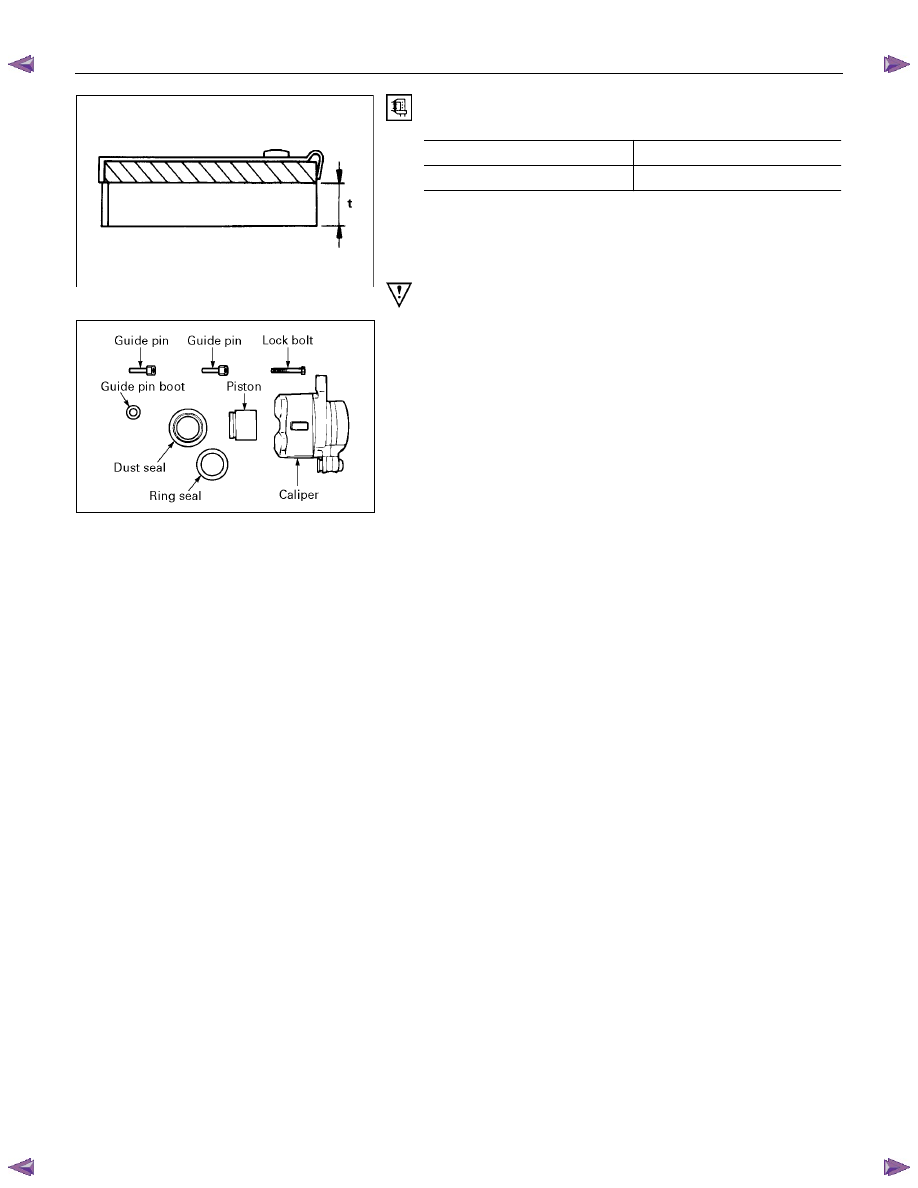

Thickness of Disc Pad

Thickness (t)

mm (in)

Standard Limit

10.0 (0.394)

1.8 (0.071)

Replace the front disc pad whenever the pad wear indicator

makes a squeaking noise or when the pad is worn to within 1.8

mm of the shoe table.

All four brake pads should be replaced together.

302R300019

Seal and Boot

The dust seal, dust boot and ring seal should be replaced each

time the caliper is overhauled.

Discard these used rubber parts.

5C-42 BRAKES

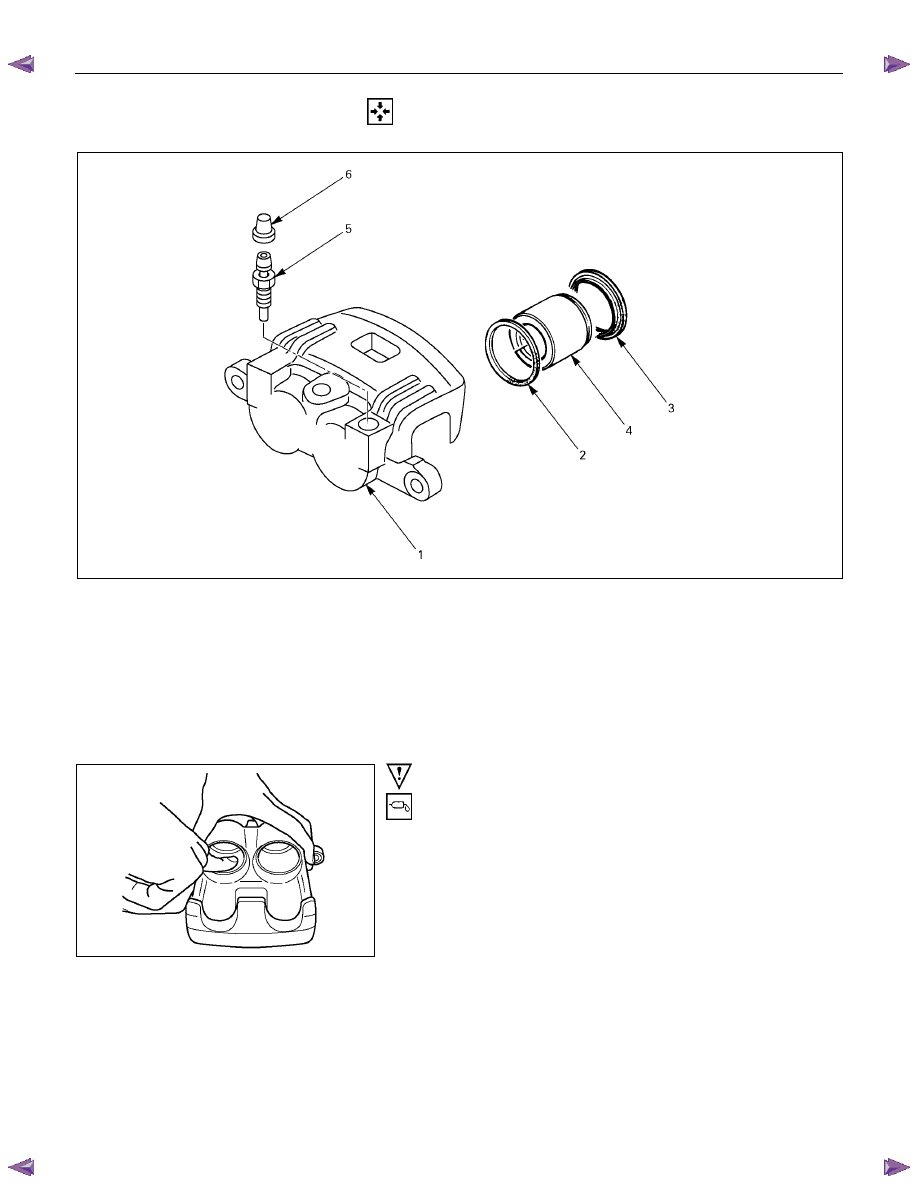

REASSEMBLY

CALIPER ASSEMBLY

Reassembly Steps

▲ 1. Body; caliper

▲ 2. Ring seal

▲ 3. Dust seal; piston

▲ 4. Piston

▲ 5. Bleeder

▲ 6. Cap

Important Operations

1. Body; Caliper

2. Ring Seal

Apply clean brake fluid to the ring seal and cylinder wall, then

insert the ring seal into the cylinder.

Ensure that the piston ring seal are not twisted in the caliper

bore grooves.

BRAKES 5C-43

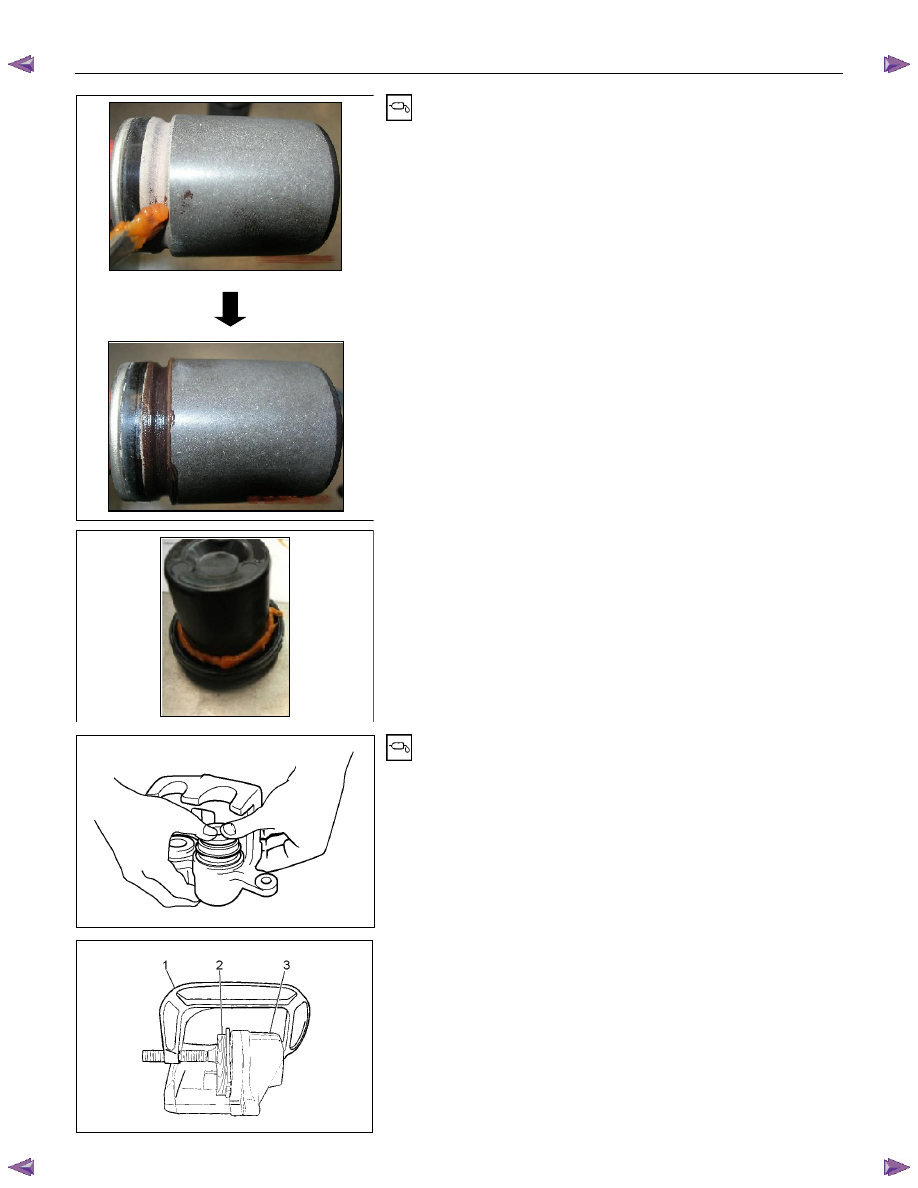

3. Dust seal; Piston

• Apply grease to piston groove and dust seal boot.

1) Make sure a piston and its groove area are free from

dust.

2) Use 0.5g to apply grease to groove area thoroughly using

a brush or finger.

Make sure color of groove changes as shown bellow

after apply grease.

3) After assembling a dust seal boot to the piston, apply

1.5g to contact area of the piston and the dust seal boot

as shown in the picture bellow.

4. Piston

Apply clean brake fluid to the piston, and attach the caliper.

When inserting the piston into the cylinder, use finger pressure

only. Do not use a mallet or other impact tool, since damage to

the cylinder wall or ring seal can result.

The movement of a caliper piston into a caliper bore should be

smooth and even. If a caliper piston is frozen or difficult to

move to the bottom, the caliper requires overhaul or

replacement.

RTW35CSH000701

When not entering with a finger, insert a discarded inner brake

pad (2) or block of wood in front of the pistons. Using 2 large

C-clamps (1) installed over the body of the caliper (3) and

against the brake pad or block of wood, slowly move the

pistons evenly into the bores.

Insert the dust seal ring into the dust seal.

CAUTION:

Pistons made of plastic material.

Do not hit the piston with a hammer etc. and don’t grasp

the face of the piston with pliers.

5C-44 BRAKES

5. Bleeder

Torque N

⋅m (kgf⋅m/Ib⋅ft)

9 – 16 (0.9 – 1.6 / 6.5 – 12)

6. Cap

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст