Isuzu KB P190. Manual — part 439

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-139

DTC P0231 or P0232 (Flash Code 69)

Circuit Description

The ECM controls the fuel pump relay which supplies

power to the fuel pump in the fuel tank. The ECM

commands the fuel pump relay ON for a certain length

of time at ignition switch is ON with the engine OFF.

During the engine running it is continuously

commanded ON. If the ECM detects an improper

voltage level on the relay control circuit, DTC P0231 or

P0232 will set.

Condition for Running the DTC

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects a low voltage condition on the

fuel pump relay control circuit for longer than 3

second when the relay is commanded OFF. (DTC

P0231)

• The ECM detects a high voltage condition on the

fuel pump relay control circuit for longer than 3

second when the relay is commanded ON. (DTC

P0232)

Action Taken When the DTC Sets

• The ECM illuminates the SVS lamp when the

diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification)

• The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM limits fuel injection quantity.

• The ECM inhibits cruise control.

Condition for Clearing the DTC

• Refer to DTC Type Definitions for Condition for

Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for

Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice:

• The fuel pump relay is commanded ON for 12

seconds at ignition switch is ON with the engine

OFF.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

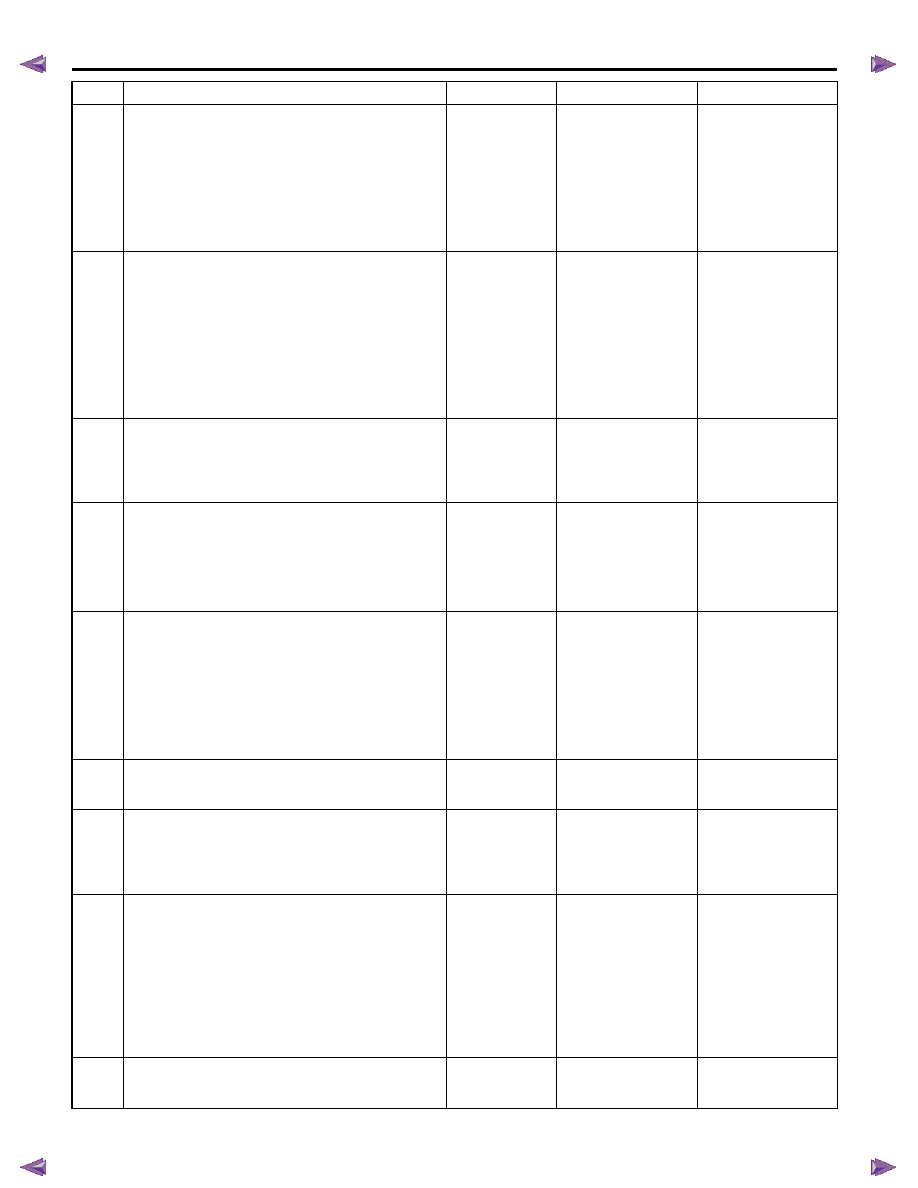

Circuit/ System Testing DTC P0231

Step

Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check -

Engine Controls?

—

Go to Step 2

Go to Diagnostic

System Check -

Engine Controls

2

1.

Install a scan tool.

2.

Turn OFF the ignition for 30 seconds.

3.

Turn ON the ignition for 20 seconds while

observing the DTC Information with a scan

tool.

Does the DTC fail this ignition?

—

Go to Step 3

Go to Diagnostic

Aids

3

1.

Turn OFF the ignition.

2.

Replace the fuel pump relay with the head

light relay or replace with a known good relay.

3.

Turn ON the ignition for 20 seconds while

observing the DTC Information with a scan

tool.

Does the DTC fail this ignition?

—

Go to Step 4

Go to Step 7

6E-140 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

4

1.

Turn OFF the ignition.

2.

Remove the fuel pump relay.

3.

Probe the ignition voltage feed circuit of the

relay coil side (pin 3 of X-13) with a test lamp

that is connected a known good ground.

4.

Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

—

Go to Step 5

Go to Step 6

5

1.

Test the control circuit between the ECM (pin

54 of C-58) and the relay (pin 5 of X-13) for

the following conditions:

• An open circuit

• A short to ground

• High resistance

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 11

Go to Step 8

6

Repair the open circuit or high resistance between

the ECM main relay (pin 1 of X-12) and the fuel

pump relay (pin 3 of X-13).

Did you complete the repair?

—

Go to Step 11

—

7

1.

Remove the fuel pump relay.

2.

Inspect for an intermittent and for a poor

connection on each relay terminal.

3.

Repair the connection(s) as necessary.

Did you find and correct the condition?

—

Go to Step 11

Go to Step 9

8

1.

Turn OFF the ignition.

2.

Disconnect the ECM harness connector.

3.

Inspect for an intermittent and for a poor

connection at the harness connector of the

ECM (pin 54 of C-58).

4.

Repair the connection(s) as necessary.

Did you find and correct the condition?

—

Go to Step 11

Go to Step 10

9

Replace the fuel pump relay.

Did you complete the replacement?

—

Go to Step 11

—

10

Important: Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement?

—

Go to Step 11

—

11

1.

Reconnect all previously disconnected fuse,

relay or harness connector(s).

2.

Clear the DTCs with a scan tool.

3.

Turn OFF the ignition for 30 seconds.

4.

Turn ON the ignition for 20 seconds while

observing the DTC Information with a scan

tool.

Did the DTC fail this ignition?

—

Go to Step 3

Go to Step 12

12

Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed?

—

Go to DTC List

System OK

Step

Action

Value(s)

Yes

No

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-141

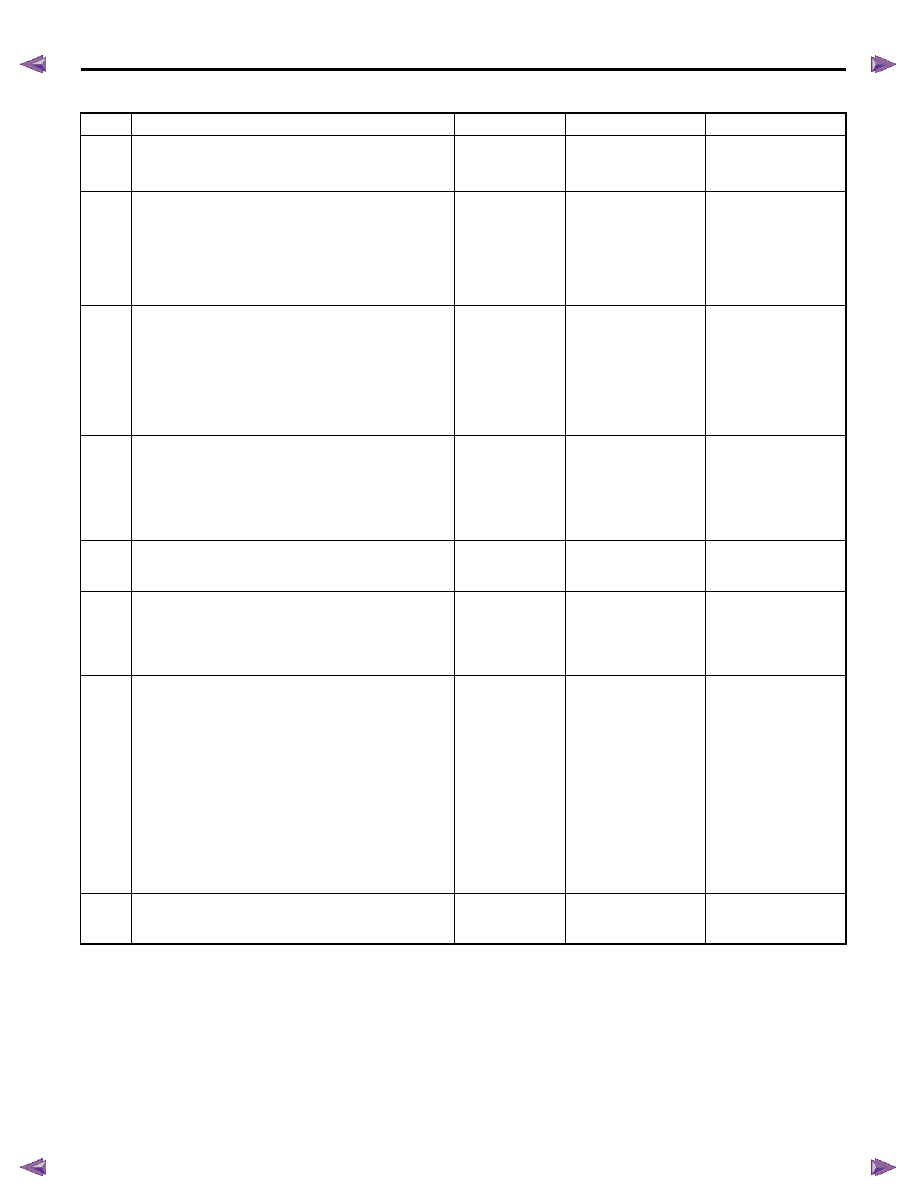

Circuit/ System Testing DTC P0232

Step

Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check -

Engine Controls?

—

Go to Step 2

Go to Diagnostic

System Check -

Engine Controls

2

1.

Install a scan tool.

2.

Turn OFF the ignition for 30 seconds.

3.

Start the engine.

4.

Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition?

—

Go to Step 3

Go to Diagnostic

Aids

3

1.

Turn OFF the ignition.

2.

Replace the fuel pump relay with the head

light relay or replace with a known good relay.

3.

Start the engine.

4.

Monitor the DTC Information with a scan tool.

Does the DTC fail?

—

Go to Step 4

Go to Step 5

4

1.

Test the control circuit between the ECM (pin

54 of C-58) and the relay (pin 5 of X-13) for a

short to battery or ignition voltage.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 7

Go to Step 6

5

Replace the fuel pump relay.

Did you complete the replacement?

—

Go to Step 7

—

6

Important: Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement?

—

Go to Step 7

—

7

1.

Reconnect all previously disconnected relay

or harness connector(s).

2.

Clear the DTCs with a scan tool.

3.

Turn OFF the ignition for 30 seconds.

4.

Start the engine.

5.

Operate the vehicle within the Conditions for

Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition?

—

Go to Step 3

Go to Step 8

8

Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed?

—

Go to DTC List

System OK

6E-142 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0234 (Flash Code 42)

Circuit Description

The boost pressure sensor is located in the air

induction tubing. The sensor is a transducer that varies

voltage according to changes in the air pressure inside

the air tubing. The ECM monitors the boost pressure

sensor signal for abnormal values. If the ECM detects

that the sensor signal is excessively high, this DTC will

set. This indicates excessive high boost pressure.

Condition for Running the DTC

• DTCs P0045, P0107 and P0108 are not set.

• The ignition switch is ON.

• The engine is running.

Condition for Setting the DTC

• The ECM detects that the actual boost pressure is

more than 20 kPa (3 psi) over the desired boost

pressure under certain conditions for longer than

10 seconds.

Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

Condition for Clearing the DTC

• Refer to DTC Type Definitions for Condition for

Clearing the MIL/ DTC - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Diagnostic Aids

• An open circuit or high resistance in the boost

pressure low reference circuit may set this DTC.

• Misrouted vacuum hoses may set this DTC.

• Check the turbocharger nozzle control actuator for

a sticking. Refer to Turbocharger in the Engine

Mechanical section.

• Use a scan tool to verify the integrity of the boost

pressure sensor signal. Compare the Boost

Pressure to the Desired Boost Pressure under all

load conditions for an excessively high value.

• The fuel with which gasoline was mixed may set

this DTC.

Test Description

The numbers below refer to the step number on the

Circuit/ System Testing.

3. A skewed boost pressure sensor value (shifted to a

higher pressure) can set this DTC. The Boost Pressure

on the scan tool should read near Barometric Pressure

(BARO) with the key ON and engine OFF.

4. A skewed BARO sensor value (shifted to a lower

pressure) may indicate a wrong boost pressure. The

BARO on the scan tool should read near surrounding

barometric pressure.

Schematic Reference: Vacuum Hose Routing

Diagram and Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0234

Step

Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check -

Engine Controls?

—

Go to Step 2

Go to Diagnostic

System - Check

Engine Controls

2

1.

Install a scan tool.

2.

Turn OFF the ignition for 30 seconds.

3.

Start the engine.

4.

Monitor the DTC Information with a scan tool.

Is DTC P0045, P0107, P0108, P0638, P1196,

P1197, P1198, P2227, P2228 or P2229 also set?

—

Go to Applicable

DTC

Go to Step 3

3

1.

Turn ON the ignition, with the engine OFF.

2.

Observe the Boost Pressure and Barometric

Pressure (BARO) with a scan tool.

Does the scan tool indicate that the difference

between the Boost Pressure and BARO is more

than the specified value?

10 kPa (1.5

psi)

Go to Step 4

Go to Step 5

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст