Isuzu KB P190. Manual — part 521

6A-70 ENGINE MECHANICAL (C24SE)

FUEL INJECTION SYSTEM

MAP SENSOR

Removal

1. Disconnect the battery cable.

2. Disconnect the electrical connector from the sensor.

3. Remove the mounting bolts securing the sensor to the

manifold.

4. Remove the sensor from the intake manifold.

Installation

1. Push MAP sensor into the manifold.

2. Install the mounting bolts and tighten them.

3. Connect electrical connector.

4. Connect the battery cable.

Pressure Regulator

Removal

1. Remove vacuum hose.

2. Remove fuel hoses.

3. Remove pressure regulator.

Installation

1. Install pressure regulator.

2. Install fuel hoses.

3. Install vacuum hoses.

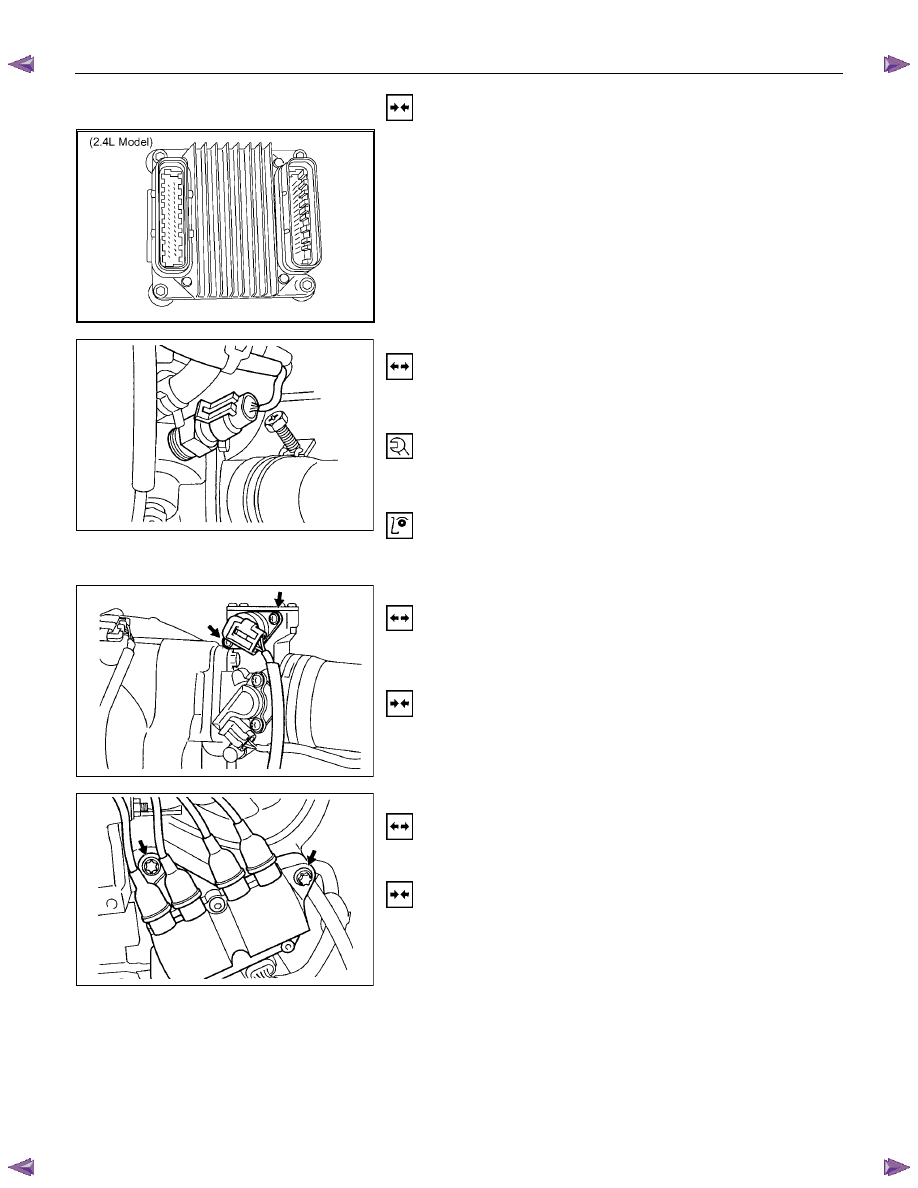

ECM (Engine Control Module)

Removal

(2.4L)

1. Disconnect the ECM connector.

2. Remove the four hex bolts and nuts.

3. Remove the ECM from the ECM bracket on engine.

ENGINE MECHANICAL (C24SE) 6A-71

Installation

(2.4L)

1. Install the ECM to the ECM bracket on engine.

2. Tighten the four screws to the bracket.

3. Connect the connector.

ECT

Removal

1. Remove wiring harness plug and coolant temperature

sensor.

Tighten (Torque)

Temperature sensor to intake pipe - 10 N

⋅m (1.0 kgf⋅m)

Wiring harness plug to temperature sensor

Inspection

Coolant level

Idle Air Control (IAC) Valve

Removal

1. Remove wiring harness plug, hose clamps and idle

speed adjuster.

Installation

1. Install idle speed adjuster, hose clamps and wiring

harness plug.

Ignition Coil

Removal

1. Remove 2 bolts, plug and ignition coil.

Installation

1. Install ignition coil, plug and bolts.

6A-72 ENGINE MECHANICAL (C24SE)

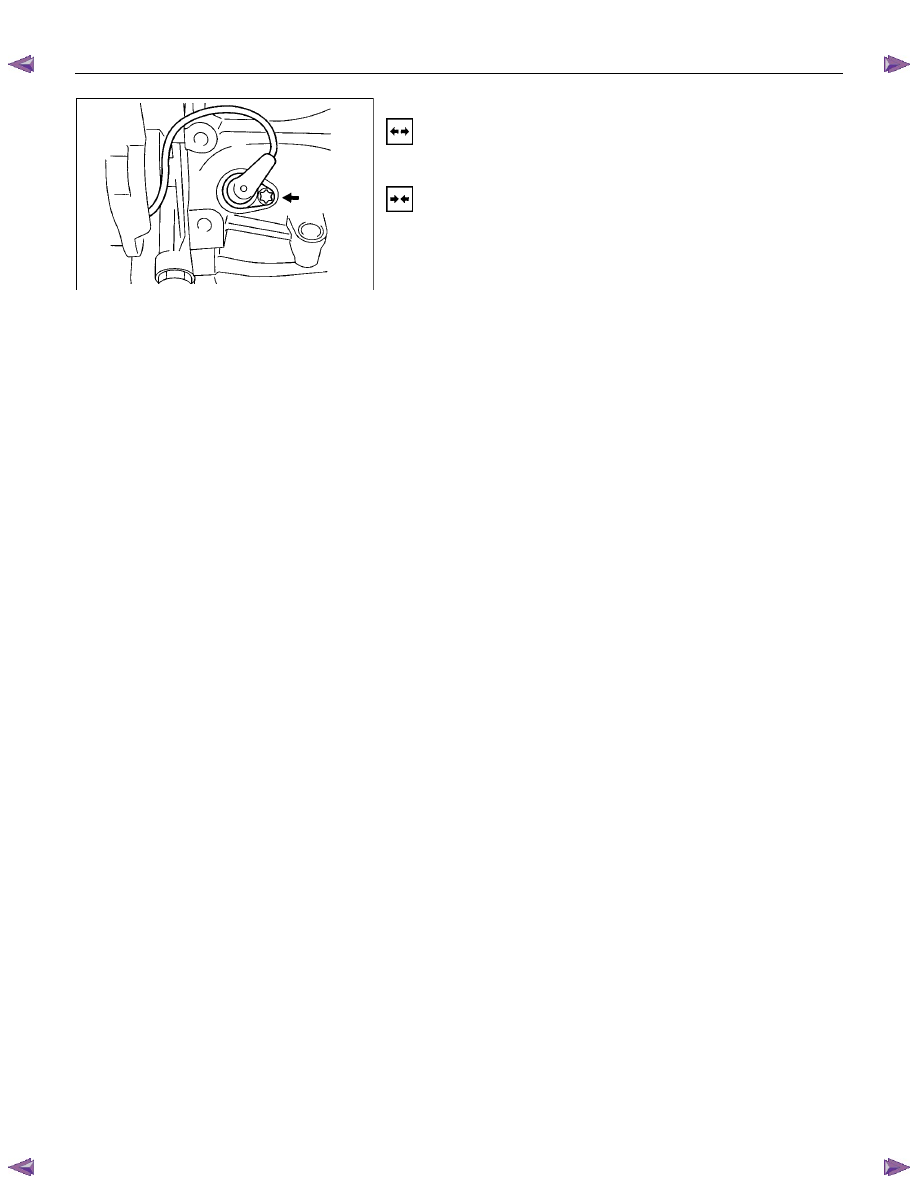

Crank Position Sensor

Removal

1. Remove crank position sensor.

Installation

1. Install crank position sensor.

ENGINE MECHANICAL (C24SE) 6A-73

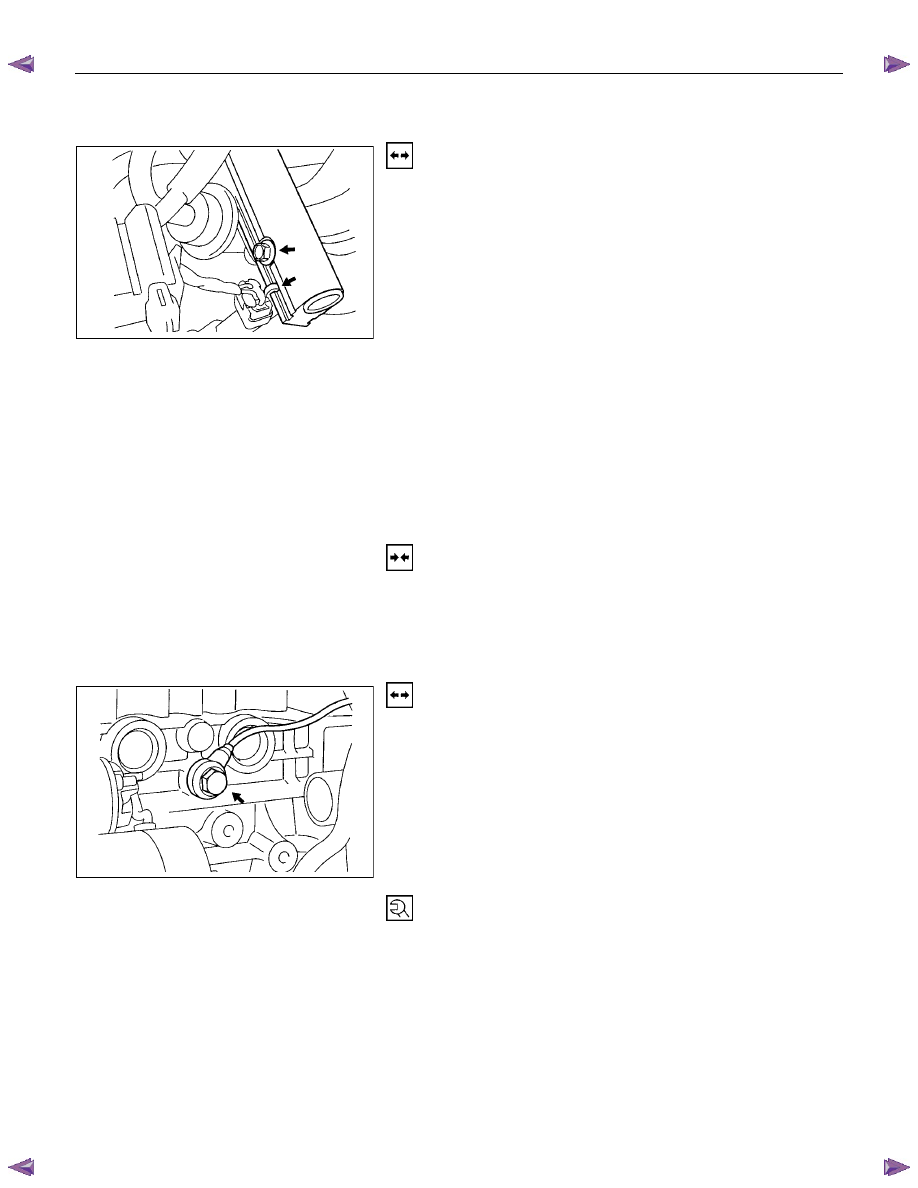

FUEL INJECTOR

Removal

Caution: To reduce the risk of fire and personal injury, it is

necessary to relieve the fuel system pressure before

servicing the fuel system components.

Caution: After relieving the fuel system pressure, a small

amount of fuel may be released when servicing fuel lines

or connections. Reduce the chance of personal injury by

covering the fuel line fitting with a shop towel before

disconnecting the fittings. The towel will absorb any fuel

that may leak out. When the disconnect is completed,

place the towel in an approved container.

1. Depressurize the fuel system.

2. Disconnect the fuel inlet.

3. Disconnect the fuel return line.

4. Remove the fuel rail from the intake manifold.

5. Remove the fuel injector from the fuel rail by disengaging

claws.

Installation

1. Install the fuel injector to the fuel rail by engaging claws.

2. Install the fuel rail to the intake manifold.

3. Connect the fuel return line firmly.

4. Connect the fuel supply line firmly.

Knock sensor

Removal

1. Remove fixing bolts.

2. Disconnect the connector at the other side.

Tighten (Torque)

Oxygen sensor in exhaust pipe - 30N

⋅m (3.1 kgf⋅m)

When re-using, insert oxygen sensor.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст