Isuzu KB P190. Manual — part 316

6E-230 Engine Control System (4JH1)

DTC P1650 (Symptom Code B) (Flash Code 44)

Circuit Description

The engine control module (ECM) calculates the

desired fuel injection quantity and timing using data sent

from various sensors. These desired data are sent to

the fuel injection pump control unit (PCU) via a

controller area network (CAN) communication bus. The

PCU also receives signals from the internal inputs:

pump camshaft position (CMP) sensor that is located

inside the fuel injection pump to determine the cam ring

rotation angle and the fuel injection pump speed. The

fuel temperature (FT) sensor is internal the PCU. These

values are used to compare the desired values sent

from the ECM then PCU determines the injection timer

piston position and fuel injection quantity, and actuates

timing control valve (TCV) & fuel injection solenoid

valve based on control maps in the PCU.

The ECM monitors CAN operational status by expecting

a constant flow of messages from the PCU. If the ECM

detects internal CAN controller does not react, this DTC

will set.

Condition for Setting the DTC

• The ECM detects internal CAN controller does not

react.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicator

lamp (MIL) when the diagnostic runs and fails.

• The ECM cuts the fuel injection.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Notice:

• CAN controller is internal to the ECM.

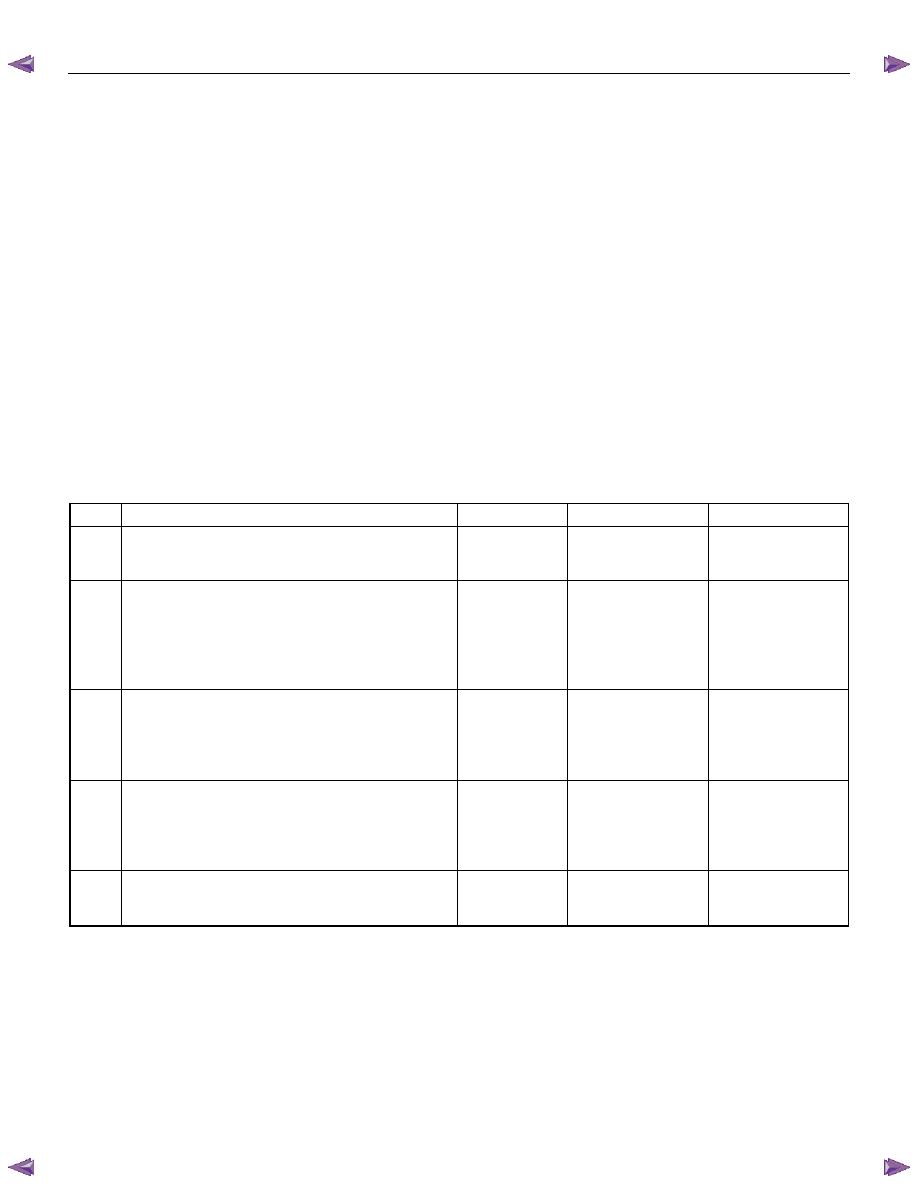

DTC P1650 (Symptom Code B) (Flash Code 44)

Step Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2

Go to Diagnostic

System Check-

Engine Controls

2

1. Install the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the Diagnostic Trouble Code (DTC)

Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3

Go to Step 4

3

Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 4

4

1. Clear the DTCs with the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 3

Go to Step 5

5

Observe the DTC Information with the scan tool.

Are there any DTCs that you have not diagnosed?

Go to Diagnostic

Trouble Code (DTC)

List System

OK

Engine Control System (4JH1) 6E-231

DTC P1651 (Symptom Code A, B) (Flash Code 45)

Circuit Description

The engine control module (ECM) calculates the

desired fuel injection quantity and timing using data sent

from various sensors. These desired data are sent to

the fuel injection pump control unit (PCU) via a

controller area network (CAN) communication bus. The

PCU also receives signals from the internal inputs:

pump camshaft position (CMP) sensor that is located

inside the fuel injection pump to determine the cam ring

rotation angle and the fuel injection pump speed. The

fuel temperature (FT) sensor is internal the PCU. These

values are used to compare the desired values sent

from the ECM then PCU determines the injection timer

piston position and fuel injection quantity, and actuates

timing control valve (TCV) & fuel injection solenoid

valve based on control maps in the PCU.

The ECM monitors CAN operational status by expecting

a constant flow of messages from the PCU. If the ECM

fails to receive an expected message from the PCU,

this will set depending on what communication is lost.

Condition for Setting the DTC

• The ECM detects that the PCU does not receive

the CAN messages from the ECM. (Symptom

Code A)

• The ECM does not receive the CAN messages

from the PCU. (Symptom Code B)

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicator

lamp (MIL) when the diagnostic runs and fails.

The ECM cuts the fuel injection.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

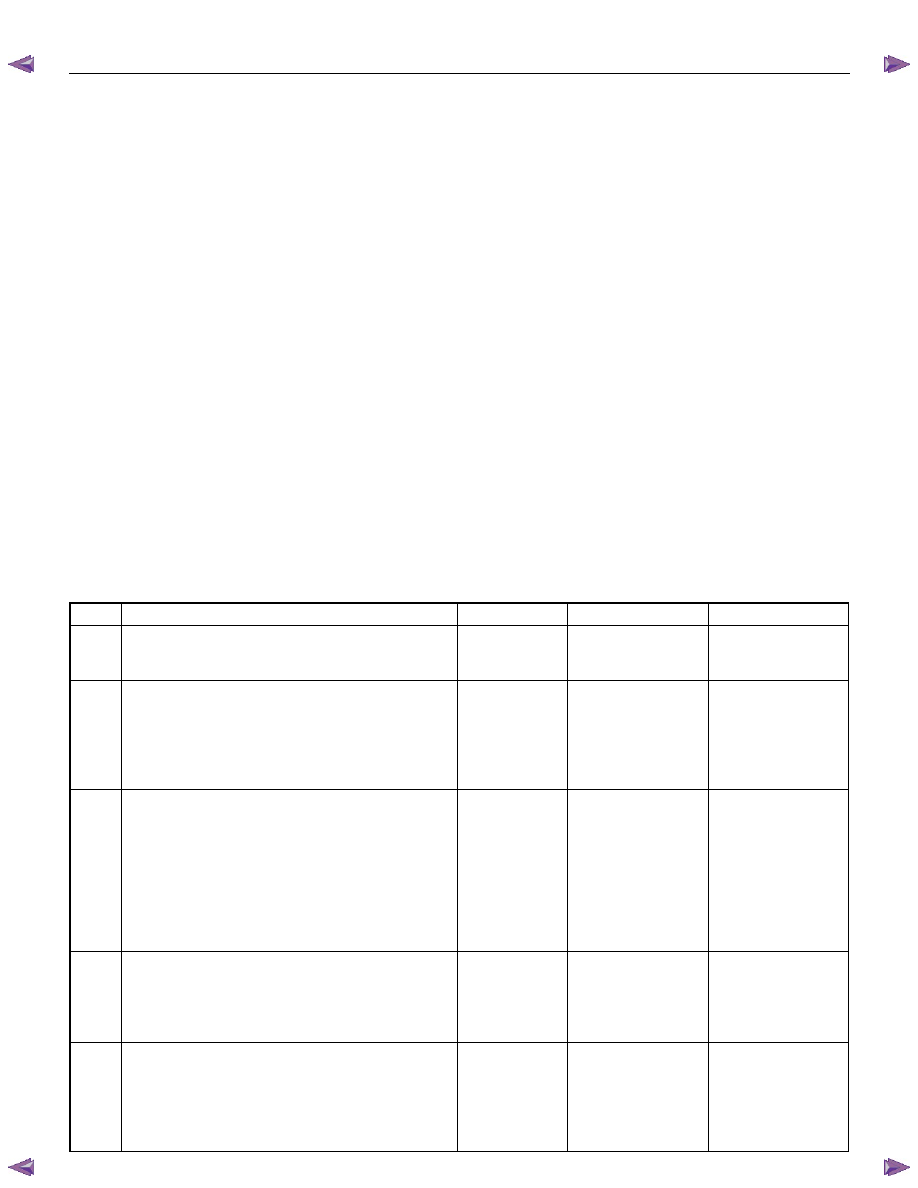

DTC P1651 (Symptom Code A, B) (Flash Code 45)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2

Go to Diagnostic

System Check-

Engine Controls

2

1. Install the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC)

Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3

Go to Step 4

3

1. Turn OFF the ignition.

2. Disconnect the fuel injection pump control unit

(PCU) harness connector.

3. Connect a DMM across the controller area

network (CAN) harness (pins 1 and 2 of E-6

connector).

4. Measure the resistance across the CAN

terminals.

Is the resistance within the specified value?

110-130Ω

Go to Step 4

Go to Step 9

4

1. Connect a DMM between the CAN Low signal

circuit (pin 1 of E-6 connector) and a known good

ground.

2. Turn ON the ignition, with the engine OFF.

Is the DMM voltage within the specified value?

1.5 – 2.5 volts

Go to Step 5

Go to Step 10

5

1. Keep the ignition switch ON, with the engine

OFF.

2. Connect a DMM between the CAN High signal

circuit (pin 2 of E-6 connector) and a known good

ground.

Is the DMM voltage within the specified value?

3.0 – 4.0 volts

Go to Step 6

Go to Step 11

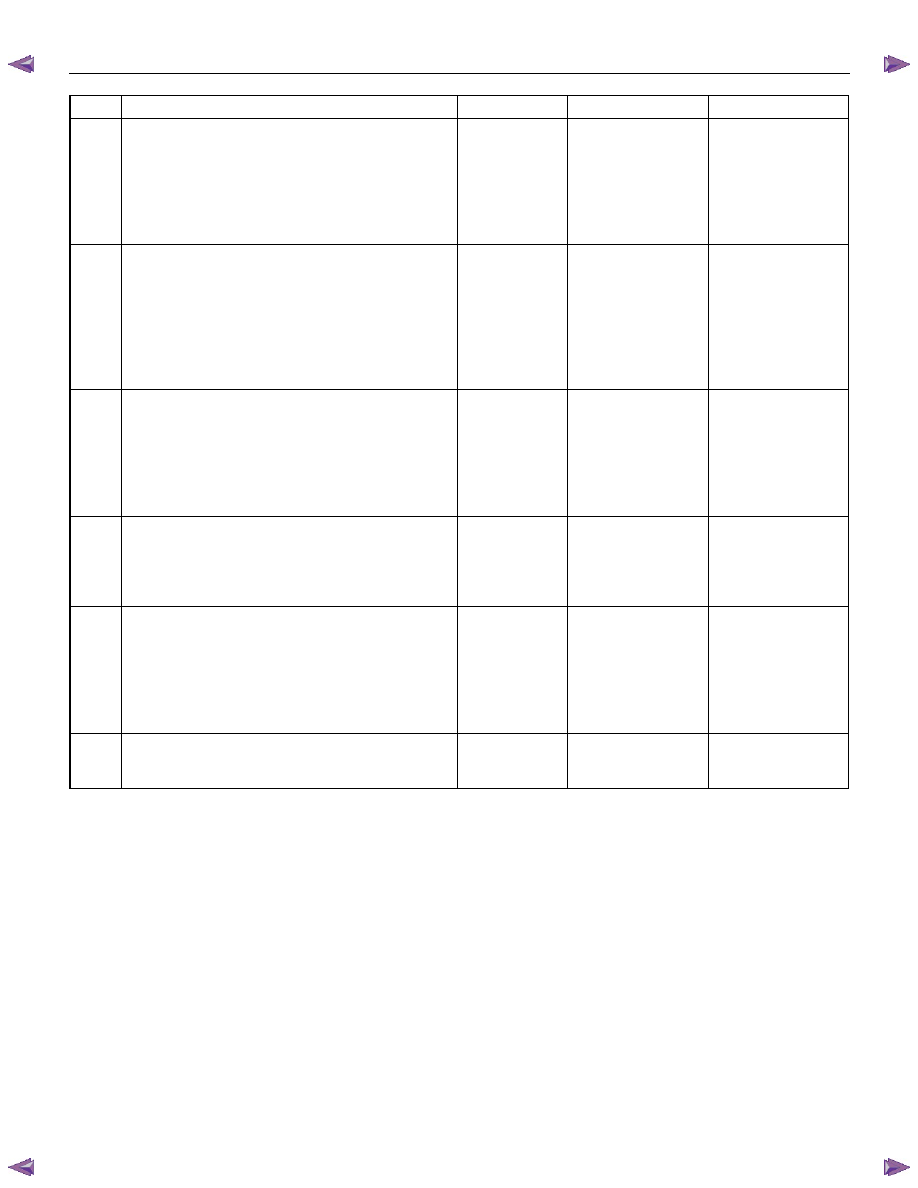

6E-232 Engine Control System (4JH1)

Step Action

Value(s)

Yes

No

6

1. Turn OFF the ignition.

2. Reconnect the PCU harness connector.

3. Disconnect the engine control module (ECM) C-

57 harness connector. Keep the ECM C-56

harness connector with connected.

4. Connect a DMM across the CAN harness pins 99

and 100 of C-57 connector).

5. Measure the resistance across the CAN

terminals.

Is the resistance within the specified value?

110-130Ω

Go to Step 7

Go to Step 13

7

1. Connect a DMM between the CAN Low signal

circuit of the ECM harness (pin 99 of C-57

connector) and a known good ground.

2. Turn ON the ignition, with the engine OFF.

Is the DMM voltage within the specified value?

1.5 – 2.5 volts

Go to Step 8

Go to Step 15

8

1. Keep the ignition switch ON, with the engine

OFF.

2. Connect a DMM between the CAN High signal

circuit of the ECM harness (pin 100 of C-57

connector) and a known good ground.

Is the DMM voltage within the specified value?

3.0 – 4.0 volts

Go to Step 12

Go to Step 15

9

1. Test the CAN Low and High circuit between the

ECM (pins 99 and 100 of C-57 connector) and

the PCU (pins 1 and 2 of E-6 connector) for the

following conditions:

• An open circuit

• A short each other

• High

resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17

Go to Step 14

10

1. Test the CAN Low circuit between the ECM (pin

99 of C-57 connector) and the PCU (pin 1 of E-9

connector) for the following conditions:

• A short to ground

• A short to battery or ignition voltage

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17

Go to Step 16

11

1. Test the CAN Low circuit between the ECM (pin

100 of C-57 connector) and the PCU (pin 2 of E-

9 connector) for the following conditions:

• A short to ground

• A short to battery or ignition voltage

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17

Go to Step 16

12

1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Turn ON the ignition, with the engine OFF.

5. Monitor the DTC Information with the scan tool.

Is DTC P0251 (Symptom Code E) set?

Go to Step 15

Go to Diagnostic

Aids

Engine Control System (4JH1) 6E-233

Step Action

Value(s)

Yes

No

13

1. Turn OFF the ignition.

2. Disconnect the PCU harness connector.

3. Inspect for an intermittent and for poor

connections at the harness connector of the PCU

(pins 1 and 2 of E-6 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 17

Go to Step 15

14

1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for poor

connections on the CAN Low or High circuits at

the harness connector of the ECM (pins 99 and

100 of C-57 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 17

Go to Step 16

15

Important: The fuel injection pump must be timed to

the engine.

Replace the fuel injection pump. Refer to Fuel

Injection Pump Replacement in engine mechanical

section. (PCU is part of the fuel injection pump

assembly)

Did you complete the replacement?

Go to Step 17

16

Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 17

17

1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Monitor the DTC Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3

Go to Step 18

18

Observe the DTC Information with the scan tool.

Are there any DTCs that you have not diagnosed?

Go to Diagnostic

Trouble Code (DTC)

List System

OK

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст