Isuzu KB P190. Manual — part 380

6A-160 ENGINE MECHANICAL (4JK1/4JJ1)

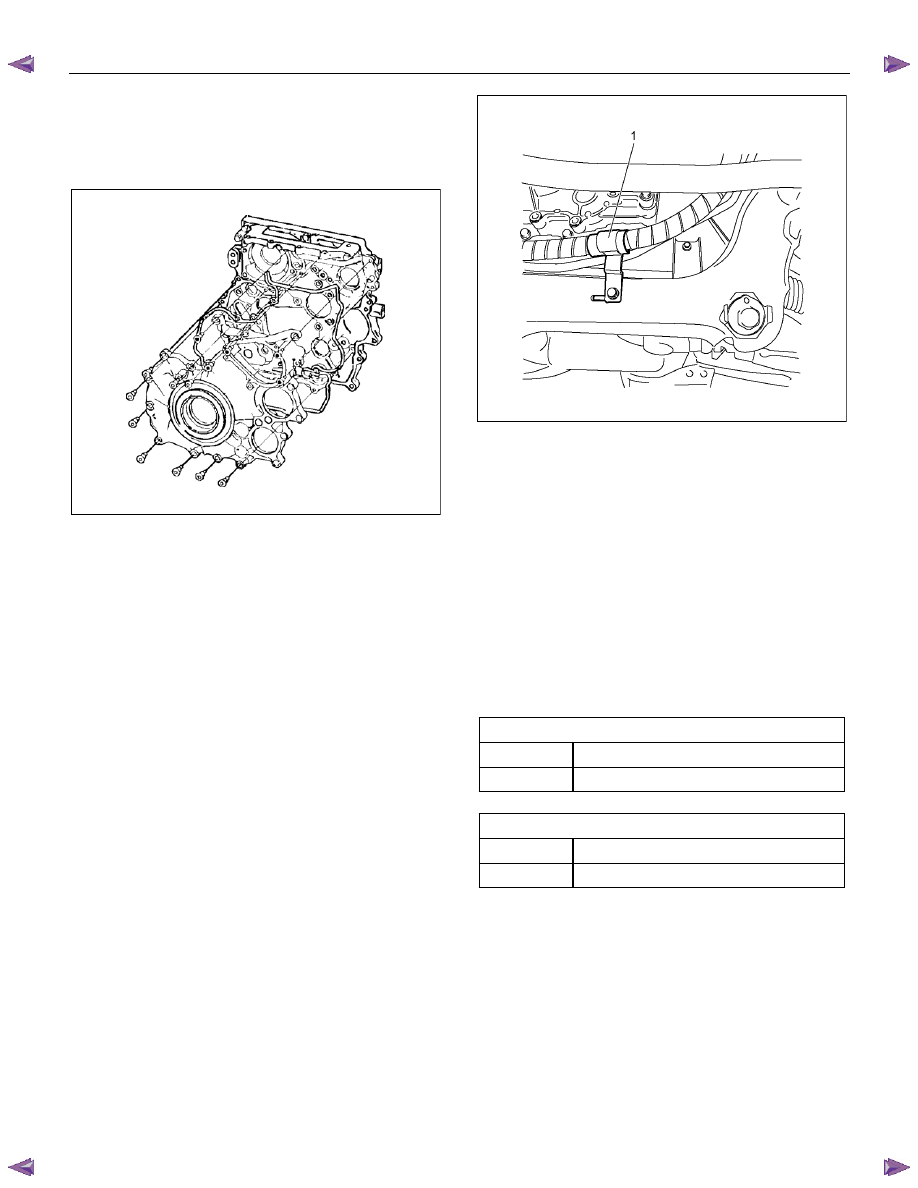

• Install the gasket in the slot of the gear case

cover.

• Tighten the bolts to the specified torque.

Tightening torque: 8 N

⋅⋅⋅⋅m (0.8 kg⋅⋅⋅⋅m / 69 lb in)

RTW56ASH012101

3. Install the crank pulley.

• Tighten the bolts to the specified torque.

Tightening torque: 294 N

⋅⋅⋅⋅m (30.0 kg⋅⋅⋅⋅m / 217 lb ft)

4. Install the noise cover to the timing chain cover

lower.

• Tighten the bolts to the specified torque.

Tightening torque: 10 N

⋅⋅⋅⋅m (1.0 kg⋅⋅⋅⋅m / 87 lb in)

5. Install the vacuum pump.

• Tighten the nuts to the specified torque.

Tightening torque: 25 N

⋅⋅⋅⋅m (2.5 kg⋅⋅⋅⋅m / 18 lb ft)

• Install the oil pipe (feed side and return side) of

vacuum pump.

• Install the vacuum pipe bracket and vacuum

pipe.

6. Install the power steering pump.

• Tighten the nuts to the specified torque.

Tightening torque: 25 N

⋅⋅⋅⋅m (2.5 kg⋅⋅⋅⋅m / 18 lb ft)

• Install the bracket of power steering oil hose

clip (1).

LTW56ASH000101

7. Install the lower fan shroud.

8. Install the fan drive belt and pulley.

• Install the fan drive belt with the fan pulley.

9. Install the fan and fan clutch.

• Tighten the bolts to the specified torque.

Tightening torque: 8 N

⋅⋅⋅⋅m (0.8 kg⋅⋅⋅⋅m / 69 lb in)

10. Adjust the drive belt of generator and A/C

compressor.

• Apply tension to the fan drive belt by moving

the generator.

• Apply a force of 98 N (10 kg / 22 lb) to the drive

belt mid portion to check the drive belt

deflection.

Generator drive belt deflection

mm (in)

New belt

5 - 6 (0.20 – 0.24)

Reuse belt

7 - 8 (0.28 – 0.31)

A/C compressor drive belt deflection

mm (in)

New belt

6 - 7 (0.24 – 0.28)

Reuse belt

8 - 9 (0.31 – 0.35)

11. Install the upper fan shroud.

12. Install the radiator upper hose.

13. Replenish the engine coolant.

ENGINE MECHANICAL (4JK1/4JJ1) 6A-161

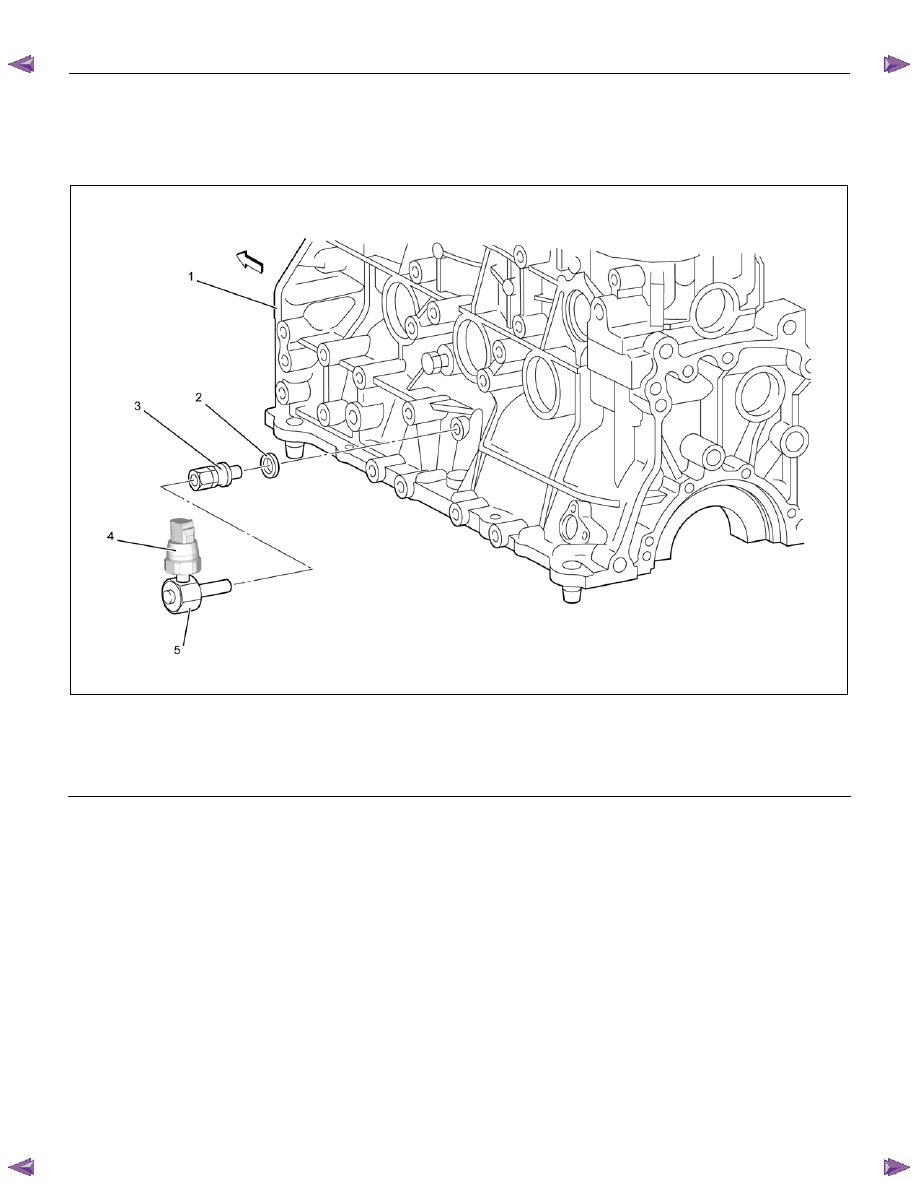

Oil Pressure SW

Components

RTW76AMF000401

Legend

1. Cylinder

Block

2. Gasket

3. Nipple; Oil Pressure Warning SW

4. Oil Pressure SW

5. Nipple; Oil Gallery

6A-162 ENGINE MECHANICAL (4JK1/4JJ1)

Removal

1. Remove the oil pressure SW.

2. Remove the nipple; oil gallery.

3. Remove the nipple; oil pressure warning SW and

gasket.

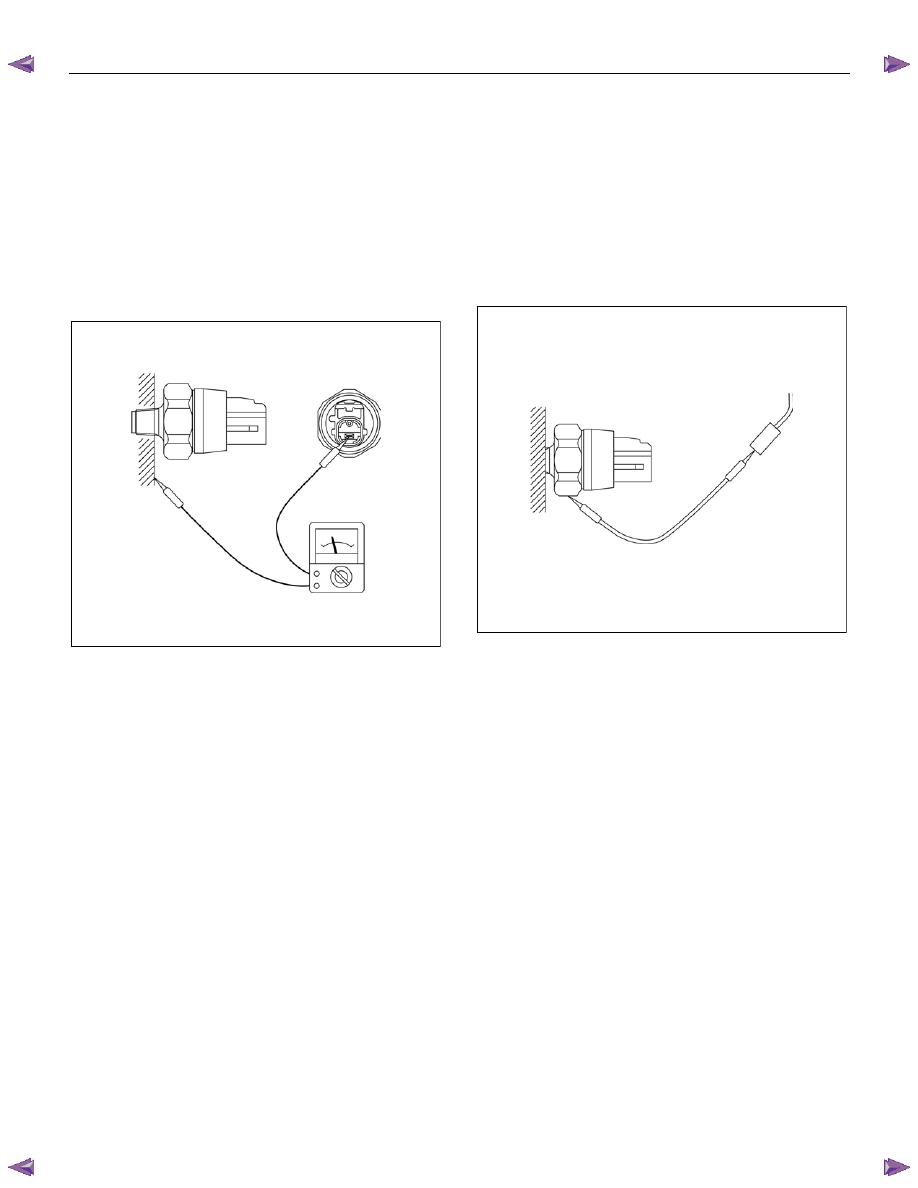

Inspection

Check the continuity between the switch terminal and

the body grounding in a no-load condition.

If there is no connectivity, replace with normal parts.

LNW21HSH003301

Circuit check

1. Turn the starter switch to ON.

2. Disconnect the oil pressure switch connector, and

confirm that the oil pressure-warning lamp lights

when the connector on the harness side is

grounded.

If the warning lamp does not light up, check the

circuit between the meter and the oil pressure

switch, and repair the disconnected locations.

LNW21HSH003401

Installation

1. Install the nipple; oil gallery, oil pressure warning

SW and gasket.

Tightening torque: 25 N

⋅⋅⋅⋅m (2.5 kg⋅⋅⋅⋅m/18 lb ft)

2. Install the Nipple.

Tightening torque: 15 N

⋅⋅⋅⋅m (1.5 kg⋅⋅⋅⋅m/11 lb ft)

3. Install the oil pressure SW.

Tightening torque: 15 N

⋅⋅⋅⋅m (1.5 kg⋅⋅⋅⋅m/11 lb ft)

ENGINE MECHANICAL (4JK1/4JJ1) 6A-163

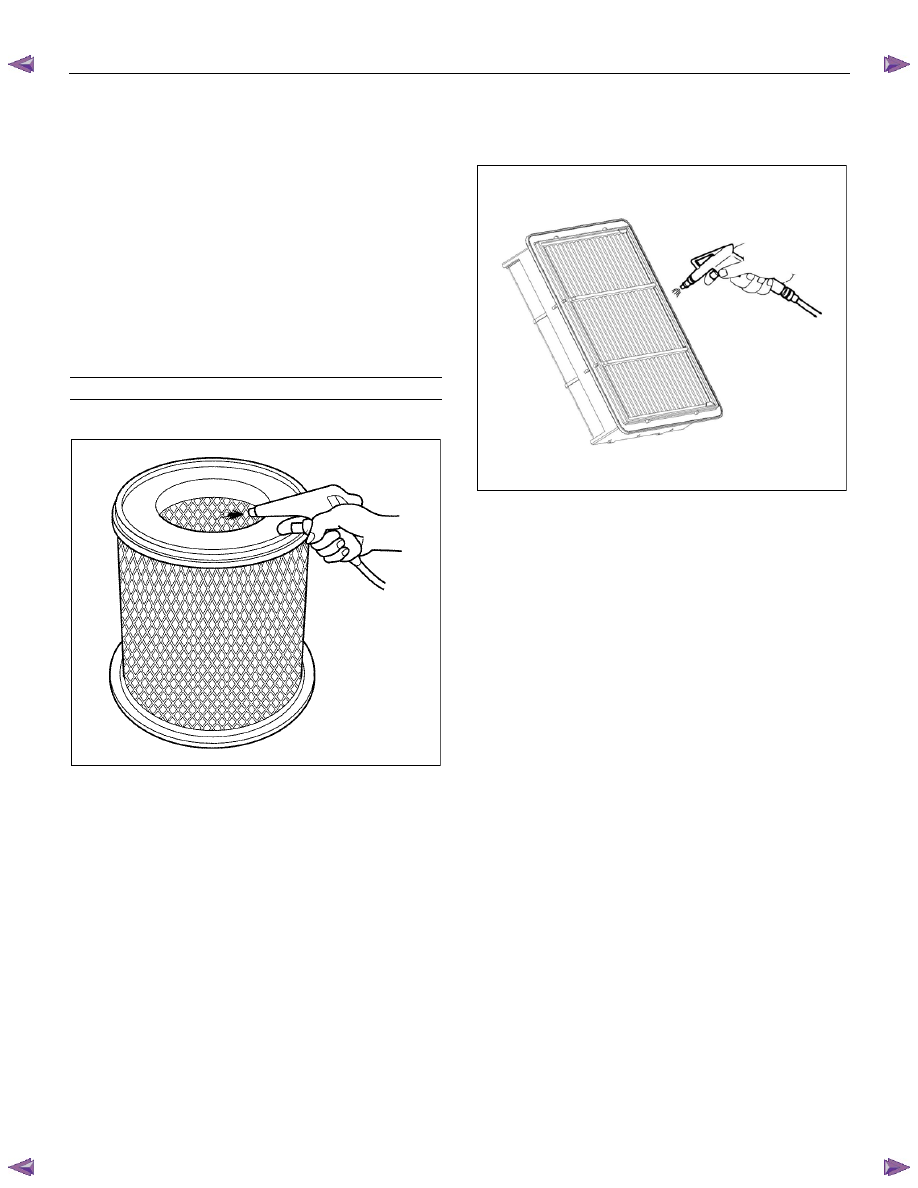

Air Cleaner Element

Removal

1. Remove the air cleaner cover fixing clip.

2. Remove the air cleaner element assembly.

Cleaning

Dry type element

• Rotate the element with your hand while applying

compressed air to the inside of the element. This

will blow the dust free.

Compressed air pressure

kPa (kg/cm

2

/psi)

392

− 490 (4 − 5/57 − 71)

Standard Output

LNW46ASH003201

High Output

LNW71BSH000201

Installation

1. Install the air cleaner element assembly.

2. Install the air cleaner cover.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст